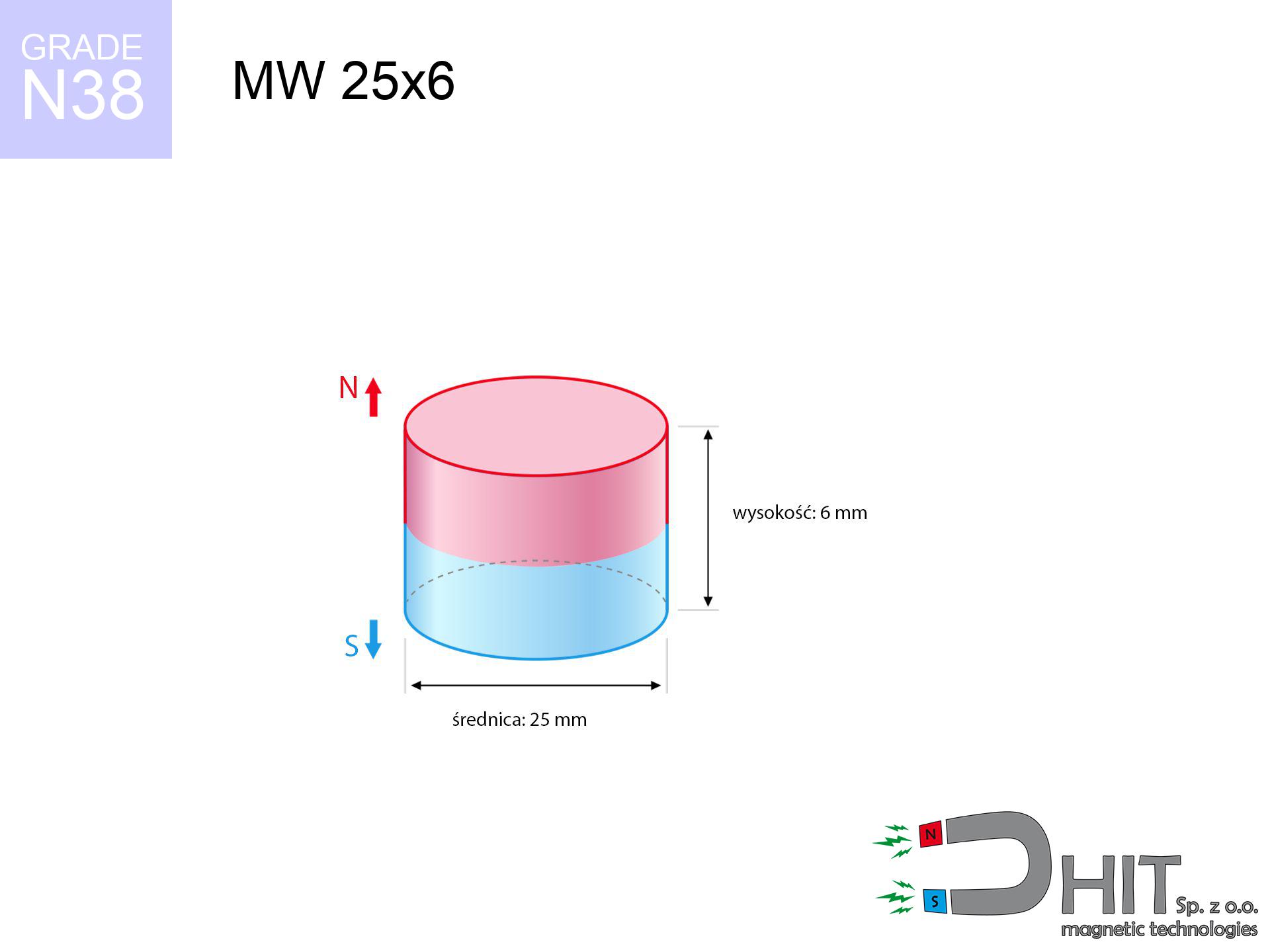

MW 25x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010050

GTIN/EAN: 5906301810490

Diameter Ø

25 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

22.09 g

Magnetization Direction

↑ axial

Load capacity

10.27 kg / 100.71 N

Magnetic Induction

268.21 mT / 2682 Gs

Coating

[NiCuNi] Nickel

7.40 ZŁ with VAT / pcs + price for transport

6.02 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

or let us know through

inquiry form

through our site.

Parameters as well as appearance of a magnet can be analyzed on our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MW 25x6 / N38 - cylindrical magnet

Specification / characteristics - MW 25x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010050 |

| GTIN/EAN | 5906301810490 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 25 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 22.09 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 10.27 kg / 100.71 N |

| Magnetic Induction ~ ? | 268.21 mT / 2682 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the magnet - technical parameters

Presented data are the result of a physical calculation. Results are based on algorithms for the material Nd2Fe14B. Actual performance may differ. Treat these data as a reference point when designing systems.

Table 1: Static force (force vs gap) - interaction chart

MW 25x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2682 Gs

268.2 mT

|

10.27 kg / 22.64 lbs

10270.0 g / 100.7 N

|

dangerous! |

| 1 mm |

2535 Gs

253.5 mT

|

9.18 kg / 20.23 lbs

9177.2 g / 90.0 N

|

medium risk |

| 2 mm |

2363 Gs

236.3 mT

|

7.97 kg / 17.57 lbs

7971.8 g / 78.2 N

|

medium risk |

| 3 mm |

2176 Gs

217.6 mT

|

6.76 kg / 14.91 lbs

6761.0 g / 66.3 N

|

medium risk |

| 5 mm |

1793 Gs

179.3 mT

|

4.59 kg / 10.13 lbs

4592.7 g / 45.1 N

|

medium risk |

| 10 mm |

1013 Gs

101.3 mT

|

1.46 kg / 3.23 lbs

1464.5 g / 14.4 N

|

weak grip |

| 15 mm |

565 Gs

56.5 mT

|

0.46 kg / 1.00 lbs

455.3 g / 4.5 N

|

weak grip |

| 20 mm |

330 Gs

33.0 mT

|

0.16 kg / 0.34 lbs

155.7 g / 1.5 N

|

weak grip |

| 30 mm |

134 Gs

13.4 mT

|

0.03 kg / 0.06 lbs

25.6 g / 0.3 N

|

weak grip |

| 50 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 lbs

1.9 g / 0.0 N

|

weak grip |

Table 2: Shear load (vertical surface)

MW 25x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.05 kg / 4.53 lbs

2054.0 g / 20.1 N

|

| 1 mm | Stal (~0.2) |

1.84 kg / 4.05 lbs

1836.0 g / 18.0 N

|

| 2 mm | Stal (~0.2) |

1.59 kg / 3.51 lbs

1594.0 g / 15.6 N

|

| 3 mm | Stal (~0.2) |

1.35 kg / 2.98 lbs

1352.0 g / 13.3 N

|

| 5 mm | Stal (~0.2) |

0.92 kg / 2.02 lbs

918.0 g / 9.0 N

|

| 10 mm | Stal (~0.2) |

0.29 kg / 0.64 lbs

292.0 g / 2.9 N

|

| 15 mm | Stal (~0.2) |

0.09 kg / 0.20 lbs

92.0 g / 0.9 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

32.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 25x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

3.08 kg / 6.79 lbs

3081.0 g / 30.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.05 kg / 4.53 lbs

2054.0 g / 20.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.03 kg / 2.26 lbs

1027.0 g / 10.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

5.14 kg / 11.32 lbs

5135.0 g / 50.4 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 25x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.51 kg / 1.13 lbs

513.5 g / 5.0 N

|

| 1 mm |

|

1.28 kg / 2.83 lbs

1283.8 g / 12.6 N

|

| 2 mm |

|

2.57 kg / 5.66 lbs

2567.5 g / 25.2 N

|

| 3 mm |

|

3.85 kg / 8.49 lbs

3851.3 g / 37.8 N

|

| 5 mm |

|

6.42 kg / 14.15 lbs

6418.7 g / 63.0 N

|

| 10 mm |

|

10.27 kg / 22.64 lbs

10270.0 g / 100.7 N

|

| 11 mm |

|

10.27 kg / 22.64 lbs

10270.0 g / 100.7 N

|

| 12 mm |

|

10.27 kg / 22.64 lbs

10270.0 g / 100.7 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 25x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

10.27 kg / 22.64 lbs

10270.0 g / 100.7 N

|

OK |

| 40 °C | -2.2% |

10.04 kg / 22.14 lbs

10044.1 g / 98.5 N

|

OK |

| 60 °C | -4.4% |

9.82 kg / 21.65 lbs

9818.1 g / 96.3 N

|

|

| 80 °C | -6.6% |

9.59 kg / 21.15 lbs

9592.2 g / 94.1 N

|

|

| 100 °C | -28.8% |

7.31 kg / 16.12 lbs

7312.2 g / 71.7 N

|

Table 6: Two magnets (repulsion) - field collision

MW 25x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

21.76 kg / 47.98 lbs

4 291 Gs

|

3.26 kg / 7.20 lbs

3264 g / 32.0 N

|

N/A |

| 1 mm |

20.66 kg / 45.54 lbs

5 225 Gs

|

3.10 kg / 6.83 lbs

3098 g / 30.4 N

|

18.59 kg / 40.98 lbs

~0 Gs

|

| 2 mm |

19.45 kg / 42.87 lbs

5 070 Gs

|

2.92 kg / 6.43 lbs

2917 g / 28.6 N

|

17.50 kg / 38.58 lbs

~0 Gs

|

| 3 mm |

18.18 kg / 40.09 lbs

4 902 Gs

|

2.73 kg / 6.01 lbs

2727 g / 26.8 N

|

16.36 kg / 36.08 lbs

~0 Gs

|

| 5 mm |

15.60 kg / 34.39 lbs

4 541 Gs

|

2.34 kg / 5.16 lbs

2340 g / 23.0 N

|

14.04 kg / 30.95 lbs

~0 Gs

|

| 10 mm |

9.73 kg / 21.46 lbs

3 587 Gs

|

1.46 kg / 3.22 lbs

1460 g / 14.3 N

|

8.76 kg / 19.31 lbs

~0 Gs

|

| 20 mm |

3.10 kg / 6.84 lbs

2 025 Gs

|

0.47 kg / 1.03 lbs

465 g / 4.6 N

|

2.79 kg / 6.16 lbs

~0 Gs

|

| 50 mm |

0.13 kg / 0.28 lbs

409 Gs

|

0.02 kg / 0.04 lbs

19 g / 0.2 N

|

0.11 kg / 0.25 lbs

~0 Gs

|

| 60 mm |

0.05 kg / 0.12 lbs

268 Gs

|

0.01 kg / 0.02 lbs

8 g / 0.1 N

|

0.05 kg / 0.11 lbs

~0 Gs

|

| 70 mm |

0.03 kg / 0.06 lbs

183 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

| 80 mm |

0.01 kg / 0.03 lbs

131 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 90 mm |

0.01 kg / 0.02 lbs

96 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 lbs

72 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 25x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 10.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 6.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 5.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MW 25x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

23.60 km/h

(6.56 m/s)

|

0.47 J | |

| 30 mm |

37.72 km/h

(10.48 m/s)

|

1.21 J | |

| 50 mm |

48.63 km/h

(13.51 m/s)

|

2.02 J | |

| 100 mm |

68.77 km/h

(19.10 m/s)

|

4.03 J |

Table 9: Corrosion resistance

MW 25x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 25x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 14 740 Mx | 147.4 µWb |

| Pc Coefficient | 0.34 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 25x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 10.27 kg | Standard |

| Water (riverbed) |

11.76 kg

(+1.49 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet retains only approx. 20-30% of its max power.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.34

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Strengths and weaknesses of Nd2Fe14B magnets.

Advantages

- They retain full power for around ten years – the drop is just ~1% (in theory),

- They show high resistance to demagnetization induced by external magnetic fields,

- A magnet with a smooth silver surface looks better,

- Magnetic induction on the working part of the magnet remains impressive,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to modularity in designing and the capacity to modify to client solutions,

- Versatile presence in electronics industry – they are utilized in magnetic memories, electric motors, medical equipment, as well as modern systems.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- To avoid cracks upon strong impacts, we recommend using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in realizing threads and complex forms in magnets, we propose using casing - magnetic mount.

- Potential hazard to health – tiny shards of magnets pose a threat, when accidentally swallowed, which gains importance in the context of child safety. Furthermore, small components of these products can complicate diagnosis medical in case of swallowing.

- With large orders the cost of neodymium magnets is economically unviable,

Pull force analysis

Maximum holding power of the magnet – what affects it?

- on a base made of structural steel, perfectly concentrating the magnetic field

- whose thickness reaches at least 10 mm

- with a plane cleaned and smooth

- without any air gap between the magnet and steel

- for force applied at a right angle (pull-off, not shear)

- in neutral thermal conditions

Lifting capacity in real conditions – factors

- Space between surfaces – every millimeter of distance (caused e.g. by veneer or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Angle of force application – maximum parameter is reached only during perpendicular pulling. The shear force of the magnet along the surface is standardly many times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Plate material – mild steel gives the best results. Alloy steels lower magnetic permeability and holding force.

- Smoothness – full contact is obtained only on smooth steel. Rough texture create air cushions, weakening the magnet.

- Thermal environment – temperature increase causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under parallel forces the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate lowers the lifting capacity.

Warnings

Shattering risk

Watch out for shards. Magnets can fracture upon uncontrolled impact, launching shards into the air. Eye protection is mandatory.

Safe operation

Handle magnets with awareness. Their huge power can shock even experienced users. Be vigilant and respect their power.

Operating temperature

Keep cool. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, look for special high-temperature series (H, SH, UH).

Bodily injuries

Danger of trauma: The attraction force is so immense that it can cause blood blisters, pinching, and even bone fractures. Protective gloves are recommended.

Swallowing risk

Always keep magnets away from children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are very dangerous.

Electronic devices

Powerful magnetic fields can corrupt files on payment cards, hard drives, and storage devices. Keep a distance of at least 10 cm.

Nickel coating and allergies

Nickel alert: The Ni-Cu-Ni coating consists of nickel. If redness occurs, immediately stop handling magnets and wear gloves.

Do not drill into magnets

Fire warning: Neodymium dust is highly flammable. Avoid machining magnets in home conditions as this risks ignition.

Danger to pacemakers

Patients with a pacemaker should maintain an large gap from magnets. The magnetism can stop the operation of the implant.

Magnetic interference

GPS units and smartphones are extremely sensitive to magnetism. Direct contact with a strong magnet can decalibrate the internal compass in your phone.

![SM 32x200 [2xM8] / N42 - magnetic separator SM 32x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-fub.jpg)