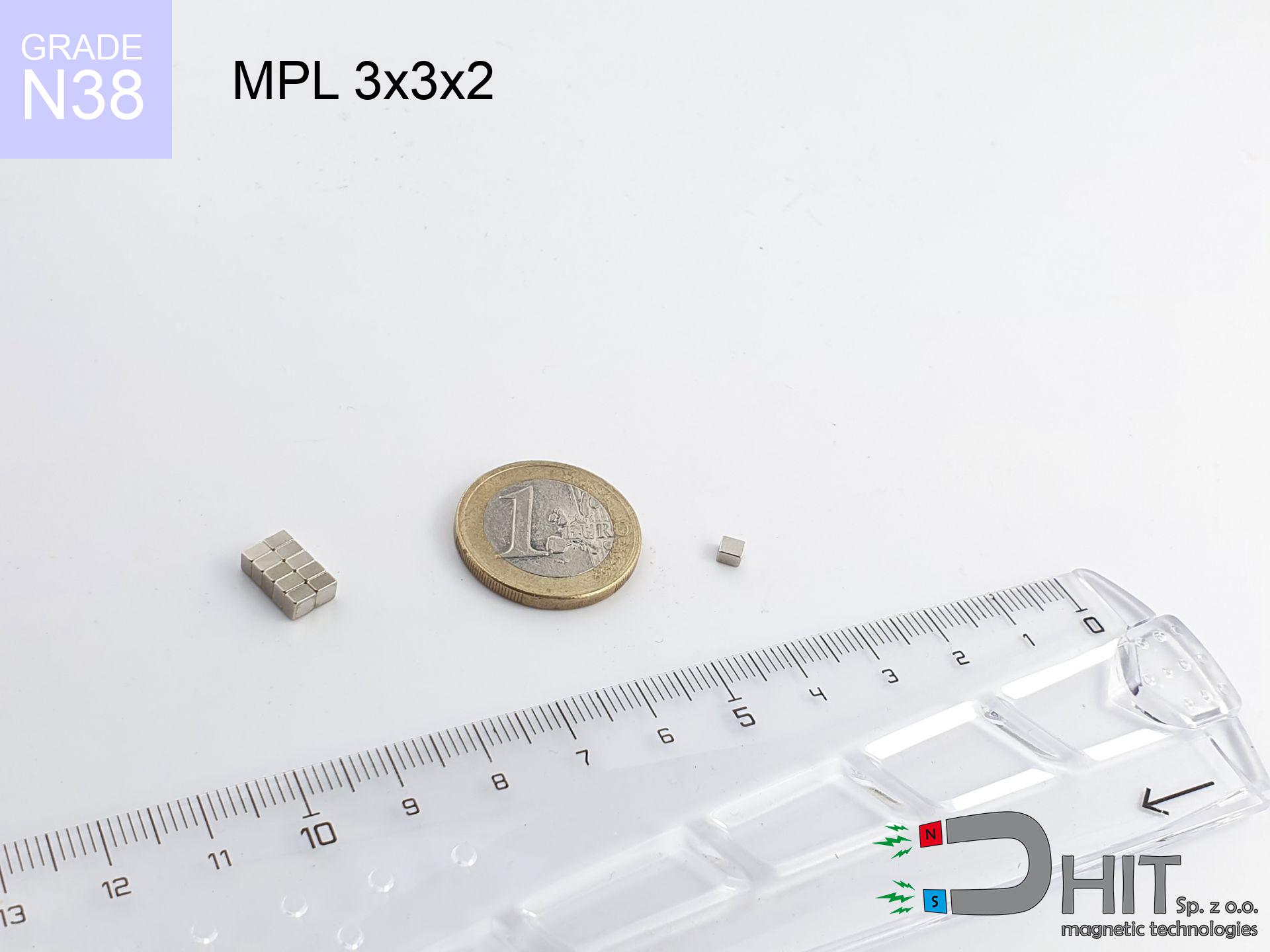

MPL 3x3x2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020147

GTIN/EAN: 5906301811534

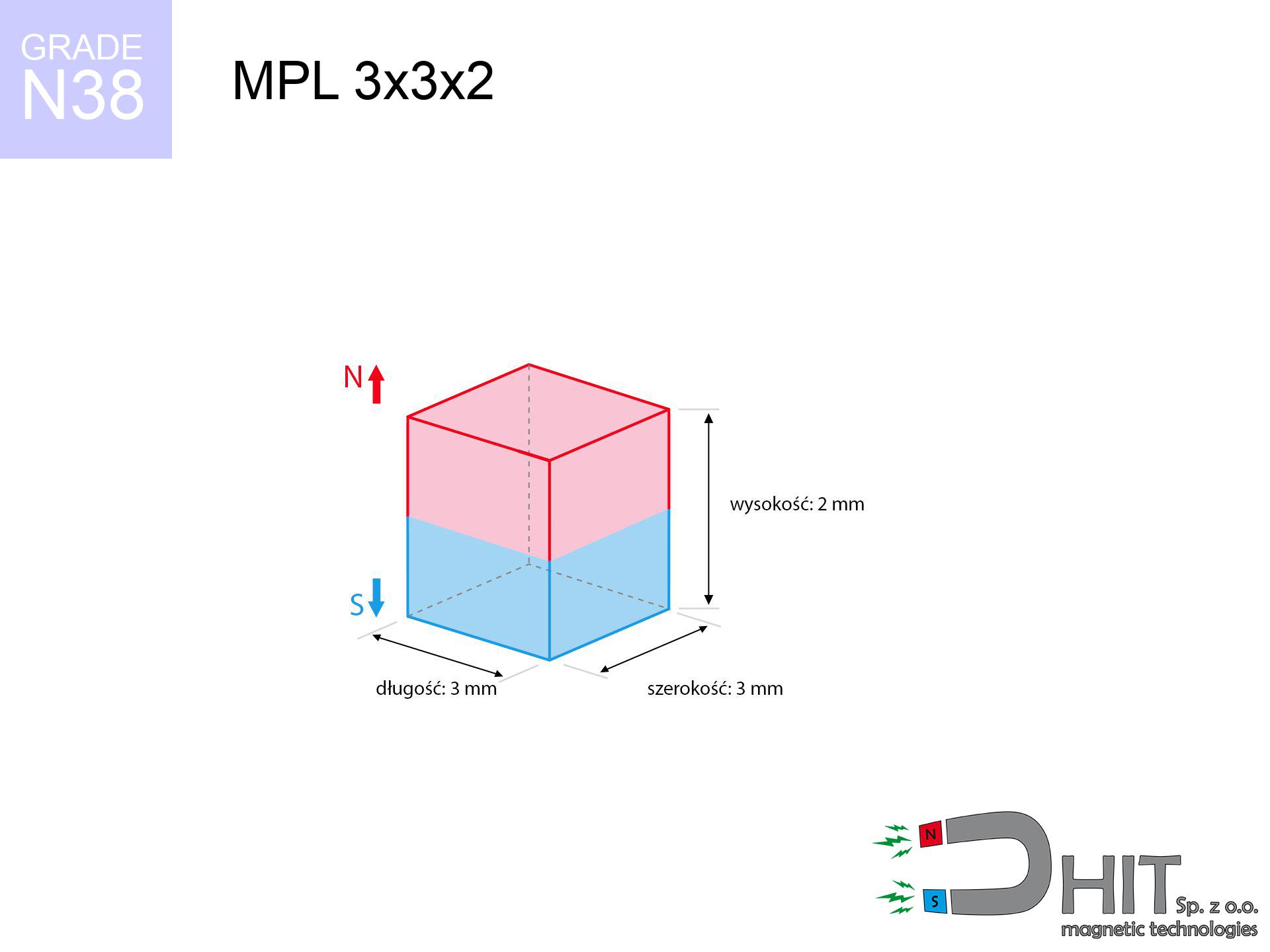

length

3 mm [±0,1 mm]

Width

3 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

0.13 g

Magnetization Direction

↑ axial

Load capacity

0.36 kg / 3.49 N

Magnetic Induction

472.94 mT / 4729 Gs

Coating

[NiCuNi] Nickel

0.1722 ZŁ with VAT / pcs + price for transport

0.1400 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer send us a note through

contact form

our website.

Parameters along with form of a magnet can be calculated with our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Technical of the product - MPL 3x3x2 / N38 - lamellar magnet

Specification / characteristics - MPL 3x3x2 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020147 |

| GTIN/EAN | 5906301811534 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 3 mm [±0,1 mm] |

| Width | 3 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 0.13 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.36 kg / 3.49 N |

| Magnetic Induction ~ ? | 472.94 mT / 4729 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the assembly - report

The following information are the result of a engineering simulation. Values rely on models for the material Nd2Fe14B. Operational conditions might slightly deviate from the simulation results. Please consider these calculations as a reference point for designers.

Table 1: Static force (pull vs distance) - power drop

MPL 3x3x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4719 Gs

471.9 mT

|

0.36 kg / 0.79 pounds

360.0 g / 3.5 N

|

safe |

| 1 mm |

2223 Gs

222.3 mT

|

0.08 kg / 0.18 pounds

79.9 g / 0.8 N

|

safe |

| 2 mm |

966 Gs

96.6 mT

|

0.02 kg / 0.03 pounds

15.1 g / 0.1 N

|

safe |

| 3 mm |

468 Gs

46.8 mT

|

0.00 kg / 0.01 pounds

3.5 g / 0.0 N

|

safe |

| 5 mm |

153 Gs

15.3 mT

|

0.00 kg / 0.00 pounds

0.4 g / 0.0 N

|

safe |

| 10 mm |

26 Gs

2.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 15 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 20 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 30 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Vertical hold (wall)

MPL 3x3x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.07 kg / 0.16 pounds

72.0 g / 0.7 N

|

| 1 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

16.0 g / 0.2 N

|

| 2 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 3x3x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.11 kg / 0.24 pounds

108.0 g / 1.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.07 kg / 0.16 pounds

72.0 g / 0.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.04 kg / 0.08 pounds

36.0 g / 0.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.18 kg / 0.40 pounds

180.0 g / 1.8 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 3x3x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.04 kg / 0.08 pounds

36.0 g / 0.4 N

|

| 1 mm |

|

0.09 kg / 0.20 pounds

90.0 g / 0.9 N

|

| 2 mm |

|

0.18 kg / 0.40 pounds

180.0 g / 1.8 N

|

| 3 mm |

|

0.27 kg / 0.60 pounds

270.0 g / 2.6 N

|

| 5 mm |

|

0.36 kg / 0.79 pounds

360.0 g / 3.5 N

|

| 10 mm |

|

0.36 kg / 0.79 pounds

360.0 g / 3.5 N

|

| 11 mm |

|

0.36 kg / 0.79 pounds

360.0 g / 3.5 N

|

| 12 mm |

|

0.36 kg / 0.79 pounds

360.0 g / 3.5 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MPL 3x3x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.36 kg / 0.79 pounds

360.0 g / 3.5 N

|

OK |

| 40 °C | -2.2% |

0.35 kg / 0.78 pounds

352.1 g / 3.5 N

|

OK |

| 60 °C | -4.4% |

0.34 kg / 0.76 pounds

344.2 g / 3.4 N

|

OK |

| 80 °C | -6.6% |

0.34 kg / 0.74 pounds

336.2 g / 3.3 N

|

|

| 100 °C | -28.8% |

0.26 kg / 0.57 pounds

256.3 g / 2.5 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MPL 3x3x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.24 kg / 2.72 pounds

5 677 Gs

|

0.19 kg / 0.41 pounds

185 g / 1.8 N

|

N/A |

| 1 mm |

0.63 kg / 1.38 pounds

6 725 Gs

|

0.09 kg / 0.21 pounds

94 g / 0.9 N

|

0.56 kg / 1.24 pounds

~0 Gs

|

| 2 mm |

0.27 kg / 0.60 pounds

4 447 Gs

|

0.04 kg / 0.09 pounds

41 g / 0.4 N

|

0.25 kg / 0.54 pounds

~0 Gs

|

| 3 mm |

0.12 kg / 0.26 pounds

2 903 Gs

|

0.02 kg / 0.04 pounds

18 g / 0.2 N

|

0.11 kg / 0.23 pounds

~0 Gs

|

| 5 mm |

0.02 kg / 0.05 pounds

1 324 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 10 mm |

0.00 kg / 0.00 pounds

306 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 pounds

52 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

4 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

1 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

1 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

1 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 3x3x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 1.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 1.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.0 cm |

| Car key | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 3x3x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

53.07 km/h

(14.74 m/s)

|

0.01 J | |

| 30 mm |

91.92 km/h

(25.53 m/s)

|

0.04 J | |

| 50 mm |

118.67 km/h

(32.96 m/s)

|

0.07 J | |

| 100 mm |

167.83 km/h

(46.62 m/s)

|

0.14 J |

Table 9: Corrosion resistance

MPL 3x3x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 3x3x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 429 Mx | 4.3 µWb |

| Pc Coefficient | 0.66 | High (Stable) |

Table 11: Submerged application

MPL 3x3x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.36 kg | Standard |

| Water (riverbed) |

0.41 kg

(+0.05 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet holds only a fraction of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Thermal stability

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.66

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Strengths as well as weaknesses of neodymium magnets.

Advantages

- They do not lose magnetism, even after approximately 10 years – the reduction in power is only ~1% (theoretically),

- Magnets very well protect themselves against demagnetization caused by ambient magnetic noise,

- By covering with a shiny coating of silver, the element presents an professional look,

- They show high magnetic induction at the operating surface, which improves attraction properties,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to freedom in designing and the ability to customize to specific needs,

- Universal use in future technologies – they serve a role in data components, brushless drives, medical devices, as well as multitasking production systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Weaknesses

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation as well as corrosion.

- Limited ability of making threads in the magnet and complicated shapes - preferred is casing - magnetic holder.

- Health risk related to microscopic parts of magnets pose a threat, when accidentally swallowed, which becomes key in the aspect of protecting the youngest. It is also worth noting that small elements of these devices can disrupt the diagnostic process medical after entering the body.

- Due to expensive raw materials, their price exceeds standard values,

Lifting parameters

Maximum lifting capacity of the magnet – what it depends on?

- on a block made of structural steel, perfectly concentrating the magnetic field

- with a cross-section minimum 10 mm

- with an polished contact surface

- without any clearance between the magnet and steel

- during detachment in a direction vertical to the mounting surface

- at temperature room level

Determinants of lifting force in real conditions

- Gap (between the magnet and the plate), as even a very small clearance (e.g. 0.5 mm) results in a decrease in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Direction of force – maximum parameter is available only during pulling at a 90° angle. The force required to slide of the magnet along the surface is standardly several times lower (approx. 1/5 of the lifting capacity).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Material type – ideal substrate is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Surface quality – the more even the plate, the larger the contact zone and stronger the hold. Roughness acts like micro-gaps.

- Temperature – temperature increase results in weakening of force. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was determined by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular detachment force, however under attempts to slide the magnet the load capacity is reduced by as much as fivefold. In addition, even a slight gap between the magnet and the plate decreases the holding force.

H&S for magnets

Heat sensitivity

Regular neodymium magnets (N-type) lose magnetization when the temperature surpasses 80°C. The loss of strength is permanent.

Electronic devices

Do not bring magnets near a wallet, computer, or screen. The magnetic field can irreversibly ruin these devices and wipe information from cards.

Warning for heart patients

Health Alert: Neodymium magnets can deactivate heart devices and defibrillators. Stay away if you have electronic implants.

Compass and GPS

An intense magnetic field negatively affects the functioning of compasses in smartphones and GPS navigation. Maintain magnets close to a smartphone to avoid breaking the sensors.

Dust is flammable

Drilling and cutting of NdFeB material carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

This is not a toy

NdFeB magnets are not toys. Accidental ingestion of several magnets can lead to them pinching intestinal walls, which constitutes a direct threat to life and necessitates urgent medical intervention.

Avoid contact if allergic

Nickel alert: The Ni-Cu-Ni coating contains nickel. If an allergic reaction happens, cease handling magnets and use protective gear.

Pinching danger

Big blocks can crush fingers in a fraction of a second. Under no circumstances put your hand between two strong magnets.

Powerful field

Handle with care. Neodymium magnets attract from a long distance and connect with huge force, often quicker than you can move away.

Protective goggles

Neodymium magnets are sintered ceramics, meaning they are prone to chipping. Collision of two magnets will cause them cracking into small pieces.

![SM 32x150 [2xM8] / N52 - magnetic separator SM 32x150 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xuc.jpg)