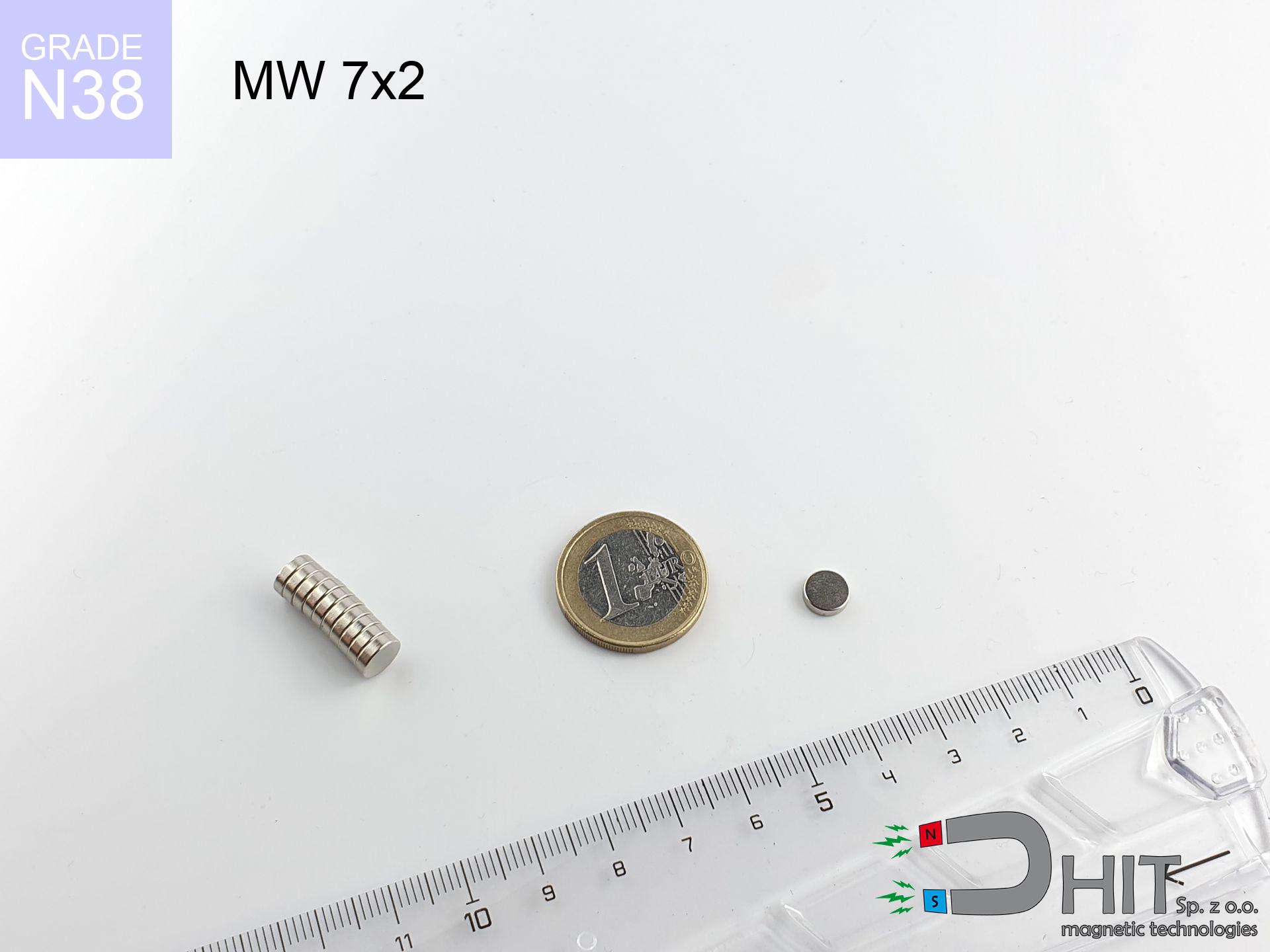

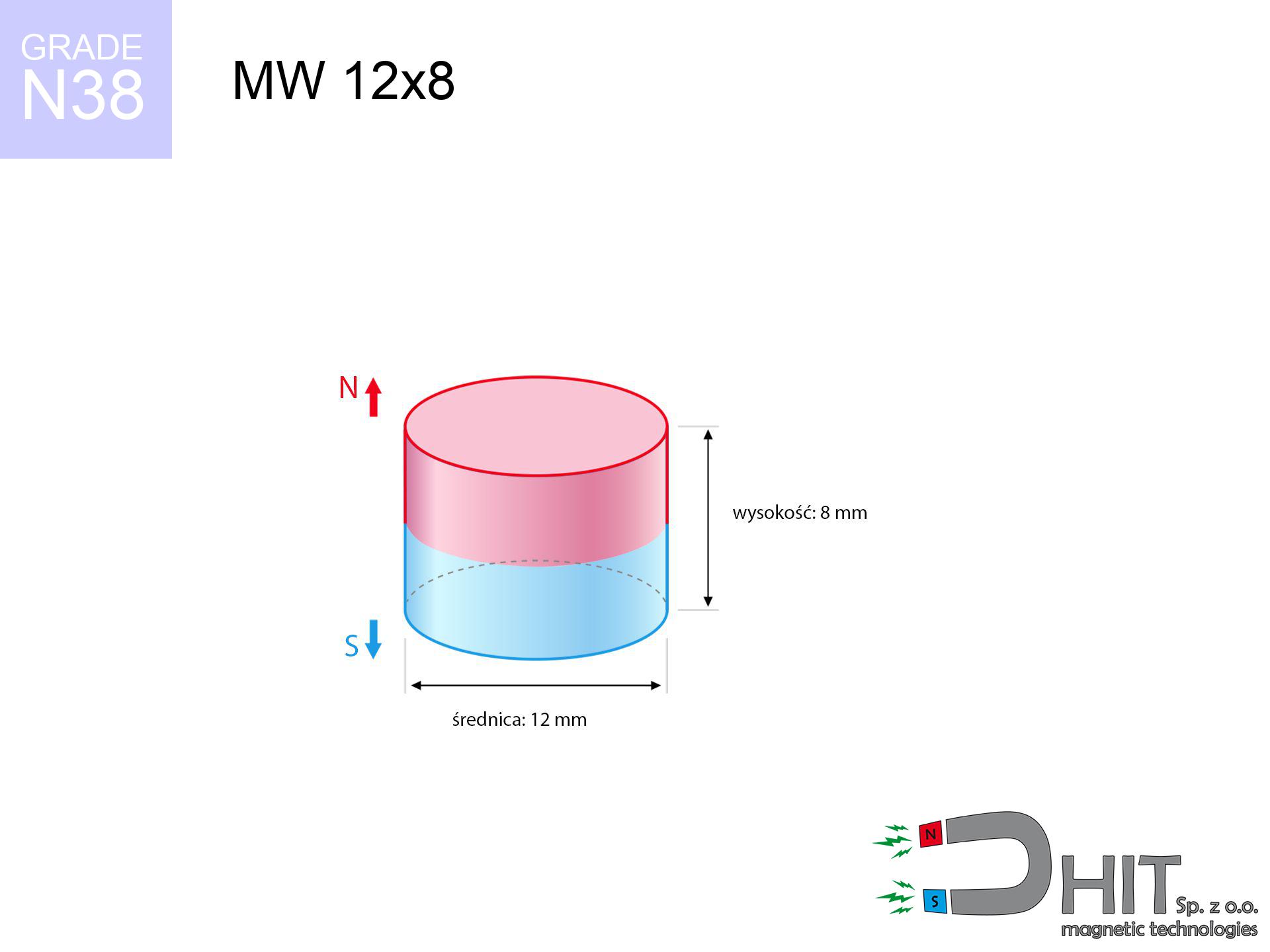

MW 12x8 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010022

GTIN/EAN: 5906301810216

Diameter Ø

12 mm [±0,1 mm]

Height

8 mm [±0,1 mm]

Weight

6.79 g

Magnetization Direction

↑ axial

Load capacity

4.93 kg / 48.32 N

Magnetic Induction

495.50 mT / 4955 Gs

Coating

[NiCuNi] Nickel

2.47 ZŁ with VAT / pcs + price for transport

2.01 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

otherwise get in touch through

contact form

our website.

Parameters along with appearance of a neodymium magnet can be tested using our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical data - MW 12x8 / N38 - cylindrical magnet

Specification / characteristics - MW 12x8 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010022 |

| GTIN/EAN | 5906301810216 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12 mm [±0,1 mm] |

| Height | 8 mm [±0,1 mm] |

| Weight | 6.79 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.93 kg / 48.32 N |

| Magnetic Induction ~ ? | 495.50 mT / 4955 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - report

Presented information constitute the direct effect of a engineering calculation. Results were calculated on models for the material Nd2Fe14B. Actual conditions might slightly differ. Use these calculations as a supplementary guide for designers.

Table 1: Static pull force (force vs gap) - power drop

MW 12x8 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4952 Gs

495.2 mT

|

4.93 kg / 10.87 lbs

4930.0 g / 48.4 N

|

medium risk |

| 1 mm |

4139 Gs

413.9 mT

|

3.44 kg / 7.59 lbs

3445.0 g / 33.8 N

|

medium risk |

| 2 mm |

3356 Gs

335.6 mT

|

2.26 kg / 4.99 lbs

2264.2 g / 22.2 N

|

medium risk |

| 3 mm |

2670 Gs

267.0 mT

|

1.43 kg / 3.16 lbs

1433.5 g / 14.1 N

|

safe |

| 5 mm |

1660 Gs

166.0 mT

|

0.55 kg / 1.22 lbs

554.1 g / 5.4 N

|

safe |

| 10 mm |

565 Gs

56.5 mT

|

0.06 kg / 0.14 lbs

64.3 g / 0.6 N

|

safe |

| 15 mm |

243 Gs

24.3 mT

|

0.01 kg / 0.03 lbs

11.8 g / 0.1 N

|

safe |

| 20 mm |

124 Gs

12.4 mT

|

0.00 kg / 0.01 lbs

3.1 g / 0.0 N

|

safe |

| 30 mm |

45 Gs

4.5 mT

|

0.00 kg / 0.00 lbs

0.4 g / 0.0 N

|

safe |

| 50 mm |

11 Gs

1.1 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Shear force (vertical surface)

MW 12x8 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.99 kg / 2.17 lbs

986.0 g / 9.7 N

|

| 1 mm | Stal (~0.2) |

0.69 kg / 1.52 lbs

688.0 g / 6.7 N

|

| 2 mm | Stal (~0.2) |

0.45 kg / 1.00 lbs

452.0 g / 4.4 N

|

| 3 mm | Stal (~0.2) |

0.29 kg / 0.63 lbs

286.0 g / 2.8 N

|

| 5 mm | Stal (~0.2) |

0.11 kg / 0.24 lbs

110.0 g / 1.1 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

12.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 12x8 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.48 kg / 3.26 lbs

1479.0 g / 14.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.99 kg / 2.17 lbs

986.0 g / 9.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.49 kg / 1.09 lbs

493.0 g / 4.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.47 kg / 5.43 lbs

2465.0 g / 24.2 N

|

Table 4: Steel thickness (saturation) - power losses

MW 12x8 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.49 kg / 1.09 lbs

493.0 g / 4.8 N

|

| 1 mm |

|

1.23 kg / 2.72 lbs

1232.5 g / 12.1 N

|

| 2 mm |

|

2.47 kg / 5.43 lbs

2465.0 g / 24.2 N

|

| 3 mm |

|

3.70 kg / 8.15 lbs

3697.5 g / 36.3 N

|

| 5 mm |

|

4.93 kg / 10.87 lbs

4930.0 g / 48.4 N

|

| 10 mm |

|

4.93 kg / 10.87 lbs

4930.0 g / 48.4 N

|

| 11 mm |

|

4.93 kg / 10.87 lbs

4930.0 g / 48.4 N

|

| 12 mm |

|

4.93 kg / 10.87 lbs

4930.0 g / 48.4 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 12x8 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.93 kg / 10.87 lbs

4930.0 g / 48.4 N

|

OK |

| 40 °C | -2.2% |

4.82 kg / 10.63 lbs

4821.5 g / 47.3 N

|

OK |

| 60 °C | -4.4% |

4.71 kg / 10.39 lbs

4713.1 g / 46.2 N

|

OK |

| 80 °C | -6.6% |

4.60 kg / 10.15 lbs

4604.6 g / 45.2 N

|

|

| 100 °C | -28.8% |

3.51 kg / 7.74 lbs

3510.2 g / 34.4 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MW 12x8 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

17.10 kg / 37.69 lbs

5 795 Gs

|

2.56 kg / 5.65 lbs

2565 g / 25.2 N

|

N/A |

| 1 mm |

14.44 kg / 31.83 lbs

9 101 Gs

|

2.17 kg / 4.77 lbs

2166 g / 21.2 N

|

12.99 kg / 28.64 lbs

~0 Gs

|

| 2 mm |

11.95 kg / 26.34 lbs

8 279 Gs

|

1.79 kg / 3.95 lbs

1792 g / 17.6 N

|

10.75 kg / 23.71 lbs

~0 Gs

|

| 3 mm |

9.74 kg / 21.48 lbs

7 477 Gs

|

1.46 kg / 3.22 lbs

1462 g / 14.3 N

|

8.77 kg / 19.33 lbs

~0 Gs

|

| 5 mm |

6.27 kg / 13.82 lbs

5 997 Gs

|

0.94 kg / 2.07 lbs

940 g / 9.2 N

|

5.64 kg / 12.44 lbs

~0 Gs

|

| 10 mm |

1.92 kg / 4.24 lbs

3 320 Gs

|

0.29 kg / 0.64 lbs

288 g / 2.8 N

|

1.73 kg / 3.81 lbs

~0 Gs

|

| 20 mm |

0.22 kg / 0.49 lbs

1 131 Gs

|

0.03 kg / 0.07 lbs

33 g / 0.3 N

|

0.20 kg / 0.44 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 lbs

142 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

89 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

59 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

41 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

30 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

23 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MW 12x8 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - warning

MW 12x8 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.40 km/h

(7.61 m/s)

|

0.20 J | |

| 30 mm |

47.07 km/h

(13.08 m/s)

|

0.58 J | |

| 50 mm |

60.77 km/h

(16.88 m/s)

|

0.97 J | |

| 100 mm |

85.94 km/h

(23.87 m/s)

|

1.93 J |

Table 9: Corrosion resistance

MW 12x8 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 12x8 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 650 Mx | 56.5 µWb |

| Pc Coefficient | 0.71 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 12x8 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.93 kg | Standard |

| Water (riverbed) |

5.64 kg

(+0.71 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet retains merely approx. 20-30% of its max power.

2. Plate thickness effect

*Thin steel (e.g. computer case) significantly reduces the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.71

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more proposals

Strengths and weaknesses of neodymium magnets.

Advantages

- They have stable power, and over more than 10 years their performance decreases symbolically – ~1% (in testing),

- They are extremely resistant to demagnetization induced by external disturbances,

- By applying a smooth coating of silver, the element gains an aesthetic look,

- Magnets possess extremely high magnetic induction on the working surface,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Considering the ability of free shaping and adaptation to unique needs, magnetic components can be produced in a broad palette of geometric configurations, which makes them more universal,

- Wide application in electronics industry – they are used in mass storage devices, motor assemblies, medical devices, also multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which enables their usage in compact constructions

Weaknesses

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a strong case, which not only secures them against impacts but also raises their durability

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can rust. Therefore while using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture

- We suggest a housing - magnetic mechanism, due to difficulties in realizing threads inside the magnet and complicated forms.

- Health risk resulting from small fragments of magnets are risky, in case of ingestion, which gains importance in the context of child safety. Additionally, small elements of these devices are able to be problematic in diagnostics medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which hinders application in large quantities

Pull force analysis

Breakaway strength of the magnet in ideal conditions – what affects it?

- on a plate made of structural steel, perfectly concentrating the magnetic field

- with a cross-section no less than 10 mm

- characterized by even structure

- with zero gap (without coatings)

- during detachment in a direction perpendicular to the plane

- at conditions approx. 20°C

Lifting capacity in practice – influencing factors

- Clearance – existence of foreign body (rust, tape, air) interrupts the magnetic circuit, which lowers power rapidly (even by 50% at 0.5 mm).

- Direction of force – highest force is reached only during perpendicular pulling. The force required to slide of the magnet along the plate is usually several times smaller (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet limits the attraction force (the magnet "punches through" it).

- Material composition – different alloys reacts the same. Alloy additives weaken the interaction with the magnet.

- Plate texture – ground elements guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Thermal conditions – neodymium magnets have a negative temperature coefficient. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity testing was carried out on a smooth plate of suitable thickness, under a perpendicular pulling force, whereas under parallel forces the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

Safe handling of neodymium magnets

GPS Danger

GPS units and mobile phones are extremely sensitive to magnetism. Direct contact with a powerful NdFeB magnet can ruin the internal compass in your phone.

Risk of cracking

Despite the nickel coating, the material is delicate and not impact-resistant. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Skin irritation risks

It is widely known that nickel (the usual finish) is a common allergen. For allergy sufferers, avoid direct skin contact and opt for coated magnets.

Safe operation

Use magnets consciously. Their immense force can surprise even experienced users. Plan your moves and respect their force.

Danger to pacemakers

Life threat: Strong magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

Power loss in heat

Regular neodymium magnets (grade N) lose power when the temperature surpasses 80°C. Damage is permanent.

Bodily injuries

Watch your fingers. Two large magnets will snap together immediately with a force of massive weight, destroying anything in their path. Exercise extreme caution!

Machining danger

Mechanical processing of NdFeB material poses a fire hazard. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Danger to the youngest

Product intended for adults. Small elements can be swallowed, leading to intestinal necrosis. Store out of reach of children and animals.

Threat to electronics

Device Safety: Strong magnets can ruin data carriers and delicate electronics (heart implants, hearing aids, mechanical watches).

![UMH 60x15x69 [M8] / N38 - magnetic holder with hook UMH 60x15x69 [M8] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-60x15x69-m8-nij.jpg)

![UMH 25x8x45 [M5] / N38 - magnetic holder with hook UMH 25x8x45 [M5] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-25x8x45-m5-cep.jpg)