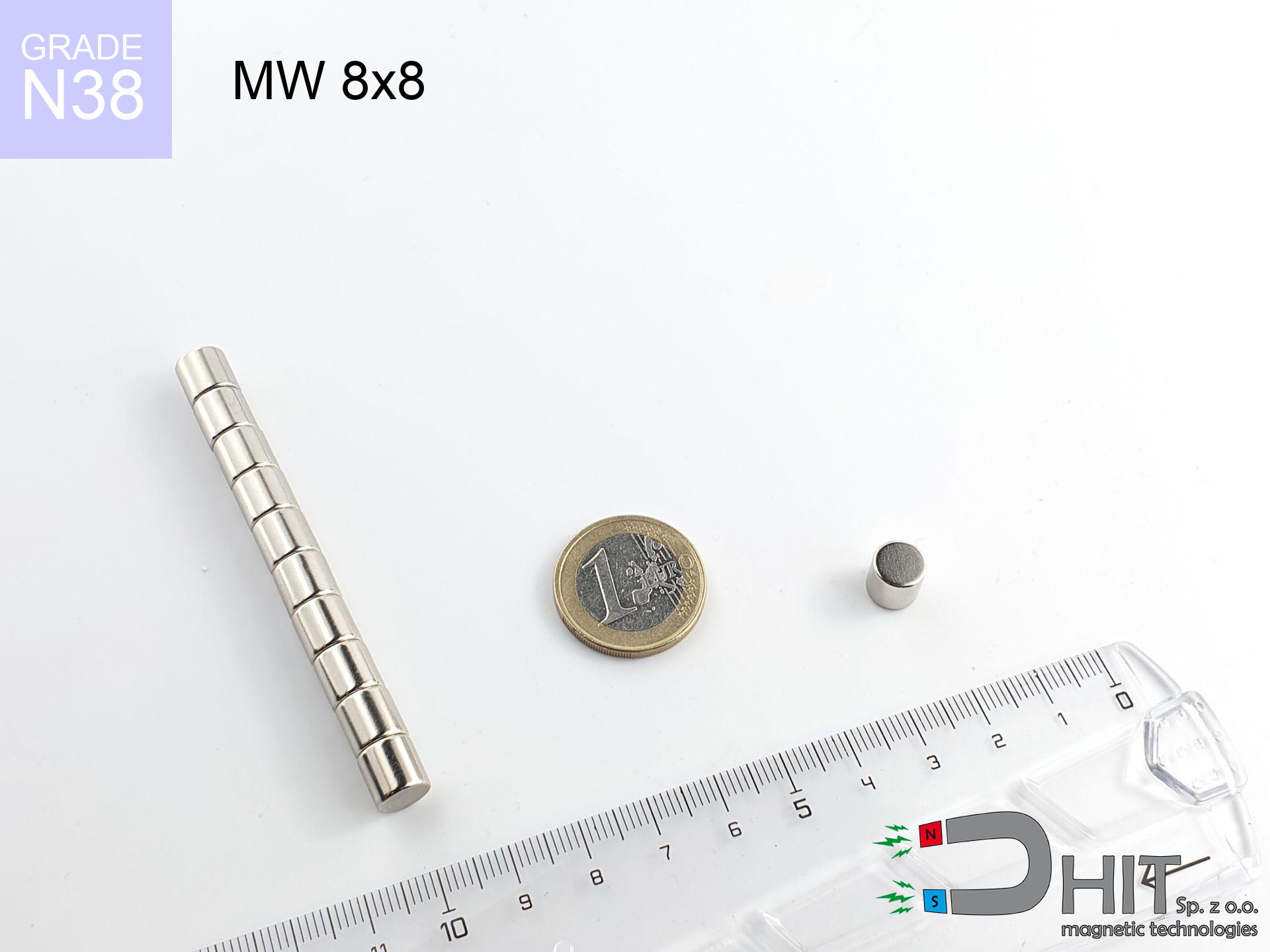

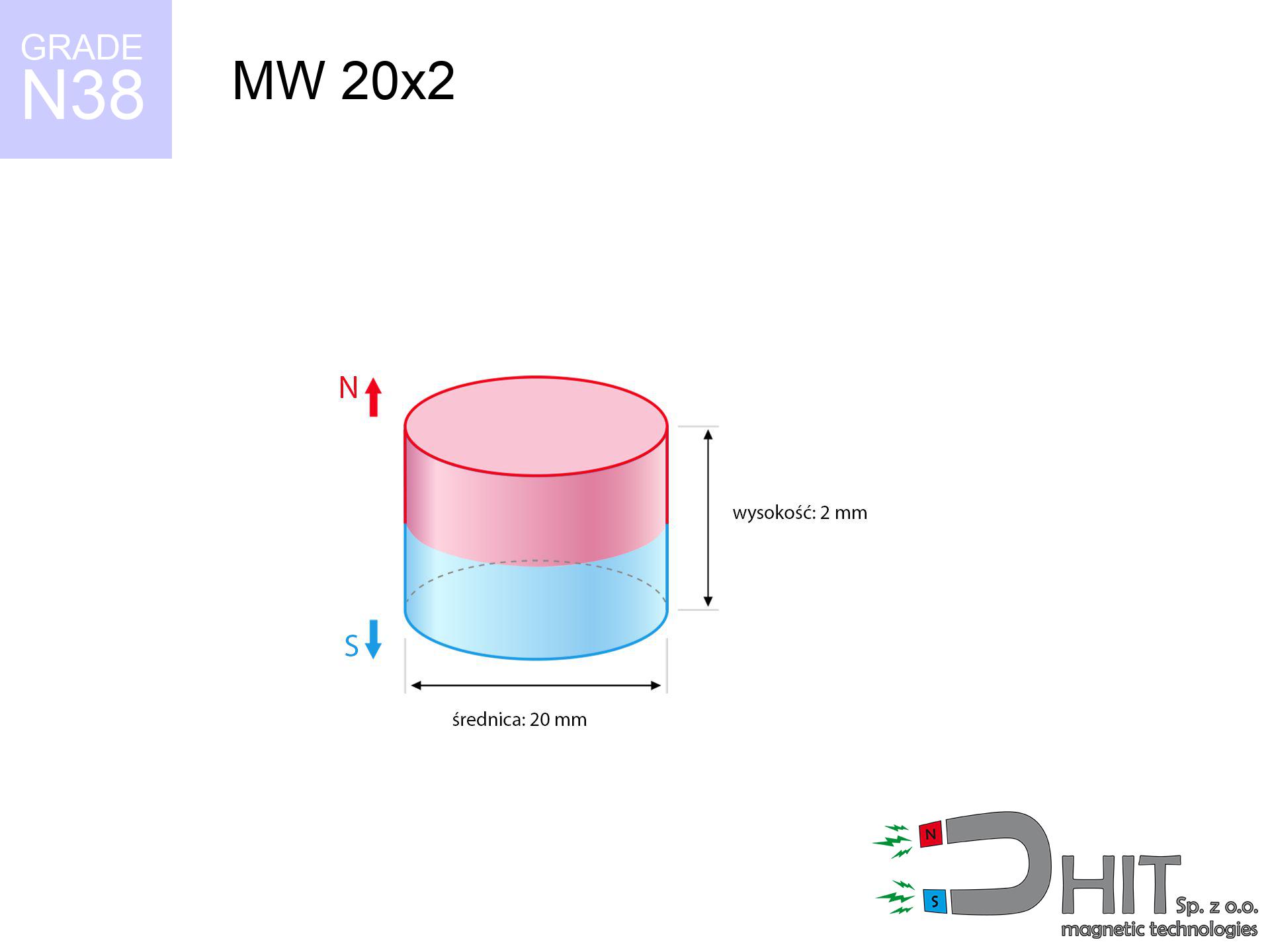

MW 20x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010041

GTIN/EAN: 5906301810407

Diameter Ø

20 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

4.71 g

Magnetization Direction

↑ axial

Load capacity

1.63 kg / 16.02 N

Magnetic Induction

121.57 mT / 1216 Gs

Coating

[NiCuNi] Nickel

2.08 ZŁ with VAT / pcs + price for transport

1.690 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively drop us a message through

form

our website.

Force and structure of a neodymium magnet can be tested on our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical details - MW 20x2 / N38 - cylindrical magnet

Specification / characteristics - MW 20x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010041 |

| GTIN/EAN | 5906301810407 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 20 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 4.71 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.63 kg / 16.02 N |

| Magnetic Induction ~ ? | 121.57 mT / 1216 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the magnet - technical parameters

The following information represent the direct effect of a engineering analysis. Values are based on algorithms for the material Nd2Fe14B. Actual performance may differ from theoretical values. Use these data as a preliminary roadmap for designers.

Table 1: Static force (force vs gap) - power drop

MW 20x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1216 Gs

121.6 mT

|

1.63 kg / 3.59 lbs

1630.0 g / 16.0 N

|

safe |

| 1 mm |

1165 Gs

116.5 mT

|

1.50 kg / 3.30 lbs

1496.3 g / 14.7 N

|

safe |

| 2 mm |

1087 Gs

108.7 mT

|

1.30 kg / 2.87 lbs

1302.7 g / 12.8 N

|

safe |

| 3 mm |

991 Gs

99.1 mT

|

1.08 kg / 2.39 lbs

1083.7 g / 10.6 N

|

safe |

| 5 mm |

783 Gs

78.3 mT

|

0.68 kg / 1.49 lbs

675.9 g / 6.6 N

|

safe |

| 10 mm |

379 Gs

37.9 mT

|

0.16 kg / 0.35 lbs

158.4 g / 1.6 N

|

safe |

| 15 mm |

185 Gs

18.5 mT

|

0.04 kg / 0.08 lbs

37.9 g / 0.4 N

|

safe |

| 20 mm |

99 Gs

9.9 mT

|

0.01 kg / 0.02 lbs

10.8 g / 0.1 N

|

safe |

| 30 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 lbs

1.4 g / 0.0 N

|

safe |

| 50 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

Table 2: Shear force (wall)

MW 20x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.33 kg / 0.72 lbs

326.0 g / 3.2 N

|

| 1 mm | Stal (~0.2) |

0.30 kg / 0.66 lbs

300.0 g / 2.9 N

|

| 2 mm | Stal (~0.2) |

0.26 kg / 0.57 lbs

260.0 g / 2.6 N

|

| 3 mm | Stal (~0.2) |

0.22 kg / 0.48 lbs

216.0 g / 2.1 N

|

| 5 mm | Stal (~0.2) |

0.14 kg / 0.30 lbs

136.0 g / 1.3 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

32.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 20x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.49 kg / 1.08 lbs

489.0 g / 4.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.33 kg / 0.72 lbs

326.0 g / 3.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.16 kg / 0.36 lbs

163.0 g / 1.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.82 kg / 1.80 lbs

815.0 g / 8.0 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 20x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.16 kg / 0.36 lbs

163.0 g / 1.6 N

|

| 1 mm |

|

0.41 kg / 0.90 lbs

407.5 g / 4.0 N

|

| 2 mm |

|

0.82 kg / 1.80 lbs

815.0 g / 8.0 N

|

| 3 mm |

|

1.22 kg / 2.70 lbs

1222.5 g / 12.0 N

|

| 5 mm |

|

1.63 kg / 3.59 lbs

1630.0 g / 16.0 N

|

| 10 mm |

|

1.63 kg / 3.59 lbs

1630.0 g / 16.0 N

|

| 11 mm |

|

1.63 kg / 3.59 lbs

1630.0 g / 16.0 N

|

| 12 mm |

|

1.63 kg / 3.59 lbs

1630.0 g / 16.0 N

|

Table 5: Thermal resistance (stability) - power drop

MW 20x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.63 kg / 3.59 lbs

1630.0 g / 16.0 N

|

OK |

| 40 °C | -2.2% |

1.59 kg / 3.51 lbs

1594.1 g / 15.6 N

|

OK |

| 60 °C | -4.4% |

1.56 kg / 3.44 lbs

1558.3 g / 15.3 N

|

|

| 80 °C | -6.6% |

1.52 kg / 3.36 lbs

1522.4 g / 14.9 N

|

|

| 100 °C | -28.8% |

1.16 kg / 2.56 lbs

1160.6 g / 11.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 20x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.86 kg / 6.31 lbs

2 301 Gs

|

0.43 kg / 0.95 lbs

429 g / 4.2 N

|

N/A |

| 1 mm |

2.76 kg / 6.09 lbs

2 388 Gs

|

0.41 kg / 0.91 lbs

414 g / 4.1 N

|

2.49 kg / 5.48 lbs

~0 Gs

|

| 2 mm |

2.63 kg / 5.79 lbs

2 329 Gs

|

0.39 kg / 0.87 lbs

394 g / 3.9 N

|

2.36 kg / 5.21 lbs

~0 Gs

|

| 3 mm |

2.47 kg / 5.44 lbs

2 257 Gs

|

0.37 kg / 0.82 lbs

370 g / 3.6 N

|

2.22 kg / 4.89 lbs

~0 Gs

|

| 5 mm |

2.10 kg / 4.62 lbs

2 081 Gs

|

0.31 kg / 0.69 lbs

315 g / 3.1 N

|

1.89 kg / 4.16 lbs

~0 Gs

|

| 10 mm |

1.19 kg / 2.62 lbs

1 565 Gs

|

0.18 kg / 0.39 lbs

178 g / 1.7 N

|

1.07 kg / 2.35 lbs

~0 Gs

|

| 20 mm |

0.28 kg / 0.61 lbs

758 Gs

|

0.04 kg / 0.09 lbs

42 g / 0.4 N

|

0.25 kg / 0.55 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.01 lbs

115 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 lbs

72 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

48 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

33 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

18 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MW 20x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MW 20x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.87 km/h

(5.52 m/s)

|

0.07 J | |

| 30 mm |

32.51 km/h

(9.03 m/s)

|

0.19 J | |

| 50 mm |

41.95 km/h

(11.65 m/s)

|

0.32 J | |

| 100 mm |

59.33 km/h

(16.48 m/s)

|

0.64 J |

Table 9: Coating parameters (durability)

MW 20x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 20x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 038 Mx | 50.4 µWb |

| Pc Coefficient | 0.16 | Low (Flat) |

Table 11: Submerged application

MW 20x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.63 kg | Standard |

| Water (riverbed) |

1.87 kg

(+0.24 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet retains merely ~20% of its nominal pull.

2. Steel thickness impact

*Thin steel (e.g. computer case) severely reduces the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.16

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Pros

- They virtually do not lose power, because even after 10 years the performance loss is only ~1% (according to literature),

- Neodymium magnets are highly resistant to demagnetization caused by external interference,

- A magnet with a metallic nickel surface is more attractive,

- Magnets exhibit excellent magnetic induction on the outer side,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for functioning at temperatures reaching 230°C and above...

- Thanks to flexibility in constructing and the capacity to adapt to client solutions,

- Significant place in innovative solutions – they are used in magnetic memories, electric motors, precision medical tools, and multitasking production systems.

- Thanks to efficiency per cm³, small magnets offer high operating force, in miniature format,

Weaknesses

- At very strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- We suggest a housing - magnetic holder, due to difficulties in creating nuts inside the magnet and complicated forms.

- Potential hazard to health – tiny shards of magnets can be dangerous, in case of ingestion, which gains importance in the context of child safety. Furthermore, small elements of these devices can disrupt the diagnostic process medical after entering the body.

- Due to neodymium price, their price is higher than average,

Holding force characteristics

Maximum magnetic pulling force – what contributes to it?

- using a sheet made of mild steel, acting as a circuit closing element

- whose transverse dimension is min. 10 mm

- characterized by lack of roughness

- under conditions of ideal adhesion (metal-to-metal)

- for force applied at a right angle (pull-off, not shear)

- in temp. approx. 20°C

Lifting capacity in practice – influencing factors

- Distance – the presence of any layer (rust, tape, air) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Force direction – catalog parameter refers to pulling vertically. When applying parallel force, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Steel thickness – too thin sheet does not accept the full field, causing part of the flux to be wasted into the air.

- Plate material – mild steel gives the best results. Higher carbon content lower magnetic permeability and lifting capacity.

- Surface condition – smooth surfaces ensure maximum contact, which increases force. Rough surfaces reduce efficiency.

- Temperature influence – hot environment reduces pulling force. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was performed on plates with a smooth surface of optimal thickness, under a perpendicular pulling force, whereas under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a small distance between the magnet and the plate reduces the holding force.

H&S for magnets

GPS and phone interference

Navigation devices and smartphones are extremely sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can ruin the internal compass in your phone.

Fire risk

Powder created during grinding of magnets is flammable. Do not drill into magnets unless you are an expert.

No play value

These products are not intended for children. Accidental ingestion of several magnets can lead to them connecting inside the digestive tract, which constitutes a direct threat to life and necessitates immediate surgery.

Handling rules

Exercise caution. Rare earth magnets act from a distance and connect with massive power, often faster than you can react.

Protective goggles

Despite the nickel coating, the material is delicate and cannot withstand shocks. Do not hit, as the magnet may crumble into hazardous fragments.

Thermal limits

Avoid heat. NdFeB magnets are sensitive to heat. If you require resistance above 80°C, inquire about HT versions (H, SH, UH).

Warning for allergy sufferers

It is widely known that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, prevent touching magnets with bare hands or choose coated magnets.

Safe distance

Very strong magnetic fields can destroy records on payment cards, hard drives, and storage devices. Maintain a gap of min. 10 cm.

Pacemakers

For implant holders: Powerful magnets disrupt medical devices. Maintain minimum 30 cm distance or request help to handle the magnets.

Pinching danger

Big blocks can crush fingers instantly. Under no circumstances put your hand betwixt two strong magnets.

![SM 25x225 [2xM8] / N52 - magnetic separator SM 25x225 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x225-2xm8-lod.jpg)

![HH 20x7.2 [M4] / N38 - through hole magnetic holder HH 20x7.2 [M4] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-20x7.2-m4-luc.jpg)