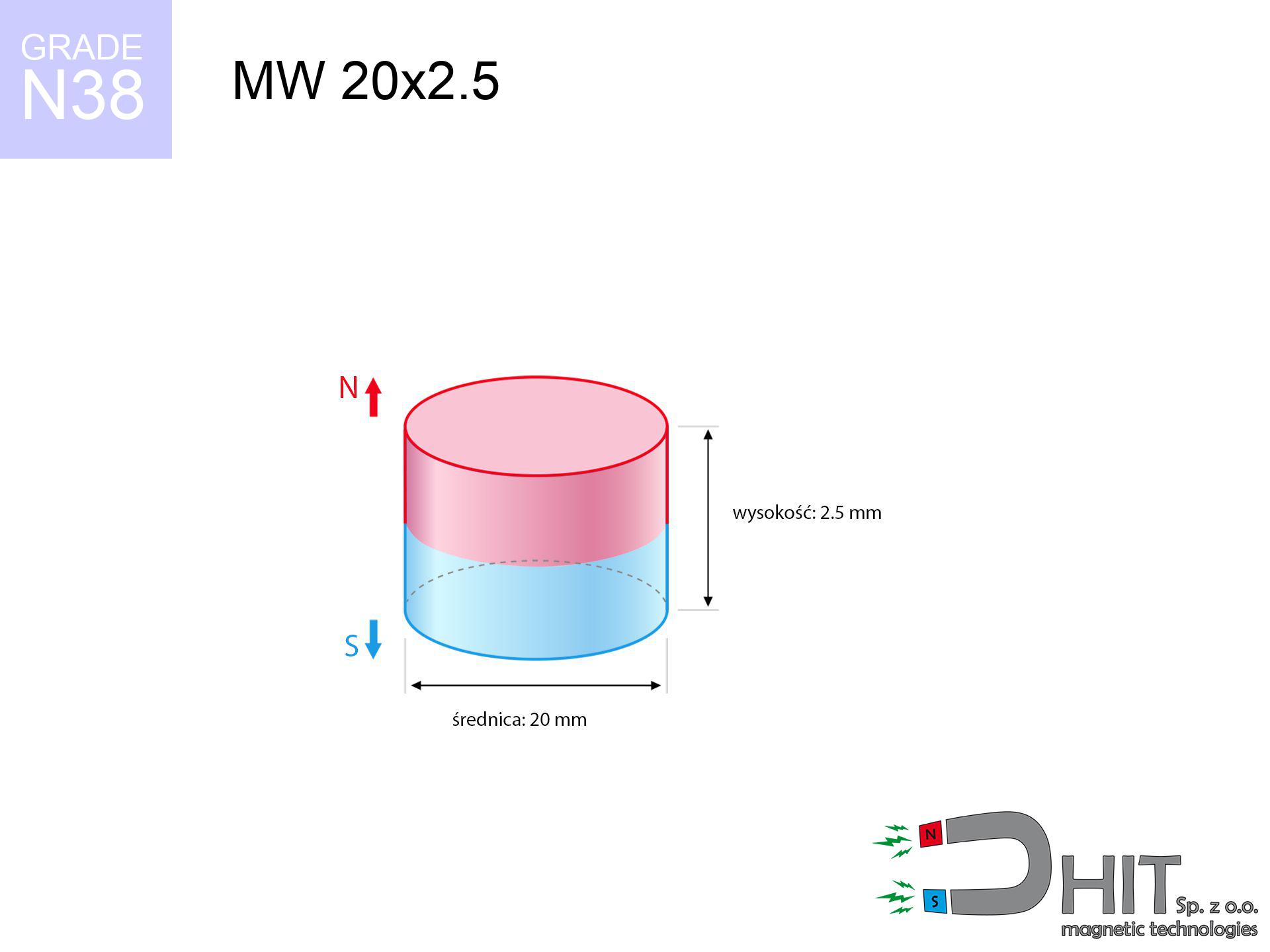

MW 20x2.5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010042

GTIN/EAN: 5906301810414

Diameter Ø

20 mm [±0,1 mm]

Height

2.5 mm [±0,1 mm]

Weight

5.89 g

Magnetization Direction

↑ axial

Load capacity

2.41 kg / 23.65 N

Magnetic Induction

150.34 mT / 1503 Gs

Coating

[NiCuNi] Nickel

2.51 ZŁ with VAT / pcs + price for transport

2.04 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

otherwise send us a note via

inquiry form

the contact page.

Lifting power along with structure of a neodymium magnet can be checked with our

online calculation tool.

Same-day processing for orders placed before 14:00.

Physical properties - MW 20x2.5 / N38 - cylindrical magnet

Specification / characteristics - MW 20x2.5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010042 |

| GTIN/EAN | 5906301810414 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 20 mm [±0,1 mm] |

| Height | 2.5 mm [±0,1 mm] |

| Weight | 5.89 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.41 kg / 23.65 N |

| Magnetic Induction ~ ? | 150.34 mT / 1503 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the product - data

The following information represent the outcome of a engineering analysis. Results were calculated on algorithms for the material Nd2Fe14B. Real-world conditions might slightly differ from theoretical values. Treat these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs gap) - interaction chart

MW 20x2.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1503 Gs

150.3 mT

|

2.41 kg / 5.31 pounds

2410.0 g / 23.6 N

|

warning |

| 1 mm |

1431 Gs

143.1 mT

|

2.18 kg / 4.82 pounds

2184.9 g / 21.4 N

|

warning |

| 2 mm |

1328 Gs

132.8 mT

|

1.88 kg / 4.15 pounds

1882.0 g / 18.5 N

|

safe |

| 3 mm |

1206 Gs

120.6 mT

|

1.55 kg / 3.42 pounds

1552.2 g / 15.2 N

|

safe |

| 5 mm |

947 Gs

94.7 mT

|

0.96 kg / 2.11 pounds

957.1 g / 9.4 N

|

safe |

| 10 mm |

457 Gs

45.7 mT

|

0.22 kg / 0.49 pounds

223.1 g / 2.2 N

|

safe |

| 15 mm |

224 Gs

22.4 mT

|

0.05 kg / 0.12 pounds

53.7 g / 0.5 N

|

safe |

| 20 mm |

120 Gs

12.0 mT

|

0.02 kg / 0.03 pounds

15.4 g / 0.2 N

|

safe |

| 30 mm |

44 Gs

4.4 mT

|

0.00 kg / 0.00 pounds

2.1 g / 0.0 N

|

safe |

| 50 mm |

11 Gs

1.1 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

safe |

Table 2: Vertical force (vertical surface)

MW 20x2.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.48 kg / 1.06 pounds

482.0 g / 4.7 N

|

| 1 mm | Stal (~0.2) |

0.44 kg / 0.96 pounds

436.0 g / 4.3 N

|

| 2 mm | Stal (~0.2) |

0.38 kg / 0.83 pounds

376.0 g / 3.7 N

|

| 3 mm | Stal (~0.2) |

0.31 kg / 0.68 pounds

310.0 g / 3.0 N

|

| 5 mm | Stal (~0.2) |

0.19 kg / 0.42 pounds

192.0 g / 1.9 N

|

| 10 mm | Stal (~0.2) |

0.04 kg / 0.10 pounds

44.0 g / 0.4 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

10.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 20x2.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.72 kg / 1.59 pounds

723.0 g / 7.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.48 kg / 1.06 pounds

482.0 g / 4.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.24 kg / 0.53 pounds

241.0 g / 2.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.21 kg / 2.66 pounds

1205.0 g / 11.8 N

|

Table 4: Material efficiency (saturation) - power losses

MW 20x2.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.24 kg / 0.53 pounds

241.0 g / 2.4 N

|

| 1 mm |

|

0.60 kg / 1.33 pounds

602.5 g / 5.9 N

|

| 2 mm |

|

1.21 kg / 2.66 pounds

1205.0 g / 11.8 N

|

| 3 mm |

|

1.81 kg / 3.98 pounds

1807.5 g / 17.7 N

|

| 5 mm |

|

2.41 kg / 5.31 pounds

2410.0 g / 23.6 N

|

| 10 mm |

|

2.41 kg / 5.31 pounds

2410.0 g / 23.6 N

|

| 11 mm |

|

2.41 kg / 5.31 pounds

2410.0 g / 23.6 N

|

| 12 mm |

|

2.41 kg / 5.31 pounds

2410.0 g / 23.6 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 20x2.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.41 kg / 5.31 pounds

2410.0 g / 23.6 N

|

OK |

| 40 °C | -2.2% |

2.36 kg / 5.20 pounds

2357.0 g / 23.1 N

|

OK |

| 60 °C | -4.4% |

2.30 kg / 5.08 pounds

2304.0 g / 22.6 N

|

|

| 80 °C | -6.6% |

2.25 kg / 4.96 pounds

2250.9 g / 22.1 N

|

|

| 100 °C | -28.8% |

1.72 kg / 3.78 pounds

1715.9 g / 16.8 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 20x2.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.38 kg / 9.65 pounds

2 771 Gs

|

0.66 kg / 1.45 pounds

656 g / 6.4 N

|

N/A |

| 1 mm |

4.20 kg / 9.25 pounds

2 944 Gs

|

0.63 kg / 1.39 pounds

629 g / 6.2 N

|

3.78 kg / 8.33 pounds

~0 Gs

|

| 2 mm |

3.97 kg / 8.75 pounds

2 862 Gs

|

0.60 kg / 1.31 pounds

595 g / 5.8 N

|

3.57 kg / 7.87 pounds

~0 Gs

|

| 3 mm |

3.70 kg / 8.17 pounds

2 766 Gs

|

0.56 kg / 1.22 pounds

556 g / 5.5 N

|

3.33 kg / 7.35 pounds

~0 Gs

|

| 5 mm |

3.12 kg / 6.88 pounds

2 538 Gs

|

0.47 kg / 1.03 pounds

468 g / 4.6 N

|

2.81 kg / 6.19 pounds

~0 Gs

|

| 10 mm |

1.74 kg / 3.83 pounds

1 895 Gs

|

0.26 kg / 0.57 pounds

261 g / 2.6 N

|

1.56 kg / 3.45 pounds

~0 Gs

|

| 20 mm |

0.41 kg / 0.89 pounds

915 Gs

|

0.06 kg / 0.13 pounds

61 g / 0.6 N

|

0.36 kg / 0.80 pounds

~0 Gs

|

| 50 mm |

0.01 kg / 0.02 pounds

140 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 pounds

88 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

58 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

41 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

29 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

22 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 20x2.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 20x2.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

21.55 km/h

(5.99 m/s)

|

0.11 J | |

| 30 mm |

35.35 km/h

(9.82 m/s)

|

0.28 J | |

| 50 mm |

45.62 km/h

(12.67 m/s)

|

0.47 J | |

| 100 mm |

64.51 km/h

(17.92 m/s)

|

0.95 J |

Table 9: Coating parameters (durability)

MW 20x2.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 20x2.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 996 Mx | 60.0 µWb |

| Pc Coefficient | 0.19 | Low (Flat) |

Table 11: Physics of underwater searching

MW 20x2.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.41 kg | Standard |

| Water (riverbed) |

2.76 kg

(+0.35 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet holds just ~20% of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. computer case) severely reduces the holding force.

3. Thermal stability

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.19

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also products

Pros and cons of rare earth magnets.

Advantages

- They have stable power, and over more than ten years their performance decreases symbolically – ~1% (in testing),

- They possess excellent resistance to magnetism drop when exposed to opposing magnetic fields,

- Thanks to the shiny finish, the coating of Ni-Cu-Ni, gold, or silver-plated gives an aesthetic appearance,

- Magnetic induction on the surface of the magnet turns out to be maximum,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- Thanks to freedom in shaping and the capacity to adapt to complex applications,

- Fundamental importance in modern industrial fields – they are commonly used in HDD drives, electric motors, medical devices, as well as multitasking production systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- Brittleness is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a special holder, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- We recommend a housing - magnetic mount, due to difficulties in producing nuts inside the magnet and complex shapes.

- Health risk to health – tiny shards of magnets are risky, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Furthermore, small components of these magnets can complicate diagnosis medical in case of swallowing.

- With mass production the cost of neodymium magnets is a challenge,

Pull force analysis

Maximum lifting capacity of the magnet – what it depends on?

- with the contact of a sheet made of special test steel, guaranteeing maximum field concentration

- whose thickness reaches at least 10 mm

- with an ground touching surface

- under conditions of gap-free contact (metal-to-metal)

- under perpendicular force direction (90-degree angle)

- in temp. approx. 20°C

Determinants of lifting force in real conditions

- Distance (between the magnet and the plate), since even a microscopic distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to paint, rust or debris).

- Angle of force application – highest force is reached only during pulling at a 90° angle. The force required to slide of the magnet along the surface is typically several times lower (approx. 1/5 of the lifting capacity).

- Base massiveness – too thin sheet does not close the flux, causing part of the flux to be wasted into the air.

- Material composition – not every steel reacts the same. High carbon content worsen the attraction effect.

- Surface finish – ideal contact is obtained only on smooth steel. Rough texture create air cushions, weakening the magnet.

- Operating temperature – NdFeB sinters have a sensitivity to temperature. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, in contrast under parallel forces the lifting capacity is smaller. Additionally, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

Safe handling of NdFeB magnets

Data carriers

Data protection: Neodymium magnets can ruin payment cards and delicate electronics (pacemakers, medical aids, timepieces).

Swallowing risk

Always keep magnets away from children. Risk of swallowing is significant, and the effects of magnets clamping inside the body are fatal.

Crushing force

Mind your fingers. Two large magnets will join instantly with a force of massive weight, crushing everything in their path. Exercise extreme caution!

Life threat

Individuals with a ICD must maintain an safe separation from magnets. The magnetism can stop the functioning of the implant.

Fire risk

Dust produced during grinding of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Skin irritation risks

Allergy Notice: The nickel-copper-nickel coating contains nickel. If an allergic reaction appears, cease working with magnets and wear gloves.

Risk of cracking

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Immense force

Handle magnets consciously. Their immense force can surprise even experienced users. Stay alert and respect their force.

Impact on smartphones

Be aware: rare earth magnets produce a field that interferes with precision electronics. Maintain a safe distance from your phone, tablet, and GPS.

Heat warning

Standard neodymium magnets (grade N) lose magnetization when the temperature surpasses 80°C. The loss of strength is permanent.

![SM 32x125 [2xM8] / N52 - magnetic separator SM 32x125 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x125-2xm8-moj.jpg)

![BM 950x180x70 [4x M8] - magnetic beam BM 950x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-950x180x70-4x-m8-ves.jpg)