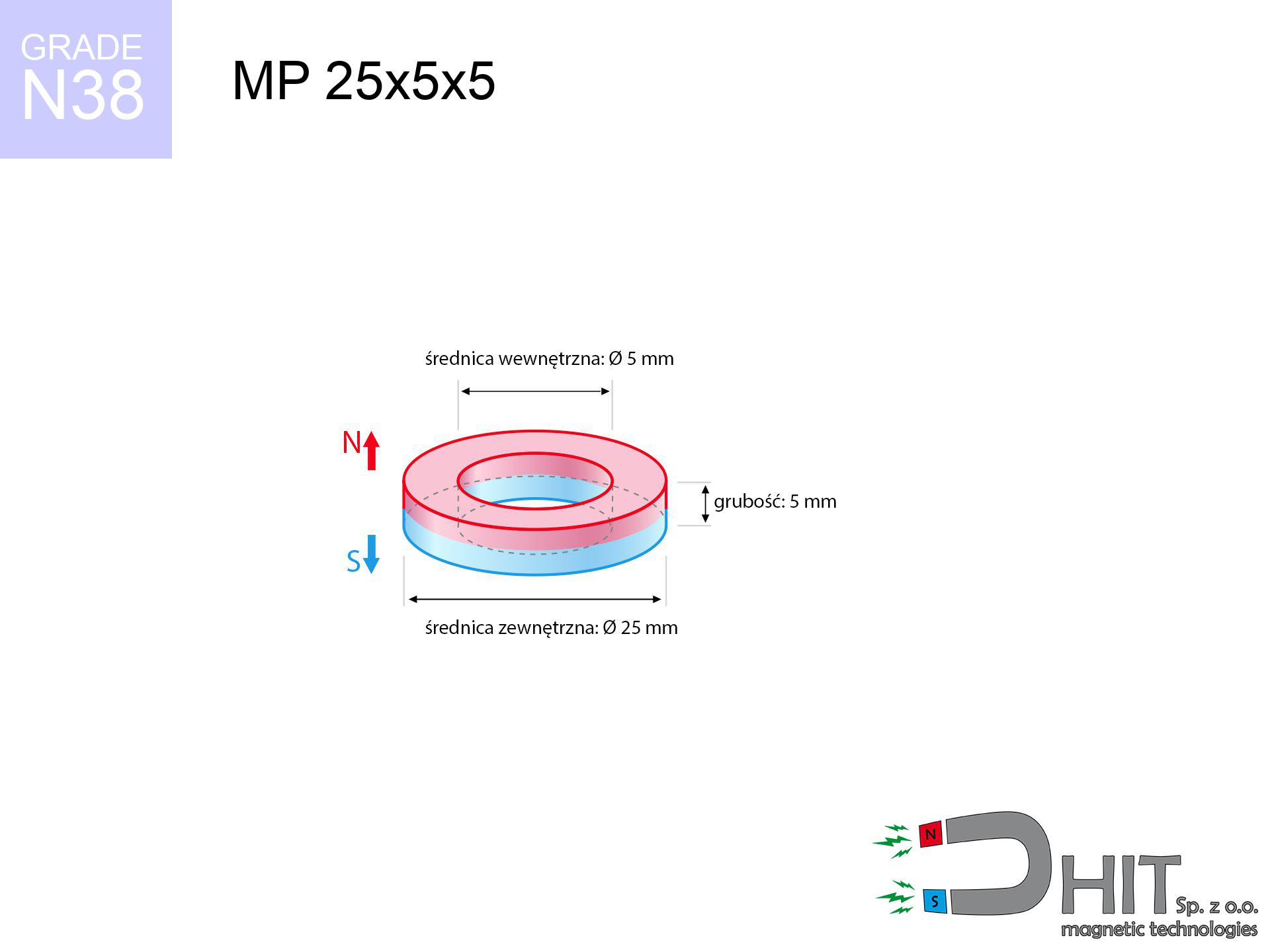

MP 25x5x5 / N38 - ring magnet

ring magnet

Catalog no 030193

GTIN/EAN: 5906301812104

Diameter

25 mm [±0,1 mm]

internal diameter Ø

5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

17.67 g

Magnetization Direction

↑ axial

Load capacity

7.66 kg / 75.12 N

Magnetic Induction

230.20 mT / 2302 Gs

Coating

[NiCuNi] Nickel

6.00 ZŁ with VAT / pcs + price for transport

4.88 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer contact us using

inquiry form

through our site.

Strength as well as structure of a neodymium magnet can be verified using our

magnetic calculator.

Same-day processing for orders placed before 14:00.

Technical details - MP 25x5x5 / N38 - ring magnet

Specification / characteristics - MP 25x5x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030193 |

| GTIN/EAN | 5906301812104 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±0,1 mm] |

| internal diameter Ø | 5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 17.67 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.66 kg / 75.12 N |

| Magnetic Induction ~ ? | 230.20 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - report

These data constitute the outcome of a engineering calculation. Results are based on algorithms for the material Nd2Fe14B. Actual parameters may differ. Please consider these data as a reference point when designing systems.

Table 1: Static pull force (force vs distance) - interaction chart

MP 25x5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5777 Gs

577.7 mT

|

7.66 kg / 16.89 pounds

7660.0 g / 75.1 N

|

warning |

| 1 mm |

5310 Gs

531.0 mT

|

6.47 kg / 14.27 pounds

6471.0 g / 63.5 N

|

warning |

| 2 mm |

4846 Gs

484.6 mT

|

5.39 kg / 11.88 pounds

5388.6 g / 52.9 N

|

warning |

| 3 mm |

4397 Gs

439.7 mT

|

4.44 kg / 9.78 pounds

4437.9 g / 43.5 N

|

warning |

| 5 mm |

3576 Gs

357.6 mT

|

2.93 kg / 6.47 pounds

2934.8 g / 28.8 N

|

warning |

| 10 mm |

2073 Gs

207.3 mT

|

0.99 kg / 2.17 pounds

985.9 g / 9.7 N

|

safe |

| 15 mm |

1231 Gs

123.1 mT

|

0.35 kg / 0.77 pounds

347.9 g / 3.4 N

|

safe |

| 20 mm |

773 Gs

77.3 mT

|

0.14 kg / 0.30 pounds

137.0 g / 1.3 N

|

safe |

| 30 mm |

356 Gs

35.6 mT

|

0.03 kg / 0.06 pounds

29.0 g / 0.3 N

|

safe |

| 50 mm |

115 Gs

11.5 mT

|

0.00 kg / 0.01 pounds

3.0 g / 0.0 N

|

safe |

Table 2: Vertical capacity (wall)

MP 25x5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.53 kg / 3.38 pounds

1532.0 g / 15.0 N

|

| 1 mm | Stal (~0.2) |

1.29 kg / 2.85 pounds

1294.0 g / 12.7 N

|

| 2 mm | Stal (~0.2) |

1.08 kg / 2.38 pounds

1078.0 g / 10.6 N

|

| 3 mm | Stal (~0.2) |

0.89 kg / 1.96 pounds

888.0 g / 8.7 N

|

| 5 mm | Stal (~0.2) |

0.59 kg / 1.29 pounds

586.0 g / 5.7 N

|

| 10 mm | Stal (~0.2) |

0.20 kg / 0.44 pounds

198.0 g / 1.9 N

|

| 15 mm | Stal (~0.2) |

0.07 kg / 0.15 pounds

70.0 g / 0.7 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.06 pounds

28.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MP 25x5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.30 kg / 5.07 pounds

2298.0 g / 22.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.53 kg / 3.38 pounds

1532.0 g / 15.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.77 kg / 1.69 pounds

766.0 g / 7.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.83 kg / 8.44 pounds

3830.0 g / 37.6 N

|

Table 4: Steel thickness (saturation) - power losses

MP 25x5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.77 kg / 1.69 pounds

766.0 g / 7.5 N

|

| 1 mm |

|

1.92 kg / 4.22 pounds

1915.0 g / 18.8 N

|

| 2 mm |

|

3.83 kg / 8.44 pounds

3830.0 g / 37.6 N

|

| 3 mm |

|

5.75 kg / 12.67 pounds

5745.0 g / 56.4 N

|

| 5 mm |

|

7.66 kg / 16.89 pounds

7660.0 g / 75.1 N

|

| 10 mm |

|

7.66 kg / 16.89 pounds

7660.0 g / 75.1 N

|

| 11 mm |

|

7.66 kg / 16.89 pounds

7660.0 g / 75.1 N

|

| 12 mm |

|

7.66 kg / 16.89 pounds

7660.0 g / 75.1 N

|

Table 5: Thermal resistance (material behavior) - power drop

MP 25x5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.66 kg / 16.89 pounds

7660.0 g / 75.1 N

|

OK |

| 40 °C | -2.2% |

7.49 kg / 16.52 pounds

7491.5 g / 73.5 N

|

OK |

| 60 °C | -4.4% |

7.32 kg / 16.14 pounds

7323.0 g / 71.8 N

|

OK |

| 80 °C | -6.6% |

7.15 kg / 15.77 pounds

7154.4 g / 70.2 N

|

|

| 100 °C | -28.8% |

5.45 kg / 12.02 pounds

5453.9 g / 53.5 N

|

Table 6: Two magnets (attraction) - field collision

MP 25x5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

82.42 kg / 181.72 pounds

6 082 Gs

|

12.36 kg / 27.26 pounds

12364 g / 121.3 N

|

N/A |

| 1 mm |

75.95 kg / 167.44 pounds

11 091 Gs

|

11.39 kg / 25.12 pounds

11392 g / 111.8 N

|

68.35 kg / 150.69 pounds

~0 Gs

|

| 2 mm |

69.63 kg / 153.51 pounds

10 620 Gs

|

10.44 kg / 23.03 pounds

10445 g / 102.5 N

|

62.67 kg / 138.16 pounds

~0 Gs

|

| 3 mm |

63.64 kg / 140.29 pounds

10 153 Gs

|

9.55 kg / 21.04 pounds

9545 g / 93.6 N

|

57.27 kg / 126.26 pounds

~0 Gs

|

| 5 mm |

52.69 kg / 116.16 pounds

9 238 Gs

|

7.90 kg / 17.42 pounds

7903 g / 77.5 N

|

47.42 kg / 104.54 pounds

~0 Gs

|

| 10 mm |

31.58 kg / 69.62 pounds

7 152 Gs

|

4.74 kg / 10.44 pounds

4737 g / 46.5 N

|

28.42 kg / 62.66 pounds

~0 Gs

|

| 20 mm |

10.61 kg / 23.39 pounds

4 145 Gs

|

1.59 kg / 3.51 pounds

1591 g / 15.6 N

|

9.55 kg / 21.05 pounds

~0 Gs

|

| 50 mm |

0.65 kg / 1.43 pounds

1 024 Gs

|

0.10 kg / 0.21 pounds

97 g / 1.0 N

|

0.58 kg / 1.28 pounds

~0 Gs

|

| 60 mm |

0.31 kg / 0.69 pounds

712 Gs

|

0.05 kg / 0.10 pounds

47 g / 0.5 N

|

0.28 kg / 0.62 pounds

~0 Gs

|

| 70 mm |

0.16 kg / 0.36 pounds

514 Gs

|

0.02 kg / 0.05 pounds

24 g / 0.2 N

|

0.15 kg / 0.32 pounds

~0 Gs

|

| 80 mm |

0.09 kg / 0.20 pounds

383 Gs

|

0.01 kg / 0.03 pounds

14 g / 0.1 N

|

0.08 kg / 0.18 pounds

~0 Gs

|

| 90 mm |

0.05 kg / 0.12 pounds

293 Gs

|

0.01 kg / 0.02 pounds

8 g / 0.1 N

|

0.05 kg / 0.11 pounds

~0 Gs

|

| 100 mm |

0.03 kg / 0.07 pounds

230 Gs

|

0.00 kg / 0.01 pounds

5 g / 0.0 N

|

0.03 kg / 0.06 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MP 25x5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 17.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 10.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 8.0 cm |

| Car key | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MP 25x5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.62 km/h

(6.28 m/s)

|

0.35 J | |

| 30 mm |

36.46 km/h

(10.13 m/s)

|

0.91 J | |

| 50 mm |

46.96 km/h

(13.05 m/s)

|

1.50 J | |

| 100 mm |

66.40 km/h

(18.45 m/s)

|

3.01 J |

Table 9: Coating parameters (durability)

MP 25x5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 25x5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 24 536 Mx | 245.4 µWb |

| Pc Coefficient | 1.03 | High (Stable) |

Table 11: Submerged application

MP 25x5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.66 kg | Standard |

| Water (riverbed) |

8.77 kg

(+1.11 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet holds just ~20% of its nominal pull.

2. Efficiency vs thickness

*Thin metal sheet (e.g. computer case) significantly reduces the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.03

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Benefits

- They do not lose strength, even over approximately ten years – the decrease in lifting capacity is only ~1% (based on measurements),

- They do not lose their magnetic properties even under close interference source,

- In other words, due to the shiny layer of gold, the element is aesthetically pleasing,

- Neodymium magnets generate maximum magnetic induction on a contact point, which allows for strong attraction,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, enabling action at temperatures reaching 230°C and above...

- Considering the ability of free shaping and customization to specialized requirements, magnetic components can be produced in a broad palette of geometric configurations, which makes them more universal,

- Fundamental importance in advanced technology sectors – they find application in data components, brushless drives, precision medical tools, and other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which allows their use in compact constructions

Limitations

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- Limited ability of producing threads in the magnet and complex shapes - preferred is casing - magnet mounting.

- Possible danger resulting from small fragments of magnets can be dangerous, if swallowed, which gains importance in the context of child health protection. Furthermore, small elements of these products can be problematic in diagnostics medical when they are in the body.

- With mass production the cost of neodymium magnets is economically unviable,

Lifting parameters

Maximum lifting capacity of the magnet – what contributes to it?

- on a base made of mild steel, optimally conducting the magnetic flux

- with a cross-section minimum 10 mm

- with an polished contact surface

- without any clearance between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- at ambient temperature room level

Determinants of practical lifting force of a magnet

- Distance – the presence of foreign body (paint, tape, air) interrupts the magnetic circuit, which lowers power rapidly (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Chemical composition of the base – low-carbon steel gives the best results. Alloy steels decrease magnetic permeability and lifting capacity.

- Base smoothness – the smoother and more polished the surface, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Temperature influence – hot environment reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was performed on plates with a smooth surface of suitable thickness, under perpendicular forces, whereas under attempts to slide the magnet the holding force is lower. In addition, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

H&S for magnets

Life threat

Warning for patients: Powerful magnets disrupt electronics. Keep at least 30 cm distance or ask another person to work with the magnets.

Permanent damage

Control the heat. Exposing the magnet above 80 degrees Celsius will ruin its magnetic structure and strength.

Beware of splinters

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Clashing of two magnets will cause them cracking into shards.

Cards and drives

Equipment safety: Strong magnets can damage data carriers and sensitive devices (pacemakers, hearing aids, mechanical watches).

Do not give to children

These products are not suitable for play. Swallowing a few magnets may result in them attracting across intestines, which poses a direct threat to life and requires urgent medical intervention.

Precision electronics

A powerful magnetic field disrupts the functioning of compasses in phones and GPS navigation. Maintain magnets close to a device to prevent damaging the sensors.

Do not drill into magnets

Mechanical processing of neodymium magnets carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Conscious usage

Handle magnets with awareness. Their huge power can surprise even experienced users. Stay alert and respect their power.

Bone fractures

Danger of trauma: The attraction force is so immense that it can result in blood blisters, pinching, and even bone fractures. Protective gloves are recommended.

Allergic reactions

Studies show that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, avoid touching magnets with bare hands and choose coated magnets.

![SM 32x450 [2xM8] / N42 - magnetic separator SM 32x450 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x450-2xm8-bex.jpg)

![SM 32x375 [2xM8] / N42 - magnetic separator SM 32x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-nif.jpg)

![SM 25x250 [2xM8] / N42 - magnetic separator SM 25x250 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x250-2xm8-ker.jpg)