SM 25x125 [2xM8] / N52 - magnetic separator

magnetic separator

Catalog no 130367

GTIN/EAN: 5906301813156

Diameter Ø

25 mm [±1 mm]

Height

125 mm [±1 mm]

Weight

460 g

Magnetic Flux

~ 8 500 Gauss [±5%]

393.60 ZŁ with VAT / pcs + price for transport

320.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

or send us a note via

inquiry form

the contact form page.

Specifications and appearance of magnets can be calculated with our

force calculator.

Same-day processing for orders placed before 14:00.

Detailed specification - SM 25x125 [2xM8] / N52 - magnetic separator

Specification / characteristics - SM 25x125 [2xM8] / N52 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130367 |

| GTIN/EAN | 5906301813156 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

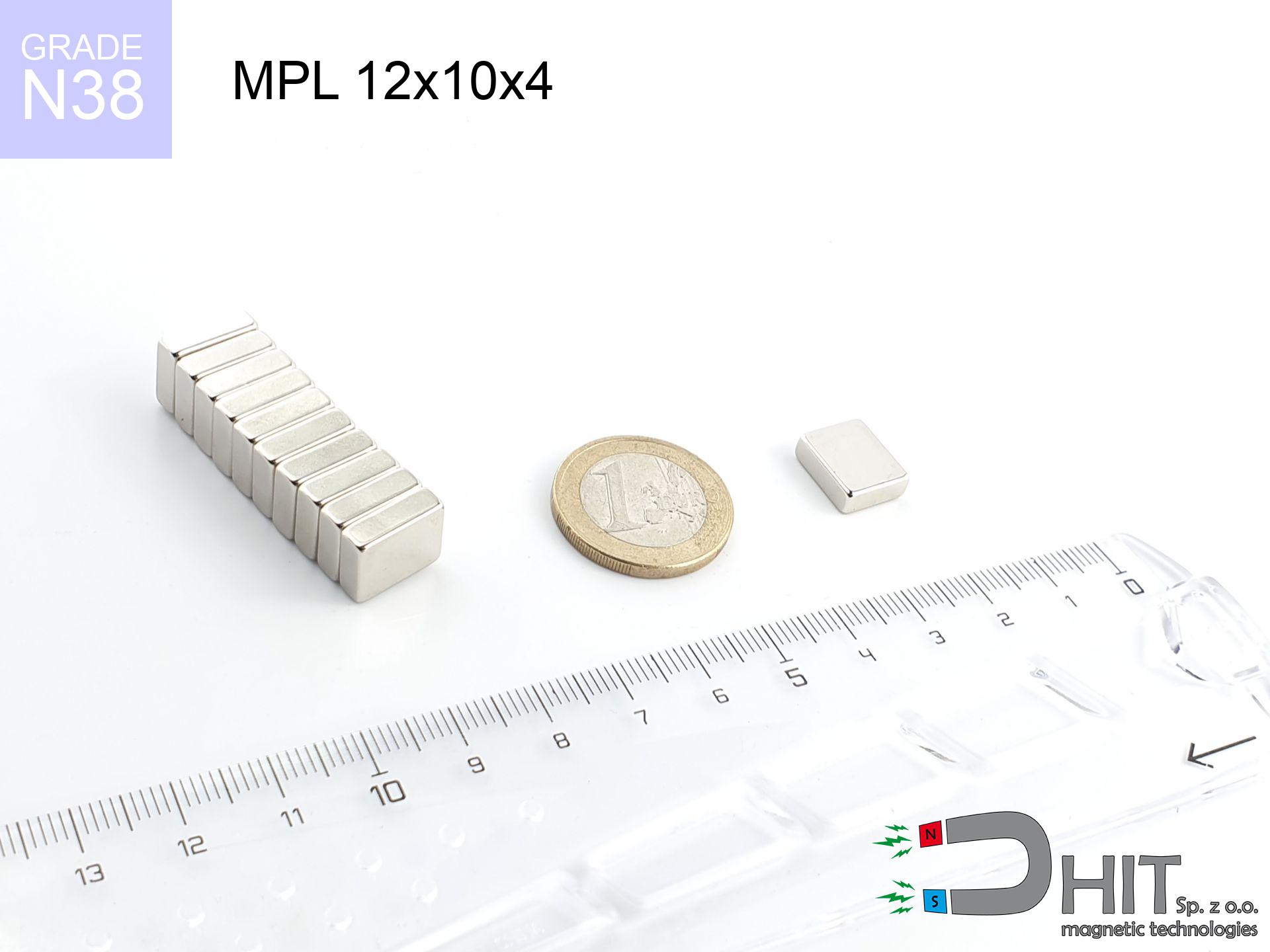

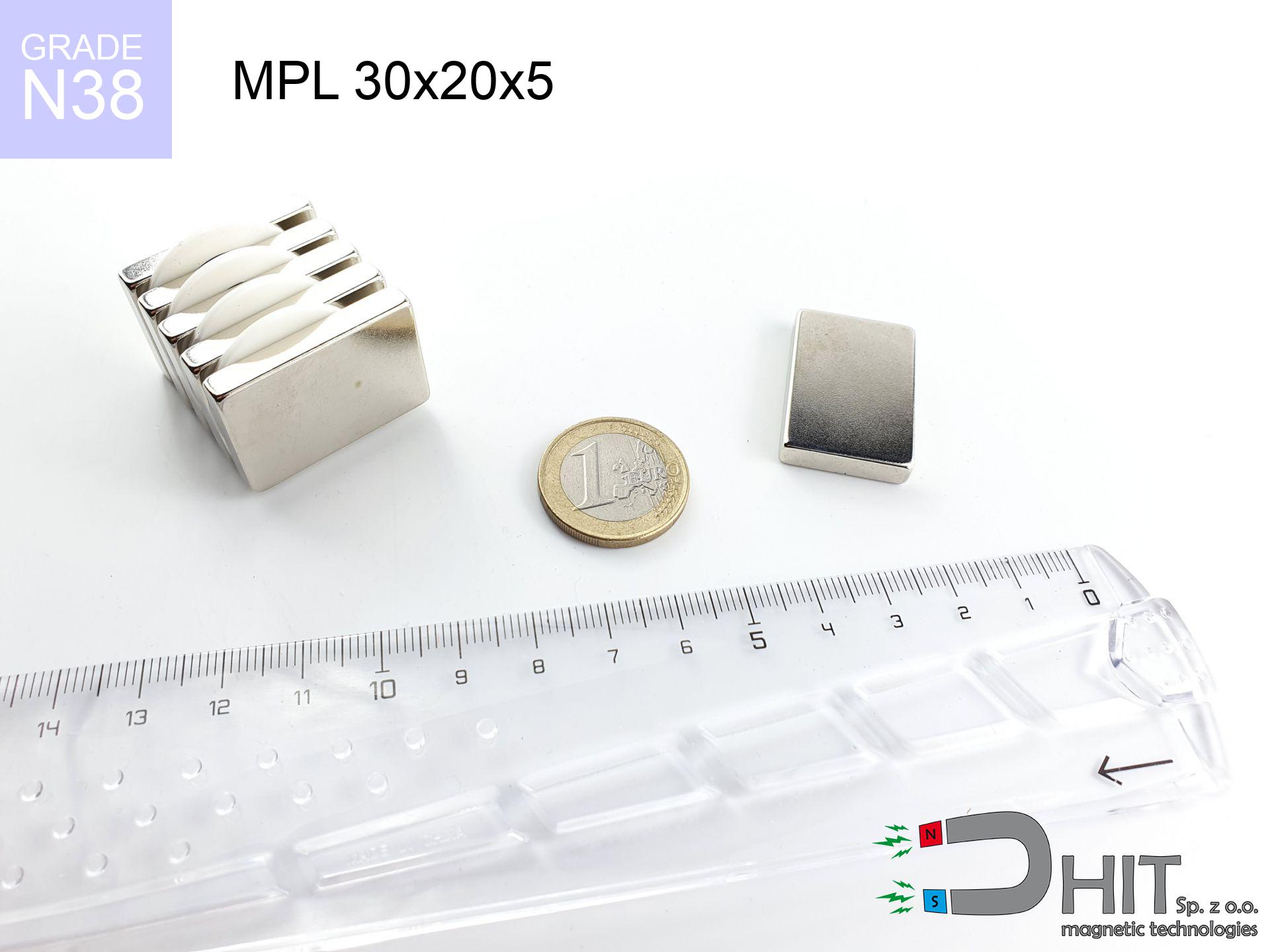

| Diameter Ø | 25 mm [±1 mm] |

| Height | 125 mm [±1 mm] |

| Weight | 460 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 8 500 Gauss [±5%] |

| Size/Mount Quantity | M8x2 |

| Polarity | circumferential - 4 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Table 1: Rod construction

SM 25x125 [2xM8] / N52

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 25 | mm |

| Total length | 125 | mm (L) |

| Active length | 89 | mm |

| Section count | 3 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~466 | g |

| Active area | 70 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 18.1 | kg (theor.) |

| Induction (surface) | ~8 500 | Gauss (Max) |

Chart 2: Field profile (3 sections)

Chart 3: Temperature performance

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also offers

Strengths and weaknesses of Nd2Fe14B magnets.

Advantages

- Their strength remains stable, and after around 10 years it drops only by ~1% (theoretically),

- They are resistant to demagnetization induced by presence of other magnetic fields,

- In other words, due to the glossy layer of silver, the element gains a professional look,

- They feature high magnetic induction at the operating surface, which increases their power,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of detailed modeling as well as optimizing to atypical applications,

- Universal use in innovative solutions – they serve a role in HDD drives, brushless drives, medical devices, as well as technologically advanced constructions.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- We suggest casing - magnetic mount, due to difficulties in producing nuts inside the magnet and complicated forms.

- Possible danger resulting from small fragments of magnets are risky, if swallowed, which becomes key in the context of child health protection. Additionally, tiny parts of these devices can be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Magnetic strength at its maximum – what contributes to it?

- with the use of a sheet made of low-carbon steel, guaranteeing maximum field concentration

- possessing a massiveness of at least 10 mm to avoid saturation

- with a plane perfectly flat

- with direct contact (no impurities)

- for force applied at a right angle (pull-off, not shear)

- at standard ambient temperature

Practical lifting capacity: influencing factors

- Space between magnet and steel – every millimeter of distance (caused e.g. by varnish or dirt) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – remember that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of generating force.

- Steel grade – the best choice is pure iron steel. Cast iron may generate lower lifting capacity.

- Base smoothness – the more even the plate, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Temperature – temperature increase causes a temporary drop of induction. Check the thermal limit for a given model.

Lifting capacity was measured by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular pulling force, whereas under parallel forces the lifting capacity is smaller. Additionally, even a small distance between the magnet and the plate decreases the holding force.

Precautions when working with neodymium magnets

Precision electronics

A strong magnetic field interferes with the operation of magnetometers in smartphones and navigation systems. Keep magnets close to a device to avoid damaging the sensors.

Protective goggles

Neodymium magnets are ceramic materials, which means they are fragile like glass. Clashing of two magnets leads to them breaking into shards.

Choking Hazard

NdFeB magnets are not intended for children. Swallowing several magnets may result in them pinching intestinal walls, which constitutes a severe health hazard and necessitates immediate surgery.

Implant safety

Life threat: Neodymium magnets can turn off heart devices and defibrillators. Do not approach if you have medical devices.

Mechanical processing

Powder created during machining of magnets is flammable. Avoid drilling into magnets unless you are an expert.

Sensitization to coating

Medical facts indicate that nickel (standard magnet coating) is a common allergen. If you have an allergy, prevent direct skin contact and select encased magnets.

Electronic devices

Device Safety: Strong magnets can ruin data carriers and delicate electronics (heart implants, hearing aids, mechanical watches).

Crushing risk

Large magnets can smash fingers instantly. Never place your hand betwixt two attracting surfaces.

Operating temperature

Standard neodymium magnets (N-type) undergo demagnetization when the temperature goes above 80°C. This process is irreversible.

Respect the power

Exercise caution. Neodymium magnets act from a long distance and snap with huge force, often quicker than you can react.

![Magnetic bar SM 25x125 [2xM8] / N52 Magnetic bar SM 25x125 [2xM8] / N52](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 25x125 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x125-2xm8-bub.jpg)

![SM 32x450 [2xM8] / N42 - magnetic separator SM 32x450 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x450-2xm8-bex.jpg)