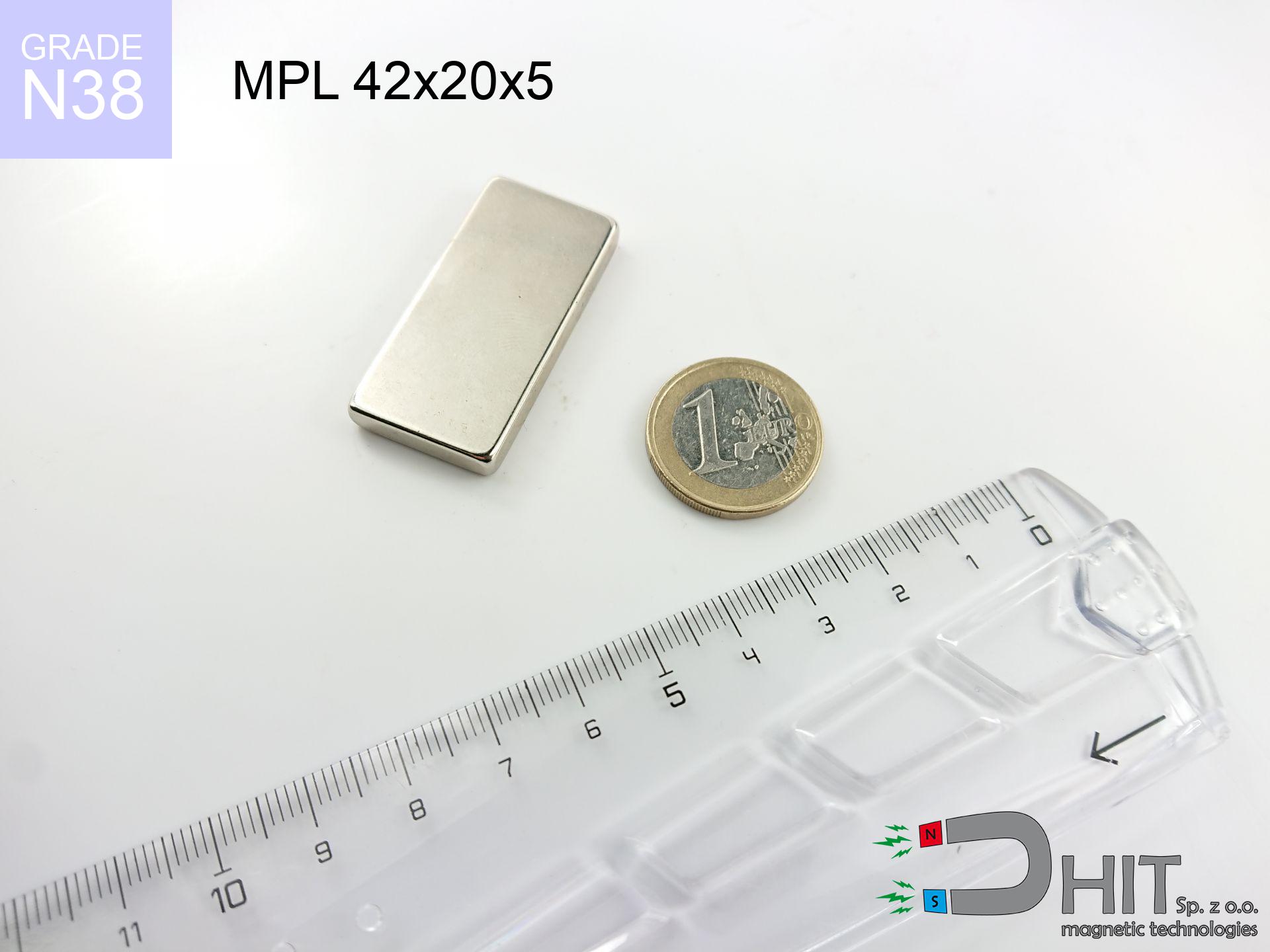

UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread

magnetic holder external thread

Catalog no 190321

GTIN/EAN: 5906301813804

Diameter Ø

16 mm [±1 mm]

Height

13 mm [±1 mm]

Height

5 mm [±1 mm]

Weight

7 g

Load capacity

5.00 kg / 49.03 N

3.89 ZŁ with VAT / pcs + price for transport

3.16 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise let us know using

inquiry form

the contact section.

Specifications and shape of magnetic components can be checked using our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread

Specification / characteristics - UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread

| properties | values |

|---|---|

| Cat. no. | 190321 |

| GTIN/EAN | 5906301813804 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 16 mm [±1 mm] |

| Height | 13 mm [±1 mm] |

| Height | 5 mm [±1 mm] |

| Weight | 7 g |

| Load capacity ~ ? | 5.00 kg / 49.03 N |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Pros and cons of Nd2Fe14B magnets.

Advantages

- They do not lose strength, even over around ten years – the decrease in power is only ~1% (theoretically),

- They show high resistance to demagnetization induced by external field influence,

- A magnet with a metallic gold surface looks better,

- The surface of neodymium magnets generates a unique magnetic field – this is a key feature,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Thanks to flexibility in shaping and the ability to customize to specific needs,

- Versatile presence in future technologies – they serve a role in hard drives, electromotive mechanisms, advanced medical instruments, also modern systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which enables their usage in compact constructions

Limitations

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- They oxidize in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited ability of making nuts in the magnet and complex forms - preferred is casing - magnetic holder.

- Potential hazard related to microscopic parts of magnets pose a threat, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Additionally, small components of these magnets are able to disrupt the diagnostic process medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum lifting force for a neodymium magnet – what contributes to it?

- with the use of a yoke made of low-carbon steel, ensuring maximum field concentration

- whose thickness equals approx. 10 mm

- with a surface free of scratches

- without the slightest air gap between the magnet and steel

- under perpendicular force direction (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Practical lifting capacity: influencing factors

- Air gap (between the magnet and the plate), since even a microscopic clearance (e.g. 0.5 mm) results in a reduction in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Force direction – remember that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Steel thickness – too thin steel does not accept the full field, causing part of the flux to be lost into the air.

- Metal type – different alloys attracts identically. Alloy additives worsen the interaction with the magnet.

- Surface condition – smooth surfaces guarantee perfect abutment, which increases field saturation. Rough surfaces weaken the grip.

- Temperature influence – hot environment weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under a perpendicular pulling force, whereas under attempts to slide the magnet the load capacity is reduced by as much as 75%. Moreover, even a small distance between the magnet’s surface and the plate decreases the holding force.

Safety rules for work with neodymium magnets

Impact on smartphones

A strong magnetic field disrupts the operation of magnetometers in phones and GPS navigation. Do not bring magnets close to a smartphone to prevent damaging the sensors.

Crushing risk

Pinching hazard: The pulling power is so immense that it can result in blood blisters, crushing, and even bone fractures. Protective gloves are recommended.

No play value

Absolutely store magnets away from children. Risk of swallowing is high, and the effects of magnets clamping inside the body are fatal.

Mechanical processing

Drilling and cutting of neodymium magnets carries a risk of fire risk. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Medical interference

Patients with a heart stimulator should maintain an large gap from magnets. The magnetism can disrupt the operation of the implant.

Warning for allergy sufferers

Nickel alert: The nickel-copper-nickel coating consists of nickel. If an allergic reaction occurs, cease working with magnets and wear gloves.

Risk of cracking

Despite metallic appearance, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Power loss in heat

Do not overheat. Neodymium magnets are susceptible to temperature. If you require operation above 80°C, look for HT versions (H, SH, UH).

Handling guide

Handle with care. Rare earth magnets attract from a long distance and snap with massive power, often quicker than you can move away.

Magnetic media

Avoid bringing magnets near a purse, computer, or screen. The magnetism can irreversibly ruin these devices and erase data from cards.

![Magnet with screw UMGZ 16x13x5 [M4] GZ / N38 Magnet with screw UMGZ 16x13x5 [M4] GZ / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-16x13x5-m4-gz-cor.jpg)

![UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread - ujęcie 2](https://cdn3.dhit.pl/graphics/products/umgw-16x13x5-m4-gz-vuz.jpg)