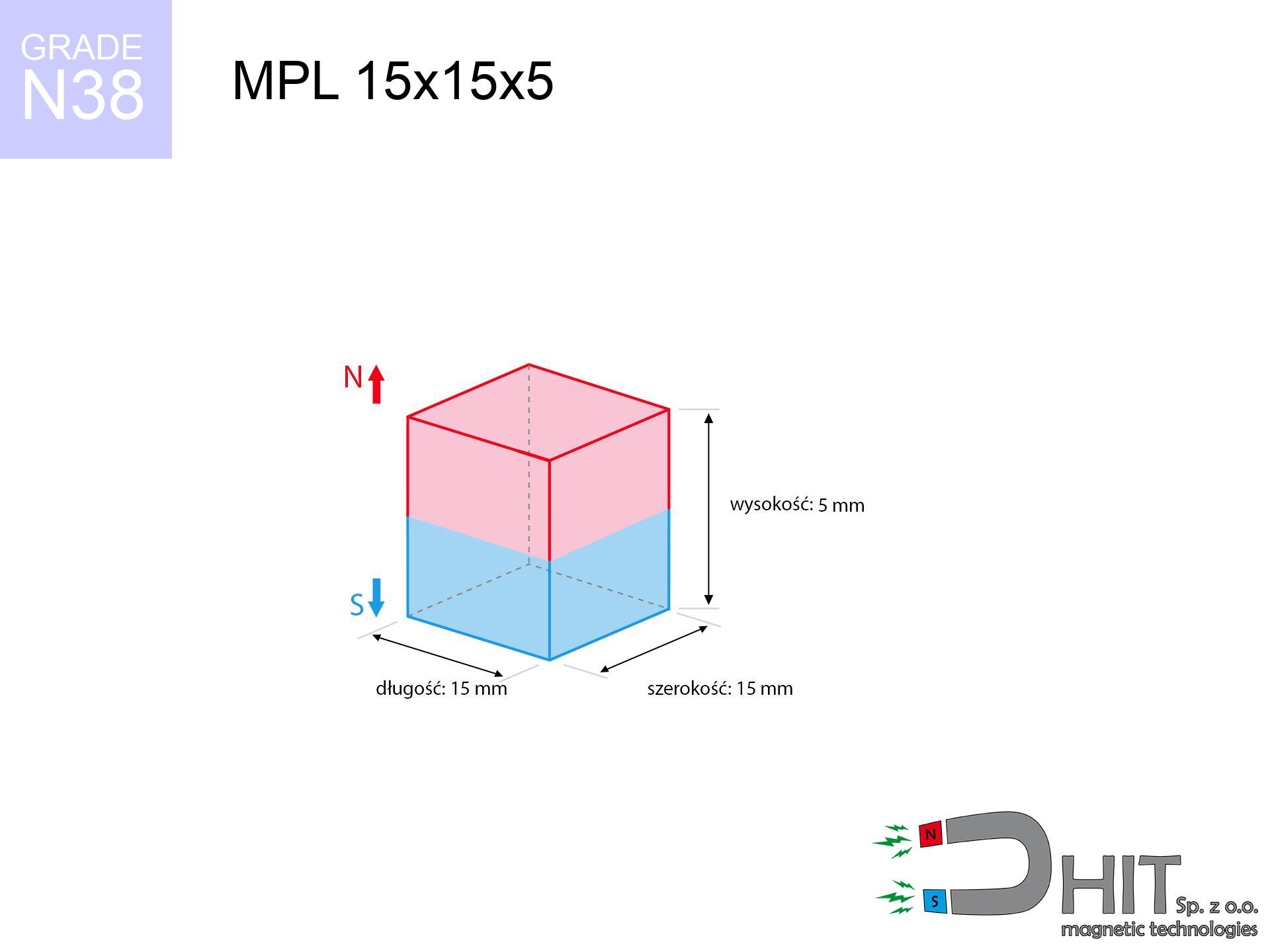

MPL 15x15x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020120

GTIN/EAN: 5906301811268

length

15 mm [±0,1 mm]

Width

15 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

8.44 g

Magnetization Direction

↑ axial

Load capacity

5.87 kg / 57.62 N

Magnetic Induction

318.00 mT / 3180 Gs

Coating

[NiCuNi] Nickel

4.03 ZŁ with VAT / pcs + price for transport

3.28 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

alternatively contact us via

form

the contact section.

Specifications and structure of magnetic components can be reviewed on our

magnetic mass calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - MPL 15x15x5 / N38 - lamellar magnet

Specification / characteristics - MPL 15x15x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020120 |

| GTIN/EAN | 5906301811268 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 15 mm [±0,1 mm] |

| Width | 15 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 8.44 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.87 kg / 57.62 N |

| Magnetic Induction ~ ? | 318.00 mT / 3180 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - data

Presented data represent the result of a physical simulation. Results were calculated on algorithms for the material Nd2Fe14B. Real-world performance might slightly differ. Treat these calculations as a reference point for designers.

Table 1: Static force (pull vs gap) - characteristics

MPL 15x15x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3179 Gs

317.9 mT

|

5.87 kg / 12.94 LBS

5870.0 g / 57.6 N

|

strong |

| 1 mm |

2873 Gs

287.3 mT

|

4.79 kg / 10.57 LBS

4794.1 g / 47.0 N

|

strong |

| 2 mm |

2528 Gs

252.8 mT

|

3.71 kg / 8.18 LBS

3712.5 g / 36.4 N

|

strong |

| 3 mm |

2181 Gs

218.1 mT

|

2.76 kg / 6.09 LBS

2763.0 g / 27.1 N

|

strong |

| 5 mm |

1565 Gs

156.5 mT

|

1.42 kg / 3.14 LBS

1422.0 g / 13.9 N

|

low risk |

| 10 mm |

659 Gs

65.9 mT

|

0.25 kg / 0.56 LBS

252.1 g / 2.5 N

|

low risk |

| 15 mm |

307 Gs

30.7 mT

|

0.05 kg / 0.12 LBS

54.7 g / 0.5 N

|

low risk |

| 20 mm |

162 Gs

16.2 mT

|

0.02 kg / 0.03 LBS

15.2 g / 0.1 N

|

low risk |

| 30 mm |

59 Gs

5.9 mT

|

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

low risk |

| 50 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

Table 2: Sliding capacity (wall)

MPL 15x15x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.17 kg / 2.59 LBS

1174.0 g / 11.5 N

|

| 1 mm | Stal (~0.2) |

0.96 kg / 2.11 LBS

958.0 g / 9.4 N

|

| 2 mm | Stal (~0.2) |

0.74 kg / 1.64 LBS

742.0 g / 7.3 N

|

| 3 mm | Stal (~0.2) |

0.55 kg / 1.22 LBS

552.0 g / 5.4 N

|

| 5 mm | Stal (~0.2) |

0.28 kg / 0.63 LBS

284.0 g / 2.8 N

|

| 10 mm | Stal (~0.2) |

0.05 kg / 0.11 LBS

50.0 g / 0.5 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 15x15x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.76 kg / 3.88 LBS

1761.0 g / 17.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.17 kg / 2.59 LBS

1174.0 g / 11.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.59 kg / 1.29 LBS

587.0 g / 5.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.94 kg / 6.47 LBS

2935.0 g / 28.8 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 15x15x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.59 kg / 1.29 LBS

587.0 g / 5.8 N

|

| 1 mm |

|

1.47 kg / 3.24 LBS

1467.5 g / 14.4 N

|

| 2 mm |

|

2.94 kg / 6.47 LBS

2935.0 g / 28.8 N

|

| 3 mm |

|

4.40 kg / 9.71 LBS

4402.5 g / 43.2 N

|

| 5 mm |

|

5.87 kg / 12.94 LBS

5870.0 g / 57.6 N

|

| 10 mm |

|

5.87 kg / 12.94 LBS

5870.0 g / 57.6 N

|

| 11 mm |

|

5.87 kg / 12.94 LBS

5870.0 g / 57.6 N

|

| 12 mm |

|

5.87 kg / 12.94 LBS

5870.0 g / 57.6 N

|

Table 5: Working in heat (stability) - thermal limit

MPL 15x15x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

5.87 kg / 12.94 LBS

5870.0 g / 57.6 N

|

OK |

| 40 °C | -2.2% |

5.74 kg / 12.66 LBS

5740.9 g / 56.3 N

|

OK |

| 60 °C | -4.4% |

5.61 kg / 12.37 LBS

5611.7 g / 55.1 N

|

|

| 80 °C | -6.6% |

5.48 kg / 12.09 LBS

5482.6 g / 53.8 N

|

|

| 100 °C | -28.8% |

4.18 kg / 9.21 LBS

4179.4 g / 41.0 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 15x15x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

14.02 kg / 30.90 LBS

4 741 Gs

|

2.10 kg / 4.64 LBS

2103 g / 20.6 N

|

N/A |

| 1 mm |

12.77 kg / 28.15 LBS

6 068 Gs

|

1.92 kg / 4.22 LBS

1916 g / 18.8 N

|

11.49 kg / 25.34 LBS

~0 Gs

|

| 2 mm |

11.45 kg / 25.24 LBS

5 746 Gs

|

1.72 kg / 3.79 LBS

1717 g / 16.8 N

|

10.30 kg / 22.72 LBS

~0 Gs

|

| 3 mm |

10.13 kg / 22.34 LBS

5 405 Gs

|

1.52 kg / 3.35 LBS

1520 g / 14.9 N

|

9.12 kg / 20.10 LBS

~0 Gs

|

| 5 mm |

7.68 kg / 16.93 LBS

4 706 Gs

|

1.15 kg / 2.54 LBS

1152 g / 11.3 N

|

6.91 kg / 15.24 LBS

~0 Gs

|

| 10 mm |

3.40 kg / 7.49 LBS

3 129 Gs

|

0.51 kg / 1.12 LBS

509 g / 5.0 N

|

3.06 kg / 6.74 LBS

~0 Gs

|

| 20 mm |

0.60 kg / 1.33 LBS

1 318 Gs

|

0.09 kg / 0.20 LBS

90 g / 0.9 N

|

0.54 kg / 1.19 LBS

~0 Gs

|

| 50 mm |

0.01 kg / 0.03 LBS

188 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 LBS

118 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

79 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

55 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

40 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

30 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MPL 15x15x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MPL 15x15x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.30 km/h

(7.58 m/s)

|

0.24 J | |

| 30 mm |

46.08 km/h

(12.80 m/s)

|

0.69 J | |

| 50 mm |

59.47 km/h

(16.52 m/s)

|

1.15 J | |

| 100 mm |

84.11 km/h

(23.36 m/s)

|

2.30 J |

Table 9: Coating parameters (durability)

MPL 15x15x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 15x15x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 7 651 Mx | 76.5 µWb |

| Pc Coefficient | 0.40 | Low (Flat) |

Table 11: Submerged application

MPL 15x15x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 5.87 kg | Standard |

| Water (riverbed) |

6.72 kg

(+0.85 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds just a fraction of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) severely weakens the holding force.

3. Temperature resistance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.40

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of neodymium magnets.

Advantages

- They retain magnetic properties for around 10 years – the loss is just ~1% (in theory),

- Neodymium magnets are characterized by exceptionally resistant to demagnetization caused by external magnetic fields,

- In other words, due to the smooth layer of gold, the element is aesthetically pleasing,

- Magnetic induction on the top side of the magnet turns out to be very high,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Possibility of exact shaping as well as optimizing to complex applications,

- Significant place in innovative solutions – they are utilized in hard drives, drive modules, medical devices, and complex engineering applications.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Disadvantages

- To avoid cracks under impact, we recommend using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in creating threads and complex shapes in magnets, we recommend using a housing - magnetic mechanism.

- Possible danger resulting from small fragments of magnets pose a threat, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, tiny parts of these devices are able to complicate diagnosis medical when they are in the body.

- With budget limitations the cost of neodymium magnets is economically unviable,

Lifting parameters

Maximum holding power of the magnet – what contributes to it?

- on a base made of structural steel, optimally conducting the magnetic flux

- whose thickness is min. 10 mm

- with a plane perfectly flat

- under conditions of ideal adhesion (surface-to-surface)

- for force acting at a right angle (pull-off, not shear)

- at room temperature

Practical lifting capacity: influencing factors

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by varnish or unevenness) drastically reduces the pulling force, often by half at just 0.5 mm.

- Direction of force – maximum parameter is obtained only during perpendicular pulling. The shear force of the magnet along the surface is typically several times smaller (approx. 1/5 of the lifting capacity).

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Chemical composition of the base – low-carbon steel attracts best. Higher carbon content reduce magnetic permeability and lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which increases field saturation. Rough surfaces reduce efficiency.

- Thermal factor – high temperature reduces magnetic field. Too high temperature can permanently damage the magnet.

Holding force was measured on the plate surface of 20 mm thickness, when the force acted perpendicularly, in contrast under parallel forces the load capacity is reduced by as much as fivefold. In addition, even a minimal clearance between the magnet and the plate decreases the holding force.

Safe handling of NdFeB magnets

Maximum temperature

Regular neodymium magnets (grade N) lose magnetization when the temperature exceeds 80°C. Damage is permanent.

Warning for heart patients

For implant holders: Strong magnetic fields affect medical devices. Maintain at least 30 cm distance or request help to handle the magnets.

Keep away from children

These products are not intended for children. Eating multiple magnets can lead to them pinching intestinal walls, which constitutes a severe health hazard and requires urgent medical intervention.

Respect the power

Handle magnets with awareness. Their powerful strength can surprise even experienced users. Be vigilant and respect their power.

Magnetic media

Do not bring magnets near a purse, laptop, or TV. The magnetic field can irreversibly ruin these devices and erase data from cards.

Flammability

Powder generated during cutting of magnets is combustible. Do not drill into magnets without proper cooling and knowledge.

Risk of cracking

Protect your eyes. Magnets can explode upon violent connection, launching sharp fragments into the air. We recommend safety glasses.

Hand protection

Big blocks can crush fingers in a fraction of a second. Under no circumstances place your hand betwixt two strong magnets.

Nickel coating and allergies

Medical facts indicate that the nickel plating (the usual finish) is a potent allergen. If your skin reacts to metals, avoid touching magnets with bare hands and choose coated magnets.

Keep away from electronics

Note: rare earth magnets produce a field that interferes with sensitive sensors. Keep a safe distance from your phone, tablet, and navigation systems.

![BM 850x180x70 [4x M8] - magnetic beam BM 850x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-850x180x70-4x-m8-mep.jpg)