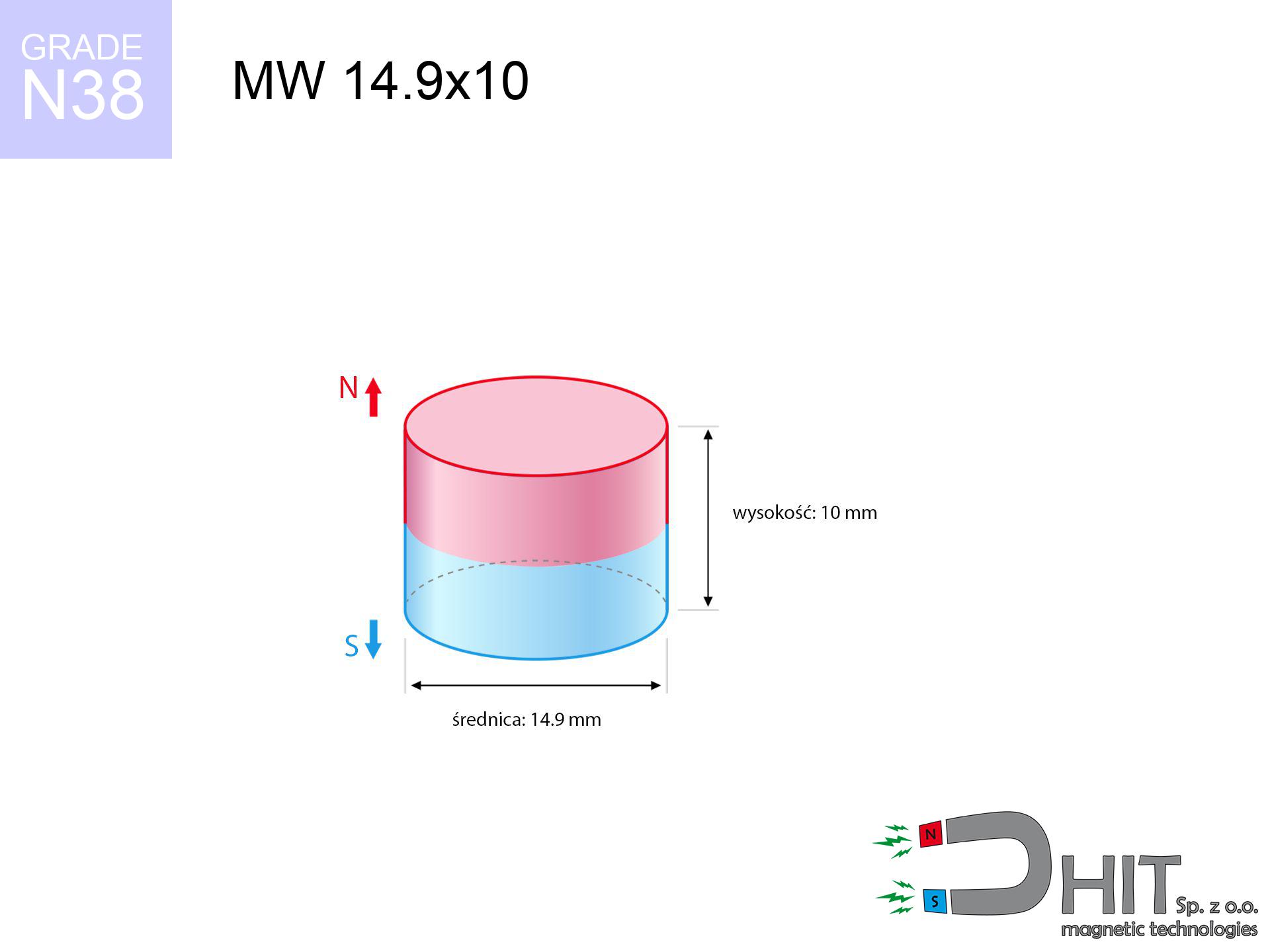

MW 14.9x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010023

GTIN/EAN: 5906301810223

Diameter Ø

14.9 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

13.08 g

Magnetization Direction

→ diametrical

Load capacity

7.60 kg / 74.57 N

Magnetic Induction

496.78 mT / 4968 Gs

Coating

[NiCuNi] Nickel

8.24 ZŁ with VAT / pcs + price for transport

6.70 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise let us know via

request form

the contact page.

Lifting power and structure of magnetic components can be reviewed using our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - MW 14.9x10 / N38 - cylindrical magnet

Specification / characteristics - MW 14.9x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010023 |

| GTIN/EAN | 5906301810223 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 14.9 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 13.08 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 7.60 kg / 74.57 N |

| Magnetic Induction ~ ? | 496.78 mT / 4968 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the assembly - report

These values represent the direct effect of a engineering calculation. Results were calculated on models for the class Nd2Fe14B. Actual conditions may differ from theoretical values. Please consider these calculations as a supplementary guide for designers.

Table 1: Static force (force vs gap) - characteristics

MW 14.9x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4965 Gs

496.5 mT

|

7.60 kg / 16.76 lbs

7600.0 g / 74.6 N

|

strong |

| 1 mm |

4309 Gs

430.9 mT

|

5.72 kg / 12.62 lbs

5722.6 g / 56.1 N

|

strong |

| 2 mm |

3660 Gs

366.0 mT

|

4.13 kg / 9.10 lbs

4129.1 g / 40.5 N

|

strong |

| 3 mm |

3063 Gs

306.3 mT

|

2.89 kg / 6.38 lbs

2892.7 g / 28.4 N

|

strong |

| 5 mm |

2098 Gs

209.8 mT

|

1.36 kg / 2.99 lbs

1356.5 g / 13.3 N

|

safe |

| 10 mm |

838 Gs

83.8 mT

|

0.22 kg / 0.48 lbs

216.5 g / 2.1 N

|

safe |

| 15 mm |

389 Gs

38.9 mT

|

0.05 kg / 0.10 lbs

46.6 g / 0.5 N

|

safe |

| 20 mm |

207 Gs

20.7 mT

|

0.01 kg / 0.03 lbs

13.2 g / 0.1 N

|

safe |

| 30 mm |

78 Gs

7.8 mT

|

0.00 kg / 0.00 lbs

1.9 g / 0.0 N

|

safe |

| 50 mm |

20 Gs

2.0 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

Table 2: Sliding force (vertical surface)

MW 14.9x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.52 kg / 3.35 lbs

1520.0 g / 14.9 N

|

| 1 mm | Stal (~0.2) |

1.14 kg / 2.52 lbs

1144.0 g / 11.2 N

|

| 2 mm | Stal (~0.2) |

0.83 kg / 1.82 lbs

826.0 g / 8.1 N

|

| 3 mm | Stal (~0.2) |

0.58 kg / 1.27 lbs

578.0 g / 5.7 N

|

| 5 mm | Stal (~0.2) |

0.27 kg / 0.60 lbs

272.0 g / 2.7 N

|

| 10 mm | Stal (~0.2) |

0.04 kg / 0.10 lbs

44.0 g / 0.4 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 14.9x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.28 kg / 5.03 lbs

2280.0 g / 22.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.52 kg / 3.35 lbs

1520.0 g / 14.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.76 kg / 1.68 lbs

760.0 g / 7.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.80 kg / 8.38 lbs

3800.0 g / 37.3 N

|

Table 4: Material efficiency (saturation) - power losses

MW 14.9x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.76 kg / 1.68 lbs

760.0 g / 7.5 N

|

| 1 mm |

|

1.90 kg / 4.19 lbs

1900.0 g / 18.6 N

|

| 2 mm |

|

3.80 kg / 8.38 lbs

3800.0 g / 37.3 N

|

| 3 mm |

|

5.70 kg / 12.57 lbs

5700.0 g / 55.9 N

|

| 5 mm |

|

7.60 kg / 16.76 lbs

7600.0 g / 74.6 N

|

| 10 mm |

|

7.60 kg / 16.76 lbs

7600.0 g / 74.6 N

|

| 11 mm |

|

7.60 kg / 16.76 lbs

7600.0 g / 74.6 N

|

| 12 mm |

|

7.60 kg / 16.76 lbs

7600.0 g / 74.6 N

|

Table 5: Thermal stability (material behavior) - power drop

MW 14.9x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.60 kg / 16.76 lbs

7600.0 g / 74.6 N

|

OK |

| 40 °C | -2.2% |

7.43 kg / 16.39 lbs

7432.8 g / 72.9 N

|

OK |

| 60 °C | -4.4% |

7.27 kg / 16.02 lbs

7265.6 g / 71.3 N

|

OK |

| 80 °C | -6.6% |

7.10 kg / 15.65 lbs

7098.4 g / 69.6 N

|

|

| 100 °C | -28.8% |

5.41 kg / 11.93 lbs

5411.2 g / 53.1 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 14.9x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

26.50 kg / 58.43 lbs

5 802 Gs

|

3.98 kg / 8.76 lbs

3975 g / 39.0 N

|

N/A |

| 1 mm |

23.16 kg / 51.05 lbs

9 283 Gs

|

3.47 kg / 7.66 lbs

3474 g / 34.1 N

|

20.84 kg / 45.95 lbs

~0 Gs

|

| 2 mm |

19.96 kg / 44.00 lbs

8 617 Gs

|

2.99 kg / 6.60 lbs

2993 g / 29.4 N

|

17.96 kg / 39.60 lbs

~0 Gs

|

| 3 mm |

17.03 kg / 37.54 lbs

7 959 Gs

|

2.55 kg / 5.63 lbs

2554 g / 25.1 N

|

15.32 kg / 33.78 lbs

~0 Gs

|

| 5 mm |

12.09 kg / 26.65 lbs

6 707 Gs

|

1.81 kg / 4.00 lbs

1813 g / 17.8 N

|

10.88 kg / 23.99 lbs

~0 Gs

|

| 10 mm |

4.73 kg / 10.43 lbs

4 196 Gs

|

0.71 kg / 1.56 lbs

710 g / 7.0 N

|

4.26 kg / 9.39 lbs

~0 Gs

|

| 20 mm |

0.76 kg / 1.66 lbs

1 676 Gs

|

0.11 kg / 0.25 lbs

113 g / 1.1 N

|

0.68 kg / 1.50 lbs

~0 Gs

|

| 50 mm |

0.02 kg / 0.04 lbs

245 Gs

|

0.00 kg / 0.01 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 60 mm |

0.01 kg / 0.01 lbs

156 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 lbs

105 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

74 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

54 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

41 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 14.9x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 5.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (kinetic energy) - warning

MW 14.9x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.74 km/h

(6.87 m/s)

|

0.31 J | |

| 30 mm |

42.11 km/h

(11.70 m/s)

|

0.89 J | |

| 50 mm |

54.36 km/h

(15.10 m/s)

|

1.49 J | |

| 100 mm |

76.87 km/h

(21.35 m/s)

|

2.98 J |

Table 9: Coating parameters (durability)

MW 14.9x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 14.9x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 8 732 Mx | 87.3 µWb |

| Pc Coefficient | 0.71 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 14.9x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.60 kg | Standard |

| Water (riverbed) |

8.70 kg

(+1.10 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical wall, the magnet retains just ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) severely reduces the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.71

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Advantages

- They virtually do not lose power, because even after ten years the decline in efficiency is only ~1% (in laboratory conditions),

- Neodymium magnets are distinguished by highly resistant to loss of magnetic properties caused by external magnetic fields,

- Thanks to the shiny finish, the plating of nickel, gold-plated, or silver-plated gives an clean appearance,

- Magnetic induction on the working layer of the magnet is impressive,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of accurate modeling and adapting to specific requirements,

- Universal use in high-tech industry – they are utilized in magnetic memories, motor assemblies, advanced medical instruments, also modern systems.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Cons

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can break. We recommend keeping them in a steel housing, which not only secures them against impacts but also increases their durability

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Limited possibility of producing nuts in the magnet and complicated forms - preferred is a housing - magnetic holder.

- Possible danger related to microscopic parts of magnets are risky, if swallowed, which gains importance in the context of child health protection. Additionally, small components of these devices can disrupt the diagnostic process medical when they are in the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which hinders application in large quantities

Pull force analysis

Breakaway strength of the magnet in ideal conditions – what it depends on?

- on a plate made of mild steel, perfectly concentrating the magnetic field

- with a thickness of at least 10 mm

- with a surface cleaned and smooth

- under conditions of gap-free contact (surface-to-surface)

- for force applied at a right angle (pull-off, not shear)

- at temperature room level

Lifting capacity in practice – influencing factors

- Clearance – the presence of any layer (paint, dirt, gap) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal limits the lifting capacity (the magnet "punches through" it).

- Metal type – different alloys reacts the same. High carbon content worsen the attraction effect.

- Base smoothness – the more even the plate, the better the adhesion and higher the lifting capacity. Unevenness acts like micro-gaps.

- Thermal environment – temperature increase causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Holding force was checked on the plate surface of 20 mm thickness, when a perpendicular force was applied, in contrast under parallel forces the lifting capacity is smaller. Moreover, even a slight gap between the magnet and the plate decreases the holding force.

Safety rules for work with neodymium magnets

Protect data

Equipment safety: Neodymium magnets can damage payment cards and sensitive devices (heart implants, hearing aids, timepieces).

Finger safety

Pinching hazard: The attraction force is so immense that it can cause blood blisters, pinching, and even bone fractures. Use thick gloves.

GPS and phone interference

A powerful magnetic field disrupts the functioning of compasses in smartphones and navigation systems. Maintain magnets near a smartphone to prevent damaging the sensors.

Danger to pacemakers

For implant holders: Strong magnetic fields affect medical devices. Maintain minimum 30 cm distance or ask another person to handle the magnets.

Danger to the youngest

These products are not intended for children. Eating multiple magnets may result in them connecting inside the digestive tract, which constitutes a direct threat to life and necessitates urgent medical intervention.

Heat warning

Regular neodymium magnets (grade N) undergo demagnetization when the temperature surpasses 80°C. Damage is permanent.

Fragile material

Protect your eyes. Magnets can fracture upon violent connection, ejecting shards into the air. We recommend safety glasses.

Handling rules

Handle with care. Neodymium magnets attract from a distance and snap with huge force, often faster than you can react.

Flammability

Mechanical processing of NdFeB material poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Avoid contact if allergic

A percentage of the population have a sensitization to Ni, which is the standard coating for NdFeB magnets. Frequent touching might lead to a rash. We recommend wear safety gloves.

![SM 32x500 [2xM8] / N52 - magnetic separator SM 32x500 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x500-2xm8-rub.jpg)

![SM 32x475 [2xM8] / N42 - magnetic separator SM 32x475 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x475-2xm8-jot.jpg)

![SM 25x250 [2xM8] / N52 - magnetic separator SM 25x250 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x250-2xm8-sam.jpg)