UI 45x13x6 [Z323] / N38 - badge holder

badge holder

Catalog no 150210

GTIN/EAN: 5906301813576

length

45 mm [±1 mm]

Width

13 mm [±1 mm]

Height

6 mm [±1 mm]

Weight

0.15 g

Load capacity

1.75 kg / 17.16 N

2.40 ZŁ with VAT / pcs + price for transport

1.950 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively send us a note using

form

the contact page.

Parameters along with shape of a neodymium magnet can be checked with our

online calculation tool.

Orders placed before 14:00 will be shipped the same business day.

Product card - UI 45x13x6 [Z323] / N38 - badge holder

Specification / characteristics - UI 45x13x6 [Z323] / N38 - badge holder

| properties | values |

|---|---|

| Cat. no. | 150210 |

| GTIN/EAN | 5906301813576 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

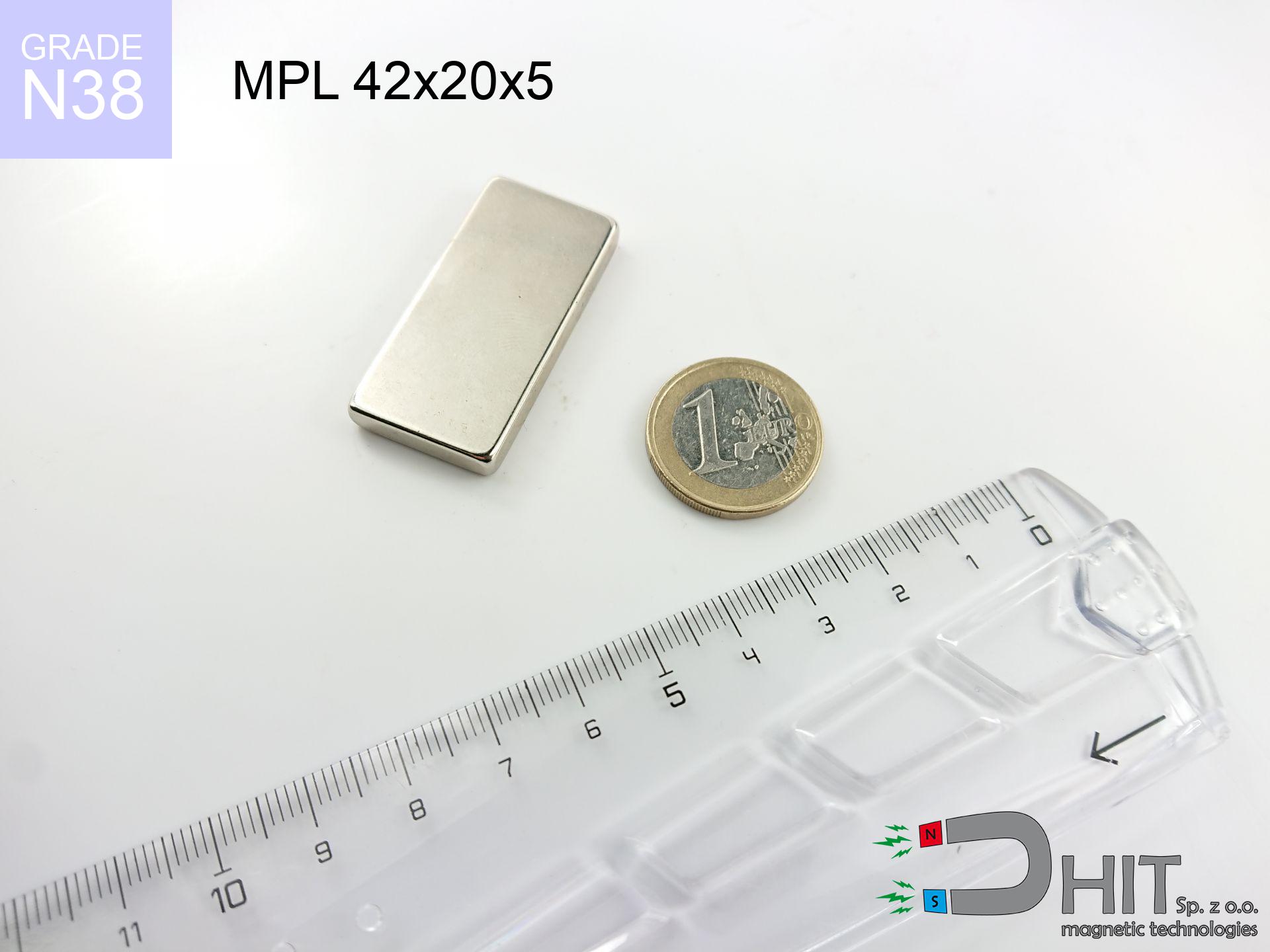

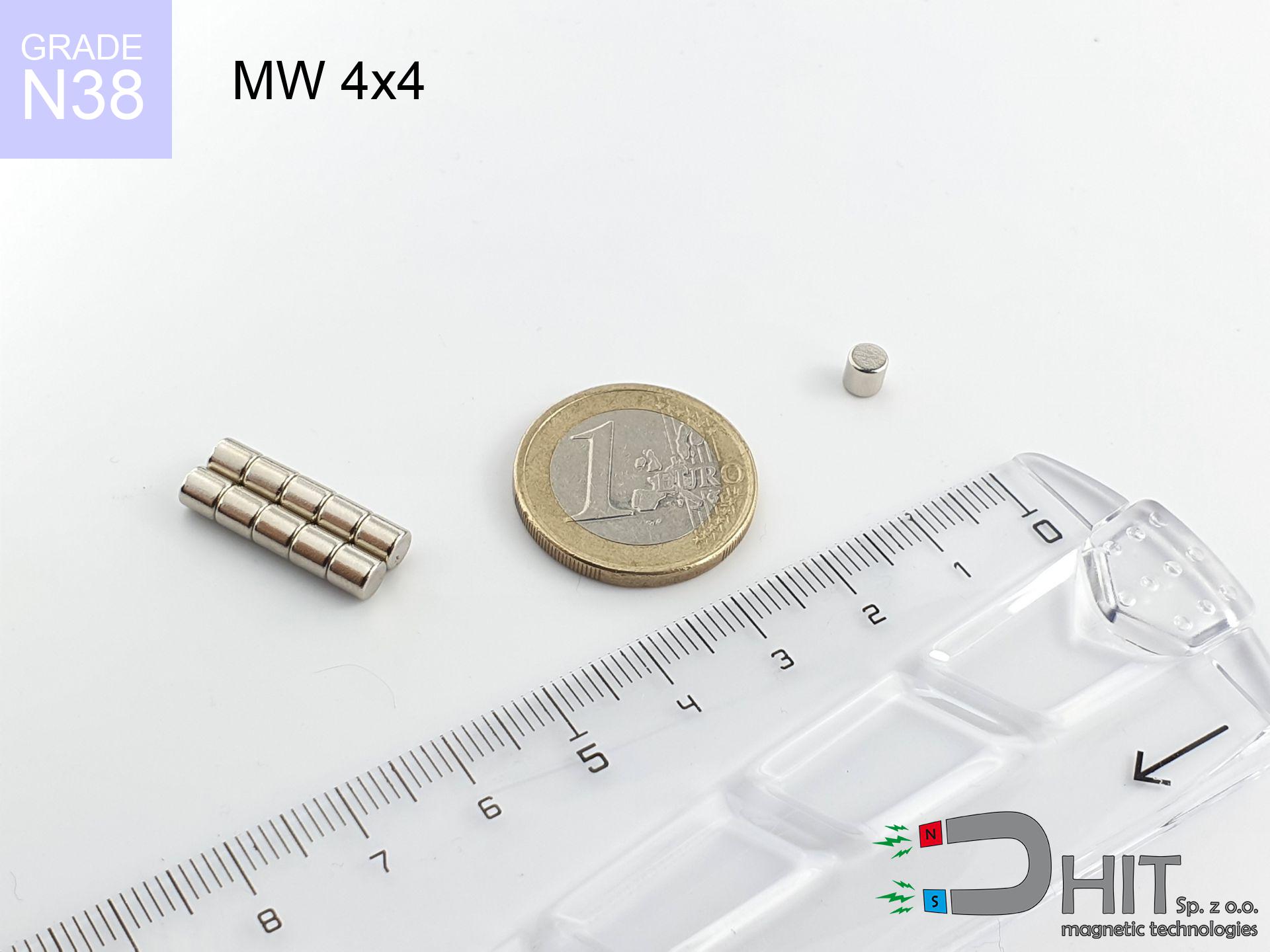

| length | 45 mm [±1 mm] |

| Width | 13 mm [±1 mm] |

| Height | 6 mm [±1 mm] |

| Weight | 0.15 g |

| Load capacity ~ ? | 1.75 kg / 17.16 N |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more proposals

Advantages and disadvantages of neodymium magnets.

Strengths

- They do not lose power, even over nearly ten years – the drop in power is only ~1% (based on measurements),

- They show high resistance to demagnetization induced by presence of other magnetic fields,

- Thanks to the shiny finish, the coating of Ni-Cu-Ni, gold, or silver gives an modern appearance,

- Neodymium magnets achieve maximum magnetic induction on a contact point, which increases force concentration,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to freedom in shaping and the capacity to customize to individual projects,

- Huge importance in innovative solutions – they find application in HDD drives, electric drive systems, diagnostic systems, also other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We recommend keeping them in a special holder, which not only protects them against impacts but also increases their durability

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in creating threads and complex forms in magnets, we recommend using a housing - magnetic holder.

- Possible danger resulting from small fragments of magnets are risky, if swallowed, which becomes key in the context of child safety. Furthermore, small components of these magnets are able to disrupt the diagnostic process medical when they are in the body.

- Due to expensive raw materials, their price is higher than average,

Lifting parameters

Maximum holding power of the magnet – what it depends on?

- on a block made of structural steel, optimally conducting the magnetic flux

- with a thickness of at least 10 mm

- with a plane perfectly flat

- without any insulating layer between the magnet and steel

- during detachment in a direction perpendicular to the plane

- at standard ambient temperature

Practical lifting capacity: influencing factors

- Distance (betwixt the magnet and the plate), because even a tiny clearance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to paint, corrosion or debris).

- Loading method – catalog parameter refers to detachment vertically. When attempting to slide, the magnet holds much less (typically approx. 20-30% of maximum force).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Steel type – mild steel attracts best. Alloy admixtures decrease magnetic properties and holding force.

- Smoothness – full contact is possible only on polished steel. Rough texture reduce the real contact area, weakening the magnet.

- Temperature influence – hot environment reduces pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under a perpendicular pulling force, whereas under attempts to slide the magnet the holding force is lower. Moreover, even a slight gap between the magnet and the plate decreases the load capacity.

H&S for magnets

Physical harm

Large magnets can smash fingers instantly. Never place your hand betwixt two attracting surfaces.

Threat to navigation

GPS units and smartphones are extremely sensitive to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Implant safety

Medical warning: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have electronic implants.

Nickel coating and allergies

Certain individuals experience a hypersensitivity to nickel, which is the common plating for NdFeB magnets. Frequent touching may cause skin redness. We strongly advise wear protective gloves.

Flammability

Fire warning: Neodymium dust is explosive. Do not process magnets in home conditions as this risks ignition.

Respect the power

Exercise caution. Rare earth magnets act from a long distance and connect with huge force, often faster than you can react.

Do not overheat magnets

Standard neodymium magnets (N-type) lose magnetization when the temperature goes above 80°C. This process is irreversible.

Shattering risk

Neodymium magnets are sintered ceramics, meaning they are prone to chipping. Clashing of two magnets leads to them shattering into shards.

Electronic devices

Do not bring magnets close to a wallet, computer, or TV. The magnetism can permanently damage these devices and erase data from cards.

Danger to the youngest

Neodymium magnets are not suitable for play. Accidental ingestion of a few magnets may result in them attracting across intestines, which constitutes a direct threat to life and necessitates urgent medical intervention.

![Magnetic name badge holder UI 45x13x6 [Z323] / N38 Magnetic name badge holder UI 45x13x6 [Z323] / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UI 45x13x6 [Z323] / N38 - badge holder](https://cdn3.dhit.pl/graphics/products/ui45x13x6-z323-fap.jpg)

![UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-48x24x11.5-m8-gz-bit.jpg)

![SM 32x175 [2xM8] / N42 - magnetic separator SM 32x175 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-tej.jpg)