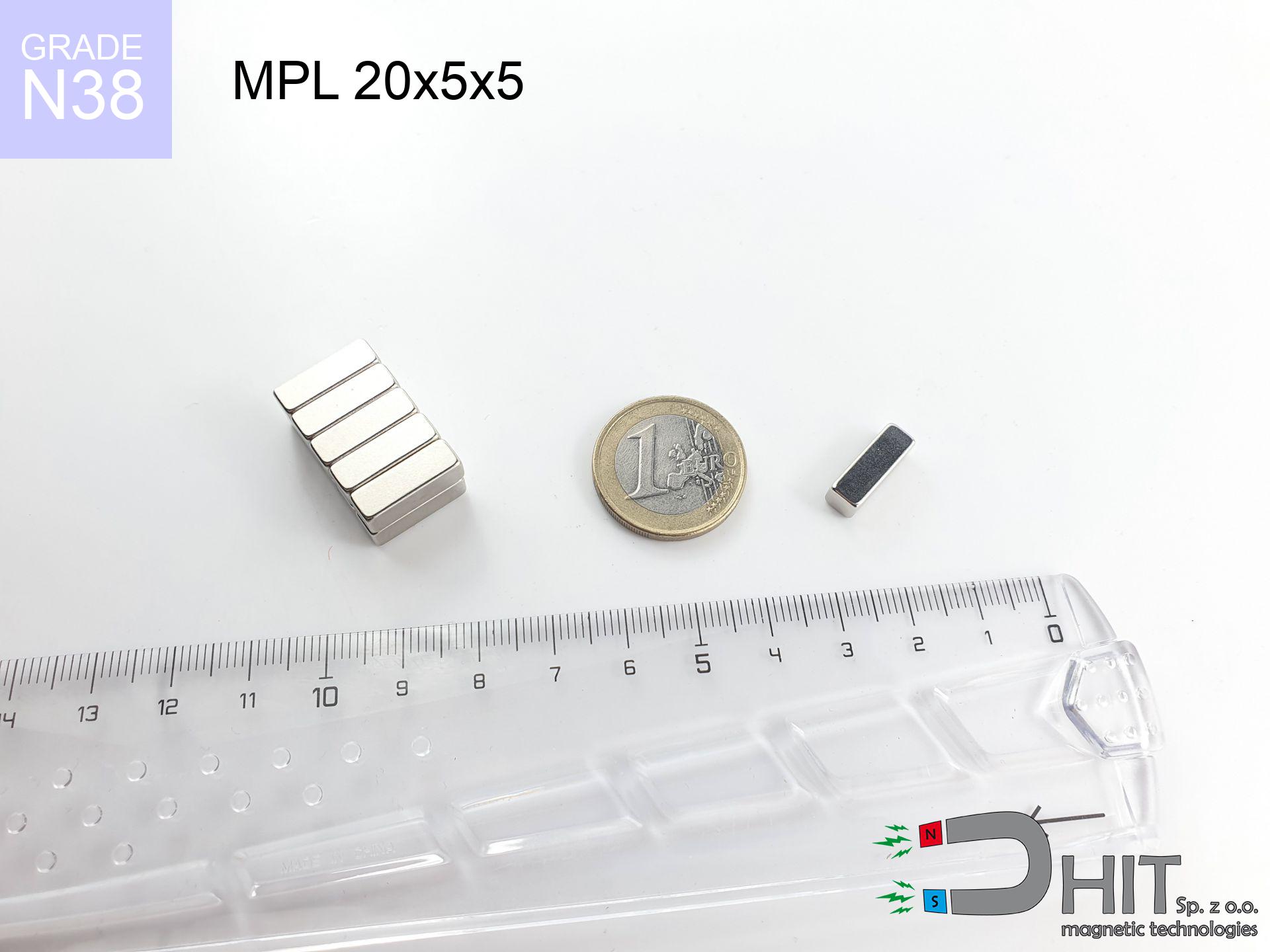

MPL 20x5x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020132

GTIN/EAN: 5906301811381

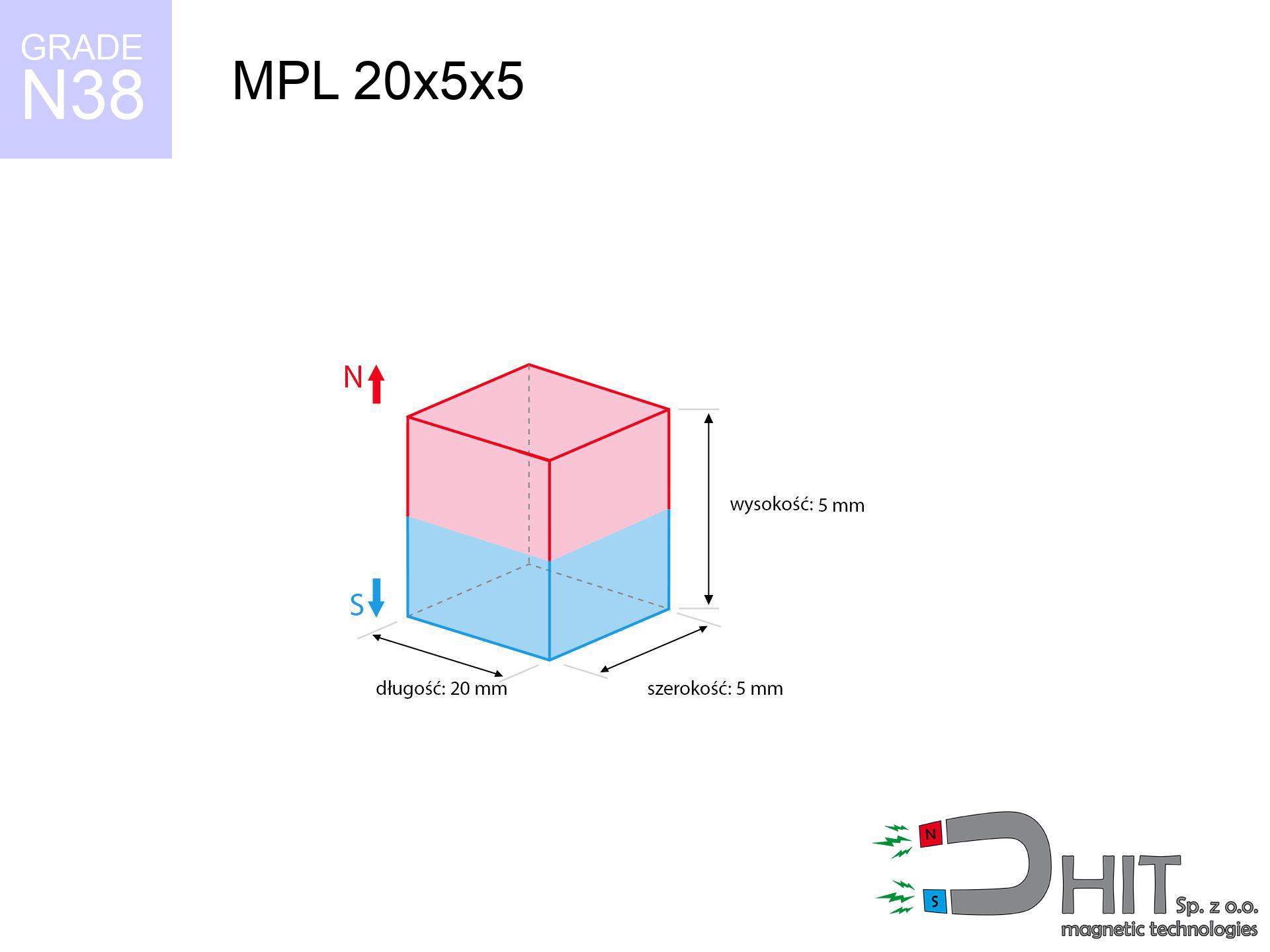

length

20 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

3.75 g

Magnetization Direction

↑ axial

Load capacity

4.42 kg / 43.32 N

Magnetic Induction

456.78 mT / 4568 Gs

Coating

[NiCuNi] Nickel

2.76 ZŁ with VAT / pcs + price for transport

2.24 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively get in touch through

inquiry form

the contact page.

Weight and form of neodymium magnets can be checked using our

modular calculator.

Same-day processing for orders placed before 14:00.

Product card - MPL 20x5x5 / N38 - lamellar magnet

Specification / characteristics - MPL 20x5x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020132 |

| GTIN/EAN | 5906301811381 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 3.75 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.42 kg / 43.32 N |

| Magnetic Induction ~ ? | 456.78 mT / 4568 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - data

Presented values represent the result of a physical simulation. Values are based on models for the material Nd2Fe14B. Operational parameters might slightly deviate from the simulation results. Please consider these data as a reference point for designers.

Table 1: Static force (pull vs gap) - power drop

MPL 20x5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4563 Gs

456.3 mT

|

4.42 kg / 9.74 lbs

4420.0 g / 43.4 N

|

warning |

| 1 mm |

3323 Gs

332.3 mT

|

2.34 kg / 5.17 lbs

2344.7 g / 23.0 N

|

warning |

| 2 mm |

2341 Gs

234.1 mT

|

1.16 kg / 2.56 lbs

1163.0 g / 11.4 N

|

safe |

| 3 mm |

1678 Gs

167.8 mT

|

0.60 kg / 1.32 lbs

597.4 g / 5.9 N

|

safe |

| 5 mm |

944 Gs

94.4 mT

|

0.19 kg / 0.42 lbs

189.2 g / 1.9 N

|

safe |

| 10 mm |

320 Gs

32.0 mT

|

0.02 kg / 0.05 lbs

21.7 g / 0.2 N

|

safe |

| 15 mm |

141 Gs

14.1 mT

|

0.00 kg / 0.01 lbs

4.2 g / 0.0 N

|

safe |

| 20 mm |

73 Gs

7.3 mT

|

0.00 kg / 0.00 lbs

1.1 g / 0.0 N

|

safe |

| 30 mm |

26 Gs

2.6 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

| 50 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Vertical hold (wall)

MPL 20x5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.88 kg / 1.95 lbs

884.0 g / 8.7 N

|

| 1 mm | Stal (~0.2) |

0.47 kg / 1.03 lbs

468.0 g / 4.6 N

|

| 2 mm | Stal (~0.2) |

0.23 kg / 0.51 lbs

232.0 g / 2.3 N

|

| 3 mm | Stal (~0.2) |

0.12 kg / 0.26 lbs

120.0 g / 1.2 N

|

| 5 mm | Stal (~0.2) |

0.04 kg / 0.08 lbs

38.0 g / 0.4 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 20x5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.33 kg / 2.92 lbs

1326.0 g / 13.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.88 kg / 1.95 lbs

884.0 g / 8.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.44 kg / 0.97 lbs

442.0 g / 4.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.21 kg / 4.87 lbs

2210.0 g / 21.7 N

|

Table 4: Steel thickness (saturation) - power losses

MPL 20x5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.44 kg / 0.97 lbs

442.0 g / 4.3 N

|

| 1 mm |

|

1.11 kg / 2.44 lbs

1105.0 g / 10.8 N

|

| 2 mm |

|

2.21 kg / 4.87 lbs

2210.0 g / 21.7 N

|

| 3 mm |

|

3.32 kg / 7.31 lbs

3315.0 g / 32.5 N

|

| 5 mm |

|

4.42 kg / 9.74 lbs

4420.0 g / 43.4 N

|

| 10 mm |

|

4.42 kg / 9.74 lbs

4420.0 g / 43.4 N

|

| 11 mm |

|

4.42 kg / 9.74 lbs

4420.0 g / 43.4 N

|

| 12 mm |

|

4.42 kg / 9.74 lbs

4420.0 g / 43.4 N

|

Table 5: Thermal resistance (stability) - thermal limit

MPL 20x5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.42 kg / 9.74 lbs

4420.0 g / 43.4 N

|

OK |

| 40 °C | -2.2% |

4.32 kg / 9.53 lbs

4322.8 g / 42.4 N

|

OK |

| 60 °C | -4.4% |

4.23 kg / 9.32 lbs

4225.5 g / 41.5 N

|

|

| 80 °C | -6.6% |

4.13 kg / 9.10 lbs

4128.3 g / 40.5 N

|

|

| 100 °C | -28.8% |

3.15 kg / 6.94 lbs

3147.0 g / 30.9 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MPL 20x5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

12.84 kg / 28.30 lbs

5 504 Gs

|

1.93 kg / 4.24 lbs

1925 g / 18.9 N

|

N/A |

| 1 mm |

9.53 kg / 21.01 lbs

7 864 Gs

|

1.43 kg / 3.15 lbs

1430 g / 14.0 N

|

8.58 kg / 18.91 lbs

~0 Gs

|

| 2 mm |

6.81 kg / 15.01 lbs

6 647 Gs

|

1.02 kg / 2.25 lbs

1021 g / 10.0 N

|

6.13 kg / 13.51 lbs

~0 Gs

|

| 3 mm |

4.79 kg / 10.57 lbs

5 577 Gs

|

0.72 kg / 1.59 lbs

719 g / 7.1 N

|

4.31 kg / 9.51 lbs

~0 Gs

|

| 5 mm |

2.40 kg / 5.30 lbs

3 949 Gs

|

0.36 kg / 0.79 lbs

360 g / 3.5 N

|

2.16 kg / 4.77 lbs

~0 Gs

|

| 10 mm |

0.55 kg / 1.21 lbs

1 888 Gs

|

0.08 kg / 0.18 lbs

82 g / 0.8 N

|

0.49 kg / 1.09 lbs

~0 Gs

|

| 20 mm |

0.06 kg / 0.14 lbs

640 Gs

|

0.01 kg / 0.02 lbs

9 g / 0.1 N

|

0.06 kg / 0.13 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

84 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

53 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

35 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

18 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

13 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MPL 20x5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - warning

MPL 20x5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

34.73 km/h

(9.65 m/s)

|

0.17 J | |

| 30 mm |

59.97 km/h

(16.66 m/s)

|

0.52 J | |

| 50 mm |

77.42 km/h

(21.51 m/s)

|

0.87 J | |

| 100 mm |

109.49 km/h

(30.41 m/s)

|

1.73 J |

Table 9: Surface protection spec

MPL 20x5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 20x5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 204 Mx | 42.0 µWb |

| Pc Coefficient | 0.54 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 20x5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.42 kg | Standard |

| Water (riverbed) |

5.06 kg

(+0.64 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet retains just approx. 20-30% of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. computer case) severely limits the holding force.

3. Thermal stability

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.54

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also proposals

Pros as well as cons of Nd2Fe14B magnets.

Benefits

- Their strength remains stable, and after approximately 10 years it decreases only by ~1% (according to research),

- They feature excellent resistance to magnetism drop as a result of opposing magnetic fields,

- The use of an elegant layer of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- They feature high magnetic induction at the operating surface, which increases their power,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for functioning at temperatures reaching 230°C and above...

- Thanks to modularity in shaping and the capacity to customize to individual projects,

- Huge importance in modern industrial fields – they are commonly used in magnetic memories, electric drive systems, advanced medical instruments, and industrial machines.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Limitations

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- Due to limitations in creating threads and complicated forms in magnets, we recommend using casing - magnetic mount.

- Health risk resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which becomes key in the context of child safety. Furthermore, tiny parts of these magnets can be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Highest magnetic holding force – what it depends on?

- using a base made of mild steel, serving as a circuit closing element

- whose thickness reaches at least 10 mm

- with a plane perfectly flat

- without any air gap between the magnet and steel

- under vertical application of breakaway force (90-degree angle)

- in neutral thermal conditions

Lifting capacity in practice – influencing factors

- Distance – existence of foreign body (rust, tape, air) interrupts the magnetic circuit, which lowers capacity steeply (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Plate material – mild steel gives the best results. Alloy steels reduce magnetic properties and holding force.

- Smoothness – ideal contact is obtained only on smooth steel. Rough texture create air cushions, reducing force.

- Thermal environment – heating the magnet causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Holding force was measured on the plate surface of 20 mm thickness, when the force acted perpendicularly, in contrast under attempts to slide the magnet the lifting capacity is smaller. In addition, even a small distance between the magnet and the plate reduces the lifting capacity.

Safety rules for work with NdFeB magnets

Keep away from children

Always store magnets out of reach of children. Ingestion danger is significant, and the consequences of magnets clamping inside the body are life-threatening.

Keep away from computers

Very strong magnetic fields can corrupt files on payment cards, hard drives, and storage devices. Stay away of at least 10 cm.

Health Danger

Health Alert: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

Eye protection

Despite the nickel coating, neodymium is delicate and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Fire warning

Fire hazard: Neodymium dust is highly flammable. Avoid machining magnets in home conditions as this may cause fire.

Safe operation

Before starting, read the rules. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Operating temperature

Avoid heat. NdFeB magnets are sensitive to heat. If you need resistance above 80°C, ask us about special high-temperature series (H, SH, UH).

Allergy Warning

Allergy Notice: The Ni-Cu-Ni coating consists of nickel. If skin irritation happens, cease working with magnets and use protective gear.

Phone sensors

Remember: neodymium magnets produce a field that disrupts precision electronics. Maintain a separation from your mobile, device, and navigation systems.

Crushing force

Risk of injury: The pulling power is so great that it can cause blood blisters, crushing, and broken bones. Protective gloves are recommended.