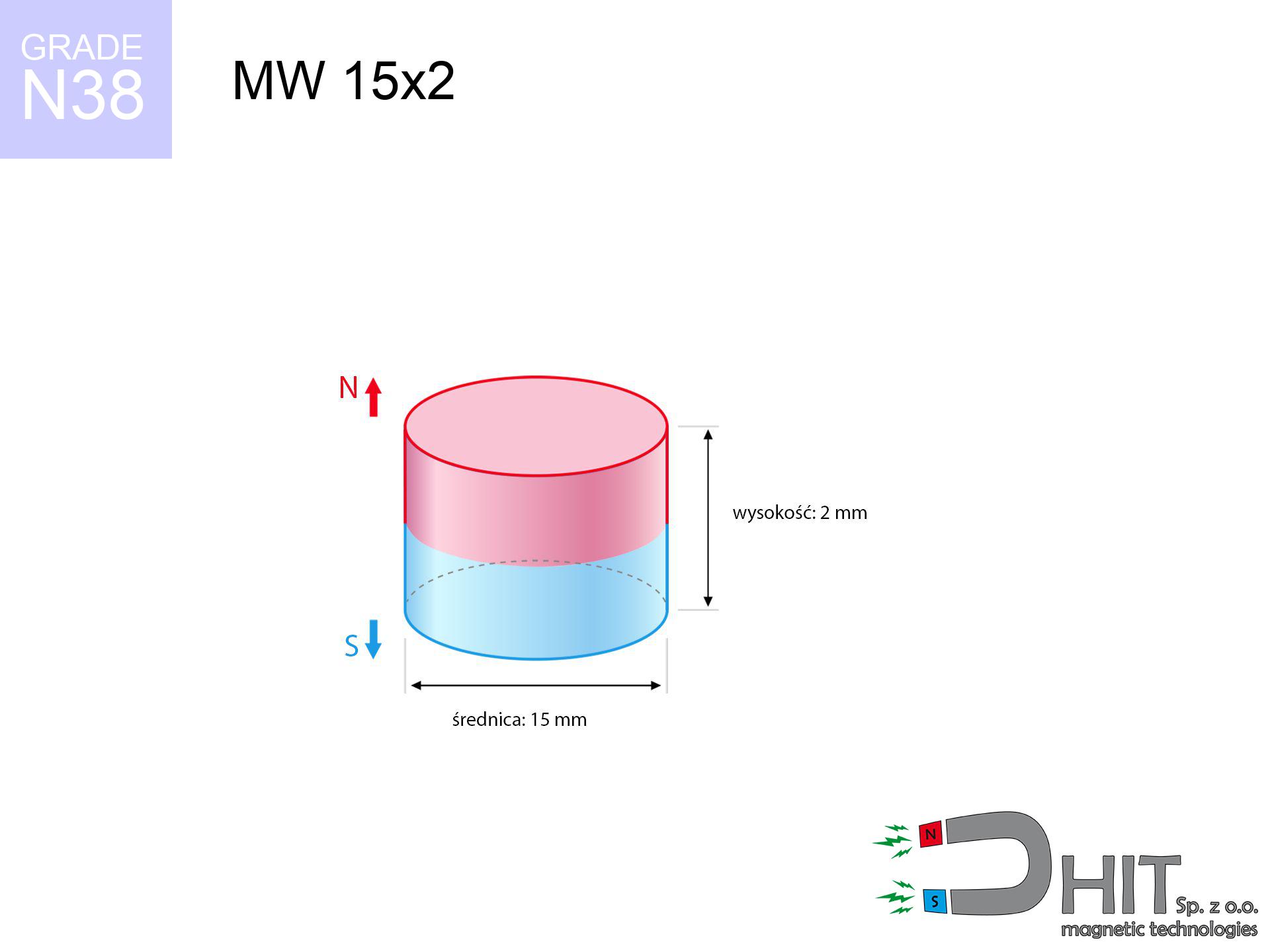

MW 15x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010028

GTIN/EAN: 5906301810278

Diameter Ø

15 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

2.65 g

Magnetization Direction

↑ axial

Load capacity

1.51 kg / 14.84 N

Magnetic Induction

159.70 mT / 1597 Gs

Coating

[NiCuNi] Nickel

1.218 ZŁ with VAT / pcs + price for transport

0.990 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer let us know via

inquiry form

the contact section.

Parameters as well as appearance of a magnet can be checked on our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MW 15x2 / N38 - cylindrical magnet

Specification / characteristics - MW 15x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010028 |

| GTIN/EAN | 5906301810278 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 15 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 2.65 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.51 kg / 14.84 N |

| Magnetic Induction ~ ? | 159.70 mT / 1597 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the assembly - technical parameters

The following values are the outcome of a engineering calculation. Results are based on algorithms for the material Nd2Fe14B. Actual parameters may deviate from the simulation results. Please consider these data as a reference point when designing systems.

Table 1: Static pull force (pull vs distance) - characteristics

MW 15x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1597 Gs

159.7 mT

|

1.51 kg / 3.33 lbs

1510.0 g / 14.8 N

|

weak grip |

| 1 mm |

1483 Gs

148.3 mT

|

1.30 kg / 2.87 lbs

1303.0 g / 12.8 N

|

weak grip |

| 2 mm |

1320 Gs

132.0 mT

|

1.03 kg / 2.28 lbs

1032.2 g / 10.1 N

|

weak grip |

| 3 mm |

1137 Gs

113.7 mT

|

0.77 kg / 1.69 lbs

765.0 g / 7.5 N

|

weak grip |

| 5 mm |

791 Gs

79.1 mT

|

0.37 kg / 0.82 lbs

370.8 g / 3.6 N

|

weak grip |

| 10 mm |

298 Gs

29.8 mT

|

0.05 kg / 0.12 lbs

52.5 g / 0.5 N

|

weak grip |

| 15 mm |

127 Gs

12.7 mT

|

0.01 kg / 0.02 lbs

9.6 g / 0.1 N

|

weak grip |

| 20 mm |

63 Gs

6.3 mT

|

0.00 kg / 0.01 lbs

2.4 g / 0.0 N

|

weak grip |

| 30 mm |

22 Gs

2.2 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

weak grip |

| 50 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Vertical hold (wall)

MW 15x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.30 kg / 0.67 lbs

302.0 g / 3.0 N

|

| 1 mm | Stal (~0.2) |

0.26 kg / 0.57 lbs

260.0 g / 2.6 N

|

| 2 mm | Stal (~0.2) |

0.21 kg / 0.45 lbs

206.0 g / 2.0 N

|

| 3 mm | Stal (~0.2) |

0.15 kg / 0.34 lbs

154.0 g / 1.5 N

|

| 5 mm | Stal (~0.2) |

0.07 kg / 0.16 lbs

74.0 g / 0.7 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 15x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.45 kg / 1.00 lbs

453.0 g / 4.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.30 kg / 0.67 lbs

302.0 g / 3.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.15 kg / 0.33 lbs

151.0 g / 1.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.76 kg / 1.66 lbs

755.0 g / 7.4 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 15x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.15 kg / 0.33 lbs

151.0 g / 1.5 N

|

| 1 mm |

|

0.38 kg / 0.83 lbs

377.5 g / 3.7 N

|

| 2 mm |

|

0.76 kg / 1.66 lbs

755.0 g / 7.4 N

|

| 3 mm |

|

1.13 kg / 2.50 lbs

1132.5 g / 11.1 N

|

| 5 mm |

|

1.51 kg / 3.33 lbs

1510.0 g / 14.8 N

|

| 10 mm |

|

1.51 kg / 3.33 lbs

1510.0 g / 14.8 N

|

| 11 mm |

|

1.51 kg / 3.33 lbs

1510.0 g / 14.8 N

|

| 12 mm |

|

1.51 kg / 3.33 lbs

1510.0 g / 14.8 N

|

Table 5: Working in heat (material behavior) - thermal limit

MW 15x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.51 kg / 3.33 lbs

1510.0 g / 14.8 N

|

OK |

| 40 °C | -2.2% |

1.48 kg / 3.26 lbs

1476.8 g / 14.5 N

|

OK |

| 60 °C | -4.4% |

1.44 kg / 3.18 lbs

1443.6 g / 14.2 N

|

|

| 80 °C | -6.6% |

1.41 kg / 3.11 lbs

1410.3 g / 13.8 N

|

|

| 100 °C | -28.8% |

1.08 kg / 2.37 lbs

1075.1 g / 10.5 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 15x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.78 kg / 6.12 lbs

2 915 Gs

|

0.42 kg / 0.92 lbs

417 g / 4.1 N

|

N/A |

| 1 mm |

2.61 kg / 5.76 lbs

3 096 Gs

|

0.39 kg / 0.86 lbs

392 g / 3.8 N

|

2.35 kg / 5.18 lbs

~0 Gs

|

| 2 mm |

2.40 kg / 5.28 lbs

2 966 Gs

|

0.36 kg / 0.79 lbs

360 g / 3.5 N

|

2.16 kg / 4.76 lbs

~0 Gs

|

| 3 mm |

2.15 kg / 4.75 lbs

2 812 Gs

|

0.32 kg / 0.71 lbs

323 g / 3.2 N

|

1.94 kg / 4.27 lbs

~0 Gs

|

| 5 mm |

1.65 kg / 3.63 lbs

2 459 Gs

|

0.25 kg / 0.54 lbs

247 g / 2.4 N

|

1.48 kg / 3.27 lbs

~0 Gs

|

| 10 mm |

0.68 kg / 1.50 lbs

1 582 Gs

|

0.10 kg / 0.23 lbs

102 g / 1.0 N

|

0.61 kg / 1.35 lbs

~0 Gs

|

| 20 mm |

0.10 kg / 0.21 lbs

595 Gs

|

0.01 kg / 0.03 lbs

14 g / 0.1 N

|

0.09 kg / 0.19 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

71 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

43 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

28 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

19 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

14 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

10 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MW 15x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - warning

MW 15x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.59 km/h

(6.83 m/s)

|

0.06 J | |

| 30 mm |

41.70 km/h

(11.58 m/s)

|

0.18 J | |

| 50 mm |

53.83 km/h

(14.95 m/s)

|

0.30 J | |

| 100 mm |

76.13 km/h

(21.15 m/s)

|

0.59 J |

Table 9: Anti-corrosion coating durability

MW 15x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 15x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 541 Mx | 35.4 µWb |

| Pc Coefficient | 0.20 | Low (Flat) |

Table 11: Submerged application

MW 15x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.51 kg | Standard |

| Water (riverbed) |

1.73 kg

(+0.22 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet retains just ~20% of its nominal pull.

2. Steel saturation

*Thin steel (e.g. computer case) severely reduces the holding force.

3. Temperature resistance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.20

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros and cons of rare earth magnets.

Advantages

- They virtually do not lose power, because even after 10 years the decline in efficiency is only ~1% (according to literature),

- They possess excellent resistance to weakening of magnetic properties when exposed to external fields,

- A magnet with a smooth gold surface looks better,

- The surface of neodymium magnets generates a strong magnetic field – this is a key feature,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Possibility of custom machining as well as modifying to atypical requirements,

- Fundamental importance in future technologies – they serve a role in computer drives, electromotive mechanisms, advanced medical instruments, and modern systems.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Limitations

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- We recommend cover - magnetic mount, due to difficulties in producing nuts inside the magnet and complex forms.

- Possible danger to health – tiny shards of magnets pose a threat, if swallowed, which gains importance in the context of child safety. Furthermore, tiny parts of these magnets can complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Maximum holding power of the magnet – what affects it?

- using a sheet made of mild steel, functioning as a circuit closing element

- whose transverse dimension is min. 10 mm

- with a surface perfectly flat

- with direct contact (without impurities)

- for force acting at a right angle (pull-off, not shear)

- at conditions approx. 20°C

Impact of factors on magnetic holding capacity in practice

- Clearance – existence of any layer (rust, tape, gap) acts as an insulator, which reduces power steeply (even by 50% at 0.5 mm).

- Angle of force application – maximum parameter is available only during pulling at a 90° angle. The force required to slide of the magnet along the surface is usually many times lower (approx. 1/5 of the lifting capacity).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Steel type – mild steel gives the best results. Higher carbon content reduce magnetic permeability and holding force.

- Surface condition – smooth surfaces ensure maximum contact, which increases force. Uneven metal weaken the grip.

- Thermal factor – high temperature reduces pulling force. Exceeding the limit temperature can permanently damage the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under shearing force the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet and the plate decreases the lifting capacity.

Safe handling of NdFeB magnets

Power loss in heat

Standard neodymium magnets (N-type) lose power when the temperature goes above 80°C. This process is irreversible.

Precision electronics

Navigation devices and mobile phones are extremely susceptible to magnetism. Close proximity with a powerful NdFeB magnet can decalibrate the internal compass in your phone.

Danger to the youngest

Only for adults. Tiny parts can be swallowed, leading to intestinal necrosis. Store away from children and animals.

Health Danger

People with a ICD have to maintain an large gap from magnets. The magnetism can interfere with the functioning of the life-saving device.

Dust is flammable

Dust produced during machining of magnets is flammable. Do not drill into magnets unless you are an expert.

Serious injuries

Mind your fingers. Two large magnets will snap together immediately with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Nickel coating and allergies

Some people have a hypersensitivity to Ni, which is the typical protective layer for NdFeB magnets. Frequent touching may cause skin redness. We recommend use safety gloves.

Electronic devices

Device Safety: Strong magnets can damage data carriers and delicate electronics (heart implants, medical aids, mechanical watches).

Magnets are brittle

Protect your eyes. Magnets can fracture upon uncontrolled impact, launching shards into the air. Wear goggles.

Safe operation

Handle with care. Rare earth magnets attract from a long distance and connect with massive power, often quicker than you can react.