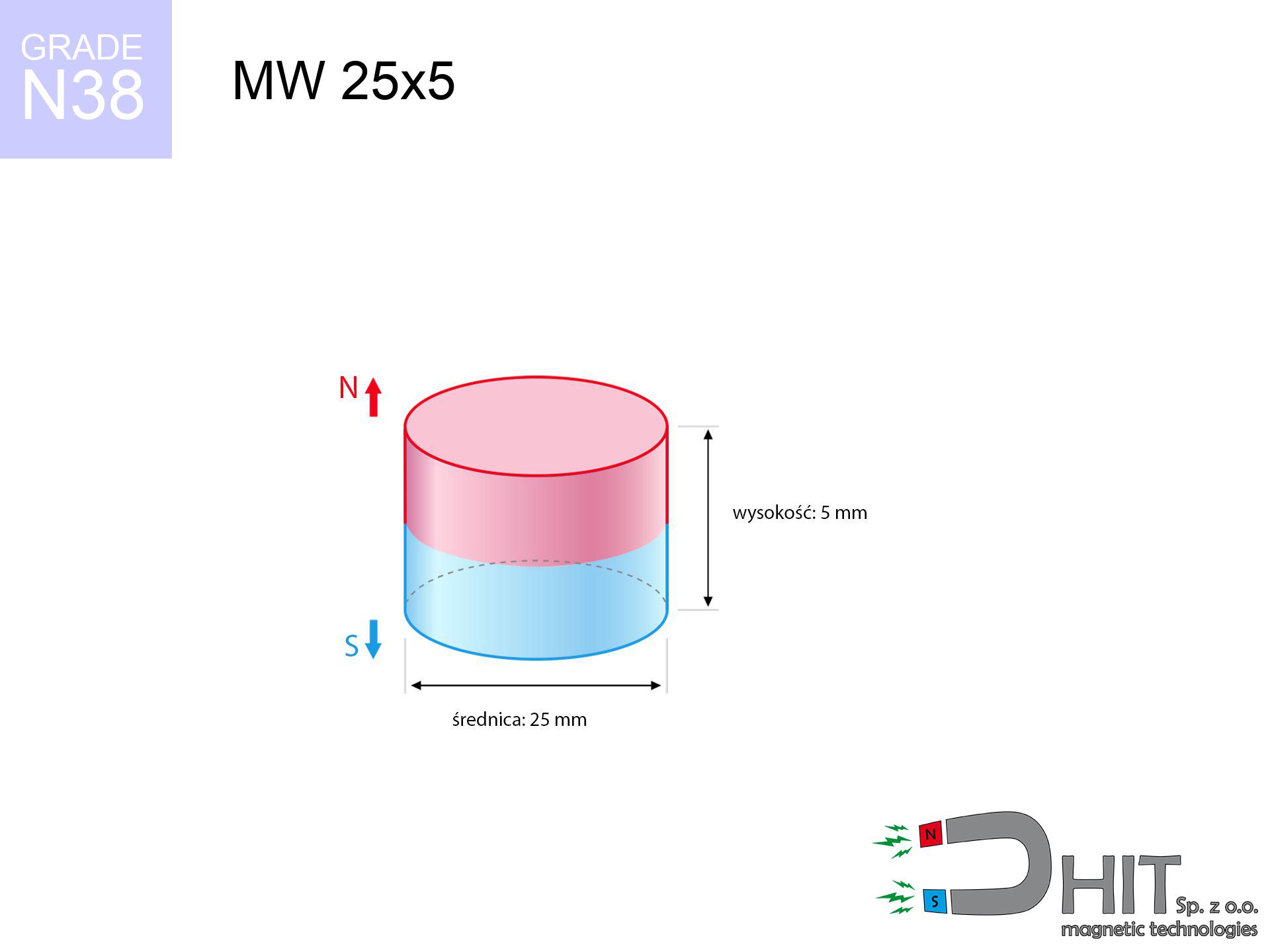

MW 25x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010049

GTIN/EAN: 5906301810483

Diameter Ø

25 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

18.41 g

Magnetization Direction

↑ axial

Load capacity

7.98 kg / 78.25 N

Magnetic Induction

230.20 mT / 2302 Gs

Coating

[NiCuNi] Nickel

8.39 ZŁ with VAT / pcs + price for transport

6.82 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer let us know using

our online form

the contact form page.

Lifting power as well as appearance of a neodymium magnet can be verified using our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - MW 25x5 / N38 - cylindrical magnet

Specification / characteristics - MW 25x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010049 |

| GTIN/EAN | 5906301810483 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 25 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 18.41 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.98 kg / 78.25 N |

| Magnetic Induction ~ ? | 230.20 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - report

These data are the direct effect of a engineering analysis. Results rely on algorithms for the class Nd2Fe14B. Real-world conditions might slightly differ. Use these calculations as a supplementary guide during assembly planning.

Table 1: Static force (force vs distance) - interaction chart

MW 25x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2302 Gs

230.2 mT

|

7.98 kg / 17.59 lbs

7980.0 g / 78.3 N

|

warning |

| 1 mm |

2189 Gs

218.9 mT

|

7.21 kg / 15.91 lbs

7214.9 g / 70.8 N

|

warning |

| 2 mm |

2050 Gs

205.0 mT

|

6.33 kg / 13.95 lbs

6329.3 g / 62.1 N

|

warning |

| 3 mm |

1895 Gs

189.5 mT

|

5.41 kg / 11.93 lbs

5410.7 g / 53.1 N

|

warning |

| 5 mm |

1570 Gs

157.0 mT

|

3.72 kg / 8.19 lbs

3715.4 g / 36.4 N

|

warning |

| 10 mm |

890 Gs

89.0 mT

|

1.19 kg / 2.63 lbs

1192.8 g / 11.7 N

|

low risk |

| 15 mm |

495 Gs

49.5 mT

|

0.37 kg / 0.81 lbs

368.5 g / 3.6 N

|

low risk |

| 20 mm |

288 Gs

28.8 mT

|

0.12 kg / 0.28 lbs

124.8 g / 1.2 N

|

low risk |

| 30 mm |

116 Gs

11.6 mT

|

0.02 kg / 0.04 lbs

20.2 g / 0.2 N

|

low risk |

| 50 mm |

31 Gs

3.1 mT

|

0.00 kg / 0.00 lbs

1.4 g / 0.0 N

|

low risk |

Table 2: Slippage load (wall)

MW 25x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.60 kg / 3.52 lbs

1596.0 g / 15.7 N

|

| 1 mm | Stal (~0.2) |

1.44 kg / 3.18 lbs

1442.0 g / 14.1 N

|

| 2 mm | Stal (~0.2) |

1.27 kg / 2.79 lbs

1266.0 g / 12.4 N

|

| 3 mm | Stal (~0.2) |

1.08 kg / 2.39 lbs

1082.0 g / 10.6 N

|

| 5 mm | Stal (~0.2) |

0.74 kg / 1.64 lbs

744.0 g / 7.3 N

|

| 10 mm | Stal (~0.2) |

0.24 kg / 0.52 lbs

238.0 g / 2.3 N

|

| 15 mm | Stal (~0.2) |

0.07 kg / 0.16 lbs

74.0 g / 0.7 N

|

| 20 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

24.0 g / 0.2 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 25x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.39 kg / 5.28 lbs

2394.0 g / 23.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.60 kg / 3.52 lbs

1596.0 g / 15.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.80 kg / 1.76 lbs

798.0 g / 7.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.99 kg / 8.80 lbs

3990.0 g / 39.1 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 25x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.80 kg / 1.76 lbs

798.0 g / 7.8 N

|

| 1 mm |

|

2.00 kg / 4.40 lbs

1995.0 g / 19.6 N

|

| 2 mm |

|

3.99 kg / 8.80 lbs

3990.0 g / 39.1 N

|

| 3 mm |

|

5.99 kg / 13.19 lbs

5985.0 g / 58.7 N

|

| 5 mm |

|

7.98 kg / 17.59 lbs

7980.0 g / 78.3 N

|

| 10 mm |

|

7.98 kg / 17.59 lbs

7980.0 g / 78.3 N

|

| 11 mm |

|

7.98 kg / 17.59 lbs

7980.0 g / 78.3 N

|

| 12 mm |

|

7.98 kg / 17.59 lbs

7980.0 g / 78.3 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 25x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.98 kg / 17.59 lbs

7980.0 g / 78.3 N

|

OK |

| 40 °C | -2.2% |

7.80 kg / 17.21 lbs

7804.4 g / 76.6 N

|

OK |

| 60 °C | -4.4% |

7.63 kg / 16.82 lbs

7628.9 g / 74.8 N

|

|

| 80 °C | -6.6% |

7.45 kg / 16.43 lbs

7453.3 g / 73.1 N

|

|

| 100 °C | -28.8% |

5.68 kg / 12.53 lbs

5681.8 g / 55.7 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MW 25x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

16.03 kg / 35.34 lbs

3 871 Gs

|

2.40 kg / 5.30 lbs

2405 g / 23.6 N

|

N/A |

| 1 mm |

15.31 kg / 33.75 lbs

4 498 Gs

|

2.30 kg / 5.06 lbs

2296 g / 22.5 N

|

13.78 kg / 30.38 lbs

~0 Gs

|

| 2 mm |

14.49 kg / 31.95 lbs

4 377 Gs

|

2.17 kg / 4.79 lbs

2174 g / 21.3 N

|

13.05 kg / 28.76 lbs

~0 Gs

|

| 3 mm |

13.62 kg / 30.03 lbs

4 243 Gs

|

2.04 kg / 4.50 lbs

2043 g / 20.0 N

|

12.26 kg / 27.03 lbs

~0 Gs

|

| 5 mm |

11.79 kg / 26.00 lbs

3 948 Gs

|

1.77 kg / 3.90 lbs

1769 g / 17.4 N

|

10.61 kg / 23.40 lbs

~0 Gs

|

| 10 mm |

7.46 kg / 16.46 lbs

3 141 Gs

|

1.12 kg / 2.47 lbs

1120 g / 11.0 N

|

6.72 kg / 14.81 lbs

~0 Gs

|

| 20 mm |

2.40 kg / 5.28 lbs

1 780 Gs

|

0.36 kg / 0.79 lbs

359 g / 3.5 N

|

2.16 kg / 4.75 lbs

~0 Gs

|

| 50 mm |

0.10 kg / 0.21 lbs

355 Gs

|

0.01 kg / 0.03 lbs

14 g / 0.1 N

|

0.09 kg / 0.19 lbs

~0 Gs

|

| 60 mm |

0.04 kg / 0.09 lbs

231 Gs

|

0.01 kg / 0.01 lbs

6 g / 0.1 N

|

0.04 kg / 0.08 lbs

~0 Gs

|

| 70 mm |

0.02 kg / 0.04 lbs

158 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

| 80 mm |

0.01 kg / 0.02 lbs

112 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.01 kg / 0.01 lbs

82 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 lbs

62 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 25x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 10.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 6.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (cracking risk) - warning

MW 25x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.87 km/h

(6.35 m/s)

|

0.37 J | |

| 30 mm |

36.43 km/h

(10.12 m/s)

|

0.94 J | |

| 50 mm |

46.96 km/h

(13.04 m/s)

|

1.57 J | |

| 100 mm |

66.40 km/h

(18.44 m/s)

|

3.13 J |

Table 9: Surface protection spec

MW 25x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 25x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 13 107 Mx | 131.1 µWb |

| Pc Coefficient | 0.29 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 25x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.98 kg | Standard |

| Water (riverbed) |

9.14 kg

(+1.16 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet retains merely a fraction of its nominal pull.

2. Steel saturation

*Thin steel (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.29

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more proposals

Pros as well as cons of neodymium magnets.

Benefits

- They have stable power, and over more than ten years their performance decreases symbolically – ~1% (in testing),

- They have excellent resistance to weakening of magnetic properties when exposed to external magnetic sources,

- By covering with a decorative coating of nickel, the element gains an professional look,

- Magnets are distinguished by very high magnetic induction on the outer side,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of individual shaping and optimizing to complex requirements,

- Huge importance in high-tech industry – they find application in mass storage devices, motor assemblies, diagnostic systems, and modern systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which enables their usage in compact constructions

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Limited ability of making threads in the magnet and complicated shapes - preferred is cover - mounting mechanism.

- Potential hazard related to microscopic parts of magnets can be dangerous, in case of ingestion, which gains importance in the aspect of protecting the youngest. Additionally, small components of these products can complicate diagnosis medical in case of swallowing.

- With large orders the cost of neodymium magnets is a challenge,

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what affects it?

- with the use of a sheet made of special test steel, ensuring maximum field concentration

- with a cross-section of at least 10 mm

- characterized by lack of roughness

- without the slightest air gap between the magnet and steel

- under axial force direction (90-degree angle)

- at ambient temperature room level

Magnet lifting force in use – key factors

- Clearance – the presence of any layer (paint, dirt, air) acts as an insulator, which reduces power steeply (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Steel grade – ideal substrate is high-permeability steel. Stainless steels may generate lower lifting capacity.

- Surface quality – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Roughness acts like micro-gaps.

- Thermal factor – hot environment reduces pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under perpendicular forces, whereas under attempts to slide the magnet the lifting capacity is smaller. In addition, even a small distance between the magnet and the plate reduces the load capacity.

Precautions when working with neodymium magnets

Immense force

Be careful. Neodymium magnets act from a distance and connect with massive power, often quicker than you can move away.

Danger to the youngest

These products are not suitable for play. Accidental ingestion of several magnets can lead to them connecting inside the digestive tract, which poses a critical condition and necessitates immediate surgery.

Maximum temperature

Avoid heat. Neodymium magnets are susceptible to heat. If you require operation above 80°C, inquire about special high-temperature series (H, SH, UH).

Avoid contact if allergic

It is widely known that the nickel plating (the usual finish) is a common allergen. For allergy sufferers, avoid direct skin contact or select coated magnets.

Health Danger

For implant holders: Powerful magnets disrupt medical devices. Maintain minimum 30 cm distance or ask another person to work with the magnets.

Magnet fragility

Protect your eyes. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Bone fractures

Watch your fingers. Two large magnets will join immediately with a force of several hundred kilograms, destroying anything in their path. Exercise extreme caution!

Precision electronics

A strong magnetic field interferes with the operation of magnetometers in smartphones and navigation systems. Keep magnets close to a device to avoid damaging the sensors.

Do not drill into magnets

Combustion risk: Rare earth powder is explosive. Do not process magnets without safety gear as this may cause fire.

Protect data

Very strong magnetic fields can corrupt files on payment cards, HDDs, and other magnetic media. Stay away of min. 10 cm.

![UI 33x13x4 [C311] / N38 - badge holder UI 33x13x4 [C311] / N38 - badge holder](https://cdn3.dhit.pl/graphics/products/ui33x13x4-c311-vub.jpg)

![SM 25x300 [2xM8] / N52 - magnetic separator SM 25x300 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x300-2xm8-dij.jpg)