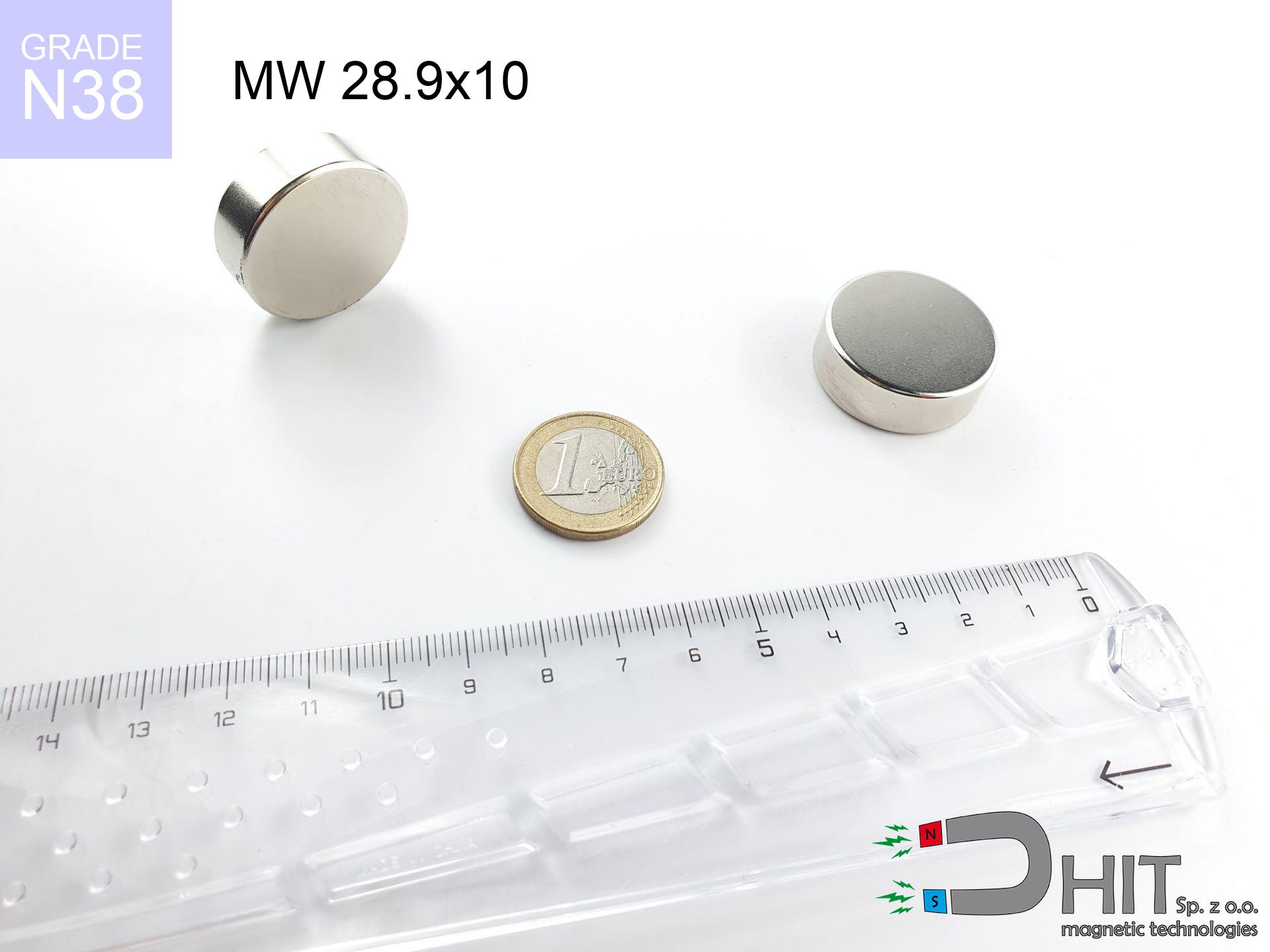

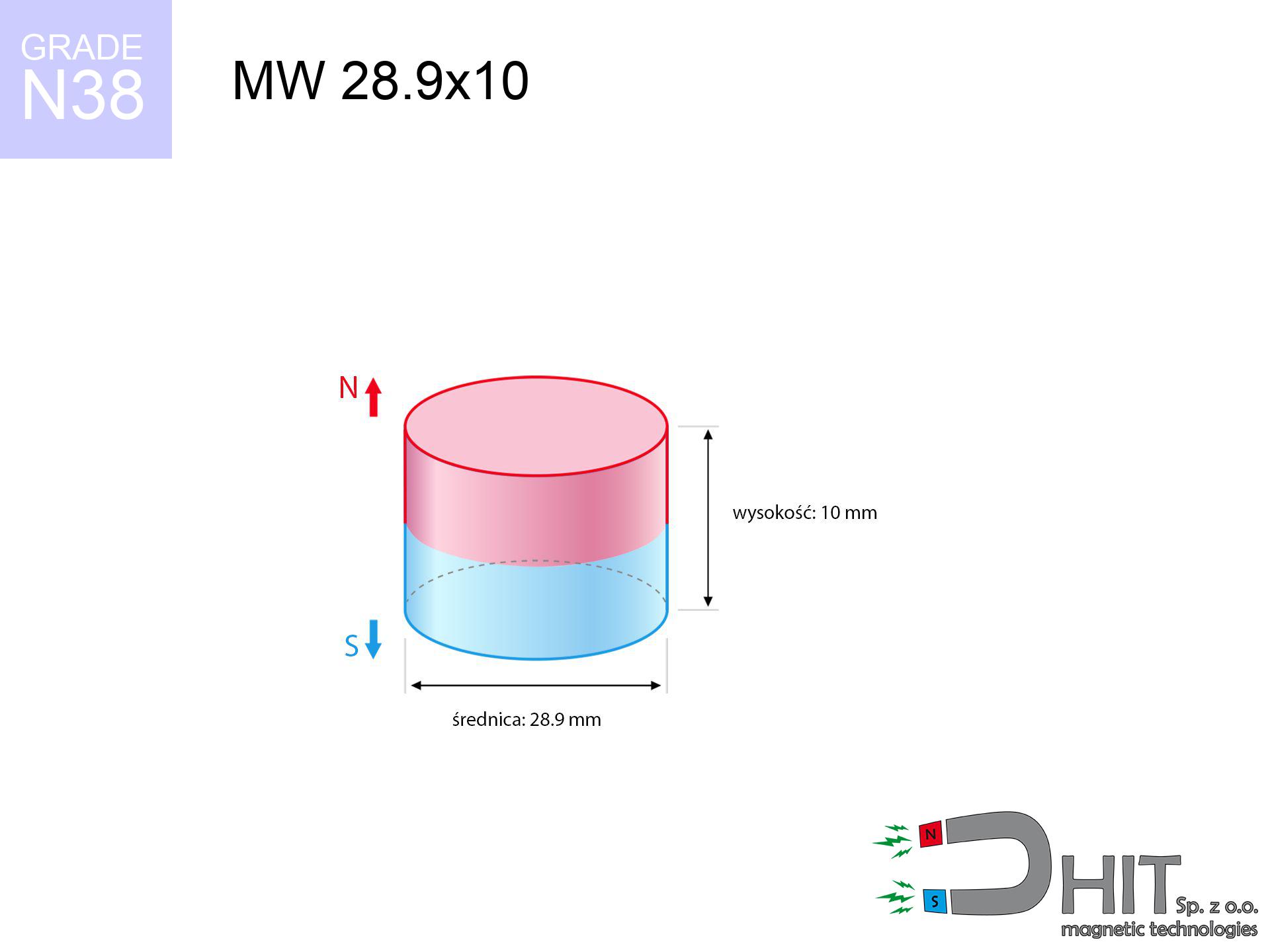

MW 28.9x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010051

GTIN/EAN: 5906301810506

Diameter Ø

28.9 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

49.2 g

Magnetization Direction

→ diametrical

Load capacity

20.74 kg / 203.46 N

Magnetic Induction

352.70 mT / 3527 Gs

Coating

[NiCuNi] Nickel

23.99 ZŁ with VAT / pcs + price for transport

19.50 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

alternatively let us know through

contact form

the contact page.

Lifting power as well as appearance of a magnet can be reviewed with our

magnetic mass calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical details - MW 28.9x10 / N38 - cylindrical magnet

Specification / characteristics - MW 28.9x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010051 |

| GTIN/EAN | 5906301810506 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 28.9 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 49.2 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 20.74 kg / 203.46 N |

| Magnetic Induction ~ ? | 352.70 mT / 3527 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - data

Presented information are the direct effect of a mathematical analysis. Values rely on models for the class Nd2Fe14B. Actual conditions may deviate from the simulation results. Use these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (force vs distance) - power drop

MW 28.9x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3526 Gs

352.6 mT

|

20.74 kg / 45.72 lbs

20740.0 g / 203.5 N

|

dangerous! |

| 1 mm |

3327 Gs

332.7 mT

|

18.47 kg / 40.71 lbs

18466.2 g / 181.2 N

|

dangerous! |

| 2 mm |

3111 Gs

311.1 mT

|

16.14 kg / 35.59 lbs

16142.6 g / 158.4 N

|

dangerous! |

| 3 mm |

2886 Gs

288.6 mT

|

13.90 kg / 30.63 lbs

13895.8 g / 136.3 N

|

dangerous! |

| 5 mm |

2438 Gs

243.8 mT

|

9.91 kg / 21.85 lbs

9912.0 g / 97.2 N

|

strong |

| 10 mm |

1497 Gs

149.7 mT

|

3.74 kg / 8.24 lbs

3739.6 g / 36.7 N

|

strong |

| 15 mm |

903 Gs

90.3 mT

|

1.36 kg / 3.00 lbs

1359.1 g / 13.3 N

|

weak grip |

| 20 mm |

560 Gs

56.0 mT

|

0.52 kg / 1.15 lbs

523.5 g / 5.1 N

|

weak grip |

| 30 mm |

245 Gs

24.5 mT

|

0.10 kg / 0.22 lbs

100.4 g / 1.0 N

|

weak grip |

| 50 mm |

71 Gs

7.1 mT

|

0.01 kg / 0.02 lbs

8.5 g / 0.1 N

|

weak grip |

Table 2: Shear hold (vertical surface)

MW 28.9x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.15 kg / 9.14 lbs

4148.0 g / 40.7 N

|

| 1 mm | Stal (~0.2) |

3.69 kg / 8.14 lbs

3694.0 g / 36.2 N

|

| 2 mm | Stal (~0.2) |

3.23 kg / 7.12 lbs

3228.0 g / 31.7 N

|

| 3 mm | Stal (~0.2) |

2.78 kg / 6.13 lbs

2780.0 g / 27.3 N

|

| 5 mm | Stal (~0.2) |

1.98 kg / 4.37 lbs

1982.0 g / 19.4 N

|

| 10 mm | Stal (~0.2) |

0.75 kg / 1.65 lbs

748.0 g / 7.3 N

|

| 15 mm | Stal (~0.2) |

0.27 kg / 0.60 lbs

272.0 g / 2.7 N

|

| 20 mm | Stal (~0.2) |

0.10 kg / 0.23 lbs

104.0 g / 1.0 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

20.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 28.9x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

6.22 kg / 13.72 lbs

6222.0 g / 61.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.15 kg / 9.14 lbs

4148.0 g / 40.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.07 kg / 4.57 lbs

2074.0 g / 20.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

10.37 kg / 22.86 lbs

10370.0 g / 101.7 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 28.9x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.04 kg / 2.29 lbs

1037.0 g / 10.2 N

|

| 1 mm |

|

2.59 kg / 5.72 lbs

2592.5 g / 25.4 N

|

| 2 mm |

|

5.19 kg / 11.43 lbs

5185.0 g / 50.9 N

|

| 3 mm |

|

7.78 kg / 17.15 lbs

7777.5 g / 76.3 N

|

| 5 mm |

|

12.96 kg / 28.58 lbs

12962.5 g / 127.2 N

|

| 10 mm |

|

20.74 kg / 45.72 lbs

20740.0 g / 203.5 N

|

| 11 mm |

|

20.74 kg / 45.72 lbs

20740.0 g / 203.5 N

|

| 12 mm |

|

20.74 kg / 45.72 lbs

20740.0 g / 203.5 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 28.9x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

20.74 kg / 45.72 lbs

20740.0 g / 203.5 N

|

OK |

| 40 °C | -2.2% |

20.28 kg / 44.72 lbs

20283.7 g / 199.0 N

|

OK |

| 60 °C | -4.4% |

19.83 kg / 43.71 lbs

19827.4 g / 194.5 N

|

|

| 80 °C | -6.6% |

19.37 kg / 42.71 lbs

19371.2 g / 190.0 N

|

|

| 100 °C | -28.8% |

14.77 kg / 32.56 lbs

14766.9 g / 144.9 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 28.9x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

50.29 kg / 110.86 lbs

5 022 Gs

|

7.54 kg / 16.63 lbs

7543 g / 74.0 N

|

N/A |

| 1 mm |

47.58 kg / 104.90 lbs

6 860 Gs

|

7.14 kg / 15.74 lbs

7138 g / 70.0 N

|

42.83 kg / 94.41 lbs

~0 Gs

|

| 2 mm |

44.77 kg / 98.71 lbs

6 655 Gs

|

6.72 kg / 14.81 lbs

6716 g / 65.9 N

|

40.30 kg / 88.84 lbs

~0 Gs

|

| 3 mm |

41.95 kg / 92.48 lbs

6 441 Gs

|

6.29 kg / 13.87 lbs

6292 g / 61.7 N

|

37.75 kg / 83.23 lbs

~0 Gs

|

| 5 mm |

36.38 kg / 80.20 lbs

5 999 Gs

|

5.46 kg / 12.03 lbs

5457 g / 53.5 N

|

32.74 kg / 72.18 lbs

~0 Gs

|

| 10 mm |

24.03 kg / 52.98 lbs

4 876 Gs

|

3.60 kg / 7.95 lbs

3605 g / 35.4 N

|

21.63 kg / 47.69 lbs

~0 Gs

|

| 20 mm |

9.07 kg / 19.99 lbs

2 995 Gs

|

1.36 kg / 3.00 lbs

1360 g / 13.3 N

|

8.16 kg / 17.99 lbs

~0 Gs

|

| 50 mm |

0.53 kg / 1.17 lbs

726 Gs

|

0.08 kg / 0.18 lbs

80 g / 0.8 N

|

0.48 kg / 1.06 lbs

~0 Gs

|

| 60 mm |

0.24 kg / 0.54 lbs

491 Gs

|

0.04 kg / 0.08 lbs

37 g / 0.4 N

|

0.22 kg / 0.48 lbs

~0 Gs

|

| 70 mm |

0.12 kg / 0.26 lbs

345 Gs

|

0.02 kg / 0.04 lbs

18 g / 0.2 N

|

0.11 kg / 0.24 lbs

~0 Gs

|

| 80 mm |

0.06 kg / 0.14 lbs

250 Gs

|

0.01 kg / 0.02 lbs

9 g / 0.1 N

|

0.06 kg / 0.13 lbs

~0 Gs

|

| 90 mm |

0.04 kg / 0.08 lbs

187 Gs

|

0.01 kg / 0.01 lbs

5 g / 0.1 N

|

0.03 kg / 0.07 lbs

~0 Gs

|

| 100 mm |

0.02 kg / 0.05 lbs

143 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 28.9x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 8.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Remote | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (kinetic energy) - warning

MW 28.9x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.92 km/h

(6.37 m/s)

|

1.00 J | |

| 30 mm |

35.97 km/h

(9.99 m/s)

|

2.46 J | |

| 50 mm |

46.31 km/h

(12.86 m/s)

|

4.07 J | |

| 100 mm |

65.48 km/h

(18.19 m/s)

|

8.14 J |

Table 9: Anti-corrosion coating durability

MW 28.9x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 28.9x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 24 347 Mx | 243.5 µWb |

| Pc Coefficient | 0.45 | Low (Flat) |

Table 11: Physics of underwater searching

MW 28.9x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 20.74 kg | Standard |

| Water (riverbed) |

23.75 kg

(+3.01 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet holds only a fraction of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) significantly limits the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.45

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more products

Strengths as well as weaknesses of neodymium magnets.

Advantages

- They do not lose strength, even over nearly 10 years – the reduction in power is only ~1% (according to tests),

- They do not lose their magnetic properties even under external field action,

- Thanks to the metallic finish, the coating of nickel, gold, or silver gives an aesthetic appearance,

- Neodymium magnets deliver maximum magnetic induction on a contact point, which allows for strong attraction,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- In view of the ability of flexible molding and customization to custom projects, magnetic components can be modeled in a wide range of forms and dimensions, which makes them more universal,

- Key role in advanced technology sectors – they find application in hard drives, electric drive systems, medical equipment, also industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which makes them useful in compact constructions

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a special holder, which not only secures them against impacts but also raises their durability

- NdFeB magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- We recommend cover - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complex forms.

- Potential hazard resulting from small fragments of magnets can be dangerous, if swallowed, which becomes key in the context of child safety. Additionally, small components of these devices can be problematic in diagnostics medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Pull force analysis

Maximum lifting capacity of the magnet – what it depends on?

- on a block made of structural steel, effectively closing the magnetic field

- possessing a thickness of min. 10 mm to avoid saturation

- with a surface free of scratches

- under conditions of gap-free contact (surface-to-surface)

- for force acting at a right angle (in the magnet axis)

- at standard ambient temperature

Determinants of lifting force in real conditions

- Space between magnet and steel – every millimeter of distance (caused e.g. by varnish or dirt) diminishes the pulling force, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Chemical composition of the base – mild steel attracts best. Higher carbon content decrease magnetic permeability and holding force.

- Plate texture – ground elements ensure maximum contact, which increases force. Uneven metal reduce efficiency.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. When it is hot they are weaker, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was performed on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, whereas under attempts to slide the magnet the holding force is lower. Moreover, even a small distance between the magnet and the plate reduces the load capacity.

H&S for magnets

Maximum temperature

Regular neodymium magnets (N-type) undergo demagnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Warning for allergy sufferers

Nickel alert: The Ni-Cu-Ni coating contains nickel. If skin irritation happens, immediately stop working with magnets and wear gloves.

Life threat

People with a pacemaker have to keep an absolute distance from magnets. The magnetism can interfere with the operation of the implant.

Crushing force

Big blocks can crush fingers instantly. Do not put your hand betwixt two attracting surfaces.

Beware of splinters

NdFeB magnets are ceramic materials, which means they are very brittle. Impact of two magnets will cause them shattering into shards.

No play value

Neodymium magnets are not toys. Swallowing several magnets can lead to them pinching intestinal walls, which poses a severe health hazard and requires urgent medical intervention.

Do not drill into magnets

Fire hazard: Rare earth powder is explosive. Avoid machining magnets in home conditions as this risks ignition.

Safe operation

Before starting, read the rules. Uncontrolled attraction can break the magnet or injure your hand. Be predictive.

Compass and GPS

Remember: rare earth magnets produce a field that confuses sensitive sensors. Maintain a safe distance from your phone, device, and GPS.

Keep away from computers

Intense magnetic fields can erase data on payment cards, HDDs, and other magnetic media. Maintain a gap of min. 10 cm.

![SM 32x400 [2xM8] / N42 - magnetic separator SM 32x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-tep.jpg)

![BM 550x180x70 [4x M8] - magnetic beam BM 550x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-550x180x70-4x-m8-nic.jpg)

![UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-88x8.5-m8-gz-waf.jpg)