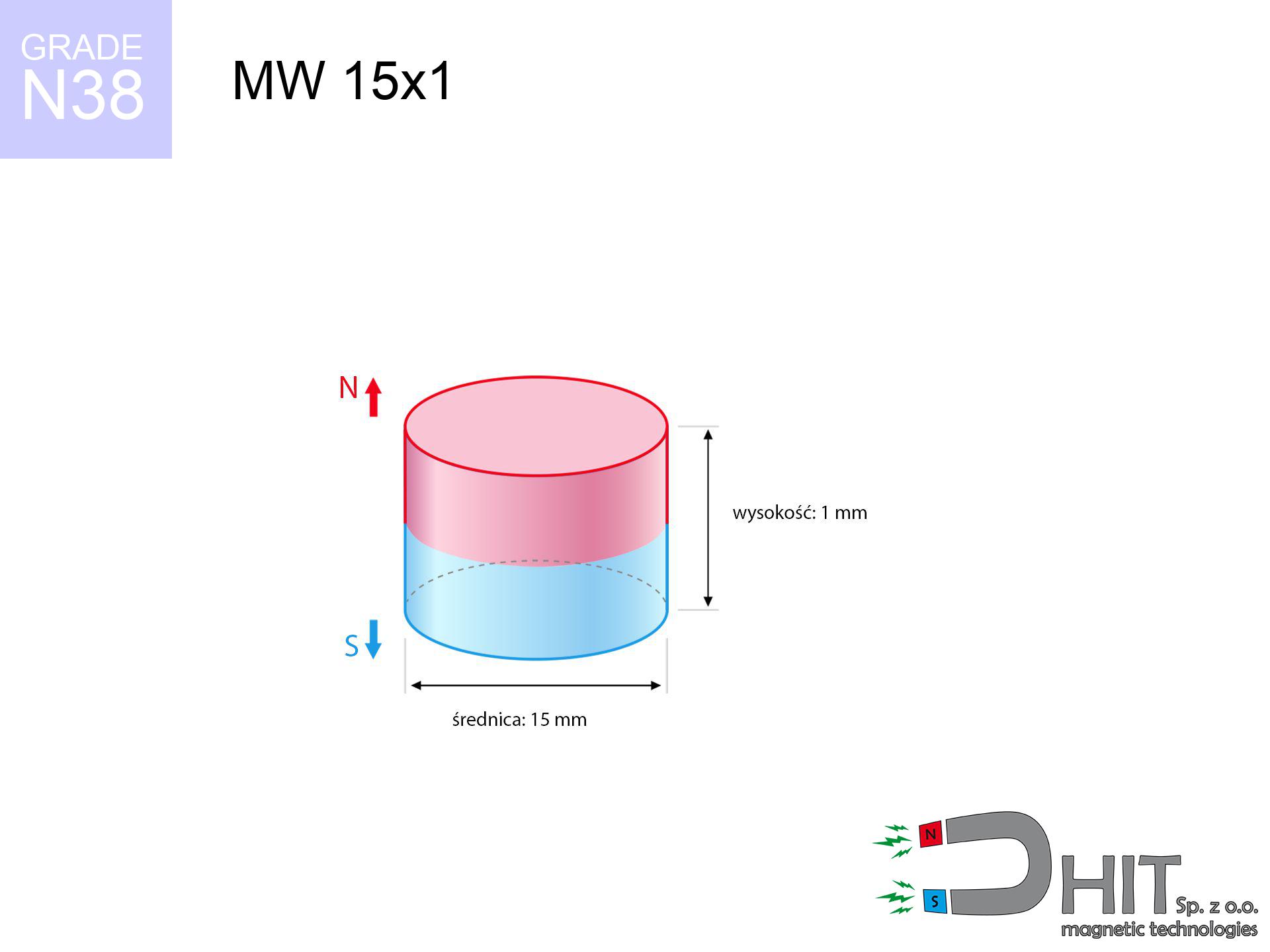

MW 15x1 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010026

GTIN/EAN: 5906301810254

Diameter Ø

15 mm [±0,1 mm]

Height

1 mm [±0,1 mm]

Weight

1.33 g

Magnetization Direction

↑ axial

Load capacity

0.44 kg / 4.29 N

Magnetic Induction

81.93 mT / 819 Gs

Coating

[NiCuNi] Nickel

0.800 ZŁ with VAT / pcs + price for transport

0.650 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

or drop us a message using

inquiry form

through our site.

Strength as well as form of magnets can be verified with our

our magnetic calculator.

Same-day processing for orders placed before 14:00.

Technical data of the product - MW 15x1 / N38 - cylindrical magnet

Specification / characteristics - MW 15x1 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010026 |

| GTIN/EAN | 5906301810254 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 15 mm [±0,1 mm] |

| Height | 1 mm [±0,1 mm] |

| Weight | 1.33 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.44 kg / 4.29 N |

| Magnetic Induction ~ ? | 81.93 mT / 819 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the magnet - data

These values represent the direct effect of a mathematical calculation. Results are based on models for the material Nd2Fe14B. Actual performance might slightly differ from theoretical values. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static pull force (pull vs gap) - characteristics

MW 15x1 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

819 Gs

81.9 mT

|

0.44 kg / 0.97 lbs

440.0 g / 4.3 N

|

low risk |

| 1 mm |

778 Gs

77.8 mT

|

0.40 kg / 0.88 lbs

397.0 g / 3.9 N

|

low risk |

| 2 mm |

705 Gs

70.5 mT

|

0.33 kg / 0.72 lbs

326.0 g / 3.2 N

|

low risk |

| 3 mm |

615 Gs

61.5 mT

|

0.25 kg / 0.55 lbs

248.0 g / 2.4 N

|

low risk |

| 5 mm |

434 Gs

43.4 mT

|

0.12 kg / 0.27 lbs

123.5 g / 1.2 N

|

low risk |

| 10 mm |

163 Gs

16.3 mT

|

0.02 kg / 0.04 lbs

17.3 g / 0.2 N

|

low risk |

| 15 mm |

68 Gs

6.8 mT

|

0.00 kg / 0.01 lbs

3.1 g / 0.0 N

|

low risk |

| 20 mm |

34 Gs

3.4 mT

|

0.00 kg / 0.00 lbs

0.7 g / 0.0 N

|

low risk |

| 30 mm |

11 Gs

1.1 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

low risk |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

Table 2: Slippage force (vertical surface)

MW 15x1 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.09 kg / 0.19 lbs

88.0 g / 0.9 N

|

| 1 mm | Stal (~0.2) |

0.08 kg / 0.18 lbs

80.0 g / 0.8 N

|

| 2 mm | Stal (~0.2) |

0.07 kg / 0.15 lbs

66.0 g / 0.6 N

|

| 3 mm | Stal (~0.2) |

0.05 kg / 0.11 lbs

50.0 g / 0.5 N

|

| 5 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

24.0 g / 0.2 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 15x1 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.13 kg / 0.29 lbs

132.0 g / 1.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.09 kg / 0.19 lbs

88.0 g / 0.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.04 kg / 0.10 lbs

44.0 g / 0.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.22 kg / 0.49 lbs

220.0 g / 2.2 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 15x1 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.04 kg / 0.10 lbs

44.0 g / 0.4 N

|

| 1 mm |

|

0.11 kg / 0.24 lbs

110.0 g / 1.1 N

|

| 2 mm |

|

0.22 kg / 0.49 lbs

220.0 g / 2.2 N

|

| 3 mm |

|

0.33 kg / 0.73 lbs

330.0 g / 3.2 N

|

| 5 mm |

|

0.44 kg / 0.97 lbs

440.0 g / 4.3 N

|

| 10 mm |

|

0.44 kg / 0.97 lbs

440.0 g / 4.3 N

|

| 11 mm |

|

0.44 kg / 0.97 lbs

440.0 g / 4.3 N

|

| 12 mm |

|

0.44 kg / 0.97 lbs

440.0 g / 4.3 N

|

Table 5: Working in heat (stability) - power drop

MW 15x1 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.44 kg / 0.97 lbs

440.0 g / 4.3 N

|

OK |

| 40 °C | -2.2% |

0.43 kg / 0.95 lbs

430.3 g / 4.2 N

|

OK |

| 60 °C | -4.4% |

0.42 kg / 0.93 lbs

420.6 g / 4.1 N

|

|

| 80 °C | -6.6% |

0.41 kg / 0.91 lbs

411.0 g / 4.0 N

|

|

| 100 °C | -28.8% |

0.31 kg / 0.69 lbs

313.3 g / 3.1 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MW 15x1 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.73 kg / 1.61 lbs

1 597 Gs

|

0.11 kg / 0.24 lbs

110 g / 1.1 N

|

N/A |

| 1 mm |

0.70 kg / 1.55 lbs

1 607 Gs

|

0.11 kg / 0.23 lbs

106 g / 1.0 N

|

0.63 kg / 1.40 lbs

~0 Gs

|

| 2 mm |

0.66 kg / 1.45 lbs

1 556 Gs

|

0.10 kg / 0.22 lbs

99 g / 1.0 N

|

0.59 kg / 1.31 lbs

~0 Gs

|

| 3 mm |

0.60 kg / 1.33 lbs

1 489 Gs

|

0.09 kg / 0.20 lbs

91 g / 0.9 N

|

0.54 kg / 1.20 lbs

~0 Gs

|

| 5 mm |

0.48 kg / 1.05 lbs

1 323 Gs

|

0.07 kg / 0.16 lbs

71 g / 0.7 N

|

0.43 kg / 0.95 lbs

~0 Gs

|

| 10 mm |

0.21 kg / 0.45 lbs

868 Gs

|

0.03 kg / 0.07 lbs

31 g / 0.3 N

|

0.18 kg / 0.41 lbs

~0 Gs

|

| 20 mm |

0.03 kg / 0.06 lbs

325 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.03 kg / 0.06 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

37 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

23 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

15 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

10 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

7 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

5 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MW 15x1 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (cracking risk) - warning

MW 15x1 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

18.79 km/h

(5.22 m/s)

|

0.02 J | |

| 30 mm |

31.78 km/h

(8.83 m/s)

|

0.05 J | |

| 50 mm |

41.02 km/h

(11.39 m/s)

|

0.09 J | |

| 100 mm |

58.01 km/h

(16.11 m/s)

|

0.17 J |

Table 9: Coating parameters (durability)

MW 15x1 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 15x1 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 025 Mx | 20.3 µWb |

| Pc Coefficient | 0.11 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 15x1 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.44 kg | Standard |

| Water (riverbed) |

0.50 kg

(+0.06 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet holds merely a fraction of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Temperature resistance

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.11

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Strengths

- Their magnetic field remains stable, and after approximately 10 years it drops only by ~1% (theoretically),

- Neodymium magnets remain highly resistant to magnetic field loss caused by magnetic disturbances,

- Thanks to the smooth finish, the layer of nickel, gold-plated, or silver gives an modern appearance,

- Neodymium magnets deliver maximum magnetic induction on a small area, which increases force concentration,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of custom machining and modifying to specific needs,

- Versatile presence in modern industrial fields – they serve a role in computer drives, electromotive mechanisms, medical devices, also industrial machines.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- At very strong impacts they can break, therefore we recommend placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in realizing threads and complicated forms in magnets, we recommend using a housing - magnetic mechanism.

- Potential hazard related to microscopic parts of magnets are risky, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Additionally, small elements of these magnets are able to disrupt the diagnostic process medical after entering the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Best holding force of the magnet in ideal parameters – what it depends on?

- using a sheet made of high-permeability steel, acting as a ideal flux conductor

- with a thickness minimum 10 mm

- characterized by even structure

- under conditions of no distance (surface-to-surface)

- during pulling in a direction perpendicular to the plane

- at standard ambient temperature

Impact of factors on magnetic holding capacity in practice

- Space between surfaces – every millimeter of separation (caused e.g. by veneer or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to pulling vertically. When applying parallel force, the magnet holds much less (typically approx. 20-30% of nominal force).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Metal type – different alloys attracts identically. Alloy additives weaken the attraction effect.

- Surface structure – the smoother and more polished the plate, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Thermal factor – hot environment weakens pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was checked on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under parallel forces the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the load capacity.

Warnings

Combustion hazard

Fire warning: Neodymium dust is explosive. Avoid machining magnets without safety gear as this may cause fire.

Swallowing risk

Neodymium magnets are not intended for children. Eating multiple magnets may result in them connecting inside the digestive tract, which constitutes a direct threat to life and requires immediate surgery.

Nickel coating and allergies

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If redness happens, immediately stop handling magnets and wear gloves.

Permanent damage

Keep cool. NdFeB magnets are sensitive to temperature. If you require resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

Threat to electronics

Intense magnetic fields can destroy records on payment cards, HDDs, and other magnetic media. Maintain a gap of min. 10 cm.

Life threat

Life threat: Strong magnets can turn off heart devices and defibrillators. Do not approach if you have electronic implants.

Bone fractures

Mind your fingers. Two powerful magnets will join immediately with a force of massive weight, destroying anything in their path. Be careful!

Magnet fragility

Neodymium magnets are sintered ceramics, meaning they are very brittle. Collision of two magnets will cause them cracking into small pieces.

Precision electronics

A strong magnetic field interferes with the operation of magnetometers in phones and navigation systems. Keep magnets near a device to avoid breaking the sensors.

Caution required

Handle magnets with awareness. Their powerful strength can surprise even experienced users. Stay alert and do not underestimate their force.

![SM 32x375 [2xM8] / N52 - magnetic separator SM 32x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-mif.jpg)