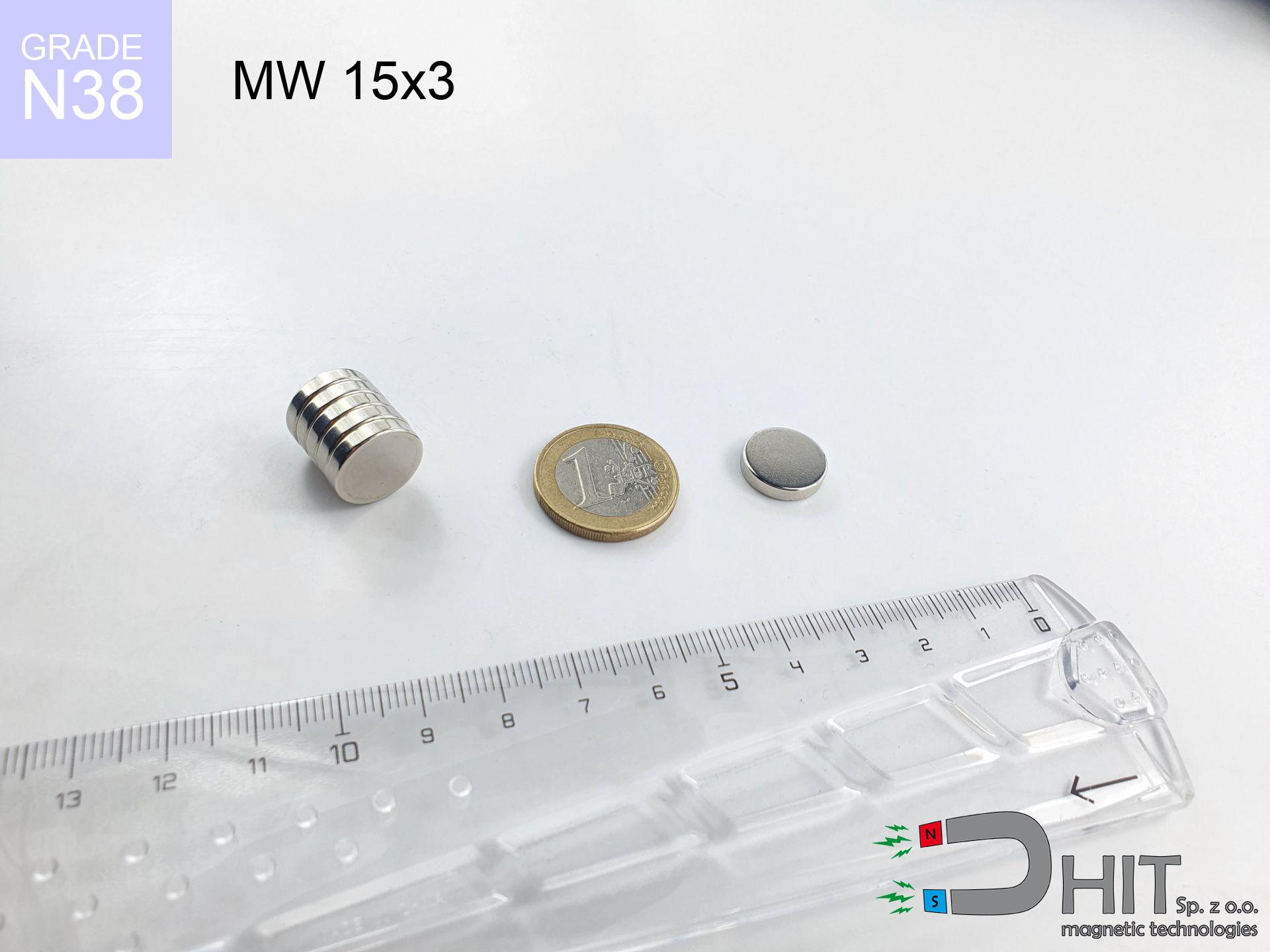

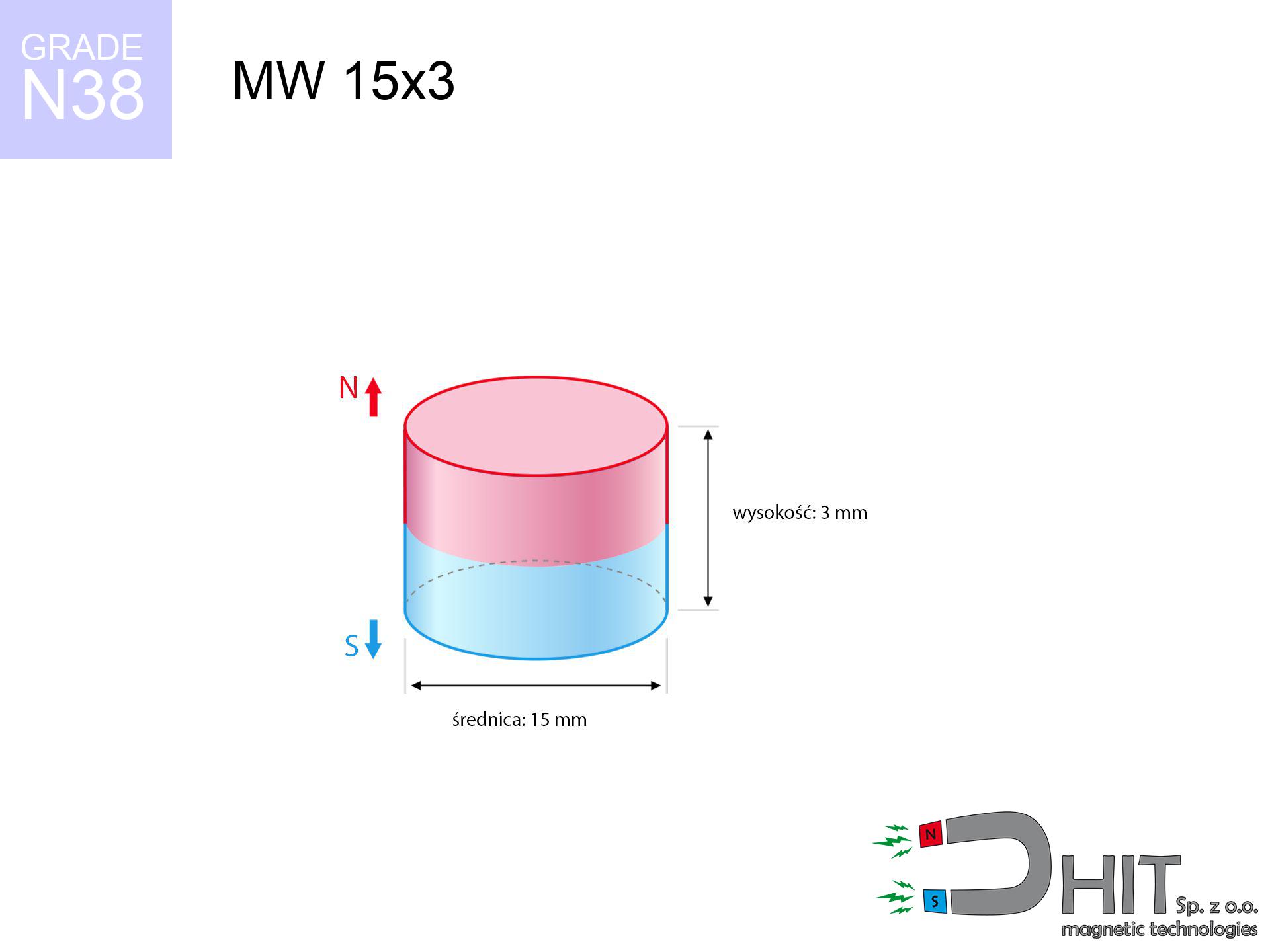

MW 15x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010029

GTIN/EAN: 5906301810285

Diameter Ø

15 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

3.98 g

Magnetization Direction

↑ axial

Load capacity

2.87 kg / 28.14 N

Magnetic Induction

230.16 mT / 2302 Gs

Coating

[NiCuNi] Nickel

1.624 ZŁ with VAT / pcs + price for transport

1.320 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

otherwise drop us a message via

contact form

the contact form page.

Lifting power as well as form of a magnet can be reviewed using our

magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Physical properties - MW 15x3 / N38 - cylindrical magnet

Specification / characteristics - MW 15x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010029 |

| GTIN/EAN | 5906301810285 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 15 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 3.98 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.87 kg / 28.14 N |

| Magnetic Induction ~ ? | 230.16 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - report

These values represent the direct effect of a physical calculation. Values were calculated on algorithms for the material Nd2Fe14B. Operational conditions might slightly deviate from the simulation results. Please consider these data as a reference point for designers.

Table 1: Static pull force (force vs gap) - interaction chart

MW 15x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2301 Gs

230.1 mT

|

2.87 kg / 6.33 pounds

2870.0 g / 28.2 N

|

strong |

| 1 mm |

2098 Gs

209.8 mT

|

2.39 kg / 5.26 pounds

2386.5 g / 23.4 N

|

strong |

| 2 mm |

1842 Gs

184.2 mT

|

1.84 kg / 4.05 pounds

1838.5 g / 18.0 N

|

low risk |

| 3 mm |

1570 Gs

157.0 mT

|

1.34 kg / 2.95 pounds

1337.0 g / 13.1 N

|

low risk |

| 5 mm |

1084 Gs

108.4 mT

|

0.64 kg / 1.40 pounds

637.0 g / 6.2 N

|

low risk |

| 10 mm |

410 Gs

41.0 mT

|

0.09 kg / 0.20 pounds

91.3 g / 0.9 N

|

low risk |

| 15 mm |

178 Gs

17.8 mT

|

0.02 kg / 0.04 pounds

17.1 g / 0.2 N

|

low risk |

| 20 mm |

89 Gs

8.9 mT

|

0.00 kg / 0.01 pounds

4.3 g / 0.0 N

|

low risk |

| 30 mm |

31 Gs

3.1 mT

|

0.00 kg / 0.00 pounds

0.5 g / 0.0 N

|

low risk |

| 50 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Shear hold (vertical surface)

MW 15x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.57 kg / 1.27 pounds

574.0 g / 5.6 N

|

| 1 mm | Stal (~0.2) |

0.48 kg / 1.05 pounds

478.0 g / 4.7 N

|

| 2 mm | Stal (~0.2) |

0.37 kg / 0.81 pounds

368.0 g / 3.6 N

|

| 3 mm | Stal (~0.2) |

0.27 kg / 0.59 pounds

268.0 g / 2.6 N

|

| 5 mm | Stal (~0.2) |

0.13 kg / 0.28 pounds

128.0 g / 1.3 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

18.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 15x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.86 kg / 1.90 pounds

861.0 g / 8.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.57 kg / 1.27 pounds

574.0 g / 5.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.29 kg / 0.63 pounds

287.0 g / 2.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.44 kg / 3.16 pounds

1435.0 g / 14.1 N

|

Table 4: Steel thickness (saturation) - power losses

MW 15x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.29 kg / 0.63 pounds

287.0 g / 2.8 N

|

| 1 mm |

|

0.72 kg / 1.58 pounds

717.5 g / 7.0 N

|

| 2 mm |

|

1.44 kg / 3.16 pounds

1435.0 g / 14.1 N

|

| 3 mm |

|

2.15 kg / 4.75 pounds

2152.5 g / 21.1 N

|

| 5 mm |

|

2.87 kg / 6.33 pounds

2870.0 g / 28.2 N

|

| 10 mm |

|

2.87 kg / 6.33 pounds

2870.0 g / 28.2 N

|

| 11 mm |

|

2.87 kg / 6.33 pounds

2870.0 g / 28.2 N

|

| 12 mm |

|

2.87 kg / 6.33 pounds

2870.0 g / 28.2 N

|

Table 5: Thermal stability (stability) - power drop

MW 15x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.87 kg / 6.33 pounds

2870.0 g / 28.2 N

|

OK |

| 40 °C | -2.2% |

2.81 kg / 6.19 pounds

2806.9 g / 27.5 N

|

OK |

| 60 °C | -4.4% |

2.74 kg / 6.05 pounds

2743.7 g / 26.9 N

|

|

| 80 °C | -6.6% |

2.68 kg / 5.91 pounds

2680.6 g / 26.3 N

|

|

| 100 °C | -28.8% |

2.04 kg / 4.51 pounds

2043.4 g / 20.0 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 15x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

5.77 kg / 12.72 pounds

3 869 Gs

|

0.87 kg / 1.91 pounds

865 g / 8.5 N

|

N/A |

| 1 mm |

5.32 kg / 11.73 pounds

4 419 Gs

|

0.80 kg / 1.76 pounds

798 g / 7.8 N

|

4.79 kg / 10.55 pounds

~0 Gs

|

| 2 mm |

4.80 kg / 10.57 pounds

4 196 Gs

|

0.72 kg / 1.59 pounds

719 g / 7.1 N

|

4.32 kg / 9.52 pounds

~0 Gs

|

| 3 mm |

4.25 kg / 9.36 pounds

3 948 Gs

|

0.64 kg / 1.40 pounds

637 g / 6.2 N

|

3.82 kg / 8.42 pounds

~0 Gs

|

| 5 mm |

3.17 kg / 6.99 pounds

3 412 Gs

|

0.48 kg / 1.05 pounds

476 g / 4.7 N

|

2.85 kg / 6.29 pounds

~0 Gs

|

| 10 mm |

1.28 kg / 2.82 pounds

2 168 Gs

|

0.19 kg / 0.42 pounds

192 g / 1.9 N

|

1.15 kg / 2.54 pounds

~0 Gs

|

| 20 mm |

0.18 kg / 0.40 pounds

821 Gs

|

0.03 kg / 0.06 pounds

28 g / 0.3 N

|

0.17 kg / 0.36 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 pounds

101 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

62 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

41 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

28 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

20 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

15 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 15x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 15x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.62 km/h

(7.67 m/s)

|

0.12 J | |

| 30 mm |

46.91 km/h

(13.03 m/s)

|

0.34 J | |

| 50 mm |

60.56 km/h

(16.82 m/s)

|

0.56 J | |

| 100 mm |

85.64 km/h

(23.79 m/s)

|

1.13 J |

Table 9: Anti-corrosion coating durability

MW 15x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 15x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 718 Mx | 47.2 µWb |

| Pc Coefficient | 0.29 | Low (Flat) |

Table 11: Submerged application

MW 15x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.87 kg | Standard |

| Water (riverbed) |

3.29 kg

(+0.42 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical wall, the magnet holds just ~20% of its nominal pull.

2. Steel saturation

*Thin steel (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.29

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of neodymium magnets.

Strengths

- They retain magnetic properties for around 10 years – the loss is just ~1% (according to analyses),

- They are resistant to demagnetization induced by presence of other magnetic fields,

- Thanks to the reflective finish, the surface of Ni-Cu-Ni, gold-plated, or silver-plated gives an elegant appearance,

- Magnets possess huge magnetic induction on the surface,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of custom forming as well as adapting to defined conditions,

- Significant place in advanced technology sectors – they serve a role in magnetic memories, electromotive mechanisms, precision medical tools, and industrial machines.

- Thanks to their power density, small magnets offer high operating force, with minimal size,

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- We recommend a housing - magnetic mechanism, due to difficulties in creating threads inside the magnet and complicated forms.

- Possible danger resulting from small fragments of magnets are risky, when accidentally swallowed, which becomes key in the context of child safety. Additionally, tiny parts of these products can disrupt the diagnostic process medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which hinders application in large quantities

Pull force analysis

Maximum magnetic pulling force – what affects it?

- with the application of a yoke made of low-carbon steel, ensuring full magnetic saturation

- possessing a massiveness of at least 10 mm to ensure full flux closure

- with a plane free of scratches

- without the slightest air gap between the magnet and steel

- under perpendicular force direction (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Lifting capacity in real conditions – factors

- Gap between surfaces – even a fraction of a millimeter of distance (caused e.g. by veneer or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – maximum parameter is available only during pulling at a 90° angle. The force required to slide of the magnet along the surface is usually several times lower (approx. 1/5 of the lifting capacity).

- Steel thickness – too thin plate does not close the flux, causing part of the power to be wasted to the other side.

- Metal type – different alloys reacts the same. High carbon content worsen the interaction with the magnet.

- Base smoothness – the more even the surface, the better the adhesion and higher the lifting capacity. Unevenness creates an air distance.

- Temperature influence – hot environment reduces pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity was assessed with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular detachment force, however under parallel forces the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate reduces the lifting capacity.

Precautions when working with neodymium magnets

Conscious usage

Use magnets with awareness. Their huge power can shock even experienced users. Plan your moves and do not underestimate their force.

Fragile material

Protect your eyes. Magnets can explode upon violent connection, launching shards into the air. We recommend safety glasses.

Do not drill into magnets

Powder created during machining of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Heat sensitivity

Standard neodymium magnets (N-type) lose magnetization when the temperature goes above 80°C. The loss of strength is permanent.

No play value

These products are not suitable for play. Accidental ingestion of a few magnets may result in them connecting inside the digestive tract, which poses a direct threat to life and necessitates urgent medical intervention.

Electronic devices

Device Safety: Strong magnets can damage payment cards and sensitive devices (pacemakers, medical aids, timepieces).

Phone sensors

GPS units and smartphones are extremely susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can decalibrate the internal compass in your phone.

Warning for allergy sufferers

Allergy Notice: The Ni-Cu-Ni coating consists of nickel. If redness happens, cease working with magnets and use protective gear.

Physical harm

Mind your fingers. Two large magnets will join immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

ICD Warning

Individuals with a ICD must maintain an safe separation from magnets. The magnetic field can interfere with the operation of the life-saving device.

![MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl-40x10x5x27-3.5-miw.jpg)

![SM 25x250 [2xM8] / N42 - magnetic separator SM 25x250 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x250-2xm8-ker.jpg)