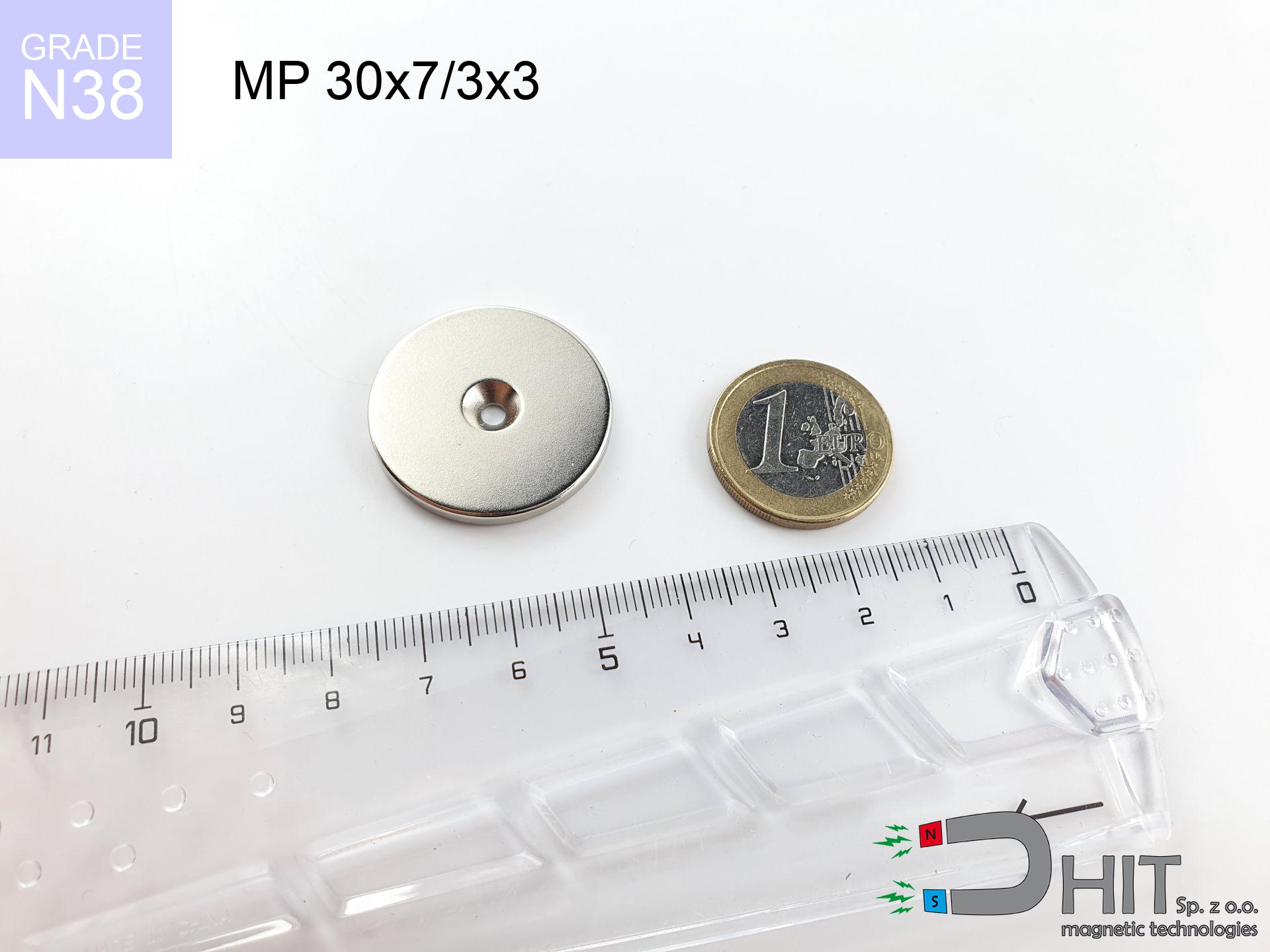

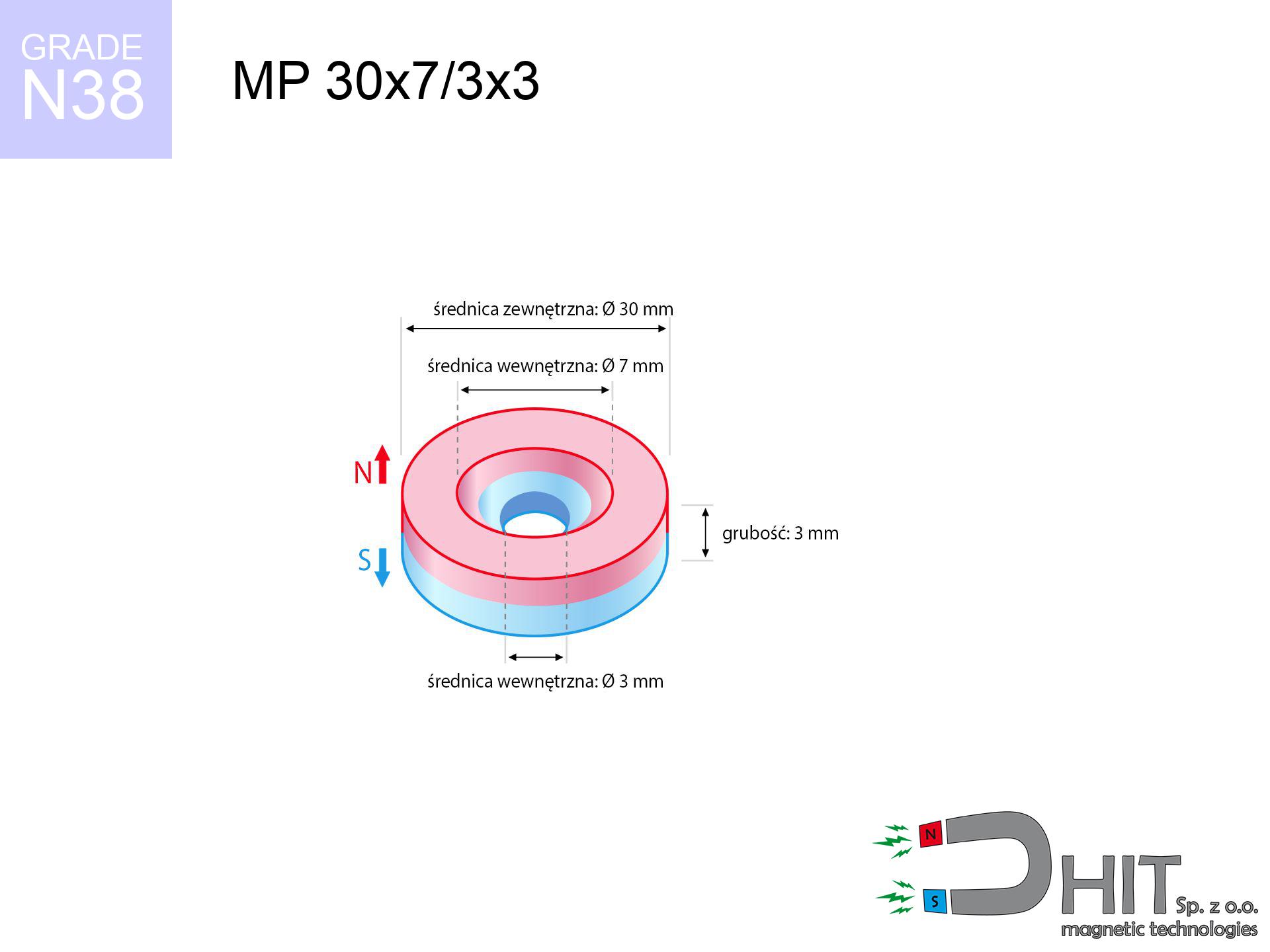

MP 30x7/3x3 / N38 - ring magnet

ring magnet

Catalog no 030250

GTIN/EAN: 5906301812265

Diameter

30 mm [±0,1 mm]

internal diameter Ø

7/3 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

15.75 g

Magnetization Direction

↑ axial

Load capacity

3.64 kg / 35.69 N

Magnetic Induction

121.58 mT / 1216 Gs

Coating

[NiCuNi] Nickel

6.84 ZŁ with VAT / pcs + price for transport

5.56 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

if you prefer drop us a message using

request form

the contact page.

Force as well as form of a neodymium magnet can be tested with our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical details - MP 30x7/3x3 / N38 - ring magnet

Specification / characteristics - MP 30x7/3x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030250 |

| GTIN/EAN | 5906301812265 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 30 mm [±0,1 mm] |

| internal diameter Ø | 7/3 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 15.75 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.64 kg / 35.69 N |

| Magnetic Induction ~ ? | 121.58 mT / 1216 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - report

These information represent the outcome of a physical analysis. Values rely on algorithms for the class Nd2Fe14B. Actual conditions might slightly differ. Please consider these data as a reference point for designers.

Table 1: Static force (pull vs gap) - interaction chart

MP 30x7/3x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1039 Gs

103.9 mT

|

3.64 kg / 8.02 pounds

3640.0 g / 35.7 N

|

medium risk |

| 1 mm |

1015 Gs

101.5 mT

|

3.48 kg / 7.67 pounds

3477.6 g / 34.1 N

|

medium risk |

| 2 mm |

980 Gs

98.0 mT

|

3.24 kg / 7.14 pounds

3240.7 g / 31.8 N

|

medium risk |

| 3 mm |

936 Gs

93.6 mT

|

2.95 kg / 6.51 pounds

2951.6 g / 29.0 N

|

medium risk |

| 5 mm |

827 Gs

82.7 mT

|

2.31 kg / 5.08 pounds

2305.8 g / 22.6 N

|

medium risk |

| 10 mm |

539 Gs

53.9 mT

|

0.98 kg / 2.16 pounds

981.0 g / 9.6 N

|

low risk |

| 15 mm |

329 Gs

32.9 mT

|

0.37 kg / 0.80 pounds

365.1 g / 3.6 N

|

low risk |

| 20 mm |

202 Gs

20.2 mT

|

0.14 kg / 0.30 pounds

137.9 g / 1.4 N

|

low risk |

| 30 mm |

85 Gs

8.5 mT

|

0.02 kg / 0.05 pounds

24.6 g / 0.2 N

|

low risk |

| 50 mm |

23 Gs

2.3 mT

|

0.00 kg / 0.00 pounds

1.8 g / 0.0 N

|

low risk |

Table 2: Slippage load (wall)

MP 30x7/3x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.73 kg / 1.60 pounds

728.0 g / 7.1 N

|

| 1 mm | Stal (~0.2) |

0.70 kg / 1.53 pounds

696.0 g / 6.8 N

|

| 2 mm | Stal (~0.2) |

0.65 kg / 1.43 pounds

648.0 g / 6.4 N

|

| 3 mm | Stal (~0.2) |

0.59 kg / 1.30 pounds

590.0 g / 5.8 N

|

| 5 mm | Stal (~0.2) |

0.46 kg / 1.02 pounds

462.0 g / 4.5 N

|

| 10 mm | Stal (~0.2) |

0.20 kg / 0.43 pounds

196.0 g / 1.9 N

|

| 15 mm | Stal (~0.2) |

0.07 kg / 0.16 pounds

74.0 g / 0.7 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.06 pounds

28.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 30x7/3x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.09 kg / 2.41 pounds

1092.0 g / 10.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.73 kg / 1.60 pounds

728.0 g / 7.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.36 kg / 0.80 pounds

364.0 g / 3.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.82 kg / 4.01 pounds

1820.0 g / 17.9 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 30x7/3x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.36 kg / 0.80 pounds

364.0 g / 3.6 N

|

| 1 mm |

|

0.91 kg / 2.01 pounds

910.0 g / 8.9 N

|

| 2 mm |

|

1.82 kg / 4.01 pounds

1820.0 g / 17.9 N

|

| 3 mm |

|

2.73 kg / 6.02 pounds

2730.0 g / 26.8 N

|

| 5 mm |

|

3.64 kg / 8.02 pounds

3640.0 g / 35.7 N

|

| 10 mm |

|

3.64 kg / 8.02 pounds

3640.0 g / 35.7 N

|

| 11 mm |

|

3.64 kg / 8.02 pounds

3640.0 g / 35.7 N

|

| 12 mm |

|

3.64 kg / 8.02 pounds

3640.0 g / 35.7 N

|

Table 5: Thermal resistance (stability) - power drop

MP 30x7/3x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.64 kg / 8.02 pounds

3640.0 g / 35.7 N

|

OK |

| 40 °C | -2.2% |

3.56 kg / 7.85 pounds

3559.9 g / 34.9 N

|

OK |

| 60 °C | -4.4% |

3.48 kg / 7.67 pounds

3479.8 g / 34.1 N

|

|

| 80 °C | -6.6% |

3.40 kg / 7.50 pounds

3399.8 g / 33.4 N

|

|

| 100 °C | -28.8% |

2.59 kg / 5.71 pounds

2591.7 g / 25.4 N

|

Table 6: Two magnets (attraction) - forces in the system

MP 30x7/3x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.96 kg / 8.73 pounds

1 995 Gs

|

0.59 kg / 1.31 pounds

594 g / 5.8 N

|

N/A |

| 1 mm |

3.88 kg / 8.56 pounds

2 058 Gs

|

0.58 kg / 1.28 pounds

582 g / 5.7 N

|

3.49 kg / 7.70 pounds

~0 Gs

|

| 2 mm |

3.78 kg / 8.34 pounds

2 031 Gs

|

0.57 kg / 1.25 pounds

567 g / 5.6 N

|

3.40 kg / 7.50 pounds

~0 Gs

|

| 3 mm |

3.66 kg / 8.07 pounds

1 998 Gs

|

0.55 kg / 1.21 pounds

549 g / 5.4 N

|

3.30 kg / 7.26 pounds

~0 Gs

|

| 5 mm |

3.37 kg / 7.43 pounds

1 918 Gs

|

0.51 kg / 1.12 pounds

506 g / 5.0 N

|

3.04 kg / 6.69 pounds

~0 Gs

|

| 10 mm |

2.51 kg / 5.53 pounds

1 654 Gs

|

0.38 kg / 0.83 pounds

376 g / 3.7 N

|

2.26 kg / 4.97 pounds

~0 Gs

|

| 20 mm |

1.07 kg / 2.35 pounds

1 079 Gs

|

0.16 kg / 0.35 pounds

160 g / 1.6 N

|

0.96 kg / 2.12 pounds

~0 Gs

|

| 50 mm |

0.06 kg / 0.13 pounds

258 Gs

|

0.01 kg / 0.02 pounds

9 g / 0.1 N

|

0.05 kg / 0.12 pounds

~0 Gs

|

| 60 mm |

0.03 kg / 0.06 pounds

171 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 70 mm |

0.01 kg / 0.03 pounds

118 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

| 80 mm |

0.01 kg / 0.01 pounds

84 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.01 pounds

62 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

47 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MP 30x7/3x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 9.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 5.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.5 cm |

| Car key | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MP 30x7/3x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.73 km/h

(4.92 m/s)

|

0.19 J | |

| 30 mm |

26.67 km/h

(7.41 m/s)

|

0.43 J | |

| 50 mm |

34.29 km/h

(9.53 m/s)

|

0.71 J | |

| 100 mm |

48.48 km/h

(13.47 m/s)

|

1.43 J |

Table 9: Corrosion resistance

MP 30x7/3x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 30x7/3x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 8 395 Mx | 84.0 µWb |

| Pc Coefficient | 0.13 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MP 30x7/3x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.64 kg | Standard |

| Water (riverbed) |

4.17 kg

(+0.53 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds only ~20% of its nominal pull.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Power loss vs temp

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.13

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths and weaknesses of rare earth magnets.

Pros

- They retain magnetic properties for nearly ten years – the drop is just ~1% (according to analyses),

- They are noted for resistance to demagnetization induced by external field influence,

- By covering with a reflective layer of nickel, the element acquires an professional look,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a distinguishing feature,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to flexibility in constructing and the capacity to adapt to specific needs,

- Huge importance in future technologies – they find application in mass storage devices, brushless drives, precision medical tools, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which makes them useful in small systems

Disadvantages

- To avoid cracks upon strong impacts, we suggest using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- NdFeB magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- We recommend a housing - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complicated shapes.

- Potential hazard to health – tiny shards of magnets can be dangerous, in case of ingestion, which is particularly important in the context of child safety. It is also worth noting that small components of these devices can disrupt the diagnostic process medical when they are in the body.

- With budget limitations the cost of neodymium magnets is economically unviable,

Pull force analysis

Detachment force of the magnet in optimal conditions – what affects it?

- with the application of a yoke made of special test steel, ensuring maximum field concentration

- possessing a massiveness of at least 10 mm to avoid saturation

- characterized by even structure

- with total lack of distance (no paint)

- for force acting at a right angle (pull-off, not shear)

- at ambient temperature approx. 20 degrees Celsius

What influences lifting capacity in practice

- Distance – the presence of any layer (rust, tape, gap) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Load vector – maximum parameter is available only during pulling at a 90° angle. The shear force of the magnet along the plate is typically several times smaller (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Steel type – mild steel gives the best results. Alloy steels reduce magnetic properties and holding force.

- Surface structure – the more even the surface, the larger the contact zone and higher the lifting capacity. Unevenness acts like micro-gaps.

- Thermal factor – hot environment weakens pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity testing was conducted on a smooth plate of optimal thickness, under perpendicular forces, in contrast under parallel forces the holding force is lower. Moreover, even a slight gap between the magnet and the plate lowers the holding force.

Precautions when working with NdFeB magnets

Magnets are brittle

Neodymium magnets are ceramic materials, which means they are prone to chipping. Clashing of two magnets leads to them breaking into small pieces.

Do not underestimate power

Handle magnets consciously. Their powerful strength can surprise even professionals. Stay alert and do not underestimate their power.

Bodily injuries

Risk of injury: The attraction force is so immense that it can cause blood blisters, crushing, and broken bones. Protective gloves are recommended.

Product not for children

Absolutely keep magnets out of reach of children. Ingestion danger is high, and the effects of magnets connecting inside the body are very dangerous.

Thermal limits

Do not overheat. Neodymium magnets are susceptible to temperature. If you need resistance above 80°C, inquire about HT versions (H, SH, UH).

Nickel coating and allergies

It is widely known that the nickel plating (standard magnet coating) is a potent allergen. If your skin reacts to metals, refrain from touching magnets with bare hands and opt for coated magnets.

Phone sensors

A powerful magnetic field negatively affects the functioning of magnetometers in smartphones and GPS navigation. Keep magnets near a device to avoid damaging the sensors.

Machining danger

Machining of NdFeB material poses a fire hazard. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

ICD Warning

For implant holders: Strong magnetic fields disrupt electronics. Maintain minimum 30 cm distance or ask another person to handle the magnets.

Data carriers

Very strong magnetic fields can destroy records on credit cards, hard drives, and storage devices. Stay away of at least 10 cm.