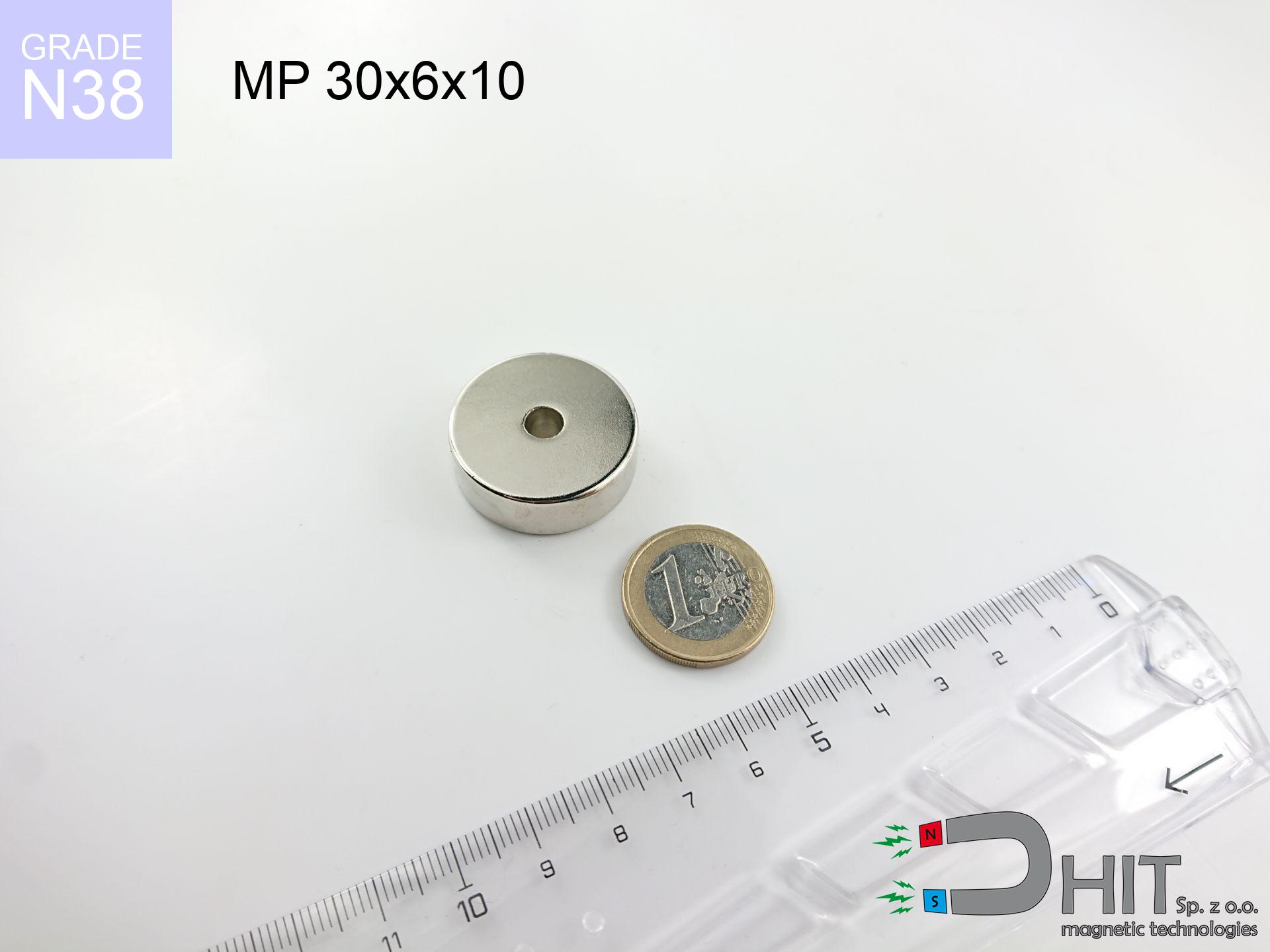

MP 30x6x10 / N38 - ring magnet

ring magnet

Catalog no 030197

GTIN/EAN: 5906301812142

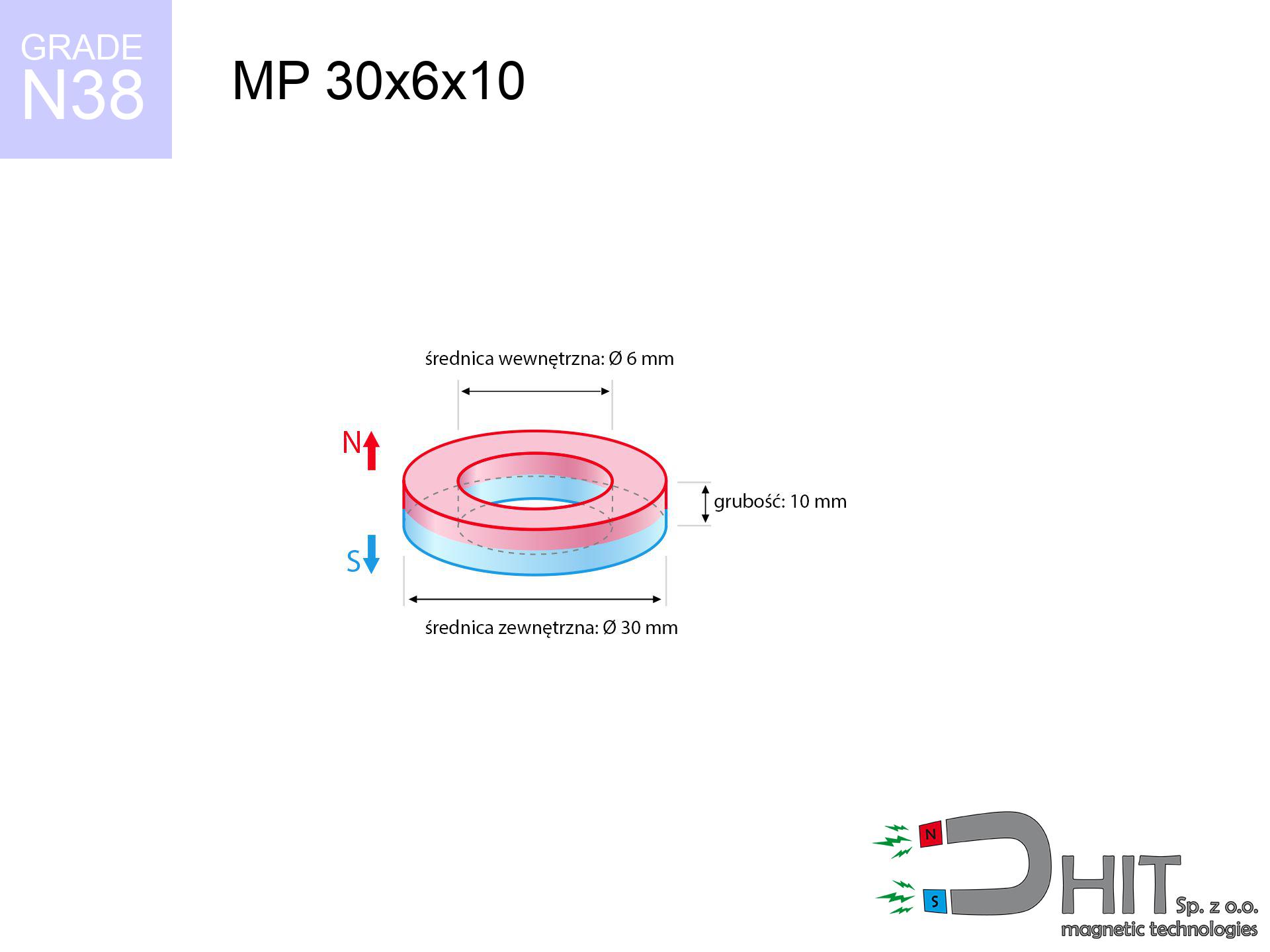

Diameter

30 mm [±0,1 mm]

internal diameter Ø

6 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

50.89 g

Magnetization Direction

↑ axial

Load capacity

20.71 kg / 203.16 N

Magnetic Induction

343.81 mT / 3438 Gs

Coating

[NiCuNi] Nickel

16.00 ZŁ with VAT / pcs + price for transport

13.01 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

if you prefer drop us a message using

inquiry form

the contact page.

Parameters and shape of magnets can be tested using our

our magnetic calculator.

Same-day processing for orders placed before 14:00.

Product card - MP 30x6x10 / N38 - ring magnet

Specification / characteristics - MP 30x6x10 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030197 |

| GTIN/EAN | 5906301812142 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 30 mm [±0,1 mm] |

| internal diameter Ø | 6 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 50.89 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 20.71 kg / 203.16 N |

| Magnetic Induction ~ ? | 343.81 mT / 3438 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

The following values constitute the result of a mathematical calculation. Values were calculated on algorithms for the material Nd2Fe14B. Real-world performance may differ from theoretical values. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs gap) - characteristics

MP 30x6x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5619 Gs

561.9 mT

|

20.71 kg / 45.66 LBS

20710.0 g / 203.2 N

|

critical level |

| 1 mm |

5241 Gs

524.1 mT

|

18.01 kg / 39.71 LBS

18011.7 g / 176.7 N

|

critical level |

| 2 mm |

4861 Gs

486.1 mT

|

15.50 kg / 34.17 LBS

15498.1 g / 152.0 N

|

critical level |

| 3 mm |

4490 Gs

449.0 mT

|

13.22 kg / 29.15 LBS

13223.5 g / 129.7 N

|

critical level |

| 5 mm |

3792 Gs

379.2 mT

|

9.43 kg / 20.79 LBS

9429.0 g / 92.5 N

|

strong |

| 10 mm |

2404 Gs

240.4 mT

|

3.79 kg / 8.36 LBS

3791.3 g / 37.2 N

|

strong |

| 15 mm |

1526 Gs

152.6 mT

|

1.53 kg / 3.37 LBS

1527.0 g / 15.0 N

|

weak grip |

| 20 mm |

1000 Gs

100.0 mT

|

0.66 kg / 1.45 LBS

655.5 g / 6.4 N

|

weak grip |

| 30 mm |

482 Gs

48.2 mT

|

0.15 kg / 0.34 LBS

152.6 g / 1.5 N

|

weak grip |

| 50 mm |

161 Gs

16.1 mT

|

0.02 kg / 0.04 LBS

17.0 g / 0.2 N

|

weak grip |

Table 2: Vertical hold (wall)

MP 30x6x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.14 kg / 9.13 LBS

4142.0 g / 40.6 N

|

| 1 mm | Stal (~0.2) |

3.60 kg / 7.94 LBS

3602.0 g / 35.3 N

|

| 2 mm | Stal (~0.2) |

3.10 kg / 6.83 LBS

3100.0 g / 30.4 N

|

| 3 mm | Stal (~0.2) |

2.64 kg / 5.83 LBS

2644.0 g / 25.9 N

|

| 5 mm | Stal (~0.2) |

1.89 kg / 4.16 LBS

1886.0 g / 18.5 N

|

| 10 mm | Stal (~0.2) |

0.76 kg / 1.67 LBS

758.0 g / 7.4 N

|

| 15 mm | Stal (~0.2) |

0.31 kg / 0.67 LBS

306.0 g / 3.0 N

|

| 20 mm | Stal (~0.2) |

0.13 kg / 0.29 LBS

132.0 g / 1.3 N

|

| 30 mm | Stal (~0.2) |

0.03 kg / 0.07 LBS

30.0 g / 0.3 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MP 30x6x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

6.21 kg / 13.70 LBS

6213.0 g / 60.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.14 kg / 9.13 LBS

4142.0 g / 40.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.07 kg / 4.57 LBS

2071.0 g / 20.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

10.36 kg / 22.83 LBS

10355.0 g / 101.6 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MP 30x6x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.04 kg / 2.28 LBS

1035.5 g / 10.2 N

|

| 1 mm |

|

2.59 kg / 5.71 LBS

2588.8 g / 25.4 N

|

| 2 mm |

|

5.18 kg / 11.41 LBS

5177.5 g / 50.8 N

|

| 3 mm |

|

7.77 kg / 17.12 LBS

7766.3 g / 76.2 N

|

| 5 mm |

|

12.94 kg / 28.54 LBS

12943.8 g / 127.0 N

|

| 10 mm |

|

20.71 kg / 45.66 LBS

20710.0 g / 203.2 N

|

| 11 mm |

|

20.71 kg / 45.66 LBS

20710.0 g / 203.2 N

|

| 12 mm |

|

20.71 kg / 45.66 LBS

20710.0 g / 203.2 N

|

Table 5: Working in heat (stability) - thermal limit

MP 30x6x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

20.71 kg / 45.66 LBS

20710.0 g / 203.2 N

|

OK |

| 40 °C | -2.2% |

20.25 kg / 44.65 LBS

20254.4 g / 198.7 N

|

OK |

| 60 °C | -4.4% |

19.80 kg / 43.65 LBS

19798.8 g / 194.2 N

|

OK |

| 80 °C | -6.6% |

19.34 kg / 42.64 LBS

19343.1 g / 189.8 N

|

|

| 100 °C | -28.8% |

14.75 kg / 32.51 LBS

14745.5 g / 144.7 N

|

Table 6: Two magnets (attraction) - forces in the system

MP 30x6x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

103.97 kg / 229.22 LBS

6 035 Gs

|

15.60 kg / 34.38 LBS

15596 g / 153.0 N

|

N/A |

| 1 mm |

97.15 kg / 214.17 LBS

10 864 Gs

|

14.57 kg / 32.13 LBS

14572 g / 143.0 N

|

87.43 kg / 192.75 LBS

~0 Gs

|

| 2 mm |

90.42 kg / 199.35 LBS

10 481 Gs

|

13.56 kg / 29.90 LBS

13564 g / 133.1 N

|

81.38 kg / 179.42 LBS

~0 Gs

|

| 3 mm |

83.97 kg / 185.13 LBS

10 100 Gs

|

12.60 kg / 27.77 LBS

12596 g / 123.6 N

|

75.57 kg / 166.61 LBS

~0 Gs

|

| 5 mm |

71.94 kg / 158.60 LBS

9 349 Gs

|

10.79 kg / 23.79 LBS

10791 g / 105.9 N

|

64.75 kg / 142.74 LBS

~0 Gs

|

| 10 mm |

47.34 kg / 104.36 LBS

7 583 Gs

|

7.10 kg / 15.65 LBS

7100 g / 69.7 N

|

42.60 kg / 93.92 LBS

~0 Gs

|

| 20 mm |

19.03 kg / 41.96 LBS

4 809 Gs

|

2.86 kg / 6.29 LBS

2855 g / 28.0 N

|

17.13 kg / 37.77 LBS

~0 Gs

|

| 50 mm |

1.53 kg / 3.37 LBS

1 363 Gs

|

0.23 kg / 0.51 LBS

229 g / 2.2 N

|

1.38 kg / 3.03 LBS

~0 Gs

|

| 60 mm |

0.77 kg / 1.69 LBS

965 Gs

|

0.11 kg / 0.25 LBS

115 g / 1.1 N

|

0.69 kg / 1.52 LBS

~0 Gs

|

| 70 mm |

0.41 kg / 0.90 LBS

706 Gs

|

0.06 kg / 0.14 LBS

61 g / 0.6 N

|

0.37 kg / 0.81 LBS

~0 Gs

|

| 80 mm |

0.23 kg / 0.51 LBS

531 Gs

|

0.03 kg / 0.08 LBS

35 g / 0.3 N

|

0.21 kg / 0.46 LBS

~0 Gs

|

| 90 mm |

0.14 kg / 0.30 LBS

409 Gs

|

0.02 kg / 0.05 LBS

21 g / 0.2 N

|

0.12 kg / 0.27 LBS

~0 Gs

|

| 100 mm |

0.09 kg / 0.19 LBS

322 Gs

|

0.01 kg / 0.03 LBS

13 g / 0.1 N

|

0.08 kg / 0.17 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MP 30x6x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 19.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 15.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 12.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 9.0 cm |

| Car key | 50 Gs (5.0 mT) | 8.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Collisions (kinetic energy) - collision effects

MP 30x6x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.55 km/h

(6.26 m/s)

|

1.00 J | |

| 30 mm |

35.40 km/h

(9.83 m/s)

|

2.46 J | |

| 50 mm |

45.52 km/h

(12.64 m/s)

|

4.07 J | |

| 100 mm |

64.34 km/h

(17.87 m/s)

|

8.13 J |

Table 9: Coating parameters (durability)

MP 30x6x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 30x6x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 31 585 Mx | 315.8 µWb |

| Pc Coefficient | 0.96 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 30x6x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 20.71 kg | Standard |

| Water (riverbed) |

23.71 kg

(+3.00 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet holds just a fraction of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.96

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages as well as disadvantages of neodymium magnets.

Benefits

- They have unchanged lifting capacity, and over more than ten years their performance decreases symbolically – ~1% (according to theory),

- Neodymium magnets are exceptionally resistant to demagnetization caused by magnetic disturbances,

- In other words, due to the aesthetic surface of nickel, the element is aesthetically pleasing,

- Magnets have impressive magnetic induction on the outer side,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for action at temperatures approaching 230°C and above...

- In view of the possibility of precise shaping and adaptation to individualized solutions, magnetic components can be modeled in a variety of shapes and sizes, which amplifies use scope,

- Significant place in high-tech industry – they are commonly used in computer drives, brushless drives, precision medical tools, also modern systems.

- Thanks to their power density, small magnets offer high operating force, with minimal size,

Weaknesses

- At very strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- We suggest casing - magnetic mechanism, due to difficulties in producing threads inside the magnet and complex shapes.

- Possible danger related to microscopic parts of magnets can be dangerous, when accidentally swallowed, which is particularly important in the context of child health protection. Furthermore, tiny parts of these products are able to complicate diagnosis medical when they are in the body.

- With large orders the cost of neodymium magnets is a challenge,

Pull force analysis

Breakaway strength of the magnet in ideal conditions – what affects it?

- on a block made of mild steel, effectively closing the magnetic flux

- whose transverse dimension is min. 10 mm

- with a surface perfectly flat

- without the slightest air gap between the magnet and steel

- for force applied at a right angle (pull-off, not shear)

- at temperature room level

Practical aspects of lifting capacity – factors

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of generating force.

- Material type – ideal substrate is high-permeability steel. Stainless steels may attract less.

- Surface finish – ideal contact is possible only on polished steel. Rough texture create air cushions, weakening the magnet.

- Thermal environment – heating the magnet causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity testing was performed on a smooth plate of suitable thickness, under perpendicular forces, however under shearing force the load capacity is reduced by as much as fivefold. Moreover, even a minimal clearance between the magnet and the plate lowers the load capacity.

Safety rules for work with neodymium magnets

Dust is flammable

Mechanical processing of NdFeB material poses a fire hazard. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Crushing force

Risk of injury: The pulling power is so immense that it can result in hematomas, pinching, and even bone fractures. Protective gloves are recommended.

Magnetic media

Powerful magnetic fields can destroy records on payment cards, HDDs, and other magnetic media. Stay away of at least 10 cm.

Health Danger

People with a heart stimulator must keep an safe separation from magnets. The magnetic field can disrupt the functioning of the implant.

Allergic reactions

Some people have a hypersensitivity to nickel, which is the common plating for neodymium magnets. Extended handling might lead to a rash. We suggest use safety gloves.

This is not a toy

Only for adults. Small elements can be swallowed, leading to severe trauma. Store out of reach of children and animals.

Protective goggles

Despite metallic appearance, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into hazardous fragments.

Threat to navigation

Note: rare earth magnets generate a field that disrupts sensitive sensors. Keep a safe distance from your mobile, device, and GPS.

Caution required

Exercise caution. Rare earth magnets act from a distance and connect with massive power, often faster than you can move away.

Do not overheat magnets

Do not overheat. NdFeB magnets are susceptible to heat. If you require resistance above 80°C, look for special high-temperature series (H, SH, UH).

![BM 950x180x70 [4x M8] - magnetic beam BM 950x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-950x180x70-4x-m8-ves.jpg)