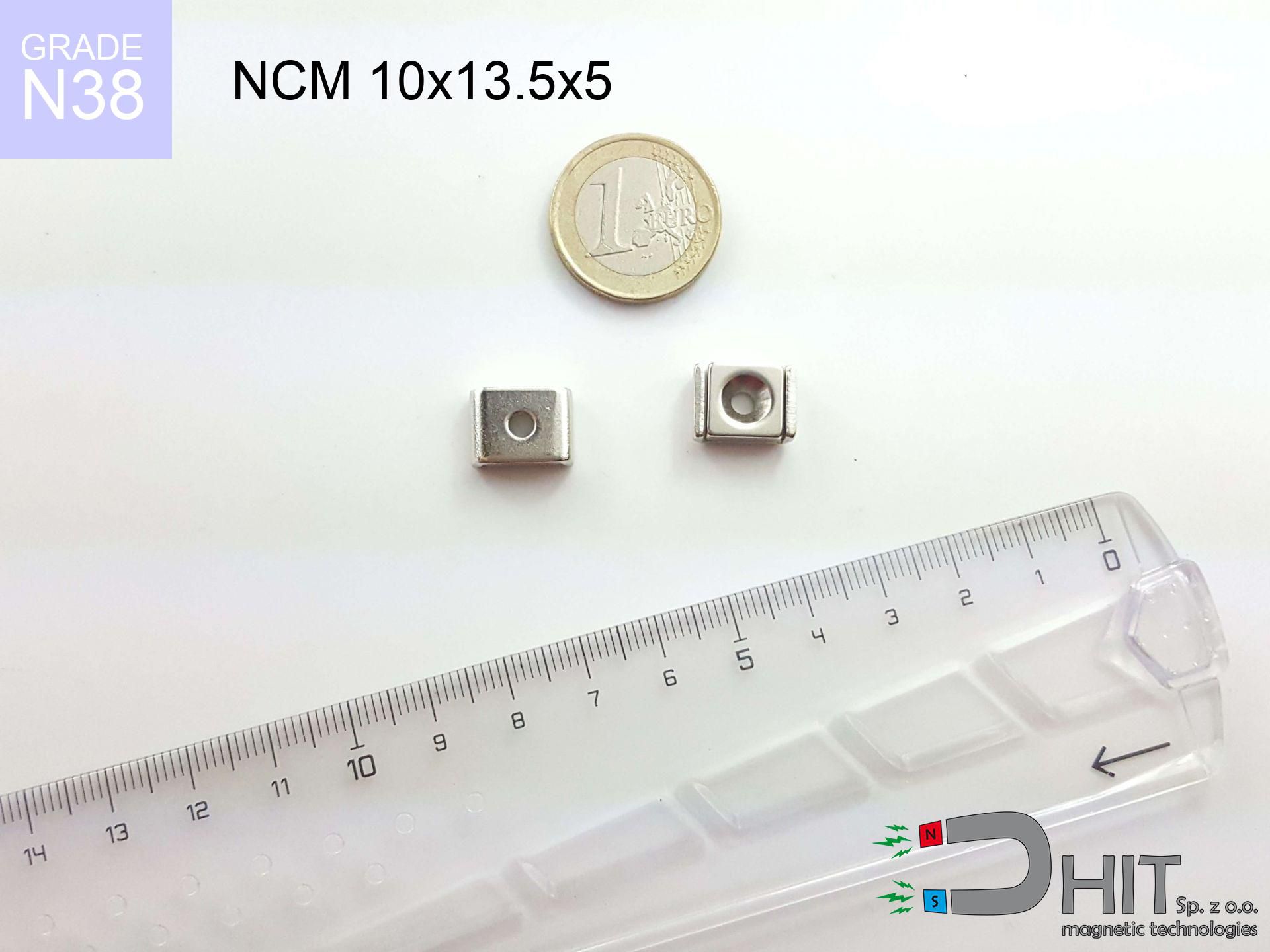

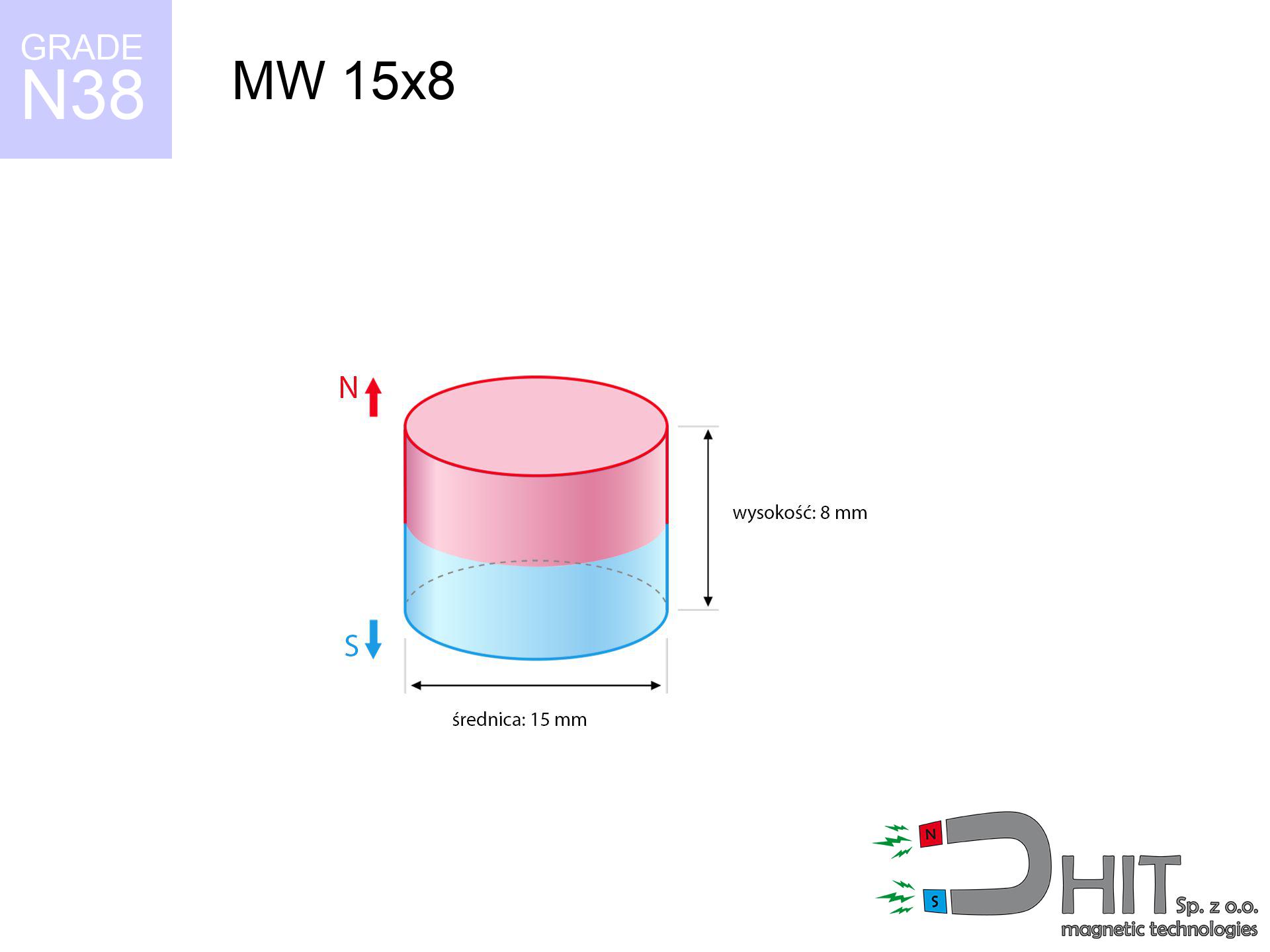

MW 15x8 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010032

GTIN/EAN: 5906301810315

Diameter Ø

15 mm [±0,1 mm]

Height

8 mm [±0,1 mm]

Weight

10.6 g

Magnetization Direction

↑ axial

Load capacity

7.37 kg / 72.28 N

Magnetic Induction

451.96 mT / 4520 Gs

Coating

[NiCuNi] Nickel

4.92 ZŁ with VAT / pcs + price for transport

4.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

or send us a note through

form

the contact page.

Parameters as well as structure of a magnet can be calculated on our

force calculator.

Orders submitted before 14:00 will be dispatched today!

Technical - MW 15x8 / N38 - cylindrical magnet

Specification / characteristics - MW 15x8 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010032 |

| GTIN/EAN | 5906301810315 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 15 mm [±0,1 mm] |

| Height | 8 mm [±0,1 mm] |

| Weight | 10.6 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.37 kg / 72.28 N |

| Magnetic Induction ~ ? | 451.96 mT / 4520 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - technical parameters

The following information constitute the direct effect of a physical calculation. Values are based on algorithms for the material Nd2Fe14B. Operational conditions may differ. Use these calculations as a supplementary guide when designing systems.

Table 1: Static force (force vs distance) - power drop

MW 15x8 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4518 Gs

451.8 mT

|

7.37 kg / 16.25 lbs

7370.0 g / 72.3 N

|

warning |

| 1 mm |

3944 Gs

394.4 mT

|

5.62 kg / 12.38 lbs

5616.2 g / 55.1 N

|

warning |

| 2 mm |

3362 Gs

336.2 mT

|

4.08 kg / 9.00 lbs

4083.1 g / 40.1 N

|

warning |

| 3 mm |

2820 Gs

282.0 mT

|

2.87 kg / 6.33 lbs

2871.9 g / 28.2 N

|

warning |

| 5 mm |

1931 Gs

193.1 mT

|

1.35 kg / 2.97 lbs

1346.9 g / 13.2 N

|

low risk |

| 10 mm |

763 Gs

76.3 mT

|

0.21 kg / 0.46 lbs

210.3 g / 2.1 N

|

low risk |

| 15 mm |

349 Gs

34.9 mT

|

0.04 kg / 0.10 lbs

44.0 g / 0.4 N

|

low risk |

| 20 mm |

184 Gs

18.4 mT

|

0.01 kg / 0.03 lbs

12.2 g / 0.1 N

|

low risk |

| 30 mm |

68 Gs

6.8 mT

|

0.00 kg / 0.00 lbs

1.7 g / 0.0 N

|

low risk |

| 50 mm |

17 Gs

1.7 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

low risk |

Table 2: Shear hold (wall)

MW 15x8 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.47 kg / 3.25 lbs

1474.0 g / 14.5 N

|

| 1 mm | Stal (~0.2) |

1.12 kg / 2.48 lbs

1124.0 g / 11.0 N

|

| 2 mm | Stal (~0.2) |

0.82 kg / 1.80 lbs

816.0 g / 8.0 N

|

| 3 mm | Stal (~0.2) |

0.57 kg / 1.27 lbs

574.0 g / 5.6 N

|

| 5 mm | Stal (~0.2) |

0.27 kg / 0.60 lbs

270.0 g / 2.6 N

|

| 10 mm | Stal (~0.2) |

0.04 kg / 0.09 lbs

42.0 g / 0.4 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 15x8 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.21 kg / 4.87 lbs

2211.0 g / 21.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.47 kg / 3.25 lbs

1474.0 g / 14.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.74 kg / 1.62 lbs

737.0 g / 7.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.69 kg / 8.12 lbs

3685.0 g / 36.1 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 15x8 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.74 kg / 1.62 lbs

737.0 g / 7.2 N

|

| 1 mm |

|

1.84 kg / 4.06 lbs

1842.5 g / 18.1 N

|

| 2 mm |

|

3.69 kg / 8.12 lbs

3685.0 g / 36.1 N

|

| 3 mm |

|

5.53 kg / 12.19 lbs

5527.5 g / 54.2 N

|

| 5 mm |

|

7.37 kg / 16.25 lbs

7370.0 g / 72.3 N

|

| 10 mm |

|

7.37 kg / 16.25 lbs

7370.0 g / 72.3 N

|

| 11 mm |

|

7.37 kg / 16.25 lbs

7370.0 g / 72.3 N

|

| 12 mm |

|

7.37 kg / 16.25 lbs

7370.0 g / 72.3 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MW 15x8 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.37 kg / 16.25 lbs

7370.0 g / 72.3 N

|

OK |

| 40 °C | -2.2% |

7.21 kg / 15.89 lbs

7207.9 g / 70.7 N

|

OK |

| 60 °C | -4.4% |

7.05 kg / 15.53 lbs

7045.7 g / 69.1 N

|

OK |

| 80 °C | -6.6% |

6.88 kg / 15.18 lbs

6883.6 g / 67.5 N

|

|

| 100 °C | -28.8% |

5.25 kg / 11.57 lbs

5247.4 g / 51.5 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 15x8 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

22.23 kg / 49.02 lbs

5 606 Gs

|

3.34 kg / 7.35 lbs

3335 g / 32.7 N

|

N/A |

| 1 mm |

19.55 kg / 43.11 lbs

8 473 Gs

|

2.93 kg / 6.47 lbs

2933 g / 28.8 N

|

17.60 kg / 38.80 lbs

~0 Gs

|

| 2 mm |

16.94 kg / 37.35 lbs

7 887 Gs

|

2.54 kg / 5.60 lbs

2541 g / 24.9 N

|

15.25 kg / 33.62 lbs

~0 Gs

|

| 3 mm |

14.52 kg / 32.00 lbs

7 301 Gs

|

2.18 kg / 4.80 lbs

2178 g / 21.4 N

|

13.07 kg / 28.80 lbs

~0 Gs

|

| 5 mm |

10.37 kg / 22.85 lbs

6 169 Gs

|

1.55 kg / 3.43 lbs

1555 g / 15.3 N

|

9.33 kg / 20.57 lbs

~0 Gs

|

| 10 mm |

4.06 kg / 8.96 lbs

3 862 Gs

|

0.61 kg / 1.34 lbs

609 g / 6.0 N

|

3.66 kg / 8.06 lbs

~0 Gs

|

| 20 mm |

0.63 kg / 1.40 lbs

1 526 Gs

|

0.10 kg / 0.21 lbs

95 g / 0.9 N

|

0.57 kg / 1.26 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.03 lbs

215 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.02 lbs

~0 Gs

|

| 60 mm |

0.01 kg / 0.01 lbs

136 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

91 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

64 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

46 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

35 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 15x8 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 5.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (cracking risk) - warning

MW 15x8 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.06 km/h

(7.52 m/s)

|

0.30 J | |

| 30 mm |

46.07 km/h

(12.80 m/s)

|

0.87 J | |

| 50 mm |

59.46 km/h

(16.52 m/s)

|

1.45 J | |

| 100 mm |

84.09 km/h

(23.36 m/s)

|

2.89 J |

Table 9: Corrosion resistance

MW 15x8 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 15x8 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 8 074 Mx | 80.7 µWb |

| Pc Coefficient | 0.61 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 15x8 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.37 kg | Standard |

| Water (riverbed) |

8.44 kg

(+1.07 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical surface, the magnet holds just approx. 20-30% of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) severely reduces the holding force.

3. Thermal stability

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.61

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths as well as weaknesses of Nd2Fe14B magnets.

Pros

- They retain full power for nearly 10 years – the drop is just ~1% (based on simulations),

- They retain their magnetic properties even under strong external field,

- Thanks to the shimmering finish, the plating of Ni-Cu-Ni, gold-plated, or silver gives an elegant appearance,

- Magnetic induction on the top side of the magnet remains extremely intense,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Due to the ability of flexible shaping and customization to individualized solutions, NdFeB magnets can be modeled in a variety of shapes and sizes, which increases their versatility,

- Fundamental importance in innovative solutions – they serve a role in HDD drives, brushless drives, diagnostic systems, as well as multitasking production systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a strong case, which not only secures them against impacts but also raises their durability

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Limited ability of making threads in the magnet and complicated forms - recommended is a housing - magnetic holder.

- Health risk related to microscopic parts of magnets pose a threat, if swallowed, which becomes key in the context of child safety. Furthermore, small elements of these magnets can complicate diagnosis medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Maximum magnetic pulling force – what affects it?

- with the use of a sheet made of special test steel, ensuring full magnetic saturation

- whose thickness reaches at least 10 mm

- with a surface cleaned and smooth

- without the slightest insulating layer between the magnet and steel

- under axial application of breakaway force (90-degree angle)

- in stable room temperature

What influences lifting capacity in practice

- Air gap (between the magnet and the metal), since even a tiny clearance (e.g. 0.5 mm) can cause a drastic drop in force by up to 50% (this also applies to paint, corrosion or debris).

- Direction of force – maximum parameter is obtained only during pulling at a 90° angle. The shear force of the magnet along the plate is usually several times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Chemical composition of the base – mild steel gives the best results. Alloy steels lower magnetic permeability and lifting capacity.

- Surface condition – ground elements guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Temperature influence – hot environment reduces magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity was determined using a steel plate with a smooth surface of optimal thickness (min. 20 mm), under vertically applied force, whereas under shearing force the holding force is lower. Moreover, even a minimal clearance between the magnet and the plate decreases the holding force.

Safe handling of NdFeB magnets

Fire risk

Machining of neodymium magnets poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Do not underestimate power

Use magnets consciously. Their huge power can surprise even experienced users. Be vigilant and respect their force.

Impact on smartphones

GPS units and mobile phones are highly sensitive to magnetic fields. Close proximity with a powerful NdFeB magnet can ruin the sensors in your phone.

Implant safety

For implant holders: Strong magnetic fields disrupt electronics. Keep at least 30 cm distance or request help to handle the magnets.

Magnets are brittle

Despite metallic appearance, the material is brittle and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Sensitization to coating

Allergy Notice: The nickel-copper-nickel coating contains nickel. If redness occurs, immediately stop handling magnets and use protective gear.

Data carriers

Data protection: Strong magnets can damage data carriers and delicate electronics (heart implants, hearing aids, mechanical watches).

Pinching danger

Mind your fingers. Two large magnets will join instantly with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Swallowing risk

Adult use only. Small elements can be swallowed, causing intestinal necrosis. Store out of reach of children and animals.

Demagnetization risk

Keep cool. NdFeB magnets are sensitive to heat. If you require operation above 80°C, inquire about special high-temperature series (H, SH, UH).

![SM 25x225 [2xM8] / N42 - magnetic separator SM 25x225 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x225-2xm8-tix.jpg)