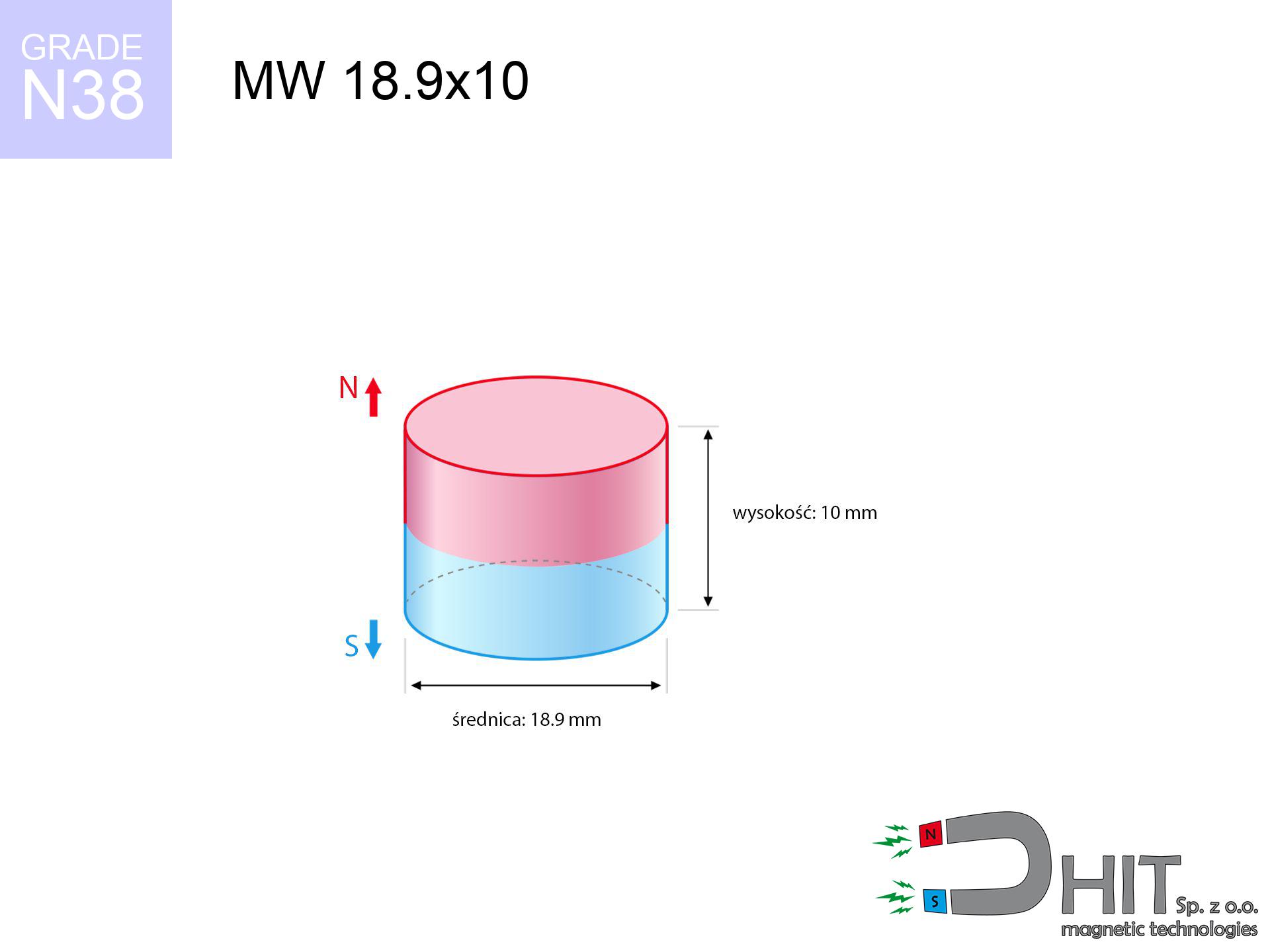

MW 18.9x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010036

GTIN/EAN: 5906301810353

Diameter Ø

18.9 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

21.04 g

Magnetization Direction

→ diametrical

Load capacity

11.68 kg / 114.54 N

Magnetic Induction

450.35 mT / 4503 Gs

Coating

[NiCuNi] Nickel

11.07 ZŁ with VAT / pcs + price for transport

9.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

or send us a note through

request form

through our site.

Force as well as shape of a neodymium magnet can be analyzed with our

our magnetic calculator.

Same-day shipping for orders placed before 14:00.

Detailed specification - MW 18.9x10 / N38 - cylindrical magnet

Specification / characteristics - MW 18.9x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010036 |

| GTIN/EAN | 5906301810353 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 18.9 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 21.04 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 11.68 kg / 114.54 N |

| Magnetic Induction ~ ? | 450.35 mT / 4503 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - data

The following data are the result of a physical calculation. Values were calculated on models for the class Nd2Fe14B. Operational performance might slightly differ from theoretical values. Please consider these calculations as a supplementary guide when designing systems.

Table 1: Static force (force vs gap) - interaction chart

MW 18.9x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4502 Gs

450.2 mT

|

11.68 kg / 25.75 lbs

11680.0 g / 114.6 N

|

critical level |

| 1 mm |

4050 Gs

405.0 mT

|

9.46 kg / 20.85 lbs

9455.2 g / 92.8 N

|

strong |

| 2 mm |

3587 Gs

358.7 mT

|

7.42 kg / 16.35 lbs

7416.3 g / 72.8 N

|

strong |

| 3 mm |

3139 Gs

313.9 mT

|

5.68 kg / 12.52 lbs

5678.8 g / 55.7 N

|

strong |

| 5 mm |

2346 Gs

234.6 mT

|

3.17 kg / 6.99 lbs

3172.5 g / 31.1 N

|

strong |

| 10 mm |

1100 Gs

110.0 mT

|

0.70 kg / 1.54 lbs

696.7 g / 6.8 N

|

safe |

| 15 mm |

554 Gs

55.4 mT

|

0.18 kg / 0.39 lbs

176.7 g / 1.7 N

|

safe |

| 20 mm |

308 Gs

30.8 mT

|

0.05 kg / 0.12 lbs

54.6 g / 0.5 N

|

safe |

| 30 mm |

120 Gs

12.0 mT

|

0.01 kg / 0.02 lbs

8.3 g / 0.1 N

|

safe |

| 50 mm |

32 Gs

3.2 mT

|

0.00 kg / 0.00 lbs

0.6 g / 0.0 N

|

safe |

Table 2: Shear capacity (vertical surface)

MW 18.9x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.34 kg / 5.15 lbs

2336.0 g / 22.9 N

|

| 1 mm | Stal (~0.2) |

1.89 kg / 4.17 lbs

1892.0 g / 18.6 N

|

| 2 mm | Stal (~0.2) |

1.48 kg / 3.27 lbs

1484.0 g / 14.6 N

|

| 3 mm | Stal (~0.2) |

1.14 kg / 2.50 lbs

1136.0 g / 11.1 N

|

| 5 mm | Stal (~0.2) |

0.63 kg / 1.40 lbs

634.0 g / 6.2 N

|

| 10 mm | Stal (~0.2) |

0.14 kg / 0.31 lbs

140.0 g / 1.4 N

|

| 15 mm | Stal (~0.2) |

0.04 kg / 0.08 lbs

36.0 g / 0.4 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 18.9x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

3.50 kg / 7.72 lbs

3504.0 g / 34.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.34 kg / 5.15 lbs

2336.0 g / 22.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.17 kg / 2.57 lbs

1168.0 g / 11.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

5.84 kg / 12.87 lbs

5840.0 g / 57.3 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 18.9x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.58 kg / 1.29 lbs

584.0 g / 5.7 N

|

| 1 mm |

|

1.46 kg / 3.22 lbs

1460.0 g / 14.3 N

|

| 2 mm |

|

2.92 kg / 6.44 lbs

2920.0 g / 28.6 N

|

| 3 mm |

|

4.38 kg / 9.66 lbs

4380.0 g / 43.0 N

|

| 5 mm |

|

7.30 kg / 16.09 lbs

7300.0 g / 71.6 N

|

| 10 mm |

|

11.68 kg / 25.75 lbs

11680.0 g / 114.6 N

|

| 11 mm |

|

11.68 kg / 25.75 lbs

11680.0 g / 114.6 N

|

| 12 mm |

|

11.68 kg / 25.75 lbs

11680.0 g / 114.6 N

|

Table 5: Thermal stability (material behavior) - power drop

MW 18.9x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

11.68 kg / 25.75 lbs

11680.0 g / 114.6 N

|

OK |

| 40 °C | -2.2% |

11.42 kg / 25.18 lbs

11423.0 g / 112.1 N

|

OK |

| 60 °C | -4.4% |

11.17 kg / 24.62 lbs

11166.1 g / 109.5 N

|

OK |

| 80 °C | -6.6% |

10.91 kg / 24.05 lbs

10909.1 g / 107.0 N

|

|

| 100 °C | -28.8% |

8.32 kg / 18.33 lbs

8316.2 g / 81.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MW 18.9x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

35.05 kg / 77.28 lbs

5 600 Gs

|

5.26 kg / 11.59 lbs

5258 g / 51.6 N

|

N/A |

| 1 mm |

31.70 kg / 69.88 lbs

8 562 Gs

|

4.75 kg / 10.48 lbs

4754 g / 46.6 N

|

28.53 kg / 62.89 lbs

~0 Gs

|

| 2 mm |

28.38 kg / 62.56 lbs

8 101 Gs

|

4.26 kg / 9.38 lbs

4256 g / 41.8 N

|

25.54 kg / 56.30 lbs

~0 Gs

|

| 3 mm |

25.22 kg / 55.59 lbs

7 636 Gs

|

3.78 kg / 8.34 lbs

3782 g / 37.1 N

|

22.69 kg / 50.03 lbs

~0 Gs

|

| 5 mm |

19.53 kg / 43.05 lbs

6 720 Gs

|

2.93 kg / 6.46 lbs

2929 g / 28.7 N

|

17.57 kg / 38.75 lbs

~0 Gs

|

| 10 mm |

9.52 kg / 20.99 lbs

4 692 Gs

|

1.43 kg / 3.15 lbs

1428 g / 14.0 N

|

8.57 kg / 18.89 lbs

~0 Gs

|

| 20 mm |

2.09 kg / 4.61 lbs

2 199 Gs

|

0.31 kg / 0.69 lbs

314 g / 3.1 N

|

1.88 kg / 4.15 lbs

~0 Gs

|

| 50 mm |

0.06 kg / 0.13 lbs

372 Gs

|

0.01 kg / 0.02 lbs

9 g / 0.1 N

|

0.05 kg / 0.12 lbs

~0 Gs

|

| 60 mm |

0.03 kg / 0.06 lbs

241 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

| 70 mm |

0.01 kg / 0.03 lbs

164 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.02 lbs

~0 Gs

|

| 80 mm |

0.01 kg / 0.01 lbs

116 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.01 lbs

86 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

65 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 18.9x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 10.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 6.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (cracking risk) - warning

MW 18.9x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.63 km/h

(6.84 m/s)

|

0.49 J | |

| 30 mm |

41.18 km/h

(11.44 m/s)

|

1.38 J | |

| 50 mm |

53.13 km/h

(14.76 m/s)

|

2.29 J | |

| 100 mm |

75.14 km/h

(20.87 m/s)

|

4.58 J |

Table 9: Surface protection spec

MW 18.9x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 18.9x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 12 775 Mx | 127.7 µWb |

| Pc Coefficient | 0.61 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 18.9x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 11.68 kg | Standard |

| Water (riverbed) |

13.37 kg

(+1.69 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet holds only approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Thermal stability

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.61

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages as well as disadvantages of rare earth magnets.

Strengths

- They retain full power for around 10 years – the loss is just ~1% (in theory),

- They are extremely resistant to demagnetization induced by presence of other magnetic fields,

- By using a shiny coating of nickel, the element has an proper look,

- Magnets have huge magnetic induction on the outer layer,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- In view of the ability of flexible forming and customization to custom needs, NdFeB magnets can be manufactured in a broad palette of geometric configurations, which makes them more universal,

- Versatile presence in future technologies – they are used in magnetic memories, motor assemblies, diagnostic systems, and multitasking production systems.

- Thanks to efficiency per cm³, small magnets offer high operating force, in miniature format,

Cons

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- Limited possibility of producing nuts in the magnet and complex forms - preferred is a housing - magnet mounting.

- Health risk resulting from small fragments of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child safety. It is also worth noting that tiny parts of these magnets are able to be problematic in diagnostics medical when they are in the body.

- Due to expensive raw materials, their price is higher than average,

Lifting parameters

Maximum lifting force for a neodymium magnet – what it depends on?

- with the contact of a sheet made of low-carbon steel, guaranteeing maximum field concentration

- possessing a massiveness of at least 10 mm to ensure full flux closure

- with an ideally smooth touching surface

- with zero gap (no coatings)

- during detachment in a direction perpendicular to the mounting surface

- at room temperature

Determinants of lifting force in real conditions

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by varnish or dirt) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Steel type – mild steel gives the best results. Higher carbon content decrease magnetic permeability and lifting capacity.

- Surface structure – the smoother and more polished the surface, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Thermal factor – high temperature weakens pulling force. Too high temperature can permanently damage the magnet.

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the holding force is lower. Additionally, even a minimal clearance between the magnet’s surface and the plate lowers the holding force.

H&S for magnets

Dust explosion hazard

Drilling and cutting of neodymium magnets poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Data carriers

Powerful magnetic fields can destroy records on credit cards, hard drives, and storage devices. Stay away of min. 10 cm.

Danger to the youngest

NdFeB magnets are not suitable for play. Swallowing several magnets can lead to them pinching intestinal walls, which constitutes a direct threat to life and necessitates urgent medical intervention.

Warning for heart patients

For implant holders: Powerful magnets affect medical devices. Maintain at least 30 cm distance or ask another person to work with the magnets.

Heat sensitivity

Control the heat. Exposing the magnet above 80 degrees Celsius will destroy its magnetic structure and pulling force.

Safe operation

Exercise caution. Rare earth magnets act from a long distance and snap with huge force, often quicker than you can move away.

Precision electronics

GPS units and mobile phones are highly susceptible to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Eye protection

Neodymium magnets are sintered ceramics, meaning they are fragile like glass. Clashing of two magnets will cause them breaking into small pieces.

Serious injuries

Big blocks can break fingers instantly. Under no circumstances put your hand betwixt two strong magnets.

Avoid contact if allergic

Studies show that the nickel plating (standard magnet coating) is a common allergen. If your skin reacts to metals, prevent direct skin contact and select encased magnets.