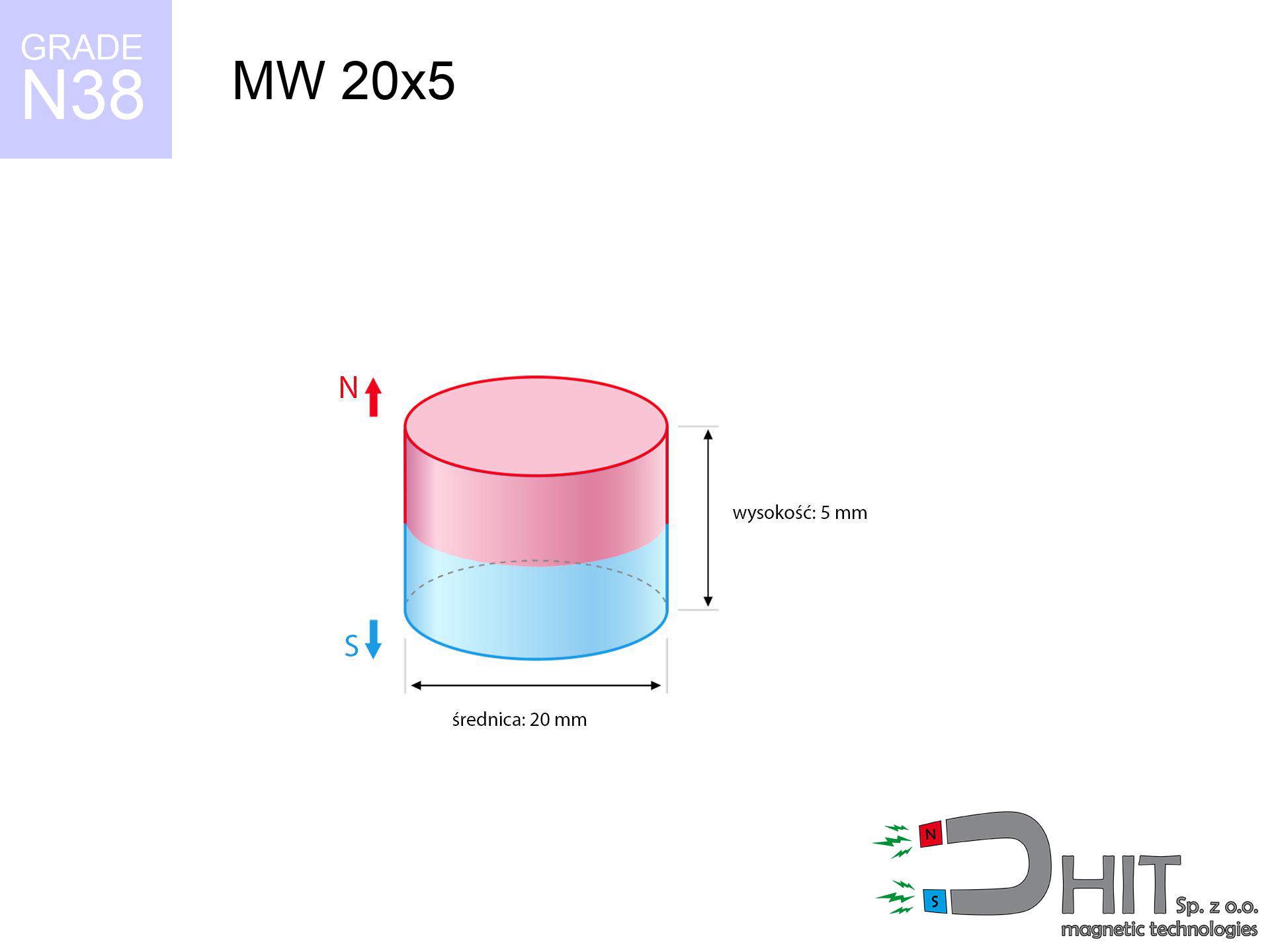

MW 20x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010044

GTIN/EAN: 5906301810438

Diameter Ø

20 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

11.78 g

Magnetization Direction

↑ axial

Load capacity

6.93 kg / 67.95 N

Magnetic Induction

277.16 mT / 2772 Gs

Coating

[NiCuNi] Nickel

5.56 ZŁ with VAT / pcs + price for transport

4.52 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively get in touch via

our online form

the contact page.

Weight along with shape of neodymium magnets can be calculated on our

force calculator.

Order by 14:00 and we’ll ship today!

Technical of the product - MW 20x5 / N38 - cylindrical magnet

Specification / characteristics - MW 20x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010044 |

| GTIN/EAN | 5906301810438 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 20 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 11.78 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.93 kg / 67.95 N |

| Magnetic Induction ~ ? | 277.16 mT / 2772 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - report

These values are the outcome of a engineering simulation. Results are based on algorithms for the class Nd2Fe14B. Operational performance may deviate from the simulation results. Please consider these data as a preliminary roadmap for designers.

Table 1: Static pull force (force vs gap) - power drop

MW 20x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2771 Gs

277.1 mT

|

6.93 kg / 15.28 lbs

6930.0 g / 68.0 N

|

strong |

| 1 mm |

2573 Gs

257.3 mT

|

5.97 kg / 13.17 lbs

5975.0 g / 58.6 N

|

strong |

| 2 mm |

2340 Gs

234.0 mT

|

4.94 kg / 10.89 lbs

4940.1 g / 48.5 N

|

strong |

| 3 mm |

2092 Gs

209.2 mT

|

3.95 kg / 8.70 lbs

3948.3 g / 38.7 N

|

strong |

| 5 mm |

1611 Gs

161.1 mT

|

2.34 kg / 5.17 lbs

2343.4 g / 23.0 N

|

strong |

| 10 mm |

775 Gs

77.5 mT

|

0.54 kg / 1.19 lbs

541.6 g / 5.3 N

|

low risk |

| 15 mm |

387 Gs

38.7 mT

|

0.13 kg / 0.30 lbs

135.0 g / 1.3 N

|

low risk |

| 20 mm |

211 Gs

21.1 mT

|

0.04 kg / 0.09 lbs

40.2 g / 0.4 N

|

low risk |

| 30 mm |

80 Gs

8.0 mT

|

0.01 kg / 0.01 lbs

5.7 g / 0.1 N

|

low risk |

| 50 mm |

20 Gs

2.0 mT

|

0.00 kg / 0.00 lbs

0.4 g / 0.0 N

|

low risk |

Table 2: Vertical force (wall)

MW 20x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.39 kg / 3.06 lbs

1386.0 g / 13.6 N

|

| 1 mm | Stal (~0.2) |

1.19 kg / 2.63 lbs

1194.0 g / 11.7 N

|

| 2 mm | Stal (~0.2) |

0.99 kg / 2.18 lbs

988.0 g / 9.7 N

|

| 3 mm | Stal (~0.2) |

0.79 kg / 1.74 lbs

790.0 g / 7.7 N

|

| 5 mm | Stal (~0.2) |

0.47 kg / 1.03 lbs

468.0 g / 4.6 N

|

| 10 mm | Stal (~0.2) |

0.11 kg / 0.24 lbs

108.0 g / 1.1 N

|

| 15 mm | Stal (~0.2) |

0.03 kg / 0.06 lbs

26.0 g / 0.3 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 20x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.08 kg / 4.58 lbs

2079.0 g / 20.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.39 kg / 3.06 lbs

1386.0 g / 13.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.69 kg / 1.53 lbs

693.0 g / 6.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.47 kg / 7.64 lbs

3465.0 g / 34.0 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 20x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.69 kg / 1.53 lbs

693.0 g / 6.8 N

|

| 1 mm |

|

1.73 kg / 3.82 lbs

1732.5 g / 17.0 N

|

| 2 mm |

|

3.47 kg / 7.64 lbs

3465.0 g / 34.0 N

|

| 3 mm |

|

5.20 kg / 11.46 lbs

5197.5 g / 51.0 N

|

| 5 mm |

|

6.93 kg / 15.28 lbs

6930.0 g / 68.0 N

|

| 10 mm |

|

6.93 kg / 15.28 lbs

6930.0 g / 68.0 N

|

| 11 mm |

|

6.93 kg / 15.28 lbs

6930.0 g / 68.0 N

|

| 12 mm |

|

6.93 kg / 15.28 lbs

6930.0 g / 68.0 N

|

Table 5: Thermal resistance (stability) - power drop

MW 20x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

6.93 kg / 15.28 lbs

6930.0 g / 68.0 N

|

OK |

| 40 °C | -2.2% |

6.78 kg / 14.94 lbs

6777.5 g / 66.5 N

|

OK |

| 60 °C | -4.4% |

6.63 kg / 14.61 lbs

6625.1 g / 65.0 N

|

|

| 80 °C | -6.6% |

6.47 kg / 14.27 lbs

6472.6 g / 63.5 N

|

|

| 100 °C | -28.8% |

4.93 kg / 10.88 lbs

4934.2 g / 48.4 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MW 20x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

14.87 kg / 32.79 lbs

4 380 Gs

|

2.23 kg / 4.92 lbs

2231 g / 21.9 N

|

N/A |

| 1 mm |

13.89 kg / 30.63 lbs

5 357 Gs

|

2.08 kg / 4.59 lbs

2084 g / 20.4 N

|

12.50 kg / 27.57 lbs

~0 Gs

|

| 2 mm |

12.82 kg / 28.27 lbs

5 146 Gs

|

1.92 kg / 4.24 lbs

1923 g / 18.9 N

|

11.54 kg / 25.44 lbs

~0 Gs

|

| 3 mm |

11.71 kg / 25.82 lbs

4 918 Gs

|

1.76 kg / 3.87 lbs

1757 g / 17.2 N

|

10.54 kg / 23.24 lbs

~0 Gs

|

| 5 mm |

9.51 kg / 20.97 lbs

4 433 Gs

|

1.43 kg / 3.15 lbs

1427 g / 14.0 N

|

8.56 kg / 18.88 lbs

~0 Gs

|

| 10 mm |

5.03 kg / 11.09 lbs

3 223 Gs

|

0.75 kg / 1.66 lbs

754 g / 7.4 N

|

4.53 kg / 9.98 lbs

~0 Gs

|

| 20 mm |

1.16 kg / 2.56 lbs

1 549 Gs

|

0.17 kg / 0.38 lbs

174 g / 1.7 N

|

1.05 kg / 2.31 lbs

~0 Gs

|

| 50 mm |

0.03 kg / 0.07 lbs

251 Gs

|

0.00 kg / 0.01 lbs

5 g / 0.0 N

|

0.03 kg / 0.06 lbs

~0 Gs

|

| 60 mm |

0.01 kg / 0.03 lbs

159 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.02 lbs

~0 Gs

|

| 70 mm |

0.01 kg / 0.01 lbs

107 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.01 lbs

75 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

54 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

41 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MW 20x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MW 20x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.63 km/h

(7.12 m/s)

|

0.30 J | |

| 30 mm |

42.39 km/h

(11.77 m/s)

|

0.82 J | |

| 50 mm |

54.70 km/h

(15.19 m/s)

|

1.36 J | |

| 100 mm |

77.35 km/h

(21.49 m/s)

|

2.72 J |

Table 9: Coating parameters (durability)

MW 20x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 20x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 9 675 Mx | 96.7 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 20x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 6.93 kg | Standard |

| Water (riverbed) |

7.93 kg

(+1.00 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet holds just ~20% of its perpendicular strength.

2. Steel saturation

*Thin steel (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Thermal stability

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Advantages and disadvantages of rare earth magnets.

Strengths

- They have constant strength, and over more than ten years their performance decreases symbolically – ~1% (according to theory),

- They retain their magnetic properties even under strong external field,

- A magnet with a smooth gold surface has better aesthetics,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a distinguishing feature,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- Thanks to modularity in constructing and the capacity to adapt to complex applications,

- Huge importance in future technologies – they find application in magnetic memories, electromotive mechanisms, advanced medical instruments, also industrial machines.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Disadvantages

- Brittleness is one of their disadvantages. Upon strong impact they can break. We recommend keeping them in a special holder, which not only protects them against impacts but also increases their durability

- Neodymium magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- They oxidize in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing threads and complex shapes in magnets, we propose using a housing - magnetic mount.

- Possible danger resulting from small fragments of magnets can be dangerous, in case of ingestion, which becomes key in the context of child safety. It is also worth noting that small elements of these products are able to disrupt the diagnostic process medical when they are in the body.

- With mass production the cost of neodymium magnets is a challenge,

Lifting parameters

Maximum lifting capacity of the magnet – what contributes to it?

- using a sheet made of low-carbon steel, acting as a magnetic yoke

- with a thickness no less than 10 mm

- with a plane perfectly flat

- under conditions of ideal adhesion (metal-to-metal)

- for force applied at a right angle (in the magnet axis)

- in stable room temperature

Practical lifting capacity: influencing factors

- Distance – existence of any layer (rust, tape, air) acts as an insulator, which reduces power steeply (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Material type – the best choice is pure iron steel. Cast iron may attract less.

- Surface structure – the smoother and more polished the surface, the larger the contact zone and stronger the hold. Roughness creates an air distance.

- Operating temperature – neodymium magnets have a sensitivity to temperature. At higher temperatures they lose power, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity was measured with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under shearing force the holding force is lower. Additionally, even a small distance between the magnet’s surface and the plate lowers the holding force.

Safety rules for work with NdFeB magnets

Crushing force

Protect your hands. Two large magnets will snap together instantly with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!

Pacemakers

Individuals with a ICD should maintain an absolute distance from magnets. The magnetism can stop the operation of the life-saving device.

Conscious usage

Before use, check safety instructions. Uncontrolled attraction can destroy the magnet or injure your hand. Be predictive.

Flammability

Dust produced during grinding of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Threat to navigation

A powerful magnetic field disrupts the functioning of magnetometers in phones and GPS navigation. Keep magnets near a device to prevent damaging the sensors.

No play value

Absolutely keep magnets away from children. Risk of swallowing is high, and the consequences of magnets connecting inside the body are life-threatening.

Power loss in heat

Monitor thermal conditions. Exposing the magnet to high heat will permanently weaken its magnetic structure and strength.

Keep away from computers

Avoid bringing magnets close to a wallet, computer, or screen. The magnetic field can permanently damage these devices and erase data from cards.

Warning for allergy sufferers

Certain individuals have a contact allergy to nickel, which is the typical protective layer for NdFeB magnets. Extended handling can result in a rash. We strongly advise wear safety gloves.

Magnets are brittle

Despite the nickel coating, the material is brittle and not impact-resistant. Do not hit, as the magnet may crumble into hazardous fragments.

![SM 25x100 [2xM8] / N52 - magnetic separator SM 25x100 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-fin.jpg)

![SM 32x350 [2xM8] / N52 - magnetic separator SM 32x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x350-2xm8-fag.jpg)