SM 18x100 [2xM5] / N42 - magnetic separator

magnetic separator

Catalog no 130269

GTIN/EAN: 5906301812715

Diameter Ø

18 mm [±1 mm]

Height

100 mm [±1 mm]

Weight

0.01 g

Magnetic Flux

~ 5 400 Gauss [±5%]

221.40 ZŁ with VAT / pcs + price for transport

180.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer contact us using

contact form

the contact form page.

Weight and structure of a magnet can be estimated using our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Physical properties - SM 18x100 [2xM5] / N42 - magnetic separator

Specification / characteristics - SM 18x100 [2xM5] / N42 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130269 |

| GTIN/EAN | 5906301812715 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

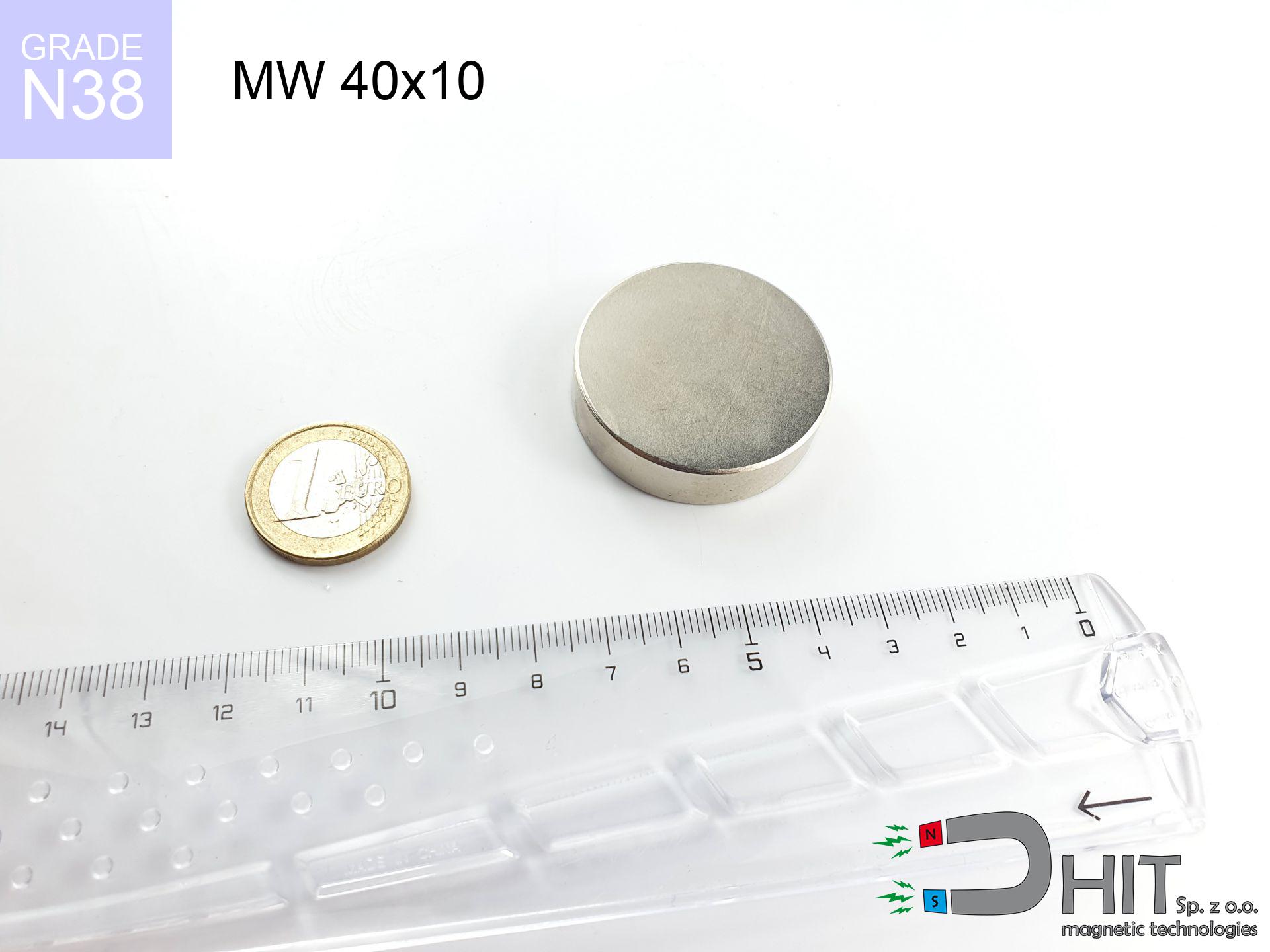

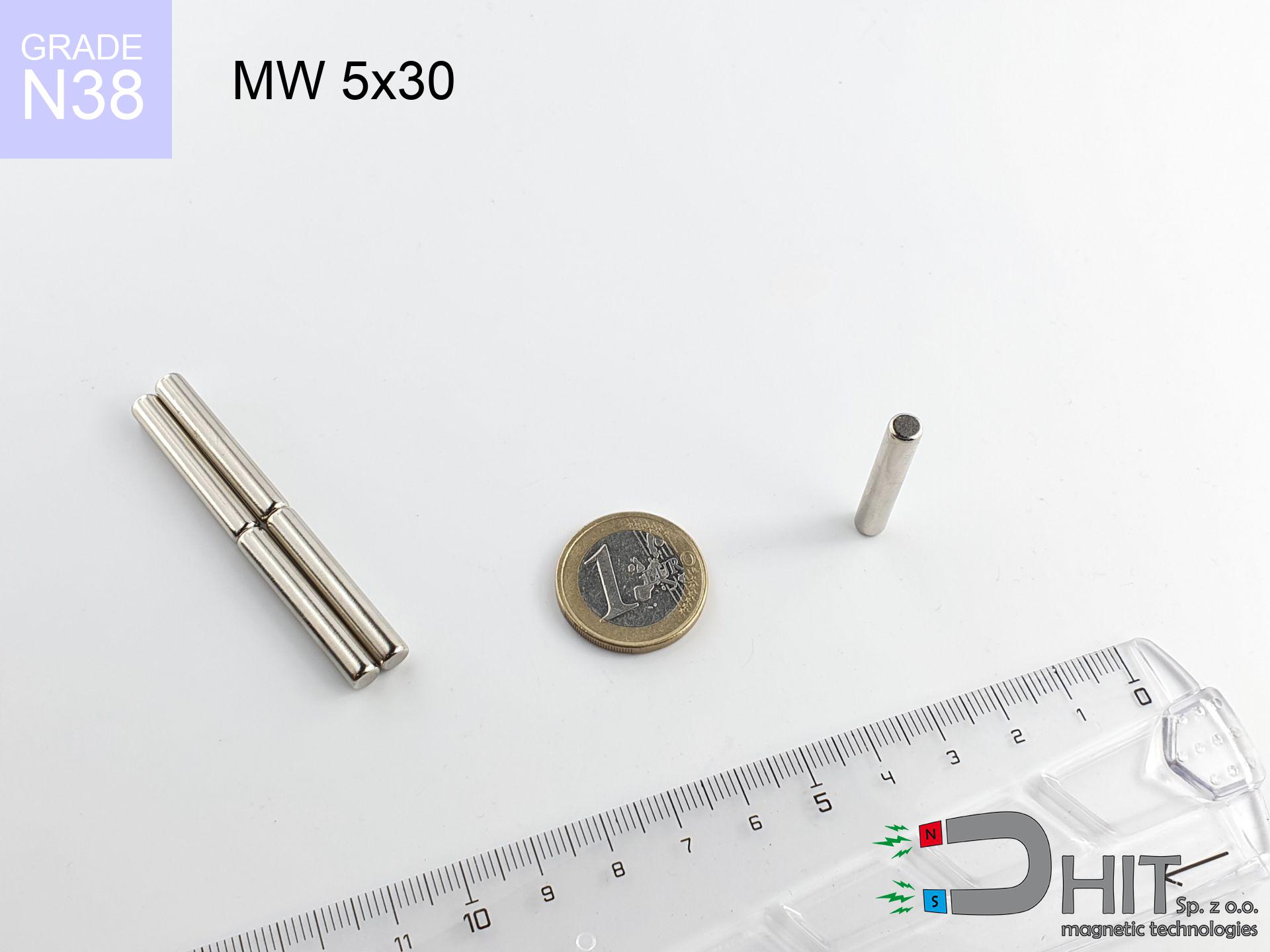

| Diameter Ø | 18 mm [±1 mm] |

| Height | 100 mm [±1 mm] |

| Weight | 0.01 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 5 400 Gauss [±5%] |

| Size/Mount Quantity | 2xM5 |

| Polarity | circumferential - 5 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N42

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.9-13.2 | kGs |

| remenance Br [min. - max.] ? | 1290-1320 | mT |

| coercivity bHc ? | 10.8-12.0 | kOe |

| coercivity bHc ? | 860-955 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 40-42 | BH max MGOe |

| energy density [min. - max.] ? | 318-334 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Table 1: Rod construction

SM 18x100 [2xM5] / N42

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 18 | mm |

| Total length | 100 | mm (L) |

| Active length | 64 | mm |

| Section count | 2 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~193 | g |

| Active area | 36 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 3.8 | kg (theor.) |

| Induction (surface) | ~5 400 | Gauss (Max) |

Chart 2: Field profile (2 sections)

Chart 3: Temperature performance

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of Nd2Fe14B magnets.

Pros

- Their power is maintained, and after around ten years it drops only by ~1% (theoretically),

- They are extremely resistant to demagnetization induced by external magnetic fields,

- A magnet with a metallic silver surface looks better,

- The surface of neodymium magnets generates a concentrated magnetic field – this is one of their assets,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- Due to the option of flexible shaping and adaptation to custom solutions, NdFeB magnets can be produced in a wide range of forms and dimensions, which amplifies use scope,

- Key role in advanced technology sectors – they are utilized in computer drives, drive modules, diagnostic systems, as well as industrial machines.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Limitations

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a steel housing, which not only protects them against impacts but also raises their durability

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- We suggest casing - magnetic mount, due to difficulties in producing threads inside the magnet and complex forms.

- Potential hazard to health – tiny shards of magnets are risky, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that small elements of these magnets can be problematic in diagnostics medical after entering the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which hinders application in large quantities

Lifting parameters

Maximum holding power of the magnet – what contributes to it?

- on a block made of structural steel, perfectly concentrating the magnetic field

- whose thickness equals approx. 10 mm

- characterized by even structure

- under conditions of ideal adhesion (metal-to-metal)

- for force acting at a right angle (pull-off, not shear)

- in neutral thermal conditions

Practical aspects of lifting capacity – factors

- Gap between surfaces – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Plate thickness – insufficiently thick plate causes magnetic saturation, causing part of the power to be escaped to the other side.

- Material composition – different alloys attracts identically. High carbon content weaken the attraction effect.

- Surface condition – smooth surfaces ensure maximum contact, which increases field saturation. Rough surfaces weaken the grip.

- Thermal environment – heating the magnet results in weakening of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity testing was performed on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, however under parallel forces the holding force is lower. In addition, even a minimal clearance between the magnet and the plate reduces the holding force.

Precautions when working with NdFeB magnets

Pinching danger

Protect your hands. Two powerful magnets will join immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

Power loss in heat

Standard neodymium magnets (grade N) undergo demagnetization when the temperature surpasses 80°C. Damage is permanent.

Pacemakers

Health Alert: Neodymium magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Beware of splinters

NdFeB magnets are sintered ceramics, meaning they are fragile like glass. Impact of two magnets leads to them cracking into shards.

Powerful field

Before starting, check safety instructions. Sudden snapping can break the magnet or hurt your hand. Think ahead.

Dust is flammable

Powder produced during machining of magnets is combustible. Do not drill into magnets unless you are an expert.

Sensitization to coating

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If skin irritation occurs, immediately stop handling magnets and wear gloves.

Phone sensors

An intense magnetic field interferes with the functioning of magnetometers in phones and GPS navigation. Do not bring magnets near a smartphone to avoid breaking the sensors.

Keep away from computers

Equipment safety: Neodymium magnets can damage data carriers and delicate electronics (pacemakers, medical aids, timepieces).

No play value

Strictly store magnets out of reach of children. Ingestion danger is significant, and the effects of magnets clamping inside the body are fatal.

![Magnetic bar SM 18x100 [2xM5] / N42 Magnetic bar SM 18x100 [2xM5] / N42](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 18x100 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x100-2xm5-pem.jpg)

![SM 25x350 [2xM8] / N42 - magnetic separator SM 25x350 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-pim.jpg)