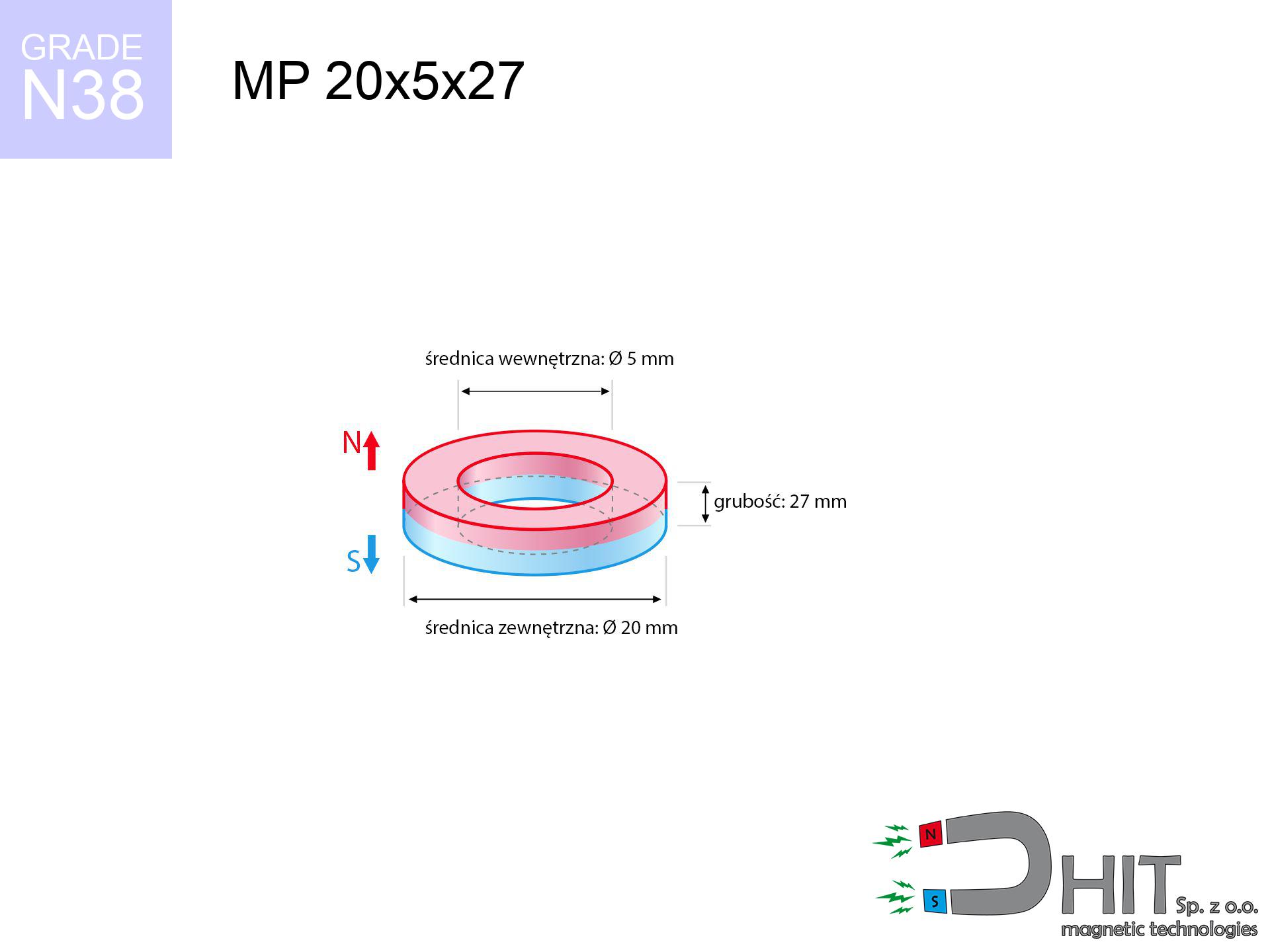

MP 20x5x27 / N38 - ring magnet

ring magnet

Catalog no 030185

GTIN/EAN: 5906301812029

Diameter

20 mm [±0,1 mm]

internal diameter Ø

5 mm [±0,1 mm]

Height

27 mm [±0,1 mm]

Weight

59.64 g

Magnetization Direction

↑ axial

Load capacity

10.36 kg / 101.60 N

Magnetic Induction

581.04 mT / 5810 Gs

Coating

[NiCuNi] Nickel

33.00 ZŁ with VAT / pcs + price for transport

26.83 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

if you prefer get in touch by means of

contact form

the contact form page.

Force and structure of magnetic components can be verified using our

magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical - MP 20x5x27 / N38 - ring magnet

Specification / characteristics - MP 20x5x27 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030185 |

| GTIN/EAN | 5906301812029 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±0,1 mm] |

| internal diameter Ø | 5 mm [±0,1 mm] |

| Height | 27 mm [±0,1 mm] |

| Weight | 59.64 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 10.36 kg / 101.60 N |

| Magnetic Induction ~ ? | 581.04 mT / 5810 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - data

These information represent the direct effect of a physical calculation. Values rely on algorithms for the class Nd2Fe14B. Real-world conditions may differ. Treat these data as a supplementary guide during assembly planning.

Table 1: Static force (force vs distance) - power drop

MP 20x5x27 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5716 Gs

571.6 mT

|

10.36 kg / 22.84 pounds

10360.0 g / 101.6 N

|

crushing |

| 1 mm |

5288 Gs

528.8 mT

|

8.87 kg / 19.55 pounds

8865.5 g / 87.0 N

|

strong |

| 2 mm |

4861 Gs

486.1 mT

|

7.49 kg / 16.51 pounds

7491.0 g / 73.5 N

|

strong |

| 3 mm |

4446 Gs

444.6 mT

|

6.27 kg / 13.82 pounds

6267.5 g / 61.5 N

|

strong |

| 5 mm |

3677 Gs

367.7 mT

|

4.29 kg / 9.45 pounds

4285.9 g / 42.0 N

|

strong |

| 10 mm |

2216 Gs

221.6 mT

|

1.56 kg / 3.43 pounds

1557.1 g / 15.3 N

|

safe |

| 15 mm |

1354 Gs

135.4 mT

|

0.58 kg / 1.28 pounds

580.9 g / 5.7 N

|

safe |

| 20 mm |

864 Gs

86.4 mT

|

0.24 kg / 0.52 pounds

236.9 g / 2.3 N

|

safe |

| 30 mm |

405 Gs

40.5 mT

|

0.05 kg / 0.11 pounds

52.1 g / 0.5 N

|

safe |

| 50 mm |

133 Gs

13.3 mT

|

0.01 kg / 0.01 pounds

5.6 g / 0.1 N

|

safe |

Table 2: Vertical hold (wall)

MP 20x5x27 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.07 kg / 4.57 pounds

2072.0 g / 20.3 N

|

| 1 mm | Stal (~0.2) |

1.77 kg / 3.91 pounds

1774.0 g / 17.4 N

|

| 2 mm | Stal (~0.2) |

1.50 kg / 3.30 pounds

1498.0 g / 14.7 N

|

| 3 mm | Stal (~0.2) |

1.25 kg / 2.76 pounds

1254.0 g / 12.3 N

|

| 5 mm | Stal (~0.2) |

0.86 kg / 1.89 pounds

858.0 g / 8.4 N

|

| 10 mm | Stal (~0.2) |

0.31 kg / 0.69 pounds

312.0 g / 3.1 N

|

| 15 mm | Stal (~0.2) |

0.12 kg / 0.26 pounds

116.0 g / 1.1 N

|

| 20 mm | Stal (~0.2) |

0.05 kg / 0.11 pounds

48.0 g / 0.5 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

10.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MP 20x5x27 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

3.11 kg / 6.85 pounds

3108.0 g / 30.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.07 kg / 4.57 pounds

2072.0 g / 20.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.04 kg / 2.28 pounds

1036.0 g / 10.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

5.18 kg / 11.42 pounds

5180.0 g / 50.8 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MP 20x5x27 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.52 kg / 1.14 pounds

518.0 g / 5.1 N

|

| 1 mm |

|

1.30 kg / 2.85 pounds

1295.0 g / 12.7 N

|

| 2 mm |

|

2.59 kg / 5.71 pounds

2590.0 g / 25.4 N

|

| 3 mm |

|

3.89 kg / 8.56 pounds

3885.0 g / 38.1 N

|

| 5 mm |

|

6.48 kg / 14.27 pounds

6475.0 g / 63.5 N

|

| 10 mm |

|

10.36 kg / 22.84 pounds

10360.0 g / 101.6 N

|

| 11 mm |

|

10.36 kg / 22.84 pounds

10360.0 g / 101.6 N

|

| 12 mm |

|

10.36 kg / 22.84 pounds

10360.0 g / 101.6 N

|

Table 5: Thermal stability (stability) - power drop

MP 20x5x27 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

10.36 kg / 22.84 pounds

10360.0 g / 101.6 N

|

OK |

| 40 °C | -2.2% |

10.13 kg / 22.34 pounds

10132.1 g / 99.4 N

|

OK |

| 60 °C | -4.4% |

9.90 kg / 21.83 pounds

9904.2 g / 97.2 N

|

OK |

| 80 °C | -6.6% |

9.68 kg / 21.33 pounds

9676.2 g / 94.9 N

|

|

| 100 °C | -28.8% |

7.38 kg / 16.26 pounds

7376.3 g / 72.4 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MP 20x5x27 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

44.24 kg / 97.54 pounds

6 064 Gs

|

6.64 kg / 14.63 pounds

6636 g / 65.1 N

|

N/A |

| 1 mm |

41.02 kg / 90.43 pounds

11 008 Gs

|

6.15 kg / 13.56 pounds

6153 g / 60.4 N

|

36.92 kg / 81.39 pounds

~0 Gs

|

| 2 mm |

37.86 kg / 83.47 pounds

10 576 Gs

|

5.68 kg / 12.52 pounds

5679 g / 55.7 N

|

34.07 kg / 75.12 pounds

~0 Gs

|

| 3 mm |

34.85 kg / 76.83 pounds

10 146 Gs

|

5.23 kg / 11.52 pounds

5227 g / 51.3 N

|

31.36 kg / 69.14 pounds

~0 Gs

|

| 5 mm |

29.30 kg / 64.58 pounds

9 303 Gs

|

4.39 kg / 9.69 pounds

4394 g / 43.1 N

|

26.37 kg / 58.13 pounds

~0 Gs

|

| 10 mm |

18.30 kg / 40.35 pounds

7 353 Gs

|

2.75 kg / 6.05 pounds

2745 g / 26.9 N

|

16.47 kg / 36.32 pounds

~0 Gs

|

| 20 mm |

6.65 kg / 14.66 pounds

4 432 Gs

|

1.00 kg / 2.20 pounds

997 g / 9.8 N

|

5.98 kg / 13.19 pounds

~0 Gs

|

| 50 mm |

0.45 kg / 1.00 pounds

1 159 Gs

|

0.07 kg / 0.15 pounds

68 g / 0.7 N

|

0.41 kg / 0.90 pounds

~0 Gs

|

| 60 mm |

0.22 kg / 0.49 pounds

811 Gs

|

0.03 kg / 0.07 pounds

33 g / 0.3 N

|

0.20 kg / 0.44 pounds

~0 Gs

|

| 70 mm |

0.12 kg / 0.26 pounds

589 Gs

|

0.02 kg / 0.04 pounds

18 g / 0.2 N

|

0.11 kg / 0.23 pounds

~0 Gs

|

| 80 mm |

0.07 kg / 0.14 pounds

440 Gs

|

0.01 kg / 0.02 pounds

10 g / 0.1 N

|

0.06 kg / 0.13 pounds

~0 Gs

|

| 90 mm |

0.04 kg / 0.09 pounds

338 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.03 kg / 0.08 pounds

~0 Gs

|

| 100 mm |

0.02 kg / 0.05 pounds

265 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MP 20x5x27 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 18.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 14.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 11.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 8.5 cm |

| Car key | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MP 20x5x27 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

14.49 km/h

(4.02 m/s)

|

0.48 J | |

| 30 mm |

23.09 km/h

(6.42 m/s)

|

1.23 J | |

| 50 mm |

29.73 km/h

(8.26 m/s)

|

2.03 J | |

| 100 mm |

42.03 km/h

(11.68 m/s)

|

4.07 J |

Table 9: Corrosion resistance

MP 20x5x27 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 20x5x27 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 14 314 Mx | 143.1 µWb |

| Pc Coefficient | 1.16 | High (Stable) |

Table 11: Physics of underwater searching

MP 20x5x27 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 10.36 kg | Standard |

| Water (riverbed) |

11.86 kg

(+1.50 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet holds merely approx. 20-30% of its perpendicular strength.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) drastically limits the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.16

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more proposals

Pros and cons of Nd2Fe14B magnets.

Benefits

- They do not lose magnetism, even over approximately ten years – the decrease in power is only ~1% (based on measurements),

- Neodymium magnets are distinguished by exceptionally resistant to magnetic field loss caused by external magnetic fields,

- The use of an refined layer of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- Neodymium magnets achieve maximum magnetic induction on a small surface, which allows for strong attraction,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can function (depending on the shape) even at a temperature of 230°C or more...

- Possibility of precise creating as well as adjusting to atypical needs,

- Fundamental importance in electronics industry – they serve a role in HDD drives, motor assemblies, medical devices, and complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which allows their use in compact constructions

Cons

- At very strong impacts they can break, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can rust. Therefore while using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in realizing nuts and complex forms in magnets, we propose using a housing - magnetic mount.

- Possible danger resulting from small fragments of magnets can be dangerous, in case of ingestion, which gains importance in the context of child safety. It is also worth noting that small components of these magnets are able to disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum lifting capacity of the magnet – what affects it?

- on a block made of structural steel, effectively closing the magnetic flux

- whose thickness equals approx. 10 mm

- with a surface free of scratches

- under conditions of gap-free contact (metal-to-metal)

- during detachment in a direction perpendicular to the plane

- in stable room temperature

Practical aspects of lifting capacity – factors

- Distance (between the magnet and the plate), since even a very small clearance (e.g. 0.5 mm) leads to a drastic drop in force by up to 50% (this also applies to varnish, corrosion or debris).

- Loading method – catalog parameter refers to pulling vertically. When attempting to slide, the magnet holds much less (often approx. 20-30% of maximum force).

- Steel thickness – too thin steel causes magnetic saturation, causing part of the flux to be wasted to the other side.

- Chemical composition of the base – low-carbon steel attracts best. Alloy steels reduce magnetic properties and lifting capacity.

- Surface condition – smooth surfaces ensure maximum contact, which improves field saturation. Uneven metal reduce efficiency.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and at low temperatures they can be stronger (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, whereas under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate decreases the holding force.

H&S for magnets

Power loss in heat

Regular neodymium magnets (N-type) lose magnetization when the temperature goes above 80°C. The loss of strength is permanent.

ICD Warning

Warning for patients: Strong magnetic fields affect electronics. Maintain minimum 30 cm distance or ask another person to handle the magnets.

Crushing risk

Risk of injury: The pulling power is so great that it can result in blood blisters, crushing, and even bone fractures. Use thick gloves.

Conscious usage

Handle magnets consciously. Their powerful strength can shock even experienced users. Plan your moves and respect their force.

Data carriers

Avoid bringing magnets near a purse, laptop, or TV. The magnetic field can permanently damage these devices and wipe information from cards.

Nickel allergy

Nickel alert: The nickel-copper-nickel coating contains nickel. If an allergic reaction occurs, cease handling magnets and use protective gear.

Dust is flammable

Fire warning: Rare earth powder is explosive. Avoid machining magnets without safety gear as this may cause fire.

Material brittleness

Despite the nickel coating, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Do not give to children

NdFeB magnets are not suitable for play. Swallowing a few magnets can lead to them attracting across intestines, which constitutes a critical condition and requires immediate surgery.

Precision electronics

GPS units and smartphones are highly sensitive to magnetic fields. Direct contact with a strong magnet can decalibrate the sensors in your phone.