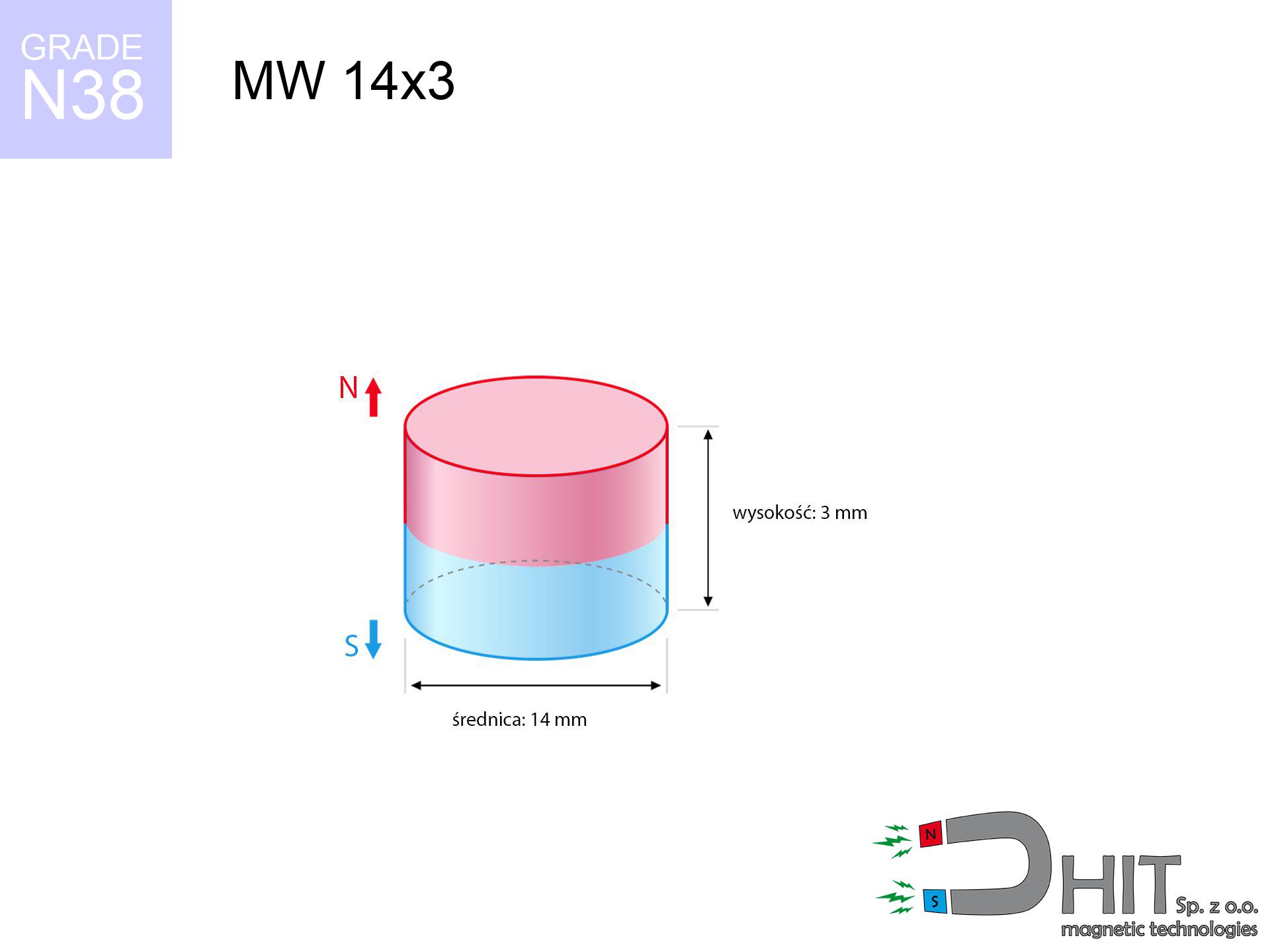

MW 14x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010025

GTIN/EAN: 5906301810247

Diameter Ø

14 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

3.46 g

Magnetization Direction

↑ axial

Load capacity

2.76 kg / 27.06 N

Magnetic Induction

244.11 mT / 2441 Gs

Coating

[NiCuNi] Nickel

1.845 ZŁ with VAT / pcs + price for transport

1.500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or drop us a message using

inquiry form

the contact section.

Weight along with structure of a magnet can be calculated using our

our magnetic calculator.

Same-day processing for orders placed before 14:00.

Technical details - MW 14x3 / N38 - cylindrical magnet

Specification / characteristics - MW 14x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010025 |

| GTIN/EAN | 5906301810247 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 14 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 3.46 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.76 kg / 27.06 N |

| Magnetic Induction ~ ? | 244.11 mT / 2441 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

These data constitute the outcome of a engineering analysis. Values were calculated on models for the material Nd2Fe14B. Real-world conditions may differ. Treat these calculations as a supplementary guide when designing systems.

Table 1: Static force (force vs gap) - interaction chart

MW 14x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2440 Gs

244.0 mT

|

2.76 kg / 6.08 lbs

2760.0 g / 27.1 N

|

strong |

| 1 mm |

2199 Gs

219.9 mT

|

2.24 kg / 4.94 lbs

2241.6 g / 22.0 N

|

strong |

| 2 mm |

1900 Gs

190.0 mT

|

1.67 kg / 3.69 lbs

1673.8 g / 16.4 N

|

weak grip |

| 3 mm |

1593 Gs

159.3 mT

|

1.18 kg / 2.59 lbs

1175.5 g / 11.5 N

|

weak grip |

| 5 mm |

1062 Gs

106.2 mT

|

0.52 kg / 1.15 lbs

523.0 g / 5.1 N

|

weak grip |

| 10 mm |

380 Gs

38.0 mT

|

0.07 kg / 0.15 lbs

66.8 g / 0.7 N

|

weak grip |

| 15 mm |

160 Gs

16.0 mT

|

0.01 kg / 0.03 lbs

11.9 g / 0.1 N

|

weak grip |

| 20 mm |

79 Gs

7.9 mT

|

0.00 kg / 0.01 lbs

2.9 g / 0.0 N

|

weak grip |

| 30 mm |

27 Gs

2.7 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

weak grip |

| 50 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Slippage hold (vertical surface)

MW 14x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.55 kg / 1.22 lbs

552.0 g / 5.4 N

|

| 1 mm | Stal (~0.2) |

0.45 kg / 0.99 lbs

448.0 g / 4.4 N

|

| 2 mm | Stal (~0.2) |

0.33 kg / 0.74 lbs

334.0 g / 3.3 N

|

| 3 mm | Stal (~0.2) |

0.24 kg / 0.52 lbs

236.0 g / 2.3 N

|

| 5 mm | Stal (~0.2) |

0.10 kg / 0.23 lbs

104.0 g / 1.0 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

14.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 14x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.83 kg / 1.83 lbs

828.0 g / 8.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.55 kg / 1.22 lbs

552.0 g / 5.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.28 kg / 0.61 lbs

276.0 g / 2.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.38 kg / 3.04 lbs

1380.0 g / 13.5 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 14x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.28 kg / 0.61 lbs

276.0 g / 2.7 N

|

| 1 mm |

|

0.69 kg / 1.52 lbs

690.0 g / 6.8 N

|

| 2 mm |

|

1.38 kg / 3.04 lbs

1380.0 g / 13.5 N

|

| 3 mm |

|

2.07 kg / 4.56 lbs

2070.0 g / 20.3 N

|

| 5 mm |

|

2.76 kg / 6.08 lbs

2760.0 g / 27.1 N

|

| 10 mm |

|

2.76 kg / 6.08 lbs

2760.0 g / 27.1 N

|

| 11 mm |

|

2.76 kg / 6.08 lbs

2760.0 g / 27.1 N

|

| 12 mm |

|

2.76 kg / 6.08 lbs

2760.0 g / 27.1 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 14x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.76 kg / 6.08 lbs

2760.0 g / 27.1 N

|

OK |

| 40 °C | -2.2% |

2.70 kg / 5.95 lbs

2699.3 g / 26.5 N

|

OK |

| 60 °C | -4.4% |

2.64 kg / 5.82 lbs

2638.6 g / 25.9 N

|

|

| 80 °C | -6.6% |

2.58 kg / 5.68 lbs

2577.8 g / 25.3 N

|

|

| 100 °C | -28.8% |

1.97 kg / 4.33 lbs

1965.1 g / 19.3 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 14x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

5.65 kg / 12.46 lbs

4 030 Gs

|

0.85 kg / 1.87 lbs

848 g / 8.3 N

|

N/A |

| 1 mm |

5.16 kg / 11.37 lbs

4 662 Gs

|

0.77 kg / 1.71 lbs

773 g / 7.6 N

|

4.64 kg / 10.23 lbs

~0 Gs

|

| 2 mm |

4.59 kg / 10.12 lbs

4 398 Gs

|

0.69 kg / 1.52 lbs

689 g / 6.8 N

|

4.13 kg / 9.11 lbs

~0 Gs

|

| 3 mm |

4.00 kg / 8.82 lbs

4 107 Gs

|

0.60 kg / 1.32 lbs

600 g / 5.9 N

|

3.60 kg / 7.94 lbs

~0 Gs

|

| 5 mm |

2.89 kg / 6.37 lbs

3 490 Gs

|

0.43 kg / 0.96 lbs

434 g / 4.3 N

|

2.60 kg / 5.74 lbs

~0 Gs

|

| 10 mm |

1.07 kg / 2.36 lbs

2 125 Gs

|

0.16 kg / 0.35 lbs

161 g / 1.6 N

|

0.96 kg / 2.12 lbs

~0 Gs

|

| 20 mm |

0.14 kg / 0.30 lbs

759 Gs

|

0.02 kg / 0.05 lbs

21 g / 0.2 N

|

0.12 kg / 0.27 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

89 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

54 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

36 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

25 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

18 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

13 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 14x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 14x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.91 km/h

(8.03 m/s)

|

0.11 J | |

| 30 mm |

49.34 km/h

(13.71 m/s)

|

0.32 J | |

| 50 mm |

63.69 km/h

(17.69 m/s)

|

0.54 J | |

| 100 mm |

90.07 km/h

(25.02 m/s)

|

1.08 J |

Table 9: Surface protection spec

MW 14x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 14x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 301 Mx | 43.0 µWb |

| Pc Coefficient | 0.31 | Low (Flat) |

Table 11: Physics of underwater searching

MW 14x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.76 kg | Standard |

| Water (riverbed) |

3.16 kg

(+0.40 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds merely ~20% of its max power.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) severely weakens the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.31

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Strengths

- They retain magnetic properties for around ten years – the loss is just ~1% (according to analyses),

- Magnets effectively resist against loss of magnetization caused by external fields,

- A magnet with a metallic nickel surface looks better,

- Magnets exhibit exceptionally strong magnetic induction on the working surface,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for operation at temperatures approaching 230°C and above...

- Possibility of detailed forming as well as adjusting to precise needs,

- Universal use in future technologies – they are commonly used in HDD drives, motor assemblies, medical equipment, and multitasking production systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They rust in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- We suggest cover - magnetic holder, due to difficulties in realizing nuts inside the magnet and complex forms.

- Health risk to health – tiny shards of magnets can be dangerous, in case of ingestion, which is particularly important in the context of child health protection. Additionally, small elements of these magnets can be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which hinders application in large quantities

Lifting parameters

Maximum lifting force for a neodymium magnet – what affects it?

- with the contact of a sheet made of special test steel, ensuring maximum field concentration

- possessing a thickness of min. 10 mm to avoid saturation

- with an ground contact surface

- with zero gap (no coatings)

- for force applied at a right angle (pull-off, not shear)

- in temp. approx. 20°C

Magnet lifting force in use – key factors

- Space between surfaces – every millimeter of distance (caused e.g. by varnish or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Angle of force application – highest force is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the surface is usually many times lower (approx. 1/5 of the lifting capacity).

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of generating force.

- Material type – ideal substrate is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Surface quality – the smoother and more polished the surface, the better the adhesion and higher the lifting capacity. Roughness creates an air distance.

- Temperature – temperature increase causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was assessed by applying a polished steel plate of suitable thickness (min. 20 mm), under vertically applied force, however under parallel forces the load capacity is reduced by as much as 5 times. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the load capacity.

H&S for magnets

Warning for heart patients

For implant holders: Powerful magnets disrupt medical devices. Maintain at least 30 cm distance or request help to work with the magnets.

Do not underestimate power

Before starting, read the rules. Uncontrolled attraction can destroy the magnet or injure your hand. Think ahead.

Skin irritation risks

Warning for allergy sufferers: The nickel-copper-nickel coating consists of nickel. If skin irritation appears, cease handling magnets and wear gloves.

Mechanical processing

Drilling and cutting of NdFeB material poses a fire hazard. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Eye protection

Beware of splinters. Magnets can explode upon uncontrolled impact, launching shards into the air. Eye protection is mandatory.

Safe distance

Equipment safety: Strong magnets can ruin payment cards and delicate electronics (heart implants, hearing aids, timepieces).

Threat to navigation

Navigation devices and mobile phones are highly susceptible to magnetic fields. Close proximity with a strong magnet can permanently damage the internal compass in your phone.

Pinching danger

Protect your hands. Two powerful magnets will join immediately with a force of massive weight, crushing anything in their path. Be careful!

Permanent damage

Avoid heat. Neodymium magnets are sensitive to temperature. If you require resistance above 80°C, inquire about HT versions (H, SH, UH).

This is not a toy

Only for adults. Tiny parts can be swallowed, leading to serious injuries. Keep away from kids and pets.

![HH 25x7.7 [M5] / N38 - through hole magnetic holder HH 25x7.7 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-25x7.7-m5-pov.jpg)

![SM 32x300 [2xM8] / N52 - magnetic separator SM 32x300 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x300-2xm8-luf.jpg)