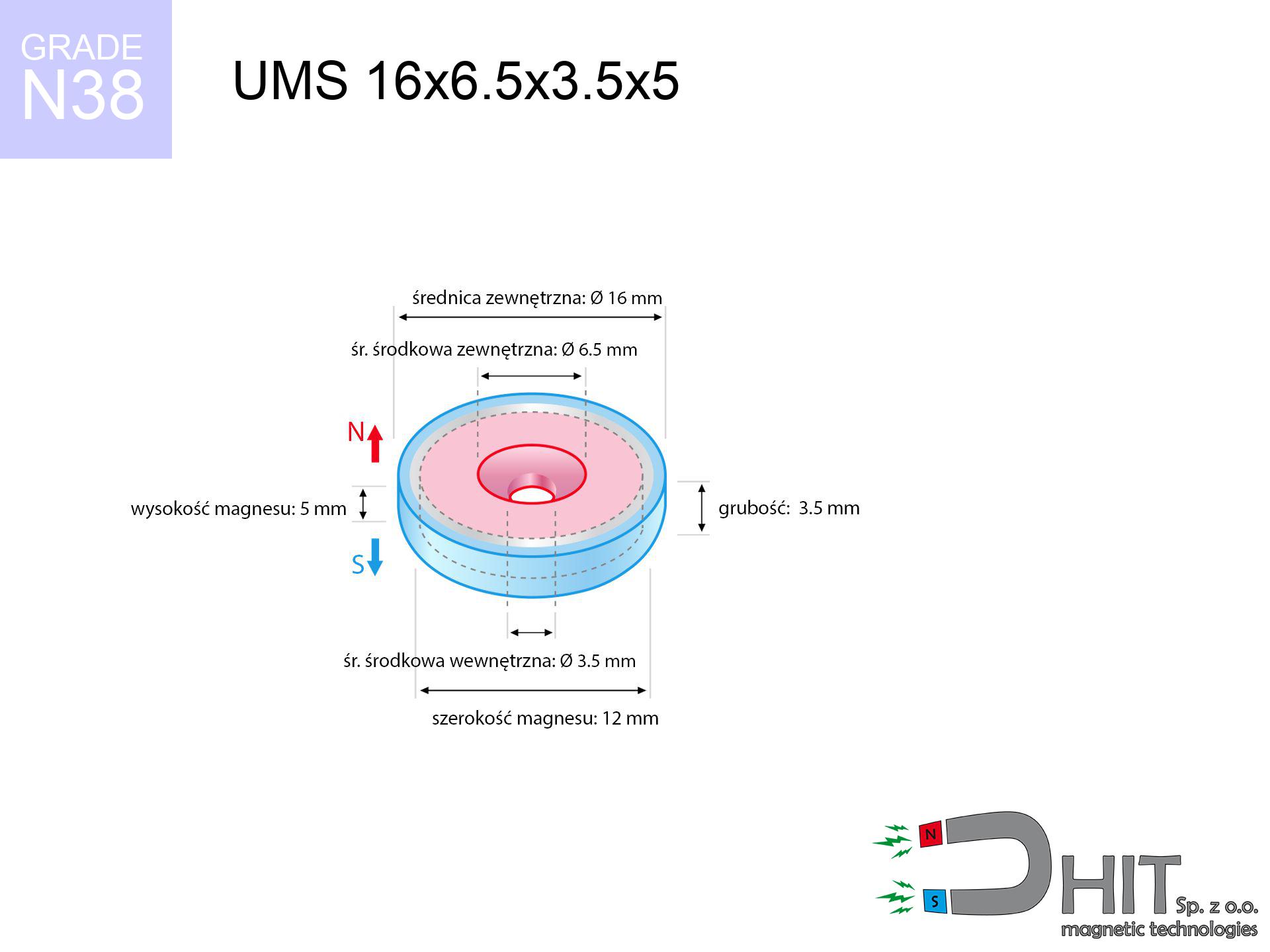

UMS 16x6.5x3.5x5 / N38 - conical magnetic holder

conical magnetic holder

Catalog no 220326

GTIN/EAN: 5906301814160

Diameter Ø

16 mm [±1 mm]

cone dimension Ø

6.5x3.5 mm [±1 mm]

Height

5 mm [±1 mm]

Weight

5.5 g

Magnetization Direction

↑ axial

Load capacity

5.00 kg / 49.03 N

Coating

[NiCuNi] Nickel

4.48 ZŁ with VAT / pcs + price for transport

3.64 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer drop us a message by means of

inquiry form

the contact section.

Force and appearance of a magnet can be reviewed using our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - UMS 16x6.5x3.5x5 / N38 - conical magnetic holder

Specification / characteristics - UMS 16x6.5x3.5x5 / N38 - conical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 220326 |

| GTIN/EAN | 5906301814160 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 16 mm [±1 mm] |

| cone dimension Ø | 6.5x3.5 mm [±1 mm] |

| Height | 5 mm [±1 mm] |

| Weight | 5.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.00 kg / 49.03 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Advantages and disadvantages of Nd2Fe14B magnets.

Benefits

- They virtually do not lose power, because even after ten years the decline in efficiency is only ~1% (according to literature),

- Magnets perfectly protect themselves against demagnetization caused by ambient magnetic noise,

- The use of an metallic finish of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- Magnets exhibit huge magnetic induction on the active area,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for operation at temperatures reaching 230°C and above...

- Thanks to freedom in constructing and the ability to adapt to individual projects,

- Significant place in future technologies – they are used in computer drives, motor assemblies, medical equipment, as well as modern systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Limitations

- At strong impacts they can crack, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- We suggest a housing - magnetic mechanism, due to difficulties in producing threads inside the magnet and complicated forms.

- Potential hazard to health – tiny shards of magnets pose a threat, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that small elements of these magnets are able to complicate diagnosis medical after entering the body.

- Due to expensive raw materials, their price exceeds standard values,

Holding force characteristics

Maximum lifting capacity of the magnet – what contributes to it?

- on a plate made of mild steel, perfectly concentrating the magnetic flux

- whose transverse dimension is min. 10 mm

- characterized by smoothness

- with zero gap (no paint)

- during pulling in a direction perpendicular to the mounting surface

- in temp. approx. 20°C

Lifting capacity in real conditions – factors

- Gap between surfaces – even a fraction of a millimeter of distance (caused e.g. by varnish or dirt) diminishes the pulling force, often by half at just 0.5 mm.

- Angle of force application – highest force is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the surface is usually many times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of generating force.

- Steel grade – ideal substrate is high-permeability steel. Stainless steels may attract less.

- Surface structure – the smoother and more polished the plate, the larger the contact zone and higher the lifting capacity. Unevenness creates an air distance.

- Temperature influence – hot environment weakens pulling force. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity was measured using a polished steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under parallel forces the holding force is lower. Moreover, even a small distance between the magnet and the plate reduces the lifting capacity.

Precautions when working with NdFeB magnets

Do not drill into magnets

Drilling and cutting of neodymium magnets carries a risk of fire risk. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Protect data

Avoid bringing magnets close to a purse, computer, or screen. The magnetic field can permanently damage these devices and erase data from cards.

Medical implants

For implant holders: Strong magnetic fields disrupt electronics. Maintain minimum 30 cm distance or request help to work with the magnets.

Threat to navigation

GPS units and mobile phones are extremely sensitive to magnetism. Direct contact with a powerful NdFeB magnet can decalibrate the internal compass in your phone.

Eye protection

Watch out for shards. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Bodily injuries

Risk of injury: The pulling power is so immense that it can cause hematomas, pinching, and even bone fractures. Protective gloves are recommended.

Demagnetization risk

Control the heat. Heating the magnet to high heat will permanently weaken its properties and pulling force.

Danger to the youngest

NdFeB magnets are not toys. Swallowing a few magnets may result in them attracting across intestines, which poses a severe health hazard and necessitates immediate surgery.

Conscious usage

Use magnets consciously. Their powerful strength can surprise even experienced users. Plan your moves and do not underestimate their force.

Allergy Warning

Warning for allergy sufferers: The nickel-copper-nickel coating consists of nickel. If redness appears, immediately stop handling magnets and wear gloves.