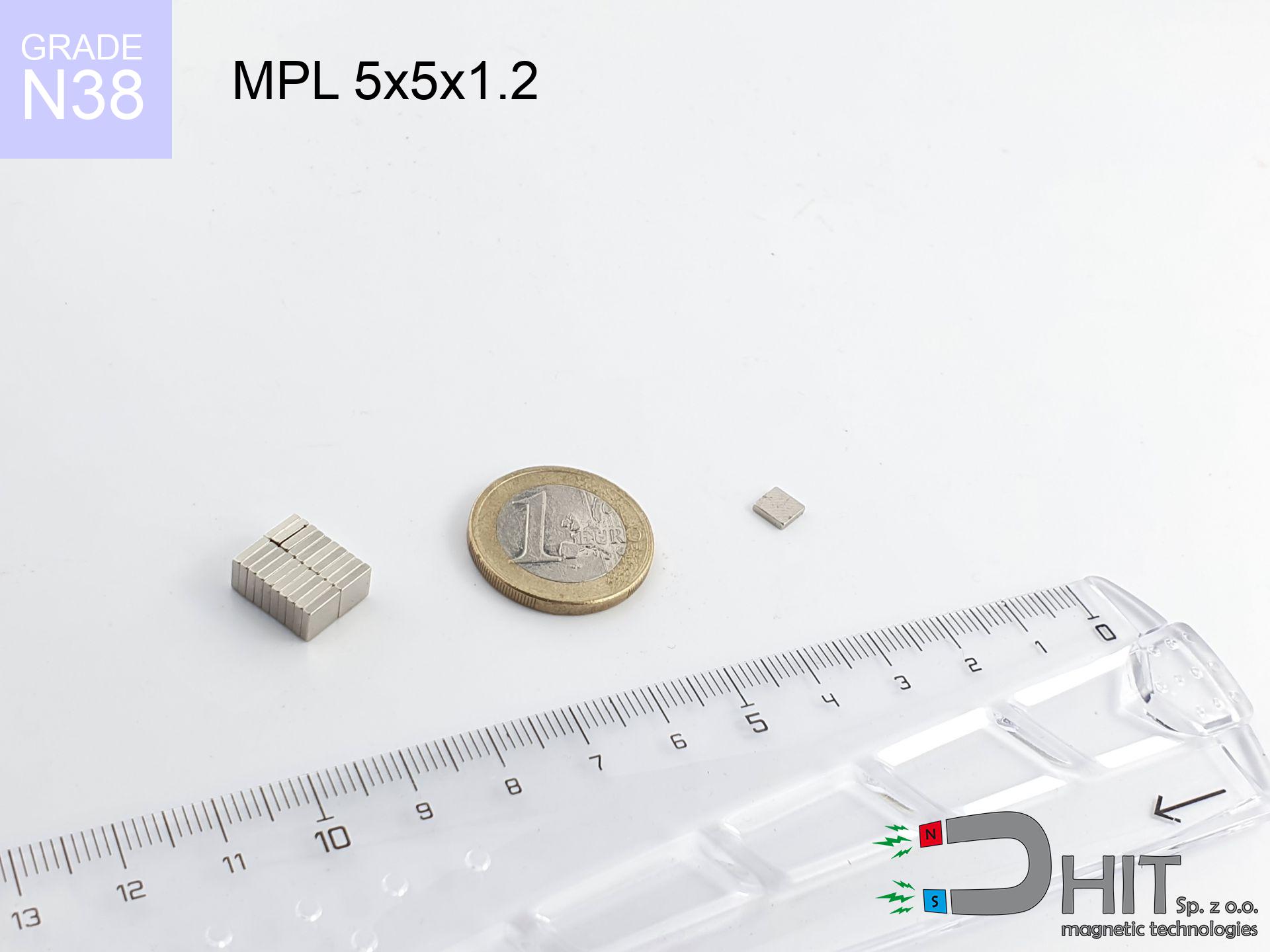

MPL 5x5x1.2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020171

GTIN/EAN: 5906301811770

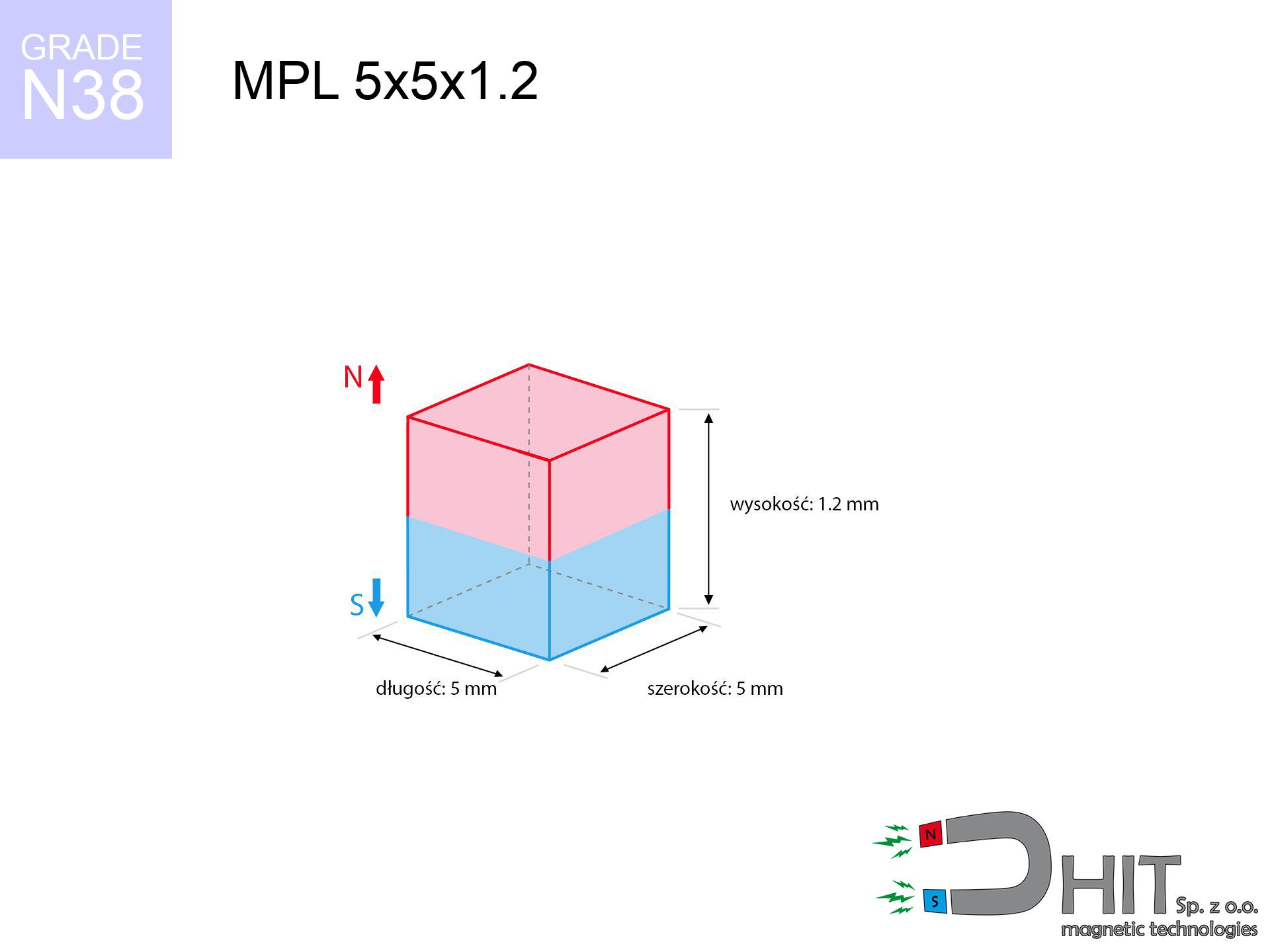

length

5 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

1.2 mm [±0,1 mm]

Weight

0.22 g

Magnetization Direction

↑ axial

Load capacity

0.44 kg / 4.28 N

Magnetic Induction

245.17 mT / 2452 Gs

Coating

[NiCuNi] Nickel

0.1845 ZŁ with VAT / pcs + price for transport

0.1500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer drop us a message through

contact form

the contact page.

Force as well as appearance of magnets can be tested using our

our magnetic calculator.

Order by 14:00 and we’ll ship today!

Product card - MPL 5x5x1.2 / N38 - lamellar magnet

Specification / characteristics - MPL 5x5x1.2 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020171 |

| GTIN/EAN | 5906301811770 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 5 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 1.2 mm [±0,1 mm] |

| Weight | 0.22 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.44 kg / 4.28 N |

| Magnetic Induction ~ ? | 245.17 mT / 2452 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - data

The following values constitute the direct effect of a mathematical analysis. Results are based on models for the class Nd2Fe14B. Real-world parameters might slightly deviate from the simulation results. Treat these calculations as a preliminary roadmap for designers.

Table 1: Static pull force (force vs distance) - interaction chart

MPL 5x5x1.2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2450 Gs

245.0 mT

|

0.44 kg / 0.97 LBS

440.0 g / 4.3 N

|

low risk |

| 1 mm |

1739 Gs

173.9 mT

|

0.22 kg / 0.49 LBS

221.8 g / 2.2 N

|

low risk |

| 2 mm |

1054 Gs

105.4 mT

|

0.08 kg / 0.18 LBS

81.4 g / 0.8 N

|

low risk |

| 3 mm |

622 Gs

62.2 mT

|

0.03 kg / 0.06 LBS

28.4 g / 0.3 N

|

low risk |

| 5 mm |

241 Gs

24.1 mT

|

0.00 kg / 0.01 LBS

4.3 g / 0.0 N

|

low risk |

| 10 mm |

45 Gs

4.5 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

| 15 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 20 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 30 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical capacity (vertical surface)

MPL 5x5x1.2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.09 kg / 0.19 LBS

88.0 g / 0.9 N

|

| 1 mm | Stal (~0.2) |

0.04 kg / 0.10 LBS

44.0 g / 0.4 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

16.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MPL 5x5x1.2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.13 kg / 0.29 LBS

132.0 g / 1.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.09 kg / 0.19 LBS

88.0 g / 0.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.04 kg / 0.10 LBS

44.0 g / 0.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.22 kg / 0.49 LBS

220.0 g / 2.2 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 5x5x1.2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.04 kg / 0.10 LBS

44.0 g / 0.4 N

|

| 1 mm |

|

0.11 kg / 0.24 LBS

110.0 g / 1.1 N

|

| 2 mm |

|

0.22 kg / 0.49 LBS

220.0 g / 2.2 N

|

| 3 mm |

|

0.33 kg / 0.73 LBS

330.0 g / 3.2 N

|

| 5 mm |

|

0.44 kg / 0.97 LBS

440.0 g / 4.3 N

|

| 10 mm |

|

0.44 kg / 0.97 LBS

440.0 g / 4.3 N

|

| 11 mm |

|

0.44 kg / 0.97 LBS

440.0 g / 4.3 N

|

| 12 mm |

|

0.44 kg / 0.97 LBS

440.0 g / 4.3 N

|

Table 5: Thermal resistance (material behavior) - power drop

MPL 5x5x1.2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.44 kg / 0.97 LBS

440.0 g / 4.3 N

|

OK |

| 40 °C | -2.2% |

0.43 kg / 0.95 LBS

430.3 g / 4.2 N

|

OK |

| 60 °C | -4.4% |

0.42 kg / 0.93 LBS

420.6 g / 4.1 N

|

|

| 80 °C | -6.6% |

0.41 kg / 0.91 LBS

411.0 g / 4.0 N

|

|

| 100 °C | -28.8% |

0.31 kg / 0.69 LBS

313.3 g / 3.1 N

|

Table 6: Two magnets (attraction) - field collision

MPL 5x5x1.2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.92 kg / 2.04 LBS

4 027 Gs

|

0.14 kg / 0.31 LBS

139 g / 1.4 N

|

N/A |

| 1 mm |

0.70 kg / 1.54 LBS

4 260 Gs

|

0.10 kg / 0.23 LBS

105 g / 1.0 N

|

0.63 kg / 1.39 LBS

~0 Gs

|

| 2 mm |

0.47 kg / 1.03 LBS

3 478 Gs

|

0.07 kg / 0.15 LBS

70 g / 0.7 N

|

0.42 kg / 0.93 LBS

~0 Gs

|

| 3 mm |

0.29 kg / 0.63 LBS

2 734 Gs

|

0.04 kg / 0.10 LBS

43 g / 0.4 N

|

0.26 kg / 0.57 LBS

~0 Gs

|

| 5 mm |

0.10 kg / 0.22 LBS

1 617 Gs

|

0.02 kg / 0.03 LBS

15 g / 0.1 N

|

0.09 kg / 0.20 LBS

~0 Gs

|

| 10 mm |

0.01 kg / 0.02 LBS

482 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

90 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

4 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MPL 5x5x1.2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 1.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 5x5x1.2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

45.11 km/h

(12.53 m/s)

|

0.02 J | |

| 30 mm |

78.12 km/h

(21.70 m/s)

|

0.05 J | |

| 50 mm |

100.85 km/h

(28.01 m/s)

|

0.09 J | |

| 100 mm |

142.63 km/h

(39.62 m/s)

|

0.17 J |

Table 9: Anti-corrosion coating durability

MPL 5x5x1.2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 5x5x1.2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 695 Mx | 7.0 µWb |

| Pc Coefficient | 0.30 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 5x5x1.2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.44 kg | Standard |

| Water (riverbed) |

0.50 kg

(+0.06 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet retains merely a fraction of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) significantly limits the holding force.

3. Heat tolerance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.30

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

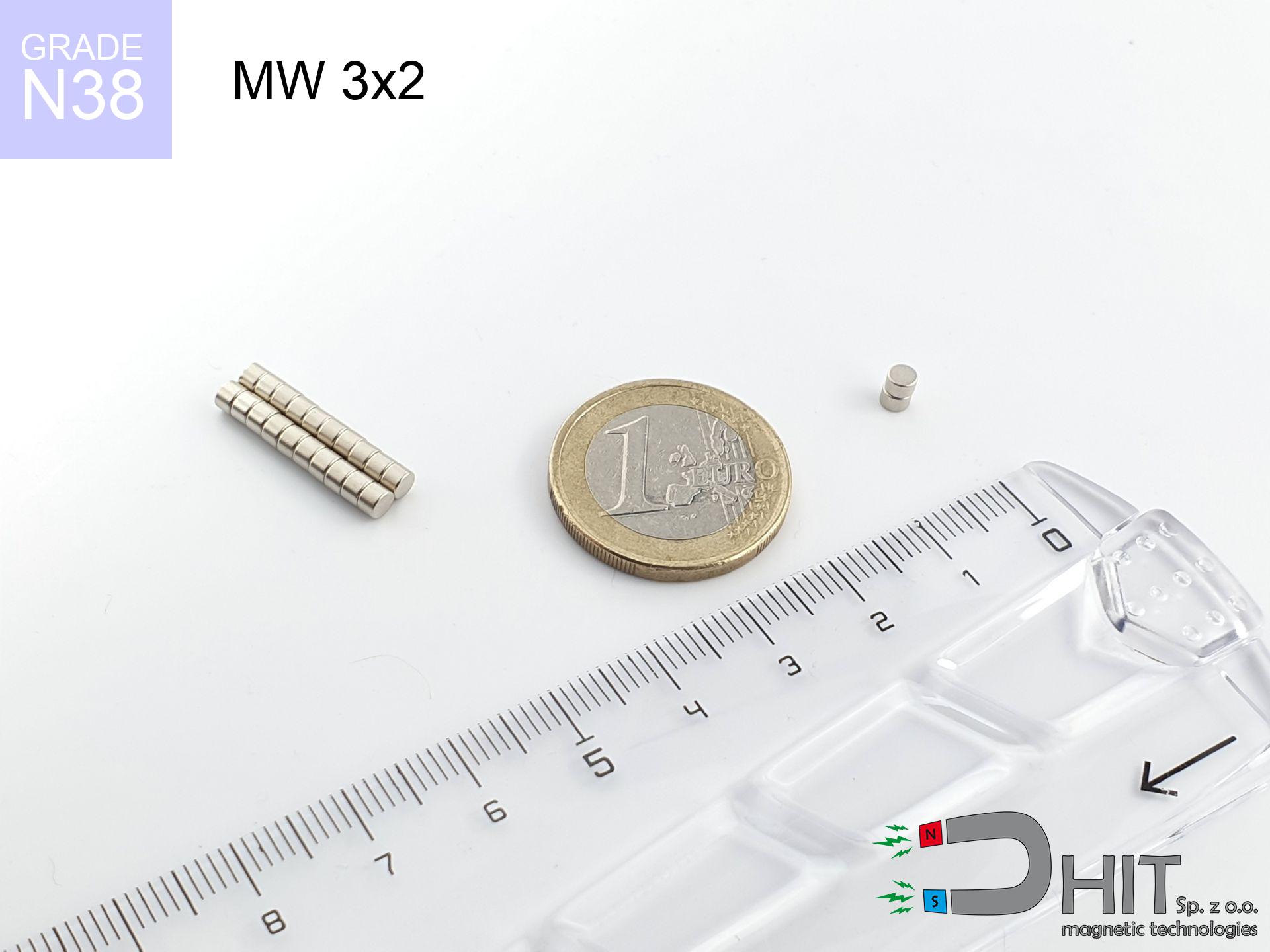

Other products

Strengths as well as weaknesses of Nd2Fe14B magnets.

Strengths

- They virtually do not lose power, because even after 10 years the performance loss is only ~1% (in laboratory conditions),

- Neodymium magnets are remarkably resistant to magnetic field loss caused by external magnetic fields,

- Thanks to the shiny finish, the plating of nickel, gold-plated, or silver gives an aesthetic appearance,

- Magnetic induction on the working part of the magnet is maximum,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Thanks to freedom in forming and the capacity to adapt to unusual requirements,

- Key role in modern industrial fields – they find application in HDD drives, electric drive systems, precision medical tools, as well as technologically advanced constructions.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Cons

- At very strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in creating threads and complicated forms in magnets, we propose using casing - magnetic mount.

- Potential hazard related to microscopic parts of magnets can be dangerous, when accidentally swallowed, which gains importance in the context of child safety. Furthermore, small components of these products can be problematic in diagnostics medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Lifting parameters

Maximum holding power of the magnet – what it depends on?

- using a base made of low-carbon steel, functioning as a circuit closing element

- whose thickness is min. 10 mm

- characterized by smoothness

- under conditions of ideal adhesion (surface-to-surface)

- for force applied at a right angle (pull-off, not shear)

- in neutral thermal conditions

Magnet lifting force in use – key factors

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Steel thickness – too thin plate does not close the flux, causing part of the flux to be escaped into the air.

- Steel type – low-carbon steel gives the best results. Higher carbon content reduce magnetic permeability and holding force.

- Plate texture – ground elements ensure maximum contact, which increases field saturation. Uneven metal reduce efficiency.

- Temperature – heating the magnet causes a temporary drop of induction. Check the thermal limit for a given model.

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under shearing force the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

Safety rules for work with NdFeB magnets

Choking Hazard

Neodymium magnets are not toys. Swallowing multiple magnets may result in them attracting across intestines, which poses a severe health hazard and necessitates immediate surgery.

Life threat

Patients with a pacemaker must keep an absolute distance from magnets. The magnetism can interfere with the functioning of the life-saving device.

GPS Danger

Be aware: rare earth magnets generate a field that interferes with sensitive sensors. Maintain a safe distance from your mobile, device, and GPS.

Allergy Warning

Studies show that nickel (standard magnet coating) is a potent allergen. If your skin reacts to metals, avoid direct skin contact and select encased magnets.

Permanent damage

Control the heat. Exposing the magnet to high heat will ruin its magnetic structure and pulling force.

Do not underestimate power

Before starting, read the rules. Uncontrolled attraction can destroy the magnet or hurt your hand. Think ahead.

Dust is flammable

Machining of NdFeB material poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Crushing risk

Watch your fingers. Two powerful magnets will snap together immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

Cards and drives

Intense magnetic fields can destroy records on credit cards, HDDs, and storage devices. Keep a distance of at least 10 cm.

Beware of splinters

Neodymium magnets are sintered ceramics, meaning they are very brittle. Impact of two magnets will cause them breaking into shards.

![UMGW 32x18x8 [M6] GW / N38 - magnetic holder internal thread UMGW 32x18x8 [M6] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um32x18x8-m6-gw--hec.jpg)

![SM 32x100 [2xM8] / N42 - magnetic separator SM 32x100 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x100-2xm8-cox.jpg)