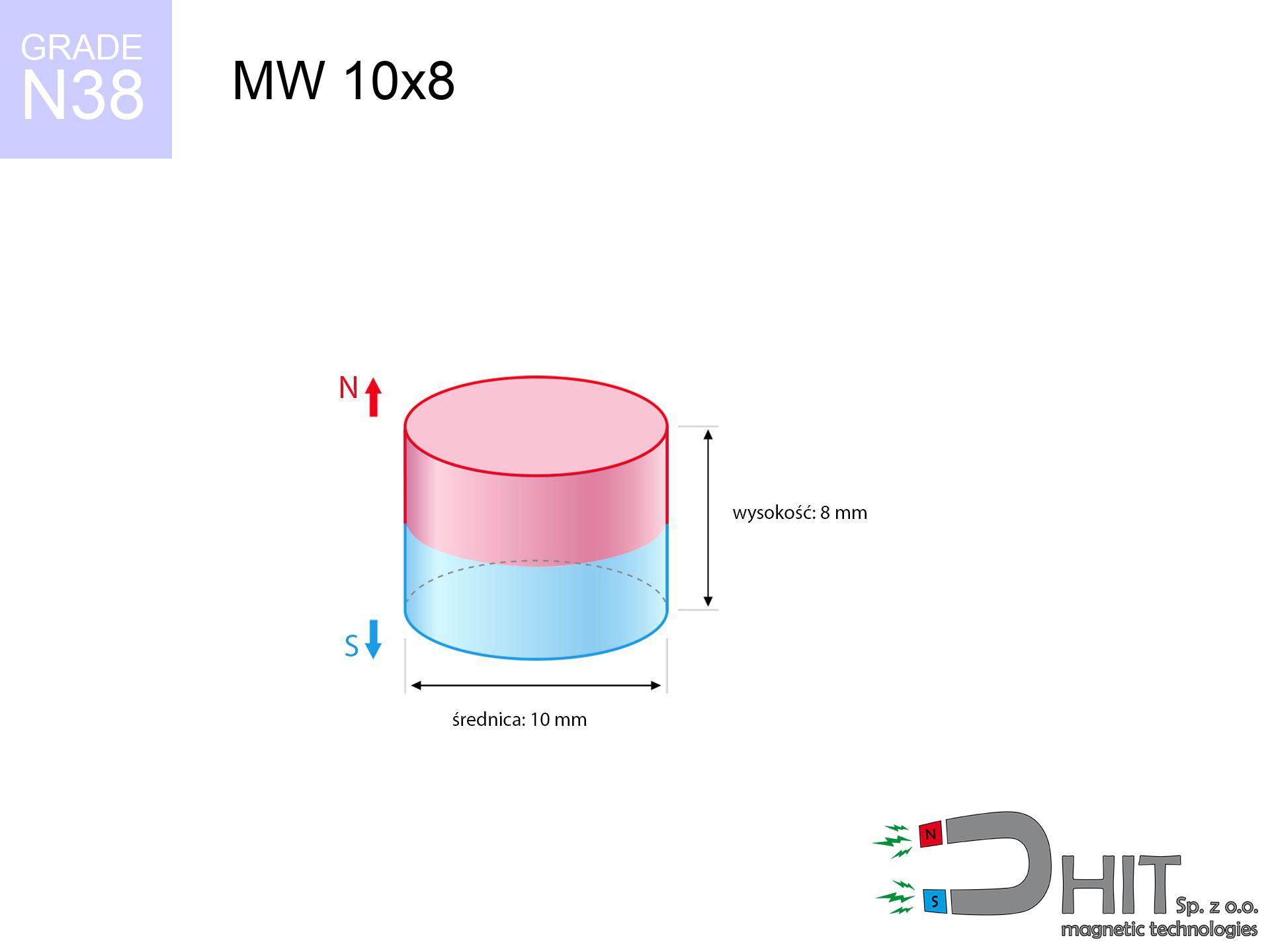

MW 10x8 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010013

GTIN/EAN: 5906301810124

Diameter Ø

10 mm [±0,1 mm]

Height

8 mm [±0,1 mm]

Weight

4.71 g

Magnetization Direction

↑ axial

Load capacity

3.38 kg / 33.16 N

Magnetic Induction

525.10 mT / 5251 Gs

Coating

[NiCuNi] Nickel

2.18 ZŁ with VAT / pcs + price for transport

1.770 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise let us know through

contact form

the contact section.

Specifications as well as appearance of a magnet can be checked with our

magnetic calculator.

Order by 14:00 and we’ll ship today!

Product card - MW 10x8 / N38 - cylindrical magnet

Specification / characteristics - MW 10x8 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010013 |

| GTIN/EAN | 5906301810124 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 8 mm [±0,1 mm] |

| Weight | 4.71 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.38 kg / 33.16 N |

| Magnetic Induction ~ ? | 525.10 mT / 5251 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - technical parameters

These values represent the direct effect of a mathematical analysis. Values are based on algorithms for the class Nd2Fe14B. Real-world conditions may differ from theoretical values. Treat these data as a supplementary guide during assembly planning.

Table 1: Static pull force (force vs distance) - power drop

MW 10x8 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5247 Gs

524.7 mT

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

warning |

| 1 mm |

4204 Gs

420.4 mT

|

2.17 kg / 4.78 LBS

2169.6 g / 21.3 N

|

warning |

| 2 mm |

3243 Gs

324.3 mT

|

1.29 kg / 2.85 LBS

1291.0 g / 12.7 N

|

weak grip |

| 3 mm |

2454 Gs

245.4 mT

|

0.74 kg / 1.63 LBS

739.6 g / 7.3 N

|

weak grip |

| 5 mm |

1403 Gs

140.3 mT

|

0.24 kg / 0.53 LBS

241.5 g / 2.4 N

|

weak grip |

| 10 mm |

428 Gs

42.8 mT

|

0.02 kg / 0.05 LBS

22.5 g / 0.2 N

|

weak grip |

| 15 mm |

177 Gs

17.7 mT

|

0.00 kg / 0.01 LBS

3.8 g / 0.0 N

|

weak grip |

| 20 mm |

89 Gs

8.9 mT

|

0.00 kg / 0.00 LBS

1.0 g / 0.0 N

|

weak grip |

| 30 mm |

31 Gs

3.1 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

| 50 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Shear load (wall)

MW 10x8 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.68 kg / 1.49 LBS

676.0 g / 6.6 N

|

| 1 mm | Stal (~0.2) |

0.43 kg / 0.96 LBS

434.0 g / 4.3 N

|

| 2 mm | Stal (~0.2) |

0.26 kg / 0.57 LBS

258.0 g / 2.5 N

|

| 3 mm | Stal (~0.2) |

0.15 kg / 0.33 LBS

148.0 g / 1.5 N

|

| 5 mm | Stal (~0.2) |

0.05 kg / 0.11 LBS

48.0 g / 0.5 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 10x8 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.01 kg / 2.24 LBS

1014.0 g / 9.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.68 kg / 1.49 LBS

676.0 g / 6.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.34 kg / 0.75 LBS

338.0 g / 3.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.69 kg / 3.73 LBS

1690.0 g / 16.6 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 10x8 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.34 kg / 0.75 LBS

338.0 g / 3.3 N

|

| 1 mm |

|

0.85 kg / 1.86 LBS

845.0 g / 8.3 N

|

| 2 mm |

|

1.69 kg / 3.73 LBS

1690.0 g / 16.6 N

|

| 3 mm |

|

2.54 kg / 5.59 LBS

2535.0 g / 24.9 N

|

| 5 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

| 10 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

| 11 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

| 12 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 10x8 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

OK |

| 40 °C | -2.2% |

3.31 kg / 7.29 LBS

3305.6 g / 32.4 N

|

OK |

| 60 °C | -4.4% |

3.23 kg / 7.12 LBS

3231.3 g / 31.7 N

|

OK |

| 80 °C | -6.6% |

3.16 kg / 6.96 LBS

3156.9 g / 31.0 N

|

|

| 100 °C | -28.8% |

2.41 kg / 5.31 LBS

2406.6 g / 23.6 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 10x8 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

13.33 kg / 29.39 LBS

5 906 Gs

|

2.00 kg / 4.41 LBS

2000 g / 19.6 N

|

N/A |

| 1 mm |

10.82 kg / 23.85 LBS

9 454 Gs

|

1.62 kg / 3.58 LBS

1623 g / 15.9 N

|

9.74 kg / 21.47 LBS

~0 Gs

|

| 2 mm |

8.56 kg / 18.86 LBS

8 408 Gs

|

1.28 kg / 2.83 LBS

1284 g / 12.6 N

|

7.70 kg / 16.98 LBS

~0 Gs

|

| 3 mm |

6.65 kg / 14.65 LBS

7 410 Gs

|

1.00 kg / 2.20 LBS

997 g / 9.8 N

|

5.98 kg / 13.19 LBS

~0 Gs

|

| 5 mm |

3.86 kg / 8.52 LBS

5 650 Gs

|

0.58 kg / 1.28 LBS

580 g / 5.7 N

|

3.48 kg / 7.67 LBS

~0 Gs

|

| 10 mm |

0.95 kg / 2.10 LBS

2 805 Gs

|

0.14 kg / 0.32 LBS

143 g / 1.4 N

|

0.86 kg / 1.89 LBS

~0 Gs

|

| 20 mm |

0.09 kg / 0.20 LBS

857 Gs

|

0.01 kg / 0.03 LBS

13 g / 0.1 N

|

0.08 kg / 0.18 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

101 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

63 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

42 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

29 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

21 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 10x8 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 10x8 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.13 km/h

(7.54 m/s)

|

0.13 J | |

| 30 mm |

46.80 km/h

(13.00 m/s)

|

0.40 J | |

| 50 mm |

60.41 km/h

(16.78 m/s)

|

0.66 J | |

| 100 mm |

85.43 km/h

(23.73 m/s)

|

1.33 J |

Table 9: Surface protection spec

MW 10x8 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 10x8 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 183 Mx | 41.8 µWb |

| Pc Coefficient | 0.79 | High (Stable) |

Table 11: Submerged application

MW 10x8 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.38 kg | Standard |

| Water (riverbed) |

3.87 kg

(+0.49 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet retains only a fraction of its nominal pull.

2. Steel saturation

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Temperature resistance

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.79

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more proposals

Pros and cons of Nd2Fe14B magnets.

Pros

- They do not lose magnetism, even after approximately 10 years – the drop in lifting capacity is only ~1% (theoretically),

- They are extremely resistant to demagnetization induced by presence of other magnetic fields,

- The use of an shiny finish of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- Magnets are characterized by impressive magnetic induction on the outer side,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of exact machining and adapting to individual conditions,

- Huge importance in future technologies – they are utilized in hard drives, electric drive systems, advanced medical instruments, also other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- To avoid cracks upon strong impacts, we suggest using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Limited ability of creating nuts in the magnet and complicated forms - recommended is casing - mounting mechanism.

- Health risk related to microscopic parts of magnets are risky, in case of ingestion, which is particularly important in the context of child health protection. It is also worth noting that small elements of these products are able to be problematic in diagnostics medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what affects it?

- on a base made of mild steel, effectively closing the magnetic field

- with a cross-section of at least 10 mm

- with an ground contact surface

- with zero gap (without impurities)

- under vertical application of breakaway force (90-degree angle)

- at temperature room level

Practical aspects of lifting capacity – factors

- Distance (between the magnet and the metal), because even a tiny clearance (e.g. 0.5 mm) can cause a decrease in force by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – note that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Base massiveness – insufficiently thick sheet causes magnetic saturation, causing part of the power to be lost into the air.

- Material composition – not every steel attracts identically. Alloy additives worsen the attraction effect.

- Surface structure – the more even the surface, the larger the contact zone and higher the lifting capacity. Unevenness acts like micro-gaps.

- Temperature – temperature increase causes a temporary drop of force. Check the thermal limit for a given model.

Holding force was checked on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, whereas under parallel forces the lifting capacity is smaller. In addition, even a minimal clearance between the magnet and the plate reduces the load capacity.

Safety rules for work with neodymium magnets

Thermal limits

Standard neodymium magnets (N-type) lose magnetization when the temperature goes above 80°C. This process is irreversible.

Metal Allergy

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If an allergic reaction appears, cease working with magnets and wear gloves.

Do not give to children

These products are not toys. Eating multiple magnets may result in them connecting inside the digestive tract, which poses a severe health hazard and requires immediate surgery.

Protective goggles

NdFeB magnets are ceramic materials, meaning they are very brittle. Impact of two magnets will cause them shattering into shards.

Health Danger

Individuals with a pacemaker have to maintain an absolute distance from magnets. The magnetism can disrupt the operation of the implant.

Bone fractures

Risk of injury: The pulling power is so immense that it can cause hematomas, crushing, and even bone fractures. Protective gloves are recommended.

Threat to electronics

Data protection: Neodymium magnets can damage data carriers and sensitive devices (pacemakers, medical aids, timepieces).

Do not drill into magnets

Dust created during grinding of magnets is self-igniting. Avoid drilling into magnets without proper cooling and knowledge.

Handling rules

Be careful. Rare earth magnets attract from a distance and connect with massive power, often quicker than you can move away.

Impact on smartphones

Navigation devices and smartphones are highly sensitive to magnetic fields. Close proximity with a strong magnet can permanently damage the sensors in your phone.

![UMP 75x25 [M10x3] GW F200 GOLD DUAL Lina / N42 - search holder UMP 75x25 [M10x3] GW F200 GOLD DUAL Lina / N42 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-gold-x2-lina-car.jpg)

![SM 25x400 [2xM8] / N42 - magnetic separator SM 25x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x400-2xm8-daj.jpg)

![AM ucho [M8] - magnetic accessories AM ucho [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m8-lib.jpg)