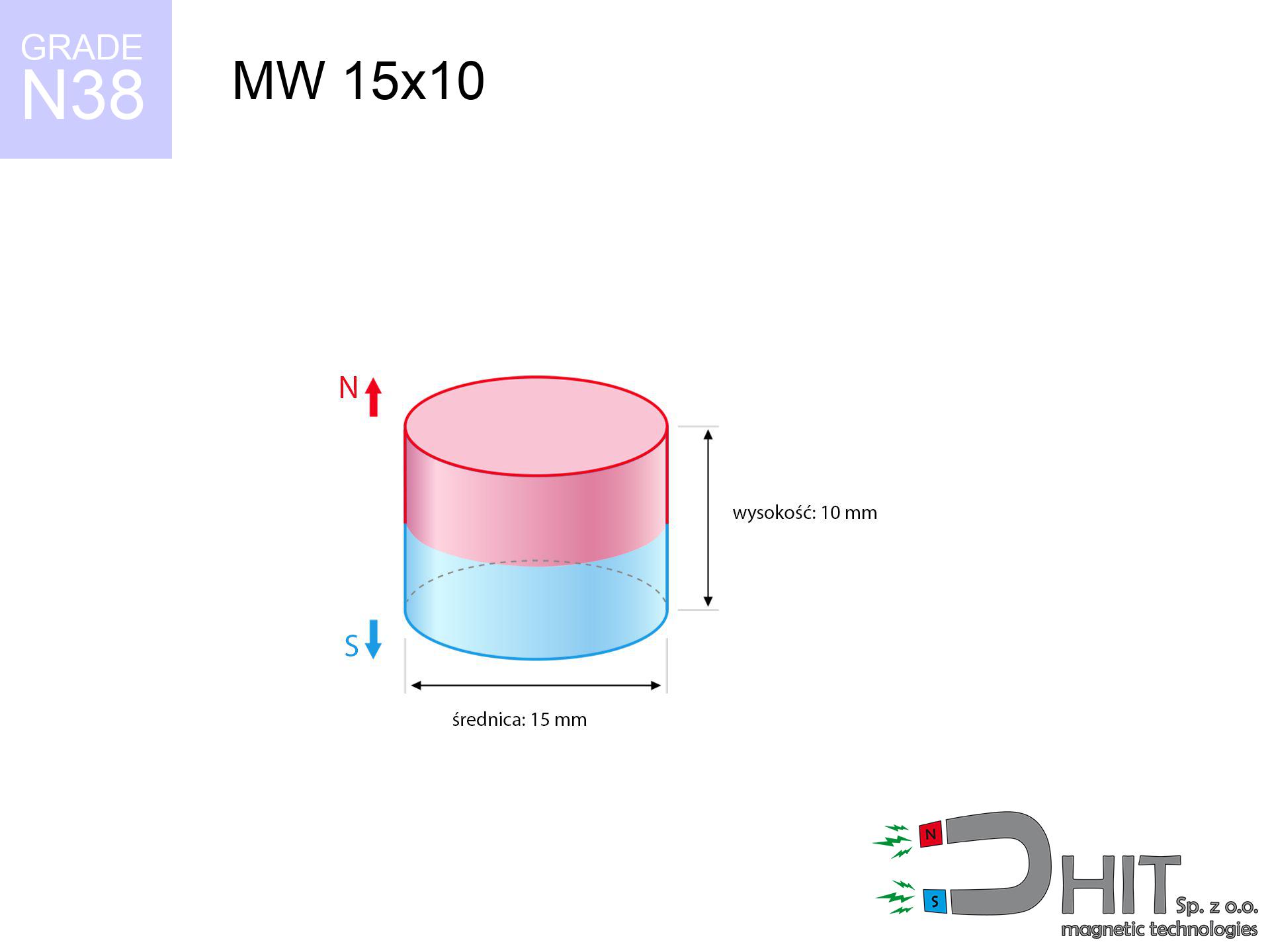

MW 15x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010027

GTIN/EAN: 5906301810261

Diameter Ø

15 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

13.25 g

Magnetization Direction

↑ axial

Load capacity

7.70 kg / 75.55 N

Magnetic Induction

495.60 mT / 4956 Gs

Coating

[NiCuNi] Nickel

4.51 ZŁ with VAT / pcs + price for transport

3.67 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer get in touch using

our online form

the contact page.

Force and shape of neodymium magnets can be estimated using our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Technical specification of the product - MW 15x10 / N38 - cylindrical magnet

Specification / characteristics - MW 15x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010027 |

| GTIN/EAN | 5906301810261 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 15 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 13.25 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.70 kg / 75.55 N |

| Magnetic Induction ~ ? | 495.60 mT / 4956 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - report

Presented data represent the direct effect of a mathematical simulation. Values rely on models for the class Nd2Fe14B. Real-world parameters might slightly differ. Please consider these calculations as a reference point when designing systems.

Table 1: Static force (force vs gap) - interaction chart

MW 15x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4954 Gs

495.4 mT

|

7.70 kg / 16.98 LBS

7700.0 g / 75.5 N

|

warning |

| 1 mm |

4303 Gs

430.3 mT

|

5.81 kg / 12.81 LBS

5810.9 g / 57.0 N

|

warning |

| 2 mm |

3660 Gs

366.0 mT

|

4.20 kg / 9.27 LBS

4203.8 g / 41.2 N

|

warning |

| 3 mm |

3068 Gs

306.8 mT

|

2.95 kg / 6.51 LBS

2953.2 g / 29.0 N

|

warning |

| 5 mm |

2106 Gs

210.6 mT

|

1.39 kg / 3.07 LBS

1392.2 g / 13.7 N

|

safe |

| 10 mm |

845 Gs

84.5 mT

|

0.22 kg / 0.49 LBS

224.2 g / 2.2 N

|

safe |

| 15 mm |

393 Gs

39.3 mT

|

0.05 kg / 0.11 LBS

48.5 g / 0.5 N

|

safe |

| 20 mm |

210 Gs

21.0 mT

|

0.01 kg / 0.03 LBS

13.8 g / 0.1 N

|

safe |

| 30 mm |

79 Gs

7.9 mT

|

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

safe |

| 50 mm |

21 Gs

2.1 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

safe |

Table 2: Vertical hold (vertical surface)

MW 15x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.54 kg / 3.40 LBS

1540.0 g / 15.1 N

|

| 1 mm | Stal (~0.2) |

1.16 kg / 2.56 LBS

1162.0 g / 11.4 N

|

| 2 mm | Stal (~0.2) |

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

| 3 mm | Stal (~0.2) |

0.59 kg / 1.30 LBS

590.0 g / 5.8 N

|

| 5 mm | Stal (~0.2) |

0.28 kg / 0.61 LBS

278.0 g / 2.7 N

|

| 10 mm | Stal (~0.2) |

0.04 kg / 0.10 LBS

44.0 g / 0.4 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 15x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.31 kg / 5.09 LBS

2310.0 g / 22.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.54 kg / 3.40 LBS

1540.0 g / 15.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.85 kg / 8.49 LBS

3850.0 g / 37.8 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 15x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

| 1 mm |

|

1.93 kg / 4.24 LBS

1925.0 g / 18.9 N

|

| 2 mm |

|

3.85 kg / 8.49 LBS

3850.0 g / 37.8 N

|

| 3 mm |

|

5.78 kg / 12.73 LBS

5775.0 g / 56.7 N

|

| 5 mm |

|

7.70 kg / 16.98 LBS

7700.0 g / 75.5 N

|

| 10 mm |

|

7.70 kg / 16.98 LBS

7700.0 g / 75.5 N

|

| 11 mm |

|

7.70 kg / 16.98 LBS

7700.0 g / 75.5 N

|

| 12 mm |

|

7.70 kg / 16.98 LBS

7700.0 g / 75.5 N

|

Table 5: Thermal stability (stability) - thermal limit

MW 15x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.70 kg / 16.98 LBS

7700.0 g / 75.5 N

|

OK |

| 40 °C | -2.2% |

7.53 kg / 16.60 LBS

7530.6 g / 73.9 N

|

OK |

| 60 °C | -4.4% |

7.36 kg / 16.23 LBS

7361.2 g / 72.2 N

|

OK |

| 80 °C | -6.6% |

7.19 kg / 15.86 LBS

7191.8 g / 70.6 N

|

|

| 100 °C | -28.8% |

5.48 kg / 12.09 LBS

5482.4 g / 53.8 N

|

Table 6: Two magnets (attraction) - field range

MW 15x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

26.73 kg / 58.93 LBS

5 797 Gs

|

4.01 kg / 8.84 LBS

4010 g / 39.3 N

|

N/A |

| 1 mm |

23.38 kg / 51.55 LBS

9 265 Gs

|

3.51 kg / 7.73 LBS

3507 g / 34.4 N

|

21.04 kg / 46.39 LBS

~0 Gs

|

| 2 mm |

20.17 kg / 44.48 LBS

8 606 Gs

|

3.03 kg / 6.67 LBS

3026 g / 29.7 N

|

18.16 kg / 40.03 LBS

~0 Gs

|

| 3 mm |

17.23 kg / 37.99 LBS

7 955 Gs

|

2.59 kg / 5.70 LBS

2585 g / 25.4 N

|

15.51 kg / 34.19 LBS

~0 Gs

|

| 5 mm |

12.27 kg / 27.05 LBS

6 712 Gs

|

1.84 kg / 4.06 LBS

1840 g / 18.1 N

|

11.04 kg / 24.34 LBS

~0 Gs

|

| 10 mm |

4.83 kg / 10.66 LBS

4 213 Gs

|

0.73 kg / 1.60 LBS

725 g / 7.1 N

|

4.35 kg / 9.59 LBS

~0 Gs

|

| 20 mm |

0.78 kg / 1.72 LBS

1 690 Gs

|

0.12 kg / 0.26 LBS

117 g / 1.1 N

|

0.70 kg / 1.54 LBS

~0 Gs

|

| 50 mm |

0.02 kg / 0.04 LBS

248 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.03 LBS

~0 Gs

|

| 60 mm |

0.01 kg / 0.01 LBS

158 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 LBS

107 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

75 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

55 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

41 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MW 15x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 15x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.75 km/h

(6.88 m/s)

|

0.31 J | |

| 30 mm |

42.12 km/h

(11.70 m/s)

|

0.91 J | |

| 50 mm |

54.36 km/h

(15.10 m/s)

|

1.51 J | |

| 100 mm |

76.88 km/h

(21.36 m/s)

|

3.02 J |

Table 9: Surface protection spec

MW 15x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 15x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 8 827 Mx | 88.3 µWb |

| Pc Coefficient | 0.71 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 15x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.70 kg | Standard |

| Water (riverbed) |

8.82 kg

(+1.12 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical wall, the magnet holds only a fraction of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.71

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Pros and cons of neodymium magnets.

Strengths

- They do not lose strength, even after around ten years – the reduction in strength is only ~1% (theoretically),

- Neodymium magnets are extremely resistant to demagnetization caused by magnetic disturbances,

- The use of an shiny finish of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- The surface of neodymium magnets generates a intense magnetic field – this is a distinguishing feature,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to the possibility of flexible forming and customization to individualized needs, NdFeB magnets can be produced in a variety of geometric configurations, which amplifies use scope,

- Universal use in high-tech industry – they find application in HDD drives, brushless drives, advanced medical instruments, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which allows their use in compact constructions

Disadvantages

- They are fragile upon heavy impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- We recommend casing - magnetic mount, due to difficulties in realizing threads inside the magnet and complicated forms.

- Health risk to health – tiny shards of magnets can be dangerous, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that small components of these devices are able to complicate diagnosis medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Optimal lifting capacity of a neodymium magnet – what it depends on?

- with the use of a sheet made of special test steel, ensuring maximum field concentration

- with a thickness no less than 10 mm

- with a surface free of scratches

- without the slightest air gap between the magnet and steel

- under axial force direction (90-degree angle)

- at room temperature

Practical lifting capacity: influencing factors

- Air gap (betwixt the magnet and the metal), as even a microscopic clearance (e.g. 0.5 mm) can cause a drastic drop in force by up to 50% (this also applies to paint, corrosion or debris).

- Pull-off angle – remember that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Material composition – not every steel reacts the same. Alloy additives weaken the attraction effect.

- Smoothness – full contact is obtained only on polished steel. Rough texture create air cushions, reducing force.

- Operating temperature – neodymium magnets have a sensitivity to temperature. At higher temperatures they are weaker, and in frost they can be stronger (up to a certain limit).

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, in contrast under shearing force the holding force is lower. Additionally, even a slight gap between the magnet’s surface and the plate lowers the lifting capacity.

Safety rules for work with neodymium magnets

No play value

NdFeB magnets are not suitable for play. Eating several magnets may result in them connecting inside the digestive tract, which constitutes a direct threat to life and requires urgent medical intervention.

Serious injuries

Big blocks can smash fingers instantly. Under no circumstances put your hand betwixt two attracting surfaces.

Maximum temperature

Monitor thermal conditions. Heating the magnet to high heat will ruin its magnetic structure and strength.

Beware of splinters

Watch out for shards. Magnets can explode upon uncontrolled impact, ejecting shards into the air. Wear goggles.

Precision electronics

An intense magnetic field disrupts the operation of magnetometers in phones and navigation systems. Maintain magnets near a device to prevent breaking the sensors.

Conscious usage

Use magnets consciously. Their powerful strength can shock even experienced users. Be vigilant and respect their force.

Danger to pacemakers

Warning for patients: Powerful magnets affect medical devices. Keep minimum 30 cm distance or request help to work with the magnets.

Cards and drives

Data protection: Neodymium magnets can ruin payment cards and sensitive devices (pacemakers, medical aids, mechanical watches).

Do not drill into magnets

Dust produced during cutting of magnets is self-igniting. Do not drill into magnets without proper cooling and knowledge.

Allergy Warning

Studies show that nickel (standard magnet coating) is a common allergen. For allergy sufferers, refrain from direct skin contact and select encased magnets.

![SM 18x150 [2xM5] / N42 - magnetic separator SM 18x150 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x150-2xm5-pec.jpg)

![UMGGW 88x8.5 [M6] GW / N38 - magnetic holder rubber internal thread UMGGW 88x8.5 [M6] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-88x8.5-m8-gw-let.jpg)