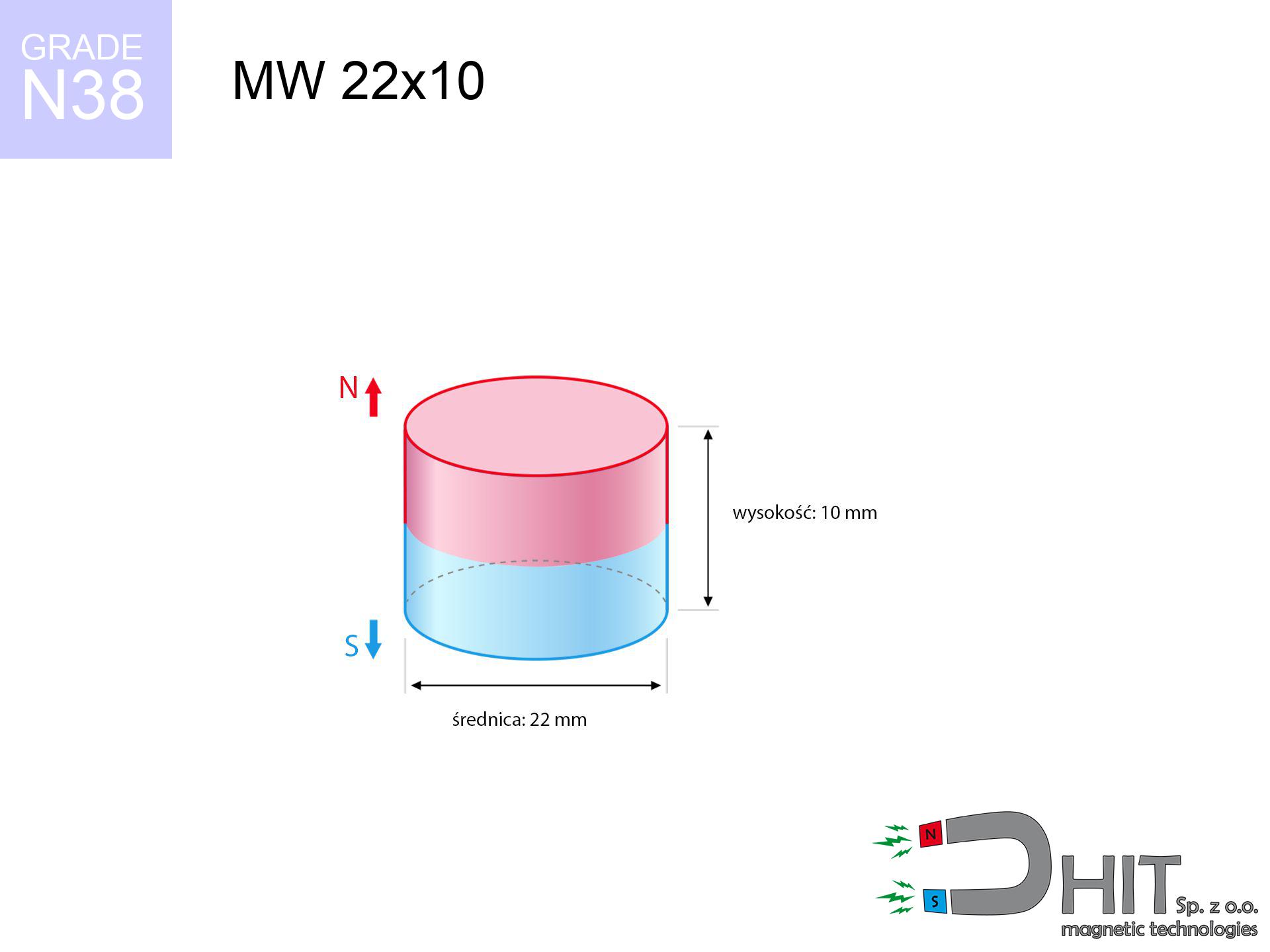

MW 22x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010046

GTIN/EAN: 5906301810452

Diameter Ø

22 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

28.51 g

Magnetization Direction

↑ axial

Load capacity

14.75 kg / 144.65 N

Magnetic Induction

416.85 mT / 4168 Gs

Coating

[NiCuNi] Nickel

11.30 ZŁ with VAT / pcs + price for transport

9.19 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or contact us via

form

the contact form page.

Strength along with form of a neodymium magnet can be verified using our

magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical data - MW 22x10 / N38 - cylindrical magnet

Specification / characteristics - MW 22x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010046 |

| GTIN/EAN | 5906301810452 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 22 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 28.51 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 14.75 kg / 144.65 N |

| Magnetic Induction ~ ? | 416.85 mT / 4168 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the assembly - technical parameters

The following information are the result of a physical simulation. Values were calculated on algorithms for the material Nd2Fe14B. Actual parameters may deviate from the simulation results. Treat these data as a supplementary guide during assembly planning.

Table 1: Static force (pull vs gap) - characteristics

MW 22x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4167 Gs

416.7 mT

|

14.75 kg / 32.52 pounds

14750.0 g / 144.7 N

|

critical level |

| 1 mm |

3823 Gs

382.3 mT

|

12.41 kg / 27.36 pounds

12412.2 g / 121.8 N

|

critical level |

| 2 mm |

3461 Gs

346.1 mT

|

10.18 kg / 22.43 pounds

10175.8 g / 99.8 N

|

critical level |

| 3 mm |

3102 Gs

310.2 mT

|

8.17 kg / 18.01 pounds

8171.3 g / 80.2 N

|

strong |

| 5 mm |

2434 Gs

243.4 mT

|

5.03 kg / 11.09 pounds

5032.6 g / 49.4 N

|

strong |

| 10 mm |

1262 Gs

126.2 mT

|

1.35 kg / 2.98 pounds

1352.7 g / 13.3 N

|

safe |

| 15 mm |

675 Gs

67.5 mT

|

0.39 kg / 0.85 pounds

387.3 g / 3.8 N

|

safe |

| 20 mm |

388 Gs

38.8 mT

|

0.13 kg / 0.28 pounds

128.2 g / 1.3 N

|

safe |

| 30 mm |

157 Gs

15.7 mT

|

0.02 kg / 0.05 pounds

20.9 g / 0.2 N

|

safe |

| 50 mm |

43 Gs

4.3 mT

|

0.00 kg / 0.00 pounds

1.6 g / 0.0 N

|

safe |

Table 2: Shear force (wall)

MW 22x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.95 kg / 6.50 pounds

2950.0 g / 28.9 N

|

| 1 mm | Stal (~0.2) |

2.48 kg / 5.47 pounds

2482.0 g / 24.3 N

|

| 2 mm | Stal (~0.2) |

2.04 kg / 4.49 pounds

2036.0 g / 20.0 N

|

| 3 mm | Stal (~0.2) |

1.63 kg / 3.60 pounds

1634.0 g / 16.0 N

|

| 5 mm | Stal (~0.2) |

1.01 kg / 2.22 pounds

1006.0 g / 9.9 N

|

| 10 mm | Stal (~0.2) |

0.27 kg / 0.60 pounds

270.0 g / 2.6 N

|

| 15 mm | Stal (~0.2) |

0.08 kg / 0.17 pounds

78.0 g / 0.8 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.06 pounds

26.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 22x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

4.43 kg / 9.76 pounds

4425.0 g / 43.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.95 kg / 6.50 pounds

2950.0 g / 28.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.48 kg / 3.25 pounds

1475.0 g / 14.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

7.38 kg / 16.26 pounds

7375.0 g / 72.3 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 22x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.74 kg / 1.63 pounds

737.5 g / 7.2 N

|

| 1 mm |

|

1.84 kg / 4.06 pounds

1843.8 g / 18.1 N

|

| 2 mm |

|

3.69 kg / 8.13 pounds

3687.5 g / 36.2 N

|

| 3 mm |

|

5.53 kg / 12.19 pounds

5531.3 g / 54.3 N

|

| 5 mm |

|

9.22 kg / 20.32 pounds

9218.8 g / 90.4 N

|

| 10 mm |

|

14.75 kg / 32.52 pounds

14750.0 g / 144.7 N

|

| 11 mm |

|

14.75 kg / 32.52 pounds

14750.0 g / 144.7 N

|

| 12 mm |

|

14.75 kg / 32.52 pounds

14750.0 g / 144.7 N

|

Table 5: Thermal stability (material behavior) - power drop

MW 22x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

14.75 kg / 32.52 pounds

14750.0 g / 144.7 N

|

OK |

| 40 °C | -2.2% |

14.43 kg / 31.80 pounds

14425.5 g / 141.5 N

|

OK |

| 60 °C | -4.4% |

14.10 kg / 31.09 pounds

14101.0 g / 138.3 N

|

|

| 80 °C | -6.6% |

13.78 kg / 30.37 pounds

13776.5 g / 135.1 N

|

|

| 100 °C | -28.8% |

10.50 kg / 23.15 pounds

10502.0 g / 103.0 N

|

Table 6: Two magnets (attraction) - field collision

MW 22x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

40.70 kg / 89.72 pounds

5 428 Gs

|

6.10 kg / 13.46 pounds

6105 g / 59.9 N

|

N/A |

| 1 mm |

37.49 kg / 82.64 pounds

7 999 Gs

|

5.62 kg / 12.40 pounds

5623 g / 55.2 N

|

33.74 kg / 74.38 pounds

~0 Gs

|

| 2 mm |

34.25 kg / 75.50 pounds

7 645 Gs

|

5.14 kg / 11.33 pounds

5137 g / 50.4 N

|

30.82 kg / 67.95 pounds

~0 Gs

|

| 3 mm |

31.10 kg / 68.56 pounds

7 285 Gs

|

4.66 kg / 10.28 pounds

4664 g / 45.8 N

|

27.99 kg / 61.70 pounds

~0 Gs

|

| 5 mm |

25.22 kg / 55.60 pounds

6 561 Gs

|

3.78 kg / 8.34 pounds

3783 g / 37.1 N

|

22.70 kg / 50.04 pounds

~0 Gs

|

| 10 mm |

13.89 kg / 30.61 pounds

4 868 Gs

|

2.08 kg / 4.59 pounds

2083 g / 20.4 N

|

12.50 kg / 27.55 pounds

~0 Gs

|

| 20 mm |

3.73 kg / 8.23 pounds

2 524 Gs

|

0.56 kg / 1.23 pounds

560 g / 5.5 N

|

3.36 kg / 7.41 pounds

~0 Gs

|

| 50 mm |

0.13 kg / 0.30 pounds

480 Gs

|

0.02 kg / 0.04 pounds

20 g / 0.2 N

|

0.12 kg / 0.27 pounds

~0 Gs

|

| 60 mm |

0.06 kg / 0.13 pounds

314 Gs

|

0.01 kg / 0.02 pounds

9 g / 0.1 N

|

0.05 kg / 0.11 pounds

~0 Gs

|

| 70 mm |

0.03 kg / 0.06 pounds

216 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 80 mm |

0.01 kg / 0.03 pounds

154 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

| 90 mm |

0.01 kg / 0.02 pounds

114 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 pounds

86 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MW 22x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 7.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.5 cm |

| Car key | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 22x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.22 km/h

(6.73 m/s)

|

0.65 J | |

| 30 mm |

39.77 km/h

(11.05 m/s)

|

1.74 J | |

| 50 mm |

51.30 km/h

(14.25 m/s)

|

2.89 J | |

| 100 mm |

72.54 km/h

(20.15 m/s)

|

5.79 J |

Table 9: Anti-corrosion coating durability

MW 22x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 22x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 16 172 Mx | 161.7 µWb |

| Pc Coefficient | 0.55 | Low (Flat) |

Table 11: Submerged application

MW 22x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 14.75 kg | Standard |

| Water (riverbed) |

16.89 kg

(+2.14 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds only ~20% of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) severely reduces the holding force.

3. Thermal stability

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.55

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Strengths

- They do not lose magnetism, even during approximately 10 years – the decrease in strength is only ~1% (according to tests),

- They possess excellent resistance to magnetism drop as a result of external fields,

- A magnet with a shiny gold surface has an effective appearance,

- Magnets possess huge magnetic induction on the outer layer,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, enabling operation at temperatures approaching 230°C and above...

- Possibility of individual forming and adjusting to defined needs,

- Fundamental importance in innovative solutions – they serve a role in mass storage devices, electric drive systems, diagnostic systems, also complex engineering applications.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Cons

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- We recommend cover - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complicated forms.

- Potential hazard related to microscopic parts of magnets pose a threat, when accidentally swallowed, which gains importance in the aspect of protecting the youngest. Additionally, small elements of these products are able to complicate diagnosis medical in case of swallowing.

- With mass production the cost of neodymium magnets can be a barrier,

Lifting parameters

Maximum lifting force for a neodymium magnet – what contributes to it?

- with the contact of a sheet made of special test steel, guaranteeing full magnetic saturation

- whose transverse dimension reaches at least 10 mm

- with an polished contact surface

- without the slightest insulating layer between the magnet and steel

- under axial application of breakaway force (90-degree angle)

- in stable room temperature

Practical aspects of lifting capacity – factors

- Space between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or unevenness) drastically reduces the pulling force, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Wall thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Plate material – low-carbon steel attracts best. Alloy steels lower magnetic permeability and holding force.

- Smoothness – ideal contact is obtained only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Temperature – temperature increase causes a temporary drop of induction. Check the thermal limit for a given model.

Lifting capacity was measured with the use of a polished steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, whereas under shearing force the holding force is lower. Additionally, even a minimal clearance between the magnet and the plate decreases the lifting capacity.

Safe handling of NdFeB magnets

Nickel coating and allergies

Nickel alert: The Ni-Cu-Ni coating contains nickel. If skin irritation happens, immediately stop working with magnets and use protective gear.

Medical interference

Individuals with a ICD must maintain an large gap from magnets. The magnetism can stop the functioning of the implant.

Risk of cracking

Despite metallic appearance, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Handling rules

Before use, read the rules. Sudden snapping can destroy the magnet or hurt your hand. Think ahead.

Permanent damage

Watch the temperature. Heating the magnet to high heat will destroy its properties and pulling force.

Hand protection

Pinching hazard: The attraction force is so immense that it can cause blood blisters, pinching, and even bone fractures. Protective gloves are recommended.

Do not drill into magnets

Combustion risk: Neodymium dust is highly flammable. Avoid machining magnets in home conditions as this risks ignition.

Keep away from electronics

Remember: neodymium magnets generate a field that confuses sensitive sensors. Keep a safe distance from your mobile, tablet, and GPS.

Safe distance

Intense magnetic fields can erase data on payment cards, HDDs, and other magnetic media. Maintain a gap of min. 10 cm.

Product not for children

Always store magnets out of reach of children. Risk of swallowing is high, and the consequences of magnets connecting inside the body are very dangerous.

![BM 550x180x70 [4x M8] - magnetic beam BM 550x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-550x180x70-4x-m8-nic.jpg)

![UMP 75x25 [M10x3] GW F200 GOLD / N42 - search holder UMP 75x25 [M10x3] GW F200 GOLD / N42 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-gold-pag.jpg)