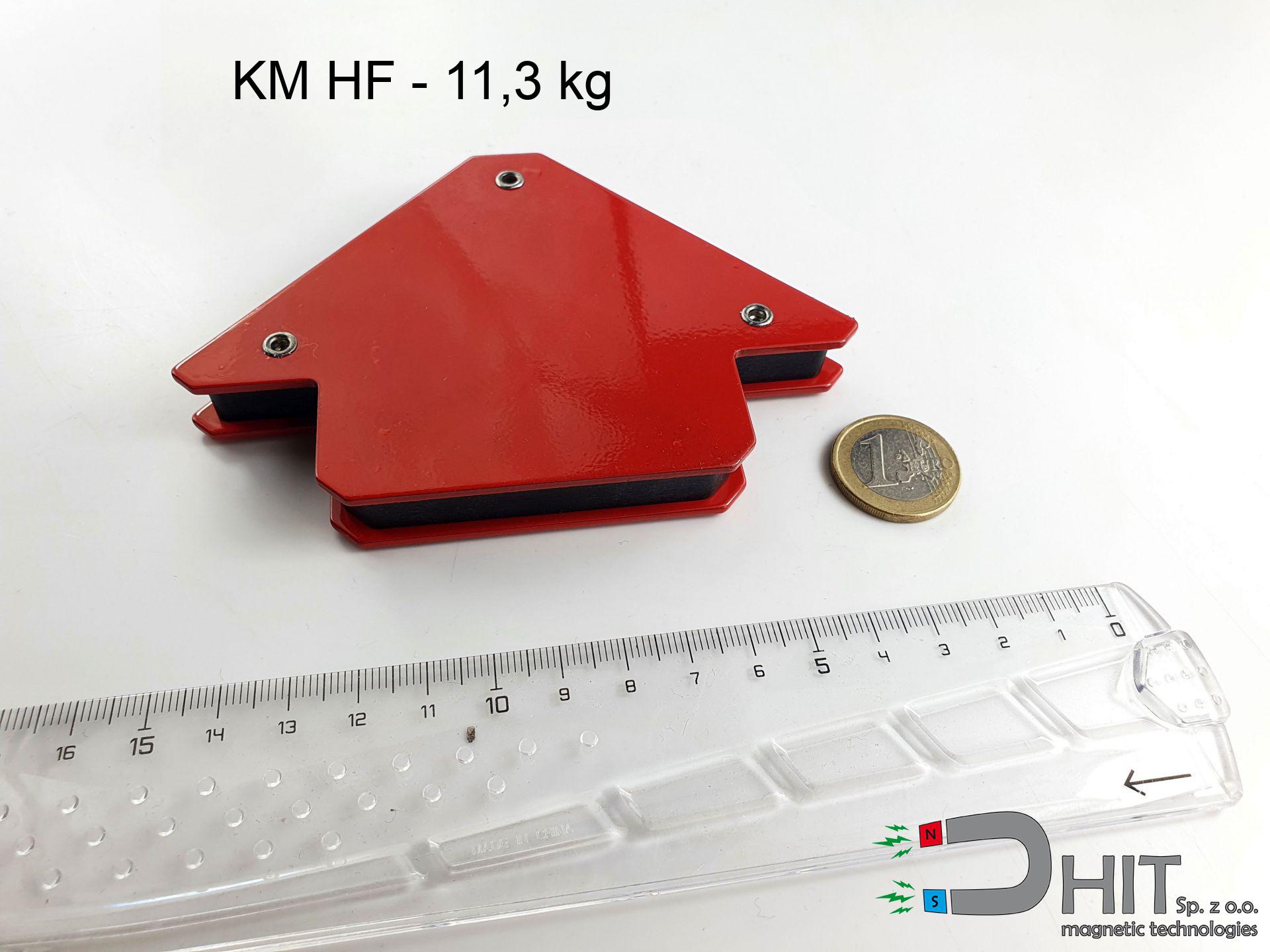

MP 5x2.7/1.2x5 Z / N38 - ring magnet

ring magnet

Catalog no 030203

GTIN/EAN: 5906301812203

Diameter

5 mm [±0,1 mm]

internal diameter Ø

2.7/1.2 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

0.69 g

Magnetization Direction

↑ axial

Load capacity

0.75 kg / 7.31 N

Magnetic Induction

553.14 mT / 5531 Gs

Coating

[NiCuNi] Nickel

0.836 ZŁ with VAT / pcs + price for transport

0.680 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

if you prefer contact us via

inquiry form

the contact page.

Lifting power along with structure of a neodymium magnet can be tested using our

modular calculator.

Same-day processing for orders placed before 14:00.

Detailed specification - MP 5x2.7/1.2x5 Z / N38 - ring magnet

Specification / characteristics - MP 5x2.7/1.2x5 Z / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030203 |

| GTIN/EAN | 5906301812203 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 5 mm [±0,1 mm] |

| internal diameter Ø | 2.7/1.2 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 0.69 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.75 kg / 7.31 N |

| Magnetic Induction ~ ? | 553.14 mT / 5531 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the magnet - report

Presented data represent the outcome of a mathematical analysis. Results were calculated on models for the class Nd2Fe14B. Real-world conditions might slightly deviate from the simulation results. Use these data as a supplementary guide when designing systems.

Table 1: Static pull force (pull vs distance) - power drop

MP 5x2.7/1.2x5 Z / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5322 Gs

532.2 mT

|

0.75 kg / 1.65 lbs

750.0 g / 7.4 N

|

safe |

| 1 mm |

3295 Gs

329.5 mT

|

0.29 kg / 0.63 lbs

287.5 g / 2.8 N

|

safe |

| 2 mm |

1883 Gs

188.3 mT

|

0.09 kg / 0.21 lbs

93.9 g / 0.9 N

|

safe |

| 3 mm |

1098 Gs

109.8 mT

|

0.03 kg / 0.07 lbs

31.9 g / 0.3 N

|

safe |

| 5 mm |

440 Gs

44.0 mT

|

0.01 kg / 0.01 lbs

5.1 g / 0.1 N

|

safe |

| 10 mm |

92 Gs

9.2 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

safe |

| 15 mm |

33 Gs

3.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 20 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Slippage force (wall)

MP 5x2.7/1.2x5 Z / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.15 kg / 0.33 lbs

150.0 g / 1.5 N

|

| 1 mm | Stal (~0.2) |

0.06 kg / 0.13 lbs

58.0 g / 0.6 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

18.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 5x2.7/1.2x5 Z / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.22 kg / 0.50 lbs

225.0 g / 2.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.15 kg / 0.33 lbs

150.0 g / 1.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.17 lbs

75.0 g / 0.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.38 kg / 0.83 lbs

375.0 g / 3.7 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MP 5x2.7/1.2x5 Z / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.17 lbs

75.0 g / 0.7 N

|

| 1 mm |

|

0.19 kg / 0.41 lbs

187.5 g / 1.8 N

|

| 2 mm |

|

0.38 kg / 0.83 lbs

375.0 g / 3.7 N

|

| 3 mm |

|

0.56 kg / 1.24 lbs

562.5 g / 5.5 N

|

| 5 mm |

|

0.75 kg / 1.65 lbs

750.0 g / 7.4 N

|

| 10 mm |

|

0.75 kg / 1.65 lbs

750.0 g / 7.4 N

|

| 11 mm |

|

0.75 kg / 1.65 lbs

750.0 g / 7.4 N

|

| 12 mm |

|

0.75 kg / 1.65 lbs

750.0 g / 7.4 N

|

Table 5: Working in heat (material behavior) - power drop

MP 5x2.7/1.2x5 Z / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.75 kg / 1.65 lbs

750.0 g / 7.4 N

|

OK |

| 40 °C | -2.2% |

0.73 kg / 1.62 lbs

733.5 g / 7.2 N

|

OK |

| 60 °C | -4.4% |

0.72 kg / 1.58 lbs

717.0 g / 7.0 N

|

OK |

| 80 °C | -6.6% |

0.70 kg / 1.54 lbs

700.5 g / 6.9 N

|

|

| 100 °C | -28.8% |

0.53 kg / 1.18 lbs

534.0 g / 5.2 N

|

Table 6: Two magnets (attraction) - forces in the system

MP 5x2.7/1.2x5 Z / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.75 kg / 6.06 lbs

5 924 Gs

|

0.41 kg / 0.91 lbs

412 g / 4.0 N

|

N/A |

| 1 mm |

1.77 kg / 3.90 lbs

8 541 Gs

|

0.27 kg / 0.58 lbs

265 g / 2.6 N

|

1.59 kg / 3.51 lbs

~0 Gs

|

| 2 mm |

1.05 kg / 2.32 lbs

6 590 Gs

|

0.16 kg / 0.35 lbs

158 g / 1.5 N

|

0.95 kg / 2.09 lbs

~0 Gs

|

| 3 mm |

0.60 kg / 1.33 lbs

4 992 Gs

|

0.09 kg / 0.20 lbs

91 g / 0.9 N

|

0.54 kg / 1.20 lbs

~0 Gs

|

| 5 mm |

0.20 kg / 0.44 lbs

2 860 Gs

|

0.03 kg / 0.07 lbs

30 g / 0.3 N

|

0.18 kg / 0.39 lbs

~0 Gs

|

| 10 mm |

0.02 kg / 0.04 lbs

880 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 lbs

184 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

16 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

10 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

6 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

4 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

3 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

2 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MP 5x2.7/1.2x5 Z / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (kinetic energy) - warning

MP 5x2.7/1.2x5 Z / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

33.26 km/h

(9.24 m/s)

|

0.03 J | |

| 30 mm |

57.59 km/h

(16.00 m/s)

|

0.09 J | |

| 50 mm |

74.35 km/h

(20.65 m/s)

|

0.15 J | |

| 100 mm |

105.14 km/h

(29.21 m/s)

|

0.29 J |

Table 9: Coating parameters (durability)

MP 5x2.7/1.2x5 Z / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 5x2.7/1.2x5 Z / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 862 Mx | 8.6 µWb |

| Pc Coefficient | 0.83 | High (Stable) |

Table 11: Submerged application

MP 5x2.7/1.2x5 Z / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.75 kg | Standard |

| Water (riverbed) |

0.86 kg

(+0.11 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds just approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Power loss vs temp

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.83

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Pros

- They virtually do not lose power, because even after 10 years the performance loss is only ~1% (in laboratory conditions),

- They are noted for resistance to demagnetization induced by external magnetic fields,

- By using a shiny layer of gold, the element presents an modern look,

- The surface of neodymium magnets generates a concentrated magnetic field – this is one of their assets,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of detailed creating as well as optimizing to atypical needs,

- Wide application in advanced technology sectors – they are utilized in mass storage devices, electric drive systems, precision medical tools, as well as other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which allows their use in compact constructions

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation and corrosion.

- Limited possibility of creating nuts in the magnet and complicated forms - preferred is casing - magnetic holder.

- Possible danger resulting from small fragments of magnets are risky, when accidentally swallowed, which gains importance in the context of child safety. Furthermore, tiny parts of these magnets are able to complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Best holding force of the magnet in ideal parameters – what affects it?

- with the contact of a sheet made of special test steel, guaranteeing maximum field concentration

- possessing a massiveness of minimum 10 mm to avoid saturation

- characterized by even structure

- with direct contact (without impurities)

- for force applied at a right angle (in the magnet axis)

- in neutral thermal conditions

Lifting capacity in real conditions – factors

- Space between magnet and steel – every millimeter of distance (caused e.g. by varnish or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Direction of force – highest force is obtained only during pulling at a 90° angle. The shear force of the magnet along the plate is standardly many times lower (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Chemical composition of the base – low-carbon steel attracts best. Alloy steels decrease magnetic permeability and lifting capacity.

- Surface structure – the smoother and more polished the surface, the larger the contact zone and stronger the hold. Unevenness acts like micro-gaps.

- Thermal factor – high temperature reduces magnetic field. Too high temperature can permanently damage the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, whereas under parallel forces the holding force is lower. In addition, even a slight gap between the magnet and the plate reduces the load capacity.

Warnings

Magnet fragility

Despite metallic appearance, the material is delicate and cannot withstand shocks. Avoid impacts, as the magnet may shatter into hazardous fragments.

Machining danger

Dust generated during cutting of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.

Implant safety

Patients with a ICD should keep an absolute distance from magnets. The magnetic field can stop the functioning of the implant.

Respect the power

Use magnets consciously. Their immense force can shock even experienced users. Plan your moves and do not underestimate their power.

Nickel coating and allergies

Some people experience a sensitization to nickel, which is the standard coating for NdFeB magnets. Extended handling might lead to an allergic reaction. We suggest wear safety gloves.

Finger safety

Big blocks can break fingers instantly. Do not put your hand betwixt two attracting surfaces.

Precision electronics

Note: rare earth magnets generate a field that interferes with sensitive sensors. Maintain a separation from your mobile, device, and GPS.

Data carriers

Avoid bringing magnets close to a wallet, computer, or screen. The magnetic field can destroy these devices and wipe information from cards.

Power loss in heat

Standard neodymium magnets (N-type) lose power when the temperature exceeds 80°C. Damage is permanent.

Danger to the youngest

Adult use only. Tiny parts pose a choking risk, leading to intestinal necrosis. Store away from kids and pets.

![UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gw-jek.jpg)

![SM 18x175 [2xM5] / N42 - magnetic separator SM 18x175 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x175-2xm5-rov.jpg)