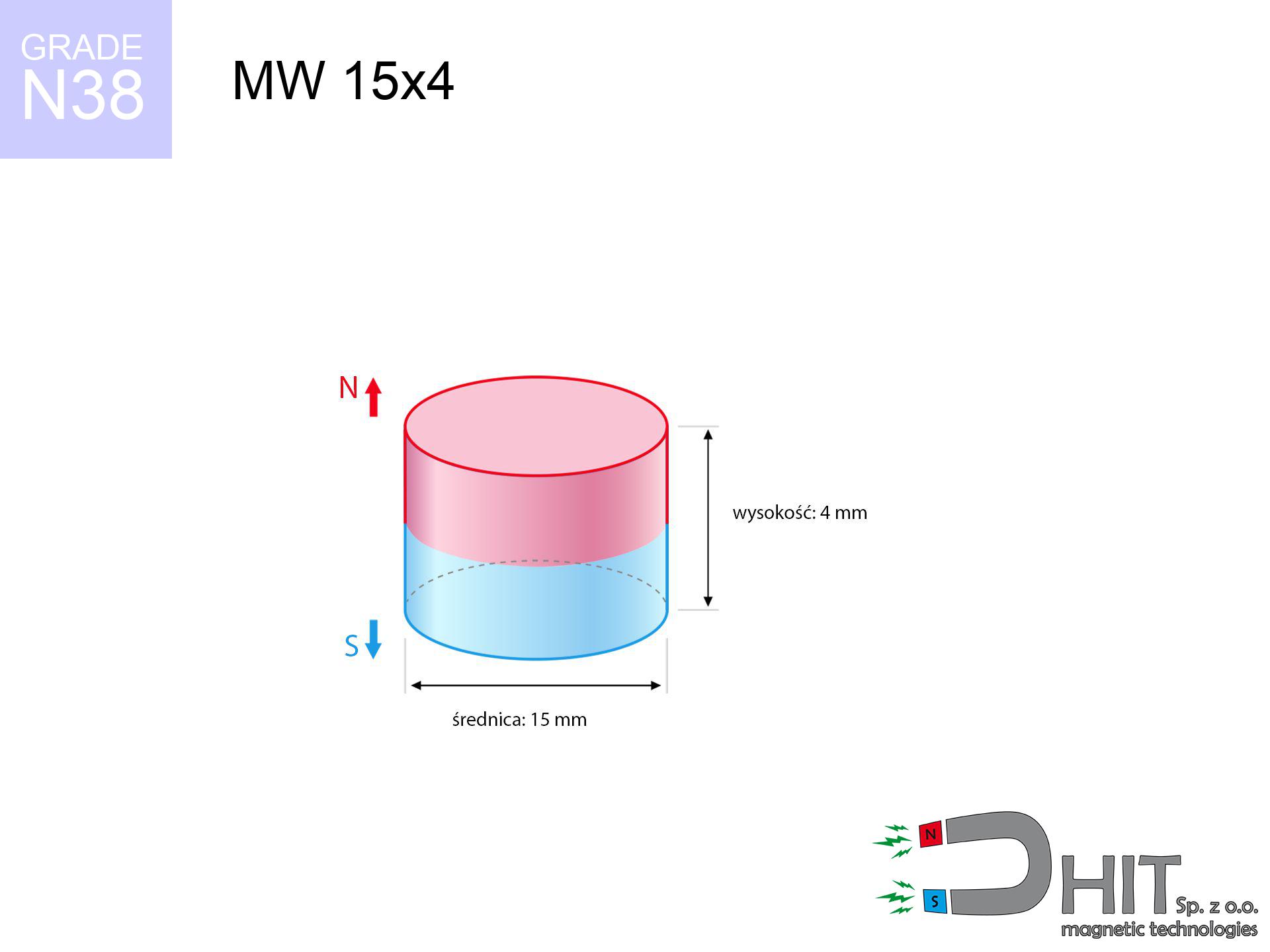

MW 15x4 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010030

GTIN/EAN: 5906301810292

Diameter Ø

15 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

5.3 g

Magnetization Direction

↑ axial

Load capacity

4.22 kg / 41.38 N

Magnetic Induction

291.60 mT / 2916 Gs

Coating

[NiCuNi] Nickel

1.968 ZŁ with VAT / pcs + price for transport

1.600 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

or let us know via

contact form

the contact page.

Force along with structure of magnetic components can be analyzed with our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - MW 15x4 / N38 - cylindrical magnet

Specification / characteristics - MW 15x4 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010030 |

| GTIN/EAN | 5906301810292 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 15 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 5.3 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.22 kg / 41.38 N |

| Magnetic Induction ~ ? | 291.60 mT / 2916 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - technical parameters

The following values are the outcome of a mathematical calculation. Values were calculated on algorithms for the material Nd2Fe14B. Operational parameters might slightly deviate from the simulation results. Use these data as a supplementary guide during assembly planning.

Table 1: Static force (pull vs gap) - power drop

MW 15x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2915 Gs

291.5 mT

|

4.22 kg / 9.30 lbs

4220.0 g / 41.4 N

|

warning |

| 1 mm |

2620 Gs

262.0 mT

|

3.41 kg / 7.51 lbs

3408.2 g / 33.4 N

|

warning |

| 2 mm |

2276 Gs

227.6 mT

|

2.57 kg / 5.67 lbs

2571.6 g / 25.2 N

|

warning |

| 3 mm |

1928 Gs

192.8 mT

|

1.85 kg / 4.07 lbs

1845.5 g / 18.1 N

|

low risk |

| 5 mm |

1324 Gs

132.4 mT

|

0.87 kg / 1.92 lbs

870.3 g / 8.5 N

|

low risk |

| 10 mm |

505 Gs

50.5 mT

|

0.13 kg / 0.28 lbs

126.7 g / 1.2 N

|

low risk |

| 15 mm |

222 Gs

22.2 mT

|

0.02 kg / 0.05 lbs

24.4 g / 0.2 N

|

low risk |

| 20 mm |

113 Gs

11.3 mT

|

0.01 kg / 0.01 lbs

6.3 g / 0.1 N

|

low risk |

| 30 mm |

40 Gs

4.0 mT

|

0.00 kg / 0.00 lbs

0.8 g / 0.0 N

|

low risk |

| 50 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical load (vertical surface)

MW 15x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.84 kg / 1.86 lbs

844.0 g / 8.3 N

|

| 1 mm | Stal (~0.2) |

0.68 kg / 1.50 lbs

682.0 g / 6.7 N

|

| 2 mm | Stal (~0.2) |

0.51 kg / 1.13 lbs

514.0 g / 5.0 N

|

| 3 mm | Stal (~0.2) |

0.37 kg / 0.82 lbs

370.0 g / 3.6 N

|

| 5 mm | Stal (~0.2) |

0.17 kg / 0.38 lbs

174.0 g / 1.7 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.06 lbs

26.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 15x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.27 kg / 2.79 lbs

1266.0 g / 12.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.84 kg / 1.86 lbs

844.0 g / 8.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.42 kg / 0.93 lbs

422.0 g / 4.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 15x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.42 kg / 0.93 lbs

422.0 g / 4.1 N

|

| 1 mm |

|

1.06 kg / 2.33 lbs

1055.0 g / 10.3 N

|

| 2 mm |

|

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

| 3 mm |

|

3.17 kg / 6.98 lbs

3165.0 g / 31.0 N

|

| 5 mm |

|

4.22 kg / 9.30 lbs

4220.0 g / 41.4 N

|

| 10 mm |

|

4.22 kg / 9.30 lbs

4220.0 g / 41.4 N

|

| 11 mm |

|

4.22 kg / 9.30 lbs

4220.0 g / 41.4 N

|

| 12 mm |

|

4.22 kg / 9.30 lbs

4220.0 g / 41.4 N

|

Table 5: Thermal resistance (stability) - thermal limit

MW 15x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.22 kg / 9.30 lbs

4220.0 g / 41.4 N

|

OK |

| 40 °C | -2.2% |

4.13 kg / 9.10 lbs

4127.2 g / 40.5 N

|

OK |

| 60 °C | -4.4% |

4.03 kg / 8.89 lbs

4034.3 g / 39.6 N

|

|

| 80 °C | -6.6% |

3.94 kg / 8.69 lbs

3941.5 g / 38.7 N

|

|

| 100 °C | -28.8% |

3.00 kg / 6.62 lbs

3004.6 g / 29.5 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 15x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

9.26 kg / 20.41 lbs

4 518 Gs

|

1.39 kg / 3.06 lbs

1389 g / 13.6 N

|

N/A |

| 1 mm |

8.40 kg / 18.53 lbs

5 555 Gs

|

1.26 kg / 2.78 lbs

1261 g / 12.4 N

|

7.56 kg / 16.68 lbs

~0 Gs

|

| 2 mm |

7.48 kg / 16.48 lbs

5 239 Gs

|

1.12 kg / 2.47 lbs

1122 g / 11.0 N

|

6.73 kg / 14.84 lbs

~0 Gs

|

| 3 mm |

6.54 kg / 14.42 lbs

4 901 Gs

|

0.98 kg / 2.16 lbs

981 g / 9.6 N

|

5.89 kg / 12.98 lbs

~0 Gs

|

| 5 mm |

4.80 kg / 10.59 lbs

4 200 Gs

|

0.72 kg / 1.59 lbs

721 g / 7.1 N

|

4.32 kg / 9.53 lbs

~0 Gs

|

| 10 mm |

1.91 kg / 4.21 lbs

2 648 Gs

|

0.29 kg / 0.63 lbs

286 g / 2.8 N

|

1.72 kg / 3.79 lbs

~0 Gs

|

| 20 mm |

0.28 kg / 0.61 lbs

1 010 Gs

|

0.04 kg / 0.09 lbs

42 g / 0.4 N

|

0.25 kg / 0.55 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 lbs

128 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

79 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

52 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

36 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

26 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

19 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 15x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - warning

MW 15x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.99 km/h

(8.05 m/s)

|

0.17 J | |

| 30 mm |

49.30 km/h

(13.69 m/s)

|

0.50 J | |

| 50 mm |

63.63 km/h

(17.68 m/s)

|

0.83 J | |

| 100 mm |

89.99 km/h

(25.00 m/s)

|

1.66 J |

Table 9: Corrosion resistance

MW 15x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 15x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 659 Mx | 56.6 µWb |

| Pc Coefficient | 0.37 | Low (Flat) |

Table 11: Physics of underwater searching

MW 15x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.22 kg | Standard |

| Water (riverbed) |

4.83 kg

(+0.61 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet holds just ~20% of its perpendicular strength.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.37

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more products

Strengths and weaknesses of rare earth magnets.

Pros

- They retain magnetic properties for nearly ten years – the loss is just ~1% (based on simulations),

- They possess excellent resistance to magnetism drop as a result of external magnetic sources,

- Thanks to the reflective finish, the plating of nickel, gold, or silver-plated gives an elegant appearance,

- Neodymium magnets create maximum magnetic induction on a small surface, which ensures high operational effectiveness,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Possibility of precise machining and adjusting to complex conditions,

- Versatile presence in advanced technology sectors – they are commonly used in HDD drives, brushless drives, advanced medical instruments, and other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- To avoid cracks upon strong impacts, we recommend using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They oxidize in a humid environment - during use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Due to limitations in realizing threads and complicated shapes in magnets, we propose using a housing - magnetic mechanism.

- Possible danger related to microscopic parts of magnets can be dangerous, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that tiny parts of these magnets are able to be problematic in diagnostics medical when they are in the body.

- Due to expensive raw materials, their price is relatively high,

Pull force analysis

Maximum lifting force for a neodymium magnet – what contributes to it?

- using a base made of high-permeability steel, serving as a circuit closing element

- whose transverse dimension is min. 10 mm

- characterized by lack of roughness

- under conditions of ideal adhesion (metal-to-metal)

- during detachment in a direction perpendicular to the mounting surface

- in stable room temperature

Lifting capacity in practice – influencing factors

- Clearance – the presence of foreign body (paint, dirt, air) interrupts the magnetic circuit, which lowers capacity rapidly (even by 50% at 0.5 mm).

- Force direction – declared lifting capacity refers to detachment vertically. When slipping, the magnet exhibits much less (often approx. 20-30% of nominal force).

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of generating force.

- Steel grade – ideal substrate is high-permeability steel. Stainless steels may have worse magnetic properties.

- Surface condition – smooth surfaces guarantee perfect abutment, which improves force. Rough surfaces weaken the grip.

- Temperature influence – high temperature weakens pulling force. Too high temperature can permanently damage the magnet.

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under shearing force the load capacity is reduced by as much as 75%. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the load capacity.

Precautions when working with neodymium magnets

Thermal limits

Avoid heat. Neodymium magnets are sensitive to temperature. If you need operation above 80°C, inquire about special high-temperature series (H, SH, UH).

Keep away from electronics

A strong magnetic field negatively affects the operation of magnetometers in smartphones and navigation systems. Keep magnets close to a smartphone to avoid damaging the sensors.

Danger to the youngest

NdFeB magnets are not toys. Accidental ingestion of a few magnets can lead to them connecting inside the digestive tract, which constitutes a direct threat to life and requires urgent medical intervention.

Serious injuries

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Eye protection

Despite metallic appearance, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into hazardous fragments.

Do not underestimate power

Be careful. Rare earth magnets attract from a long distance and connect with huge force, often quicker than you can move away.

Skin irritation risks

It is widely known that the nickel plating (the usual finish) is a common allergen. If you have an allergy, prevent direct skin contact or choose coated magnets.

Life threat

Warning for patients: Strong magnetic fields disrupt medical devices. Maintain at least 30 cm distance or ask another person to handle the magnets.

Cards and drives

Very strong magnetic fields can destroy records on credit cards, hard drives, and other magnetic media. Keep a distance of at least 10 cm.

Dust explosion hazard

Mechanical processing of neodymium magnets poses a fire risk. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

![UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-29x8-m4-gw-duf.jpg)

![SM 32x200 [2xM8] / N52 - magnetic separator SM 32x200 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-tus.jpg)