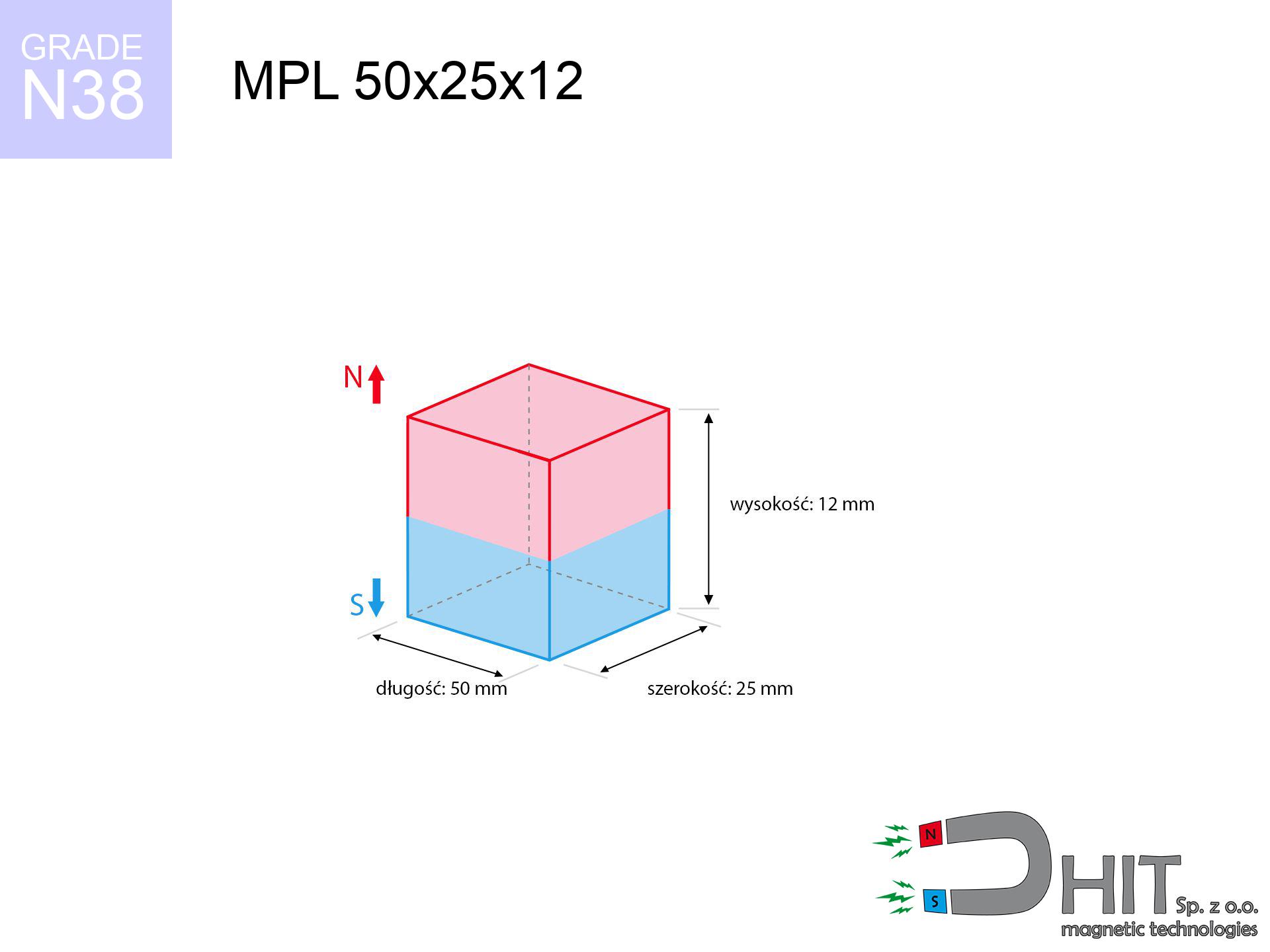

MPL 50x25x12 / N38 - lamellar magnet

lamellar magnet

Catalog no 020343

GTIN/EAN: 5906301811855

length

50 mm [±0,1 mm]

Width

25 mm [±0,1 mm]

Height

12 mm [±0,1 mm]

Weight

112.5 g

Magnetization Direction

↑ axial

Load capacity

37.12 kg / 364.18 N

Magnetic Induction

340.43 mT / 3404 Gs

Coating

[NiCuNi] Nickel

45.51 ZŁ with VAT / pcs + price for transport

37.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

or get in touch via

form

through our site.

Lifting power and shape of a neodymium magnet can be tested using our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Technical - MPL 50x25x12 / N38 - lamellar magnet

Specification / characteristics - MPL 50x25x12 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020343 |

| GTIN/EAN | 5906301811855 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±0,1 mm] |

| Width | 25 mm [±0,1 mm] |

| Height | 12 mm [±0,1 mm] |

| Weight | 112.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 37.12 kg / 364.18 N |

| Magnetic Induction ~ ? | 340.43 mT / 3404 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - technical parameters

Presented information represent the result of a mathematical calculation. Results rely on models for the class Nd2Fe14B. Actual conditions might slightly differ from theoretical values. Please consider these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (force vs distance) - characteristics

MPL 50x25x12 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3404 Gs

340.4 mT

|

37.12 kg / 81.84 LBS

37120.0 g / 364.1 N

|

critical level |

| 1 mm |

3234 Gs

323.4 mT

|

33.50 kg / 73.86 LBS

33501.5 g / 328.6 N

|

critical level |

| 2 mm |

3052 Gs

305.2 mT

|

29.85 kg / 65.80 LBS

29847.1 g / 292.8 N

|

critical level |

| 3 mm |

2866 Gs

286.6 mT

|

26.32 kg / 58.02 LBS

26317.3 g / 258.2 N

|

critical level |

| 5 mm |

2496 Gs

249.6 mT

|

19.97 kg / 44.02 LBS

19965.4 g / 195.9 N

|

critical level |

| 10 mm |

1702 Gs

170.2 mT

|

9.28 kg / 20.45 LBS

9278.2 g / 91.0 N

|

strong |

| 15 mm |

1151 Gs

115.1 mT

|

4.25 kg / 9.36 LBS

4246.0 g / 41.7 N

|

strong |

| 20 mm |

792 Gs

79.2 mT

|

2.01 kg / 4.44 LBS

2012.1 g / 19.7 N

|

strong |

| 30 mm |

404 Gs

40.4 mT

|

0.52 kg / 1.15 LBS

523.0 g / 5.1 N

|

safe |

| 50 mm |

137 Gs

13.7 mT

|

0.06 kg / 0.13 LBS

60.1 g / 0.6 N

|

safe |

Table 2: Shear load (vertical surface)

MPL 50x25x12 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

7.42 kg / 16.37 LBS

7424.0 g / 72.8 N

|

| 1 mm | Stal (~0.2) |

6.70 kg / 14.77 LBS

6700.0 g / 65.7 N

|

| 2 mm | Stal (~0.2) |

5.97 kg / 13.16 LBS

5970.0 g / 58.6 N

|

| 3 mm | Stal (~0.2) |

5.26 kg / 11.61 LBS

5264.0 g / 51.6 N

|

| 5 mm | Stal (~0.2) |

3.99 kg / 8.81 LBS

3994.0 g / 39.2 N

|

| 10 mm | Stal (~0.2) |

1.86 kg / 4.09 LBS

1856.0 g / 18.2 N

|

| 15 mm | Stal (~0.2) |

0.85 kg / 1.87 LBS

850.0 g / 8.3 N

|

| 20 mm | Stal (~0.2) |

0.40 kg / 0.89 LBS

402.0 g / 3.9 N

|

| 30 mm | Stal (~0.2) |

0.10 kg / 0.23 LBS

104.0 g / 1.0 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MPL 50x25x12 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

11.14 kg / 24.55 LBS

11136.0 g / 109.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

7.42 kg / 16.37 LBS

7424.0 g / 72.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

3.71 kg / 8.18 LBS

3712.0 g / 36.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

18.56 kg / 40.92 LBS

18560.0 g / 182.1 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 50x25x12 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.86 kg / 4.09 LBS

1856.0 g / 18.2 N

|

| 1 mm |

|

4.64 kg / 10.23 LBS

4640.0 g / 45.5 N

|

| 2 mm |

|

9.28 kg / 20.46 LBS

9280.0 g / 91.0 N

|

| 3 mm |

|

13.92 kg / 30.69 LBS

13920.0 g / 136.6 N

|

| 5 mm |

|

23.20 kg / 51.15 LBS

23200.0 g / 227.6 N

|

| 10 mm |

|

37.12 kg / 81.84 LBS

37120.0 g / 364.1 N

|

| 11 mm |

|

37.12 kg / 81.84 LBS

37120.0 g / 364.1 N

|

| 12 mm |

|

37.12 kg / 81.84 LBS

37120.0 g / 364.1 N

|

Table 5: Working in heat (stability) - thermal limit

MPL 50x25x12 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

37.12 kg / 81.84 LBS

37120.0 g / 364.1 N

|

OK |

| 40 °C | -2.2% |

36.30 kg / 80.04 LBS

36303.4 g / 356.1 N

|

OK |

| 60 °C | -4.4% |

35.49 kg / 78.23 LBS

35486.7 g / 348.1 N

|

|

| 80 °C | -6.6% |

34.67 kg / 76.43 LBS

34670.1 g / 340.1 N

|

|

| 100 °C | -28.8% |

26.43 kg / 58.27 LBS

26429.4 g / 259.3 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 50x25x12 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

89.28 kg / 196.82 LBS

4 856 Gs

|

13.39 kg / 29.52 LBS

13392 g / 131.4 N

|

N/A |

| 1 mm |

84.99 kg / 187.37 LBS

6 642 Gs

|

12.75 kg / 28.11 LBS

12749 g / 125.1 N

|

76.49 kg / 168.63 LBS

~0 Gs

|

| 2 mm |

80.57 kg / 177.64 LBS

6 467 Gs

|

12.09 kg / 26.65 LBS

12086 g / 118.6 N

|

72.52 kg / 159.87 LBS

~0 Gs

|

| 3 mm |

76.16 kg / 167.90 LBS

6 287 Gs

|

11.42 kg / 25.19 LBS

11424 g / 112.1 N

|

68.54 kg / 151.11 LBS

~0 Gs

|

| 5 mm |

67.49 kg / 148.78 LBS

5 919 Gs

|

10.12 kg / 22.32 LBS

10123 g / 99.3 N

|

60.74 kg / 133.91 LBS

~0 Gs

|

| 10 mm |

48.02 kg / 105.86 LBS

4 992 Gs

|

7.20 kg / 15.88 LBS

7203 g / 70.7 N

|

43.22 kg / 95.28 LBS

~0 Gs

|

| 20 mm |

22.32 kg / 49.20 LBS

3 403 Gs

|

3.35 kg / 7.38 LBS

3347 g / 32.8 N

|

20.08 kg / 44.28 LBS

~0 Gs

|

| 50 mm |

2.41 kg / 5.31 LBS

1 118 Gs

|

0.36 kg / 0.80 LBS

361 g / 3.5 N

|

2.17 kg / 4.78 LBS

~0 Gs

|

| 60 mm |

1.26 kg / 2.77 LBS

808 Gs

|

0.19 kg / 0.42 LBS

189 g / 1.9 N

|

1.13 kg / 2.50 LBS

~0 Gs

|

| 70 mm |

0.69 kg / 1.52 LBS

598 Gs

|

0.10 kg / 0.23 LBS

103 g / 1.0 N

|

0.62 kg / 1.37 LBS

~0 Gs

|

| 80 mm |

0.39 kg / 0.87 LBS

452 Gs

|

0.06 kg / 0.13 LBS

59 g / 0.6 N

|

0.35 kg / 0.78 LBS

~0 Gs

|

| 90 mm |

0.23 kg / 0.52 LBS

349 Gs

|

0.04 kg / 0.08 LBS

35 g / 0.3 N

|

0.21 kg / 0.47 LBS

~0 Gs

|

| 100 mm |

0.14 kg / 0.32 LBS

274 Gs

|

0.02 kg / 0.05 LBS

22 g / 0.2 N

|

0.13 kg / 0.29 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MPL 50x25x12 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 17.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 14.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 11.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 8.5 cm |

| Remote | 50 Gs (5.0 mT) | 8.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 50x25x12 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.99 km/h

(5.83 m/s)

|

1.91 J | |

| 30 mm |

32.01 km/h

(8.89 m/s)

|

4.45 J | |

| 50 mm |

41.00 km/h

(11.39 m/s)

|

7.30 J | |

| 100 mm |

57.93 km/h

(16.09 m/s)

|

14.57 J |

Table 9: Surface protection spec

MPL 50x25x12 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 50x25x12 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 42 945 Mx | 429.5 µWb |

| Pc Coefficient | 0.40 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 50x25x12 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 37.12 kg | Standard |

| Water (riverbed) |

42.50 kg

(+5.38 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet retains merely ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) significantly reduces the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.40

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also products

Strengths as well as weaknesses of rare earth magnets.

Strengths

- They have unchanged lifting capacity, and over around 10 years their attraction force decreases symbolically – ~1% (in testing),

- Neodymium magnets are exceptionally resistant to demagnetization caused by external interference,

- Thanks to the shimmering finish, the surface of nickel, gold-plated, or silver-plated gives an elegant appearance,

- Magnetic induction on the top side of the magnet is strong,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Due to the potential of flexible molding and adaptation to unique needs, neodymium magnets can be created in a variety of geometric configurations, which increases their versatility,

- Fundamental importance in electronics industry – they are commonly used in data components, electric drive systems, precision medical tools, as well as other advanced devices.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Weaknesses

- At very strong impacts they can break, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in producing threads and complex forms in magnets, we recommend using a housing - magnetic holder.

- Potential hazard related to microscopic parts of magnets can be dangerous, in case of ingestion, which is particularly important in the context of child health protection. Additionally, small elements of these devices can be problematic in diagnostics medical after entering the body.

- Due to complex production process, their price is relatively high,

Pull force analysis

Maximum holding power of the magnet – what contributes to it?

- on a plate made of mild steel, perfectly concentrating the magnetic flux

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- with an ground touching surface

- without the slightest air gap between the magnet and steel

- under axial force direction (90-degree angle)

- at temperature room level

What influences lifting capacity in practice

- Gap between magnet and steel – every millimeter of separation (caused e.g. by varnish or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – highest force is reached only during pulling at a 90° angle. The force required to slide of the magnet along the plate is usually several times lower (approx. 1/5 of the lifting capacity).

- Steel thickness – insufficiently thick plate does not accept the full field, causing part of the power to be wasted to the other side.

- Material type – ideal substrate is high-permeability steel. Stainless steels may attract less.

- Surface structure – the more even the surface, the larger the contact zone and higher the lifting capacity. Roughness creates an air distance.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. When it is hot they are weaker, and in frost they can be stronger (up to a certain limit).

Lifting capacity was measured with the use of a polished steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, however under parallel forces the load capacity is reduced by as much as fivefold. Moreover, even a minimal clearance between the magnet and the plate reduces the holding force.

Warnings

Health Danger

Medical warning: Neodymium magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Handling rules

Exercise caution. Rare earth magnets attract from a long distance and connect with huge force, often quicker than you can react.

Risk of cracking

Despite metallic appearance, the material is brittle and cannot withstand shocks. Do not hit, as the magnet may shatter into hazardous fragments.

Threat to electronics

Avoid bringing magnets near a wallet, laptop, or screen. The magnetism can irreversibly ruin these devices and erase data from cards.

Pinching danger

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, destroying everything in their path. Be careful!

Phone sensors

GPS units and mobile phones are extremely sensitive to magnetism. Direct contact with a powerful NdFeB magnet can ruin the sensors in your phone.

Adults only

NdFeB magnets are not toys. Accidental ingestion of a few magnets may result in them pinching intestinal walls, which constitutes a critical condition and requires urgent medical intervention.

Allergy Warning

It is widely known that nickel (the usual finish) is a common allergen. If your skin reacts to metals, prevent direct skin contact and choose encased magnets.

Do not overheat magnets

Monitor thermal conditions. Exposing the magnet to high heat will ruin its properties and pulling force.

Flammability

Powder generated during machining of magnets is combustible. Do not drill into magnets unless you are an expert.

![UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-34x8-m4-gw-kek.jpg)

![UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-48x24x11.5-m8-gz-bit.jpg)

![BM 510x180x70 [4x M8] - magnetic beam BM 510x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-510x180x70-4x-m8-cem.jpg)