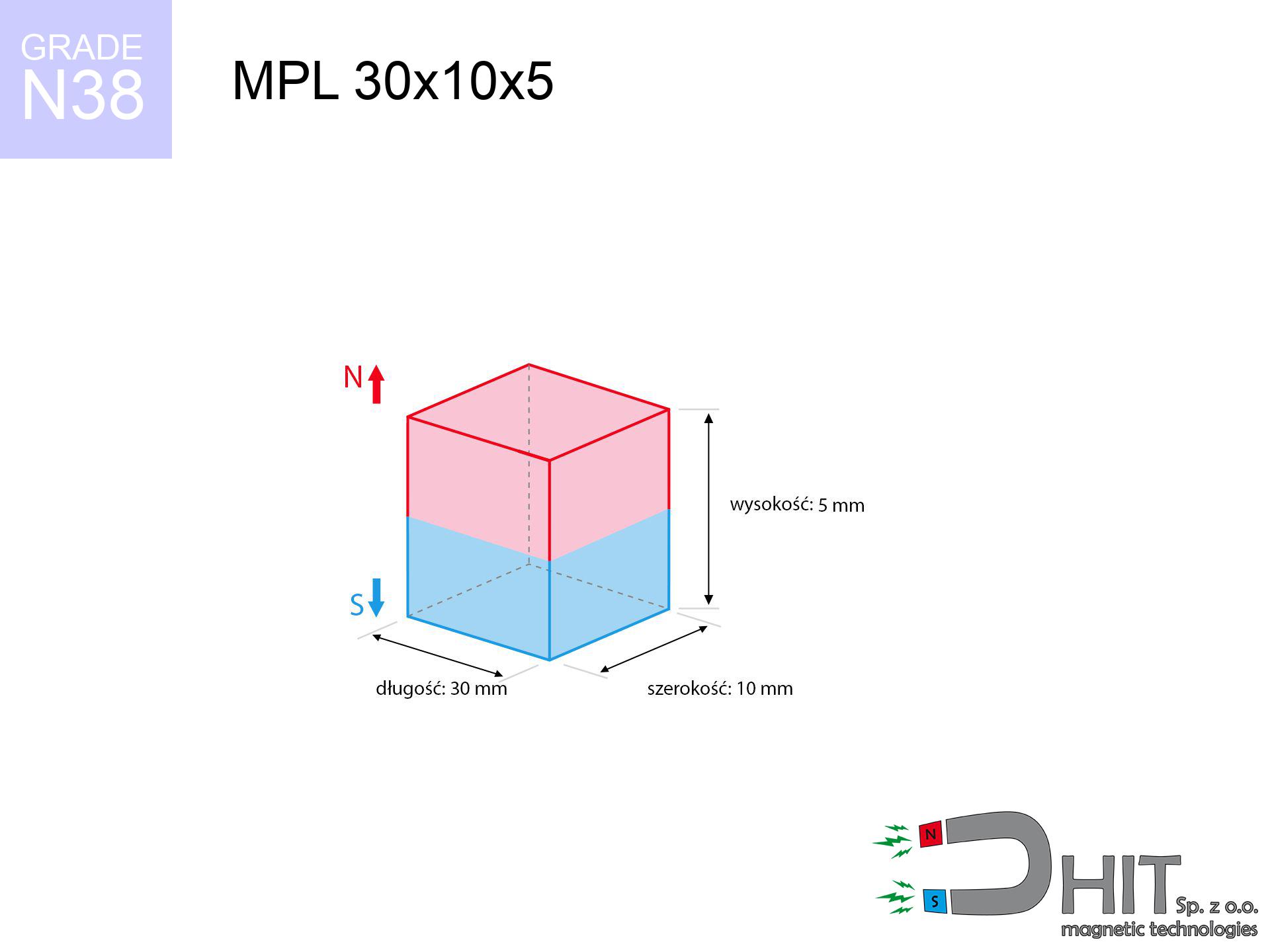

MPL 30x10x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020138

GTIN/EAN: 5906301811442

length

30 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

11.25 g

Magnetization Direction

↑ axial

Load capacity

8.89 kg / 87.23 N

Magnetic Induction

329.52 mT / 3295 Gs

Coating

[NiCuNi] Nickel

4.26 ZŁ with VAT / pcs + price for transport

3.46 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

or get in touch using

inquiry form

the contact section.

Lifting power as well as form of a neodymium magnet can be reviewed using our

online calculation tool.

Same-day processing for orders placed before 14:00.

Technical - MPL 30x10x5 / N38 - lamellar magnet

Specification / characteristics - MPL 30x10x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020138 |

| GTIN/EAN | 5906301811442 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 30 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 11.25 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 8.89 kg / 87.23 N |

| Magnetic Induction ~ ? | 329.52 mT / 3295 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - data

Presented values constitute the result of a physical simulation. Results were calculated on algorithms for the class Nd2Fe14B. Operational performance may differ. Please consider these calculations as a preliminary roadmap when designing systems.

Table 1: Static force (pull vs distance) - characteristics

MPL 30x10x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3294 Gs

329.4 mT

|

8.89 kg / 19.60 pounds

8890.0 g / 87.2 N

|

warning |

| 1 mm |

2866 Gs

286.6 mT

|

6.73 kg / 14.84 pounds

6731.1 g / 66.0 N

|

warning |

| 2 mm |

2424 Gs

242.4 mT

|

4.82 kg / 10.62 pounds

4816.4 g / 47.2 N

|

warning |

| 3 mm |

2022 Gs

202.2 mT

|

3.35 kg / 7.38 pounds

3349.6 g / 32.9 N

|

warning |

| 5 mm |

1397 Gs

139.7 mT

|

1.60 kg / 3.53 pounds

1600.3 g / 15.7 N

|

safe |

| 10 mm |

615 Gs

61.5 mT

|

0.31 kg / 0.68 pounds

309.8 g / 3.0 N

|

safe |

| 15 mm |

314 Gs

31.4 mT

|

0.08 kg / 0.18 pounds

80.6 g / 0.8 N

|

safe |

| 20 mm |

177 Gs

17.7 mT

|

0.03 kg / 0.06 pounds

25.8 g / 0.3 N

|

safe |

| 30 mm |

70 Gs

7.0 mT

|

0.00 kg / 0.01 pounds

4.1 g / 0.0 N

|

safe |

| 50 mm |

19 Gs

1.9 mT

|

0.00 kg / 0.00 pounds

0.3 g / 0.0 N

|

safe |

Table 2: Vertical force (wall)

MPL 30x10x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.78 kg / 3.92 pounds

1778.0 g / 17.4 N

|

| 1 mm | Stal (~0.2) |

1.35 kg / 2.97 pounds

1346.0 g / 13.2 N

|

| 2 mm | Stal (~0.2) |

0.96 kg / 2.13 pounds

964.0 g / 9.5 N

|

| 3 mm | Stal (~0.2) |

0.67 kg / 1.48 pounds

670.0 g / 6.6 N

|

| 5 mm | Stal (~0.2) |

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

| 10 mm | Stal (~0.2) |

0.06 kg / 0.14 pounds

62.0 g / 0.6 N

|

| 15 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

16.0 g / 0.2 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MPL 30x10x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.67 kg / 5.88 pounds

2667.0 g / 26.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.78 kg / 3.92 pounds

1778.0 g / 17.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.89 kg / 1.96 pounds

889.0 g / 8.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.45 kg / 9.80 pounds

4445.0 g / 43.6 N

|

Table 4: Material efficiency (saturation) - power losses

MPL 30x10x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.89 kg / 1.96 pounds

889.0 g / 8.7 N

|

| 1 mm |

|

2.22 kg / 4.90 pounds

2222.5 g / 21.8 N

|

| 2 mm |

|

4.45 kg / 9.80 pounds

4445.0 g / 43.6 N

|

| 3 mm |

|

6.67 kg / 14.70 pounds

6667.5 g / 65.4 N

|

| 5 mm |

|

8.89 kg / 19.60 pounds

8890.0 g / 87.2 N

|

| 10 mm |

|

8.89 kg / 19.60 pounds

8890.0 g / 87.2 N

|

| 11 mm |

|

8.89 kg / 19.60 pounds

8890.0 g / 87.2 N

|

| 12 mm |

|

8.89 kg / 19.60 pounds

8890.0 g / 87.2 N

|

Table 5: Working in heat (stability) - power drop

MPL 30x10x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

8.89 kg / 19.60 pounds

8890.0 g / 87.2 N

|

OK |

| 40 °C | -2.2% |

8.69 kg / 19.17 pounds

8694.4 g / 85.3 N

|

OK |

| 60 °C | -4.4% |

8.50 kg / 18.74 pounds

8498.8 g / 83.4 N

|

|

| 80 °C | -6.6% |

8.30 kg / 18.31 pounds

8303.3 g / 81.5 N

|

|

| 100 °C | -28.8% |

6.33 kg / 13.95 pounds

6329.7 g / 62.1 N

|

Table 6: Two magnets (repulsion) - field range

MPL 30x10x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

20.06 kg / 44.23 pounds

4 689 Gs

|

3.01 kg / 6.63 pounds

3010 g / 29.5 N

|

N/A |

| 1 mm |

17.63 kg / 38.86 pounds

6 174 Gs

|

2.64 kg / 5.83 pounds

2644 g / 25.9 N

|

15.86 kg / 34.98 pounds

~0 Gs

|

| 2 mm |

15.19 kg / 33.49 pounds

5 732 Gs

|

2.28 kg / 5.02 pounds

2279 g / 22.4 N

|

13.67 kg / 30.14 pounds

~0 Gs

|

| 3 mm |

12.92 kg / 28.47 pounds

5 285 Gs

|

1.94 kg / 4.27 pounds

1937 g / 19.0 N

|

11.62 kg / 25.63 pounds

~0 Gs

|

| 5 mm |

9.08 kg / 20.03 pounds

4 432 Gs

|

1.36 kg / 3.00 pounds

1363 g / 13.4 N

|

8.18 kg / 18.02 pounds

~0 Gs

|

| 10 mm |

3.61 kg / 7.96 pounds

2 795 Gs

|

0.54 kg / 1.19 pounds

542 g / 5.3 N

|

3.25 kg / 7.17 pounds

~0 Gs

|

| 20 mm |

0.70 kg / 1.54 pounds

1 230 Gs

|

0.10 kg / 0.23 pounds

105 g / 1.0 N

|

0.63 kg / 1.39 pounds

~0 Gs

|

| 50 mm |

0.02 kg / 0.05 pounds

217 Gs

|

0.00 kg / 0.01 pounds

3 g / 0.0 N

|

0.02 kg / 0.04 pounds

~0 Gs

|

| 60 mm |

0.01 kg / 0.02 pounds

141 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 pounds

96 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

68 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

50 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

38 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 30x10x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 5.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (cracking risk) - warning

MPL 30x10x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.96 km/h

(8.04 m/s)

|

0.36 J | |

| 30 mm |

49.12 km/h

(13.64 m/s)

|

1.05 J | |

| 50 mm |

63.39 km/h

(17.61 m/s)

|

1.74 J | |

| 100 mm |

89.65 km/h

(24.90 m/s)

|

3.49 J |

Table 9: Coating parameters (durability)

MPL 30x10x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 30x10x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 9 370 Mx | 93.7 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 30x10x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 8.89 kg | Standard |

| Water (riverbed) |

10.18 kg

(+1.29 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet retains merely approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also deals

Strengths as well as weaknesses of neodymium magnets.

Advantages

- Their power is durable, and after approximately ten years it drops only by ~1% (according to research),

- They do not lose their magnetic properties even under strong external field,

- By covering with a lustrous coating of nickel, the element acquires an elegant look,

- Neodymium magnets ensure maximum magnetic induction on a small area, which ensures high operational effectiveness,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, enabling action at temperatures reaching 230°C and above...

- Possibility of custom creating as well as adapting to complex requirements,

- Huge importance in advanced technology sectors – they are utilized in data components, brushless drives, diagnostic systems, as well as modern systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- We suggest cover - magnetic holder, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Possible danger related to microscopic parts of magnets pose a threat, in case of ingestion, which gains importance in the context of child safety. Furthermore, tiny parts of these products are able to disrupt the diagnostic process medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which hinders application in large quantities

Holding force characteristics

Maximum lifting capacity of the magnet – what it depends on?

- using a plate made of low-carbon steel, functioning as a magnetic yoke

- with a cross-section minimum 10 mm

- with a surface free of scratches

- with zero gap (without paint)

- during pulling in a direction perpendicular to the mounting surface

- at temperature approx. 20 degrees Celsius

What influences lifting capacity in practice

- Space between magnet and steel – every millimeter of separation (caused e.g. by varnish or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Steel thickness – insufficiently thick steel causes magnetic saturation, causing part of the power to be wasted into the air.

- Chemical composition of the base – low-carbon steel gives the best results. Alloy steels reduce magnetic permeability and holding force.

- Surface structure – the smoother and more polished the surface, the larger the contact zone and stronger the hold. Roughness acts like micro-gaps.

- Temperature influence – hot environment reduces pulling force. Too high temperature can permanently damage the magnet.

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, in contrast under parallel forces the holding force is lower. In addition, even a small distance between the magnet and the plate decreases the holding force.

Safety rules for work with NdFeB magnets

Allergic reactions

Some people experience a contact allergy to nickel, which is the standard coating for NdFeB magnets. Prolonged contact may cause a rash. It is best to use safety gloves.

GPS and phone interference

GPS units and smartphones are extremely sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can permanently damage the sensors in your phone.

Medical implants

Medical warning: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Fire warning

Mechanical processing of neodymium magnets carries a risk of fire hazard. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Permanent damage

Do not overheat. Neodymium magnets are sensitive to temperature. If you need resistance above 80°C, inquire about HT versions (H, SH, UH).

Handling guide

Handle with care. Neodymium magnets attract from a distance and connect with huge force, often quicker than you can react.

Physical harm

Mind your fingers. Two large magnets will join instantly with a force of several hundred kilograms, destroying anything in their path. Be careful!

Electronic devices

Powerful magnetic fields can corrupt files on credit cards, HDDs, and storage devices. Keep a distance of at least 10 cm.

Eye protection

Watch out for shards. Magnets can explode upon uncontrolled impact, launching shards into the air. We recommend safety glasses.

Danger to the youngest

These products are not intended for children. Eating several magnets may result in them pinching intestinal walls, which constitutes a critical condition and requires urgent medical intervention.

![UMGGZ 22x6 [M4] GZ / N38 - rubber magnetic holder external thread UMGGZ 22x6 [M4] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gz-hiw.jpg)

![SM 32x375 [2xM8] / N52 - magnetic separator SM 32x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-mif.jpg)