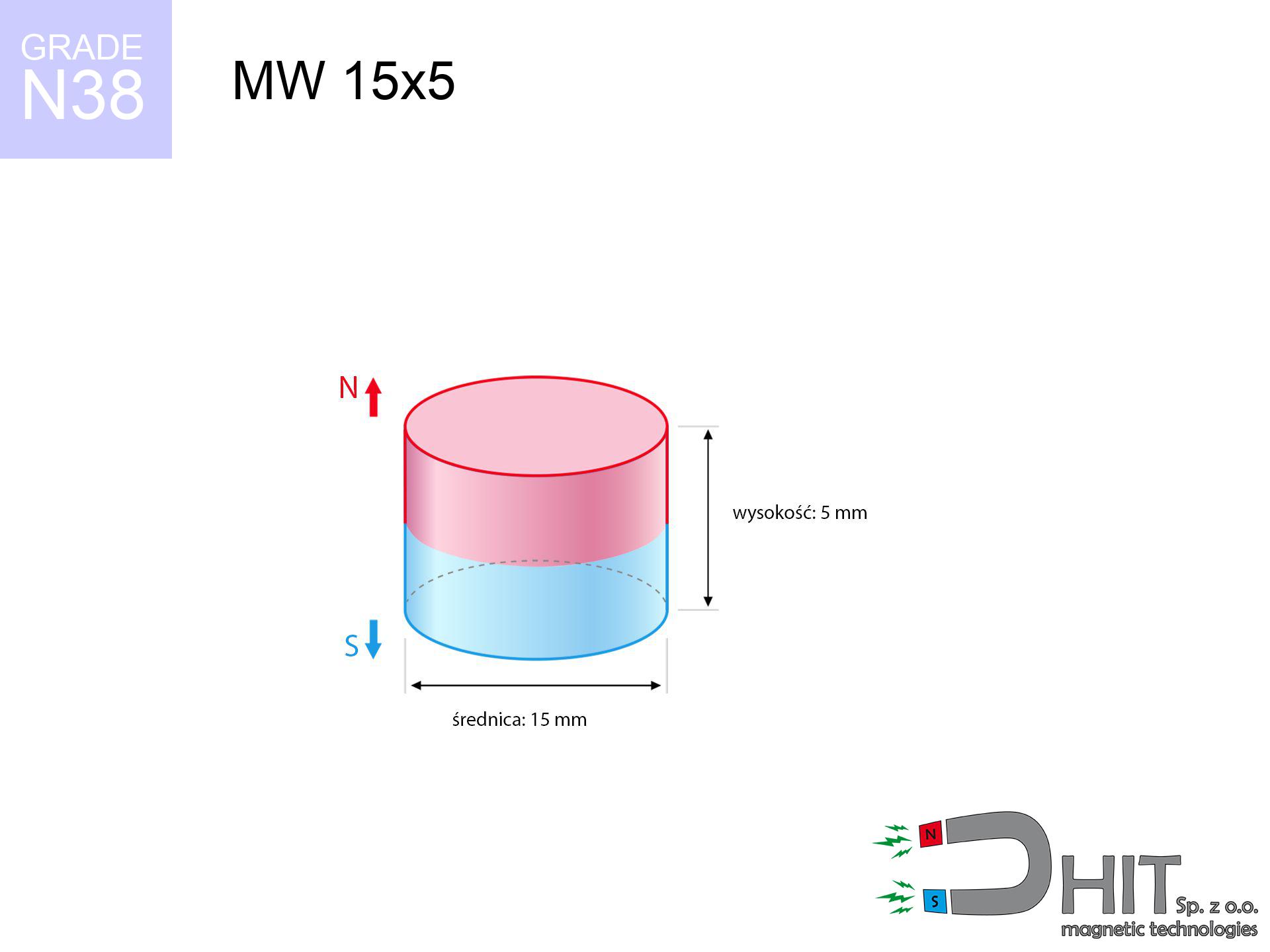

MW 15x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010031

GTIN/EAN: 5906301810308

Diameter Ø

15 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

6.63 g

Magnetization Direction

↑ axial

Load capacity

5.39 kg / 52.83 N

Magnetic Induction

343.70 mT / 3437 Gs

Coating

[NiCuNi] Nickel

3.20 ZŁ with VAT / pcs + price for transport

2.60 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or contact us by means of

inquiry form

our website.

Lifting power along with shape of magnetic components can be tested using our

modular calculator.

Same-day shipping for orders placed before 14:00.

Technical data - MW 15x5 / N38 - cylindrical magnet

Specification / characteristics - MW 15x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010031 |

| GTIN/EAN | 5906301810308 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 15 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 6.63 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.39 kg / 52.83 N |

| Magnetic Induction ~ ? | 343.70 mT / 3437 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the assembly - data

Presented information are the direct effect of a physical calculation. Results are based on algorithms for the class Nd2Fe14B. Actual conditions may differ from theoretical values. Treat these calculations as a reference point when designing systems.

Table 1: Static pull force (force vs distance) - characteristics

MW 15x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3436 Gs

343.6 mT

|

5.39 kg / 11.88 lbs

5390.0 g / 52.9 N

|

medium risk |

| 1 mm |

3054 Gs

305.4 mT

|

4.26 kg / 9.39 lbs

4258.2 g / 41.8 N

|

medium risk |

| 2 mm |

2633 Gs

263.3 mT

|

3.17 kg / 6.98 lbs

3165.4 g / 31.1 N

|

medium risk |

| 3 mm |

2221 Gs

222.1 mT

|

2.25 kg / 4.96 lbs

2251.5 g / 22.1 N

|

medium risk |

| 5 mm |

1521 Gs

152.1 mT

|

1.06 kg / 2.33 lbs

1056.2 g / 10.4 N

|

low risk |

| 10 mm |

585 Gs

58.5 mT

|

0.16 kg / 0.35 lbs

156.5 g / 1.5 N

|

low risk |

| 15 mm |

260 Gs

26.0 mT

|

0.03 kg / 0.07 lbs

30.8 g / 0.3 N

|

low risk |

| 20 mm |

133 Gs

13.3 mT

|

0.01 kg / 0.02 lbs

8.1 g / 0.1 N

|

low risk |

| 30 mm |

47 Gs

4.7 mT

|

0.00 kg / 0.00 lbs

1.0 g / 0.0 N

|

low risk |

| 50 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

low risk |

Table 2: Sliding load (wall)

MW 15x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.08 kg / 2.38 lbs

1078.0 g / 10.6 N

|

| 1 mm | Stal (~0.2) |

0.85 kg / 1.88 lbs

852.0 g / 8.4 N

|

| 2 mm | Stal (~0.2) |

0.63 kg / 1.40 lbs

634.0 g / 6.2 N

|

| 3 mm | Stal (~0.2) |

0.45 kg / 0.99 lbs

450.0 g / 4.4 N

|

| 5 mm | Stal (~0.2) |

0.21 kg / 0.47 lbs

212.0 g / 2.1 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

32.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 15x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.62 kg / 3.56 lbs

1617.0 g / 15.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.08 kg / 2.38 lbs

1078.0 g / 10.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.54 kg / 1.19 lbs

539.0 g / 5.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.70 kg / 5.94 lbs

2695.0 g / 26.4 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 15x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.54 kg / 1.19 lbs

539.0 g / 5.3 N

|

| 1 mm |

|

1.35 kg / 2.97 lbs

1347.5 g / 13.2 N

|

| 2 mm |

|

2.70 kg / 5.94 lbs

2695.0 g / 26.4 N

|

| 3 mm |

|

4.04 kg / 8.91 lbs

4042.5 g / 39.7 N

|

| 5 mm |

|

5.39 kg / 11.88 lbs

5390.0 g / 52.9 N

|

| 10 mm |

|

5.39 kg / 11.88 lbs

5390.0 g / 52.9 N

|

| 11 mm |

|

5.39 kg / 11.88 lbs

5390.0 g / 52.9 N

|

| 12 mm |

|

5.39 kg / 11.88 lbs

5390.0 g / 52.9 N

|

Table 5: Working in heat (stability) - thermal limit

MW 15x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

5.39 kg / 11.88 lbs

5390.0 g / 52.9 N

|

OK |

| 40 °C | -2.2% |

5.27 kg / 11.62 lbs

5271.4 g / 51.7 N

|

OK |

| 60 °C | -4.4% |

5.15 kg / 11.36 lbs

5152.8 g / 50.5 N

|

|

| 80 °C | -6.6% |

5.03 kg / 11.10 lbs

5034.3 g / 49.4 N

|

|

| 100 °C | -28.8% |

3.84 kg / 8.46 lbs

3837.7 g / 37.6 N

|

Table 6: Two magnets (attraction) - field range

MW 15x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

12.86 kg / 28.35 lbs

4 954 Gs

|

1.93 kg / 4.25 lbs

1929 g / 18.9 N

|

N/A |

| 1 mm |

11.54 kg / 25.43 lbs

6 508 Gs

|

1.73 kg / 3.81 lbs

1730 g / 17.0 N

|

10.38 kg / 22.89 lbs

~0 Gs

|

| 2 mm |

10.16 kg / 22.40 lbs

6 107 Gs

|

1.52 kg / 3.36 lbs

1524 g / 14.9 N

|

9.14 kg / 20.16 lbs

~0 Gs

|

| 3 mm |

8.82 kg / 19.44 lbs

5 689 Gs

|

1.32 kg / 2.92 lbs

1322 g / 13.0 N

|

7.93 kg / 17.49 lbs

~0 Gs

|

| 5 mm |

6.40 kg / 14.11 lbs

4 847 Gs

|

0.96 kg / 2.12 lbs

960 g / 9.4 N

|

5.76 kg / 12.70 lbs

~0 Gs

|

| 10 mm |

2.52 kg / 5.56 lbs

3 042 Gs

|

0.38 kg / 0.83 lbs

378 g / 3.7 N

|

2.27 kg / 5.00 lbs

~0 Gs

|

| 20 mm |

0.37 kg / 0.82 lbs

1 171 Gs

|

0.06 kg / 0.12 lbs

56 g / 0.5 N

|

0.34 kg / 0.74 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.01 lbs

153 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 lbs

95 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

63 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

44 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

32 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

23 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MW 15x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - collision effects

MW 15x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.27 km/h

(8.13 m/s)

|

0.22 J | |

| 30 mm |

49.81 km/h

(13.84 m/s)

|

0.63 J | |

| 50 mm |

64.30 km/h

(17.86 m/s)

|

1.06 J | |

| 100 mm |

90.93 km/h

(25.26 m/s)

|

2.12 J |

Table 9: Surface protection spec

MW 15x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 15x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 6 428 Mx | 64.3 µWb |

| Pc Coefficient | 0.44 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 15x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 5.39 kg | Standard |

| Water (riverbed) |

6.17 kg

(+0.78 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet retains just a fraction of its perpendicular strength.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly limits the holding force.

3. Temperature resistance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.44

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Pros and cons of rare earth magnets.

Benefits

- They retain magnetic properties for around ten years – the drop is just ~1% (in theory),

- Neodymium magnets remain remarkably resistant to magnetic field loss caused by external field sources,

- A magnet with a shiny gold surface looks better,

- Magnetic induction on the working part of the magnet turns out to be impressive,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- In view of the option of flexible shaping and customization to unique solutions, magnetic components can be manufactured in a variety of geometric configurations, which expands the range of possible applications,

- Versatile presence in high-tech industry – they are utilized in magnetic memories, drive modules, advanced medical instruments, and modern systems.

- Thanks to their power density, small magnets offer high operating force, with minimal size,

Cons

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a strong case, which not only protects them against impacts but also raises their durability

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- We recommend cover - magnetic mount, due to difficulties in creating threads inside the magnet and complicated shapes.

- Health risk resulting from small fragments of magnets pose a threat, if swallowed, which becomes key in the context of child safety. Additionally, tiny parts of these magnets are able to complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which can limit application in large quantities

Lifting parameters

Highest magnetic holding force – what it depends on?

- using a base made of mild steel, functioning as a ideal flux conductor

- whose thickness reaches at least 10 mm

- with an ground touching surface

- under conditions of ideal adhesion (metal-to-metal)

- for force applied at a right angle (in the magnet axis)

- in neutral thermal conditions

Lifting capacity in real conditions – factors

- Space between surfaces – even a fraction of a millimeter of distance (caused e.g. by veneer or dirt) diminishes the pulling force, often by half at just 0.5 mm.

- Force direction – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Material type – ideal substrate is high-permeability steel. Cast iron may attract less.

- Surface finish – ideal contact is possible only on polished steel. Rough texture reduce the real contact area, weakening the magnet.

- Heat – neodymium magnets have a negative temperature coefficient. At higher temperatures they are weaker, and in frost they can be stronger (up to a certain limit).

Lifting capacity was determined with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular detachment force, in contrast under attempts to slide the magnet the load capacity is reduced by as much as fivefold. In addition, even a minimal clearance between the magnet’s surface and the plate reduces the holding force.

Warnings

Medical interference

People with a pacemaker should keep an large gap from magnets. The magnetism can interfere with the operation of the implant.

Sensitization to coating

A percentage of the population suffer from a sensitization to Ni, which is the common plating for neodymium magnets. Extended handling might lead to skin redness. We recommend wear safety gloves.

Electronic devices

Do not bring magnets near a wallet, laptop, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Thermal limits

Regular neodymium magnets (grade N) lose magnetization when the temperature exceeds 80°C. Damage is permanent.

Handling rules

Before starting, check safety instructions. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Dust explosion hazard

Powder generated during cutting of magnets is flammable. Do not drill into magnets without proper cooling and knowledge.

Fragile material

Beware of splinters. Magnets can fracture upon violent connection, launching shards into the air. Eye protection is mandatory.

Choking Hazard

Only for adults. Tiny parts can be swallowed, leading to serious injuries. Keep away from children and animals.

Compass and GPS

A powerful magnetic field negatively affects the functioning of compasses in phones and navigation systems. Do not bring magnets close to a smartphone to prevent breaking the sensors.

Crushing force

Big blocks can break fingers instantly. Do not put your hand betwixt two attracting surfaces.

![UMP 75x25 [M10x3] GW F200 GOLD DUAL / N42 - search holder UMP 75x25 [M10x3] GW F200 GOLD DUAL / N42 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-gold-dual-xoc.jpg)

![UMGGZ 34x6 [M4] GZ / N38 - rubber magnetic holder external thread UMGGZ 34x6 [M4] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-34x6-m4-gz-rad.jpg)