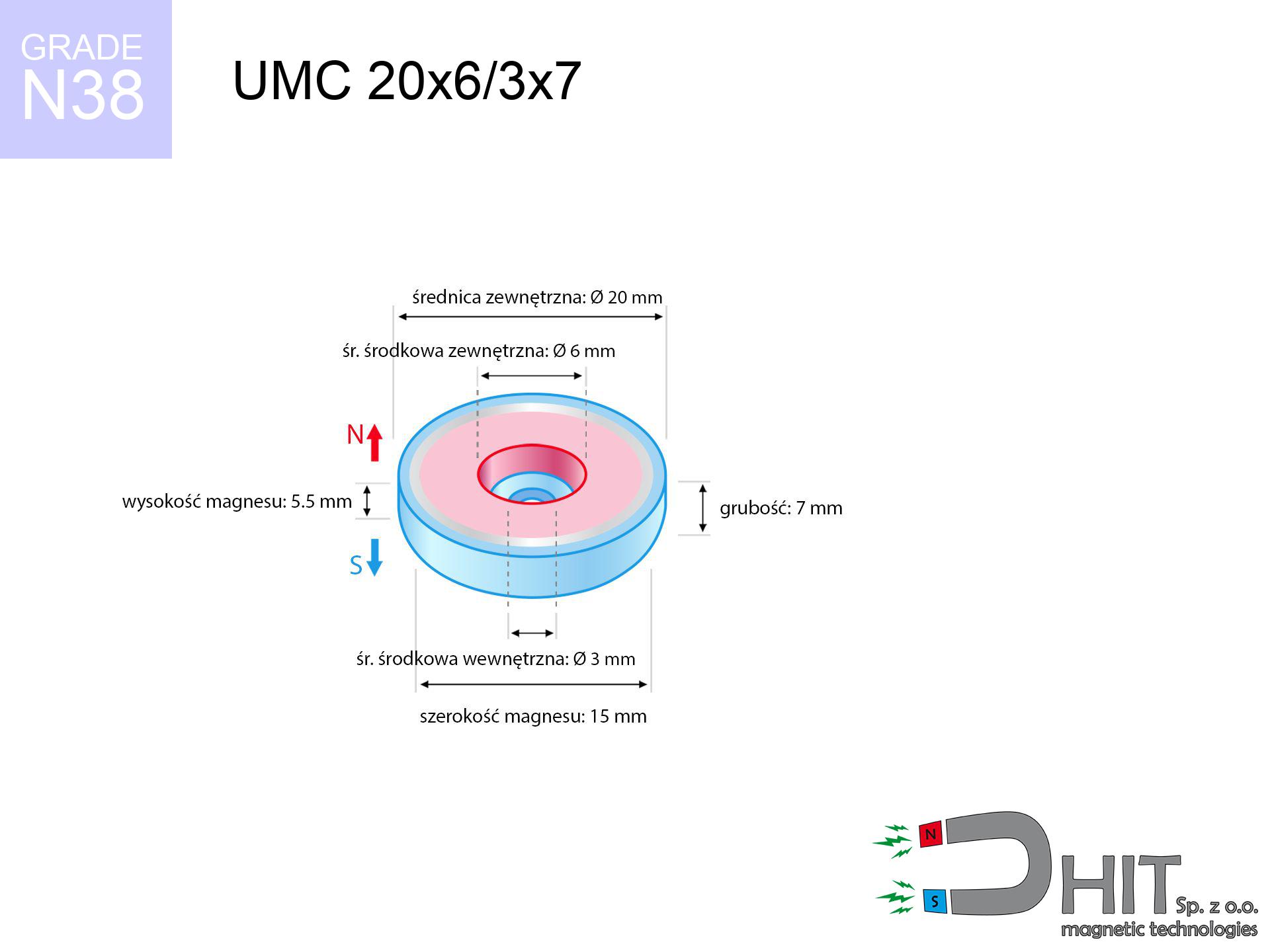

UMC 20x6/3x7 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320407

GTIN/EAN: 5906301814634

Diameter

20 mm [±1 mm]

internal diameter Ø

6/3 mm [±1 mm]

Height

7 mm [±1 mm]

Weight

12 g

Load capacity

6.00 kg / 58.84 N

Coating

[NiCuNi] Nickel

6.99 ZŁ with VAT / pcs + price for transport

5.68 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or drop us a message using

inquiry form

the contact section.

Weight as well as structure of magnets can be estimated using our

magnetic mass calculator.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - UMC 20x6/3x7 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 20x6/3x7 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320407 |

| GTIN/EAN | 5906301814634 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±1 mm] |

| internal diameter Ø | 6/3 mm [±1 mm] |

| Height | 7 mm [±1 mm] |

| Weight | 12 g |

| Load capacity ~ ? | 6.00 kg / 58.84 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths and weaknesses of rare earth magnets.

Benefits

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (based on calculations),

- They have excellent resistance to magnetic field loss when exposed to external magnetic sources,

- A magnet with a metallic silver surface looks better,

- Magnetic induction on the working layer of the magnet turns out to be exceptional,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, enabling action at temperatures reaching 230°C and above...

- Thanks to freedom in designing and the capacity to customize to unusual requirements,

- Versatile presence in modern technologies – they are utilized in magnetic memories, electric motors, medical devices, as well as other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in small dimensions, which enables their usage in small systems

Limitations

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Due to limitations in realizing threads and complicated forms in magnets, we propose using a housing - magnetic mount.

- Possible danger resulting from small fragments of magnets are risky, if swallowed, which is particularly important in the context of child health protection. It is also worth noting that small components of these devices are able to disrupt the diagnostic process medical in case of swallowing.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Magnetic strength at its maximum – what affects it?

- with the contact of a yoke made of special test steel, ensuring full magnetic saturation

- possessing a thickness of at least 10 mm to avoid saturation

- with an ideally smooth touching surface

- without the slightest clearance between the magnet and steel

- during pulling in a direction perpendicular to the mounting surface

- at ambient temperature approx. 20 degrees Celsius

Impact of factors on magnetic holding capacity in practice

- Gap (between the magnet and the metal), because even a very small clearance (e.g. 0.5 mm) results in a reduction in force by up to 50% (this also applies to varnish, rust or dirt).

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal limits the lifting capacity (the magnet "punches through" it).

- Steel type – mild steel attracts best. Alloy admixtures reduce magnetic permeability and lifting capacity.

- Surface finish – ideal contact is obtained only on smooth steel. Any scratches and bumps reduce the real contact area, weakening the magnet.

- Temperature influence – hot environment weakens pulling force. Too high temperature can permanently damage the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, whereas under attempts to slide the magnet the holding force is lower. Additionally, even a minimal clearance between the magnet and the plate decreases the load capacity.

Safe handling of NdFeB magnets

Health Danger

Health Alert: Neodymium magnets can turn off pacemakers and defibrillators. Stay away if you have electronic implants.

Magnets are brittle

Despite the nickel coating, neodymium is delicate and not impact-resistant. Do not hit, as the magnet may shatter into hazardous fragments.

Nickel coating and allergies

Certain individuals experience a sensitization to nickel, which is the standard coating for NdFeB magnets. Prolonged contact might lead to skin redness. We recommend use protective gloves.

Pinching danger

Danger of trauma: The pulling power is so immense that it can result in hematomas, crushing, and broken bones. Protective gloves are recommended.

Powerful field

Exercise caution. Rare earth magnets attract from a distance and connect with huge force, often faster than you can react.

Demagnetization risk

Standard neodymium magnets (N-type) lose power when the temperature goes above 80°C. Damage is permanent.

Threat to electronics

Powerful magnetic fields can erase data on credit cards, HDDs, and storage devices. Keep a distance of at least 10 cm.

Machining danger

Machining of NdFeB material carries a risk of fire risk. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Keep away from electronics

Be aware: neodymium magnets generate a field that interferes with precision electronics. Keep a safe distance from your mobile, tablet, and GPS.

Danger to the youngest

These products are not toys. Swallowing several magnets may result in them connecting inside the digestive tract, which constitutes a severe health hazard and necessitates immediate surgery.

![SM 32x450 [2xM8] / N42 - magnetic separator SM 32x450 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x450-2xm8-bex.jpg)