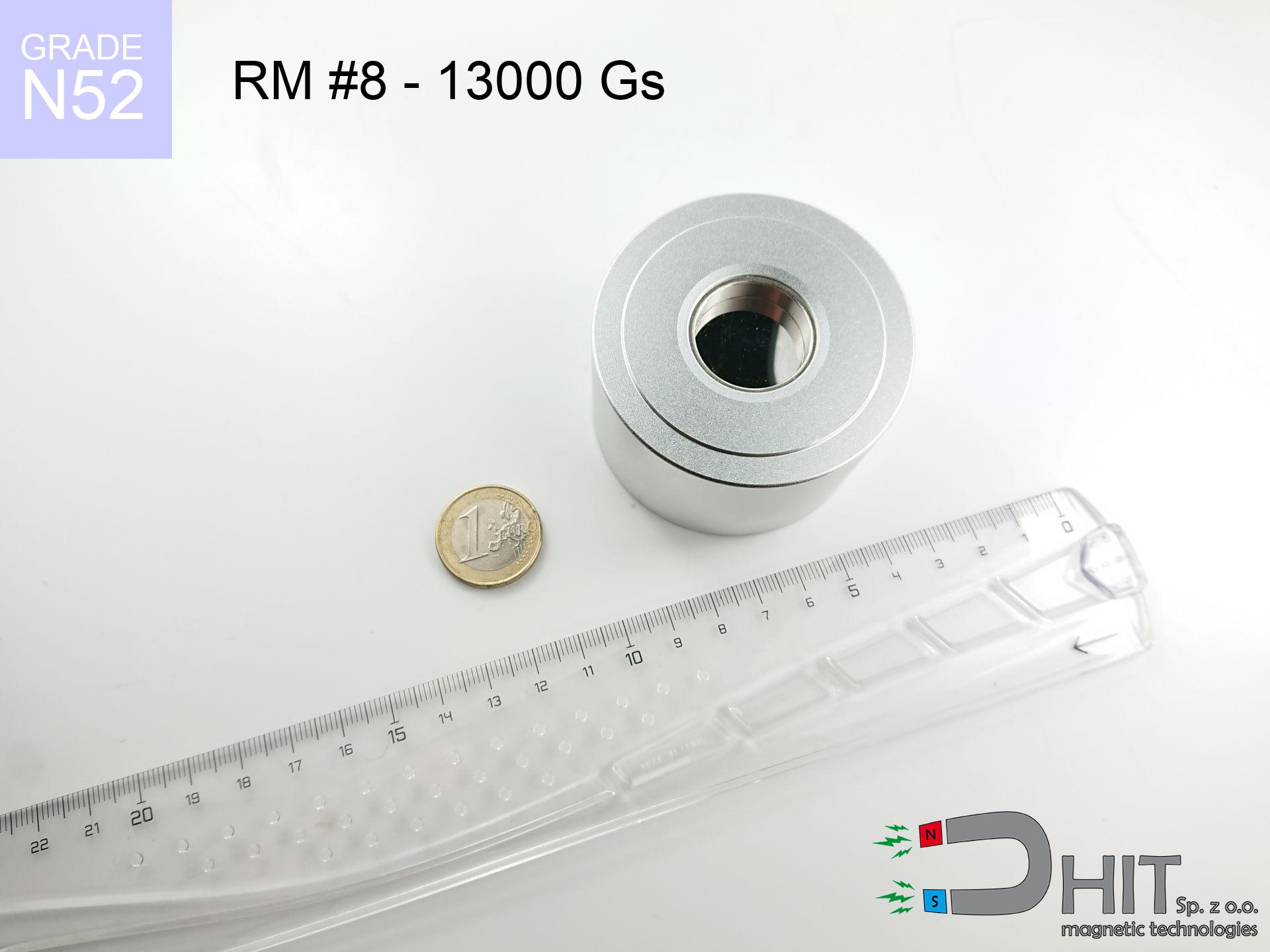

RM R8 ULTRA - 13000 Gs / N52 - magnetic distributor

magnetic distributor

Catalog no 280400

GTIN/EAN: 5906301814498

Weight

382 g

Magnetization Direction

↑ axial

Coating

[NiCuNi] Nickel

200.00 ZŁ with VAT / pcs + price for transport

162.60 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

alternatively contact us using

form

the contact section.

Specifications along with form of a neodymium magnet can be verified on our

power calculator.

Order by 14:00 and we’ll ship today!

Product card - RM R8 ULTRA - 13000 Gs / N52 - magnetic distributor

Specification / characteristics - RM R8 ULTRA - 13000 Gs / N52 - magnetic distributor

| properties | values |

|---|---|

| Cat. no. | 280400 |

| GTIN/EAN | 5906301814498 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 382 g |

| Magnetization Direction | ↑ axial |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

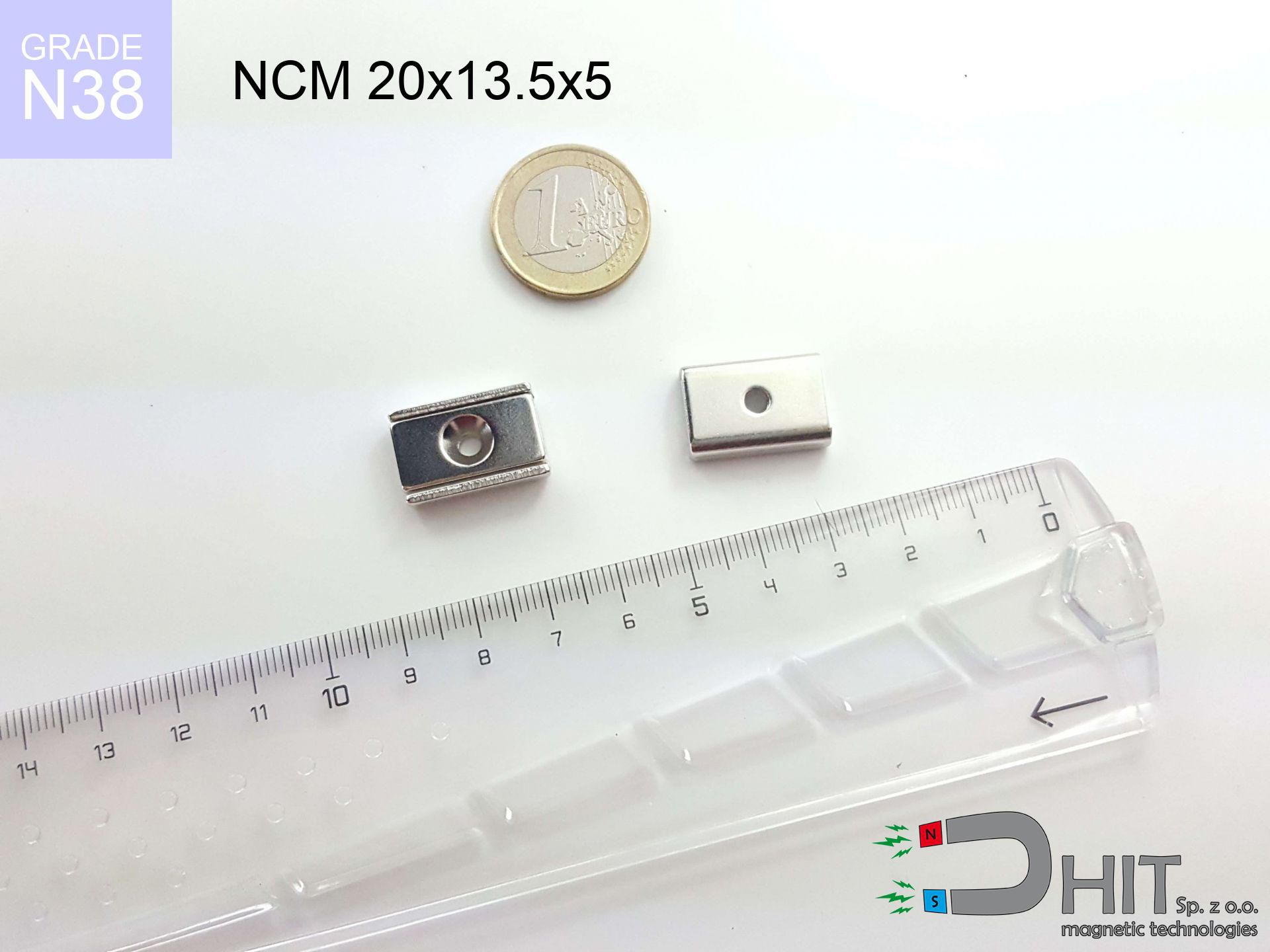

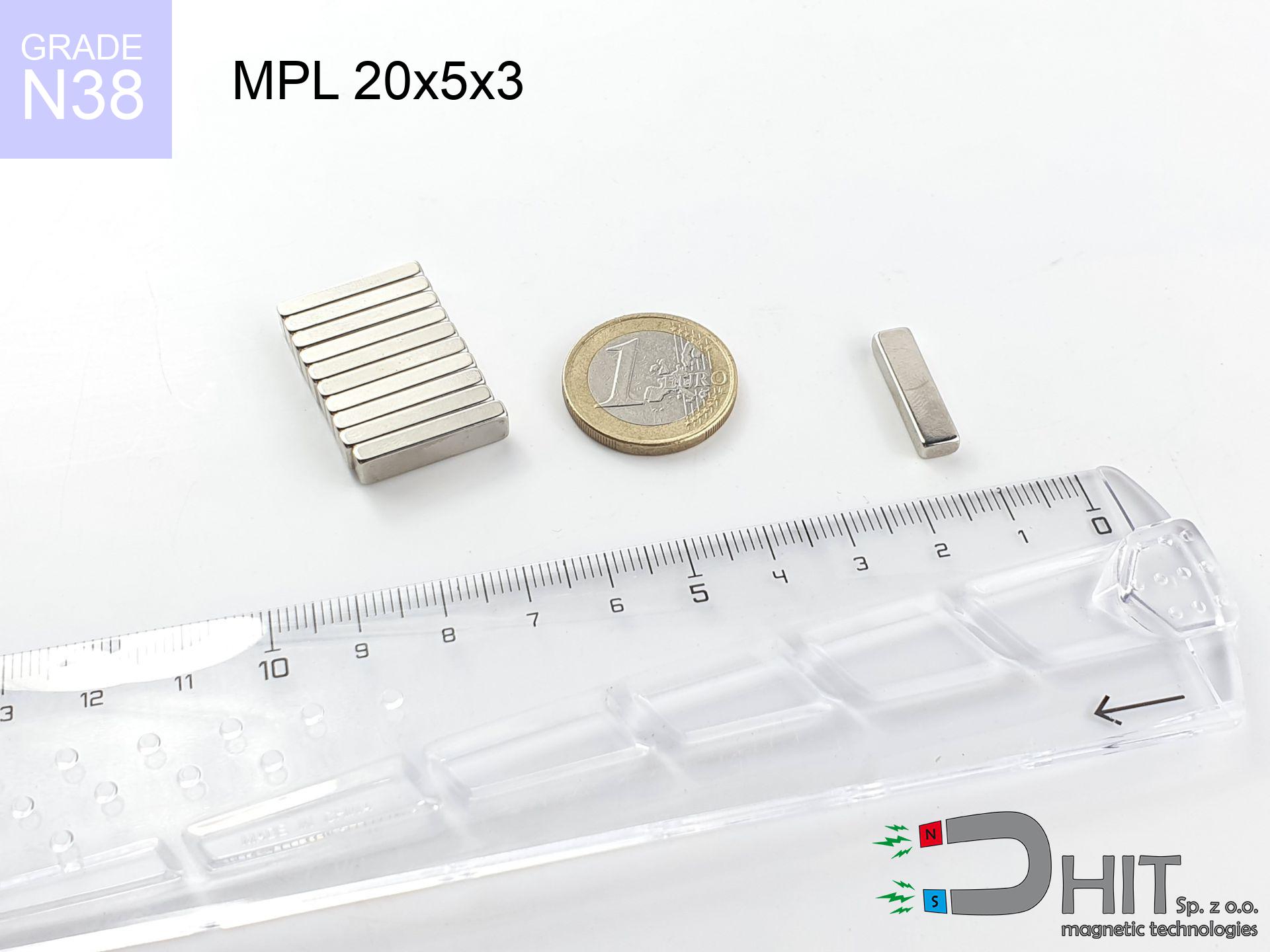

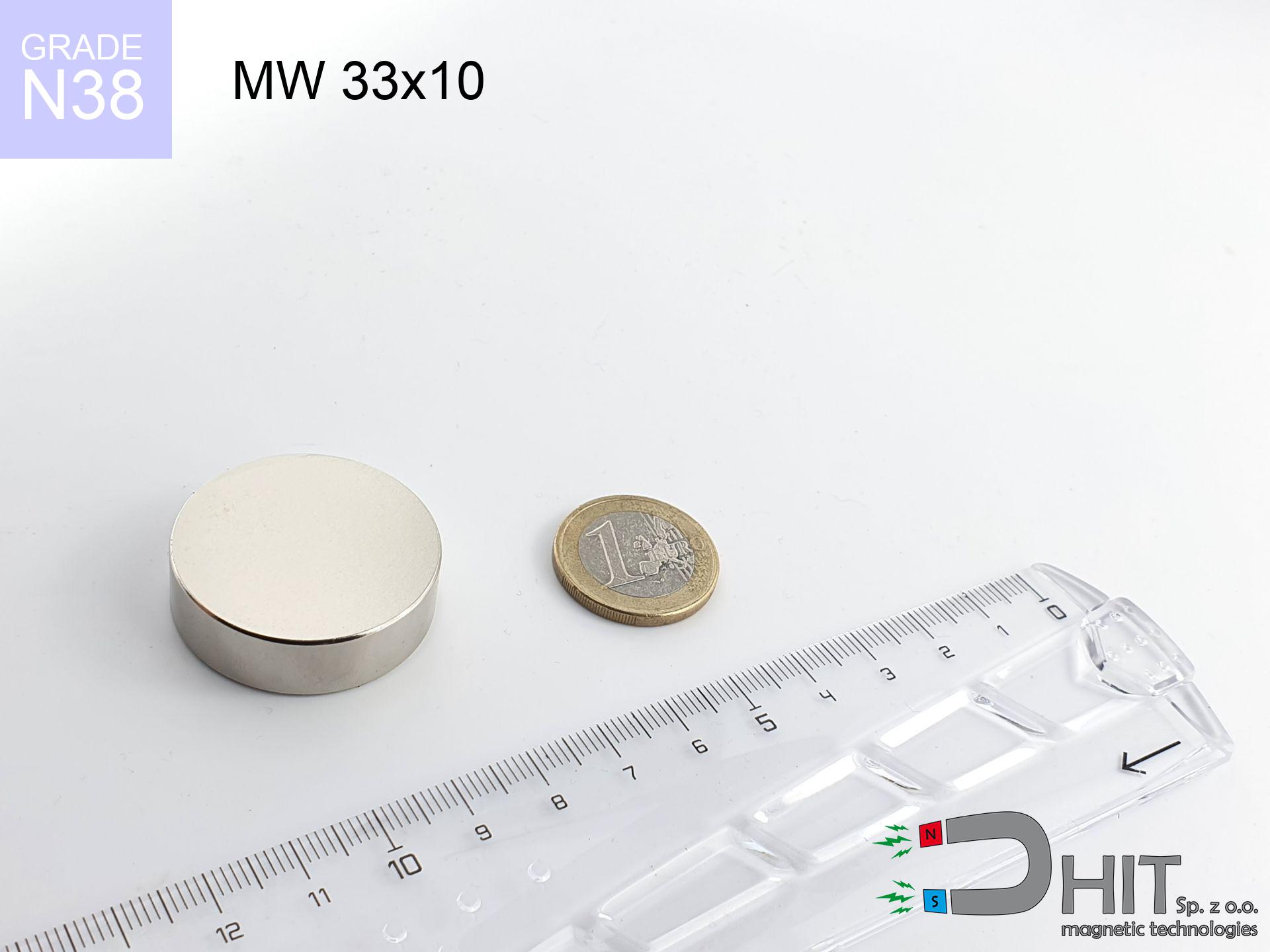

Check out more proposals

Advantages and disadvantages of neodymium magnets.

Strengths

- They have constant strength, and over around 10 years their attraction force decreases symbolically – ~1% (in testing),

- They do not lose their magnetic properties even under strong external field,

- In other words, due to the glossy layer of nickel, the element gains a professional look,

- The surface of neodymium magnets generates a maximum magnetic field – this is one of their assets,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- Thanks to flexibility in constructing and the capacity to customize to individual projects,

- Huge importance in high-tech industry – they find application in computer drives, electric drive systems, medical equipment, as well as industrial machines.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Cons

- To avoid cracks under impact, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in creating threads and complicated forms in magnets, we propose using casing - magnetic holder.

- Health risk to health – tiny shards of magnets can be dangerous, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Furthermore, small components of these devices can be problematic in diagnostics medical in case of swallowing.

- Due to expensive raw materials, their price is relatively high,

Pull force analysis

Magnetic strength at its maximum – what it depends on?

- using a plate made of high-permeability steel, functioning as a circuit closing element

- possessing a massiveness of minimum 10 mm to avoid saturation

- with a surface free of scratches

- without the slightest air gap between the magnet and steel

- for force acting at a right angle (in the magnet axis)

- in stable room temperature

Magnet lifting force in use – key factors

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by veneer or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to pulling vertically. When slipping, the magnet holds much less (often approx. 20-30% of maximum force).

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Steel type – mild steel gives the best results. Higher carbon content lower magnetic permeability and holding force.

- Surface condition – ground elements guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Temperature – temperature increase results in weakening of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity testing was performed on plates with a smooth surface of optimal thickness, under a perpendicular pulling force, in contrast under shearing force the holding force is lower. Additionally, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of neodymium magnets

Dust explosion hazard

Fire warning: Rare earth powder is highly flammable. Do not process magnets without safety gear as this may cause fire.

Conscious usage

Use magnets consciously. Their huge power can shock even experienced users. Plan your moves and do not underestimate their force.

Safe distance

Intense magnetic fields can corrupt files on payment cards, HDDs, and storage devices. Keep a distance of at least 10 cm.

Pacemakers

People with a pacemaker must maintain an absolute distance from magnets. The magnetic field can interfere with the operation of the life-saving device.

Thermal limits

Do not overheat. NdFeB magnets are sensitive to heat. If you need operation above 80°C, look for special high-temperature series (H, SH, UH).

Protective goggles

Neodymium magnets are sintered ceramics, which means they are prone to chipping. Impact of two magnets will cause them cracking into small pieces.

Physical harm

Large magnets can break fingers in a fraction of a second. Under no circumstances place your hand between two strong magnets.

Compass and GPS

Navigation devices and mobile phones are extremely susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Danger to the youngest

Product intended for adults. Tiny parts can be swallowed, leading to intestinal necrosis. Store away from kids and pets.

Allergic reactions

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If redness happens, immediately stop handling magnets and use protective gear.