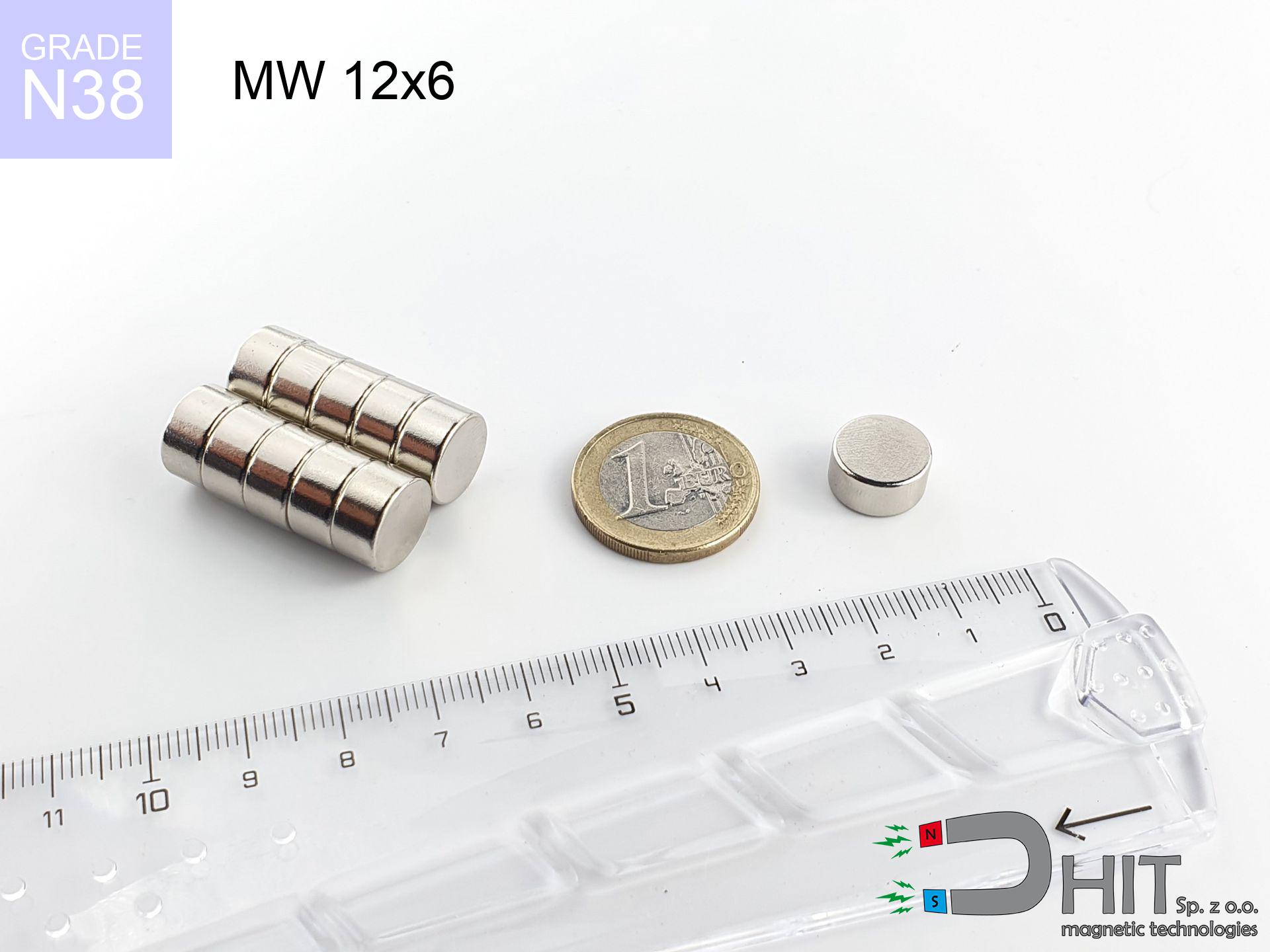

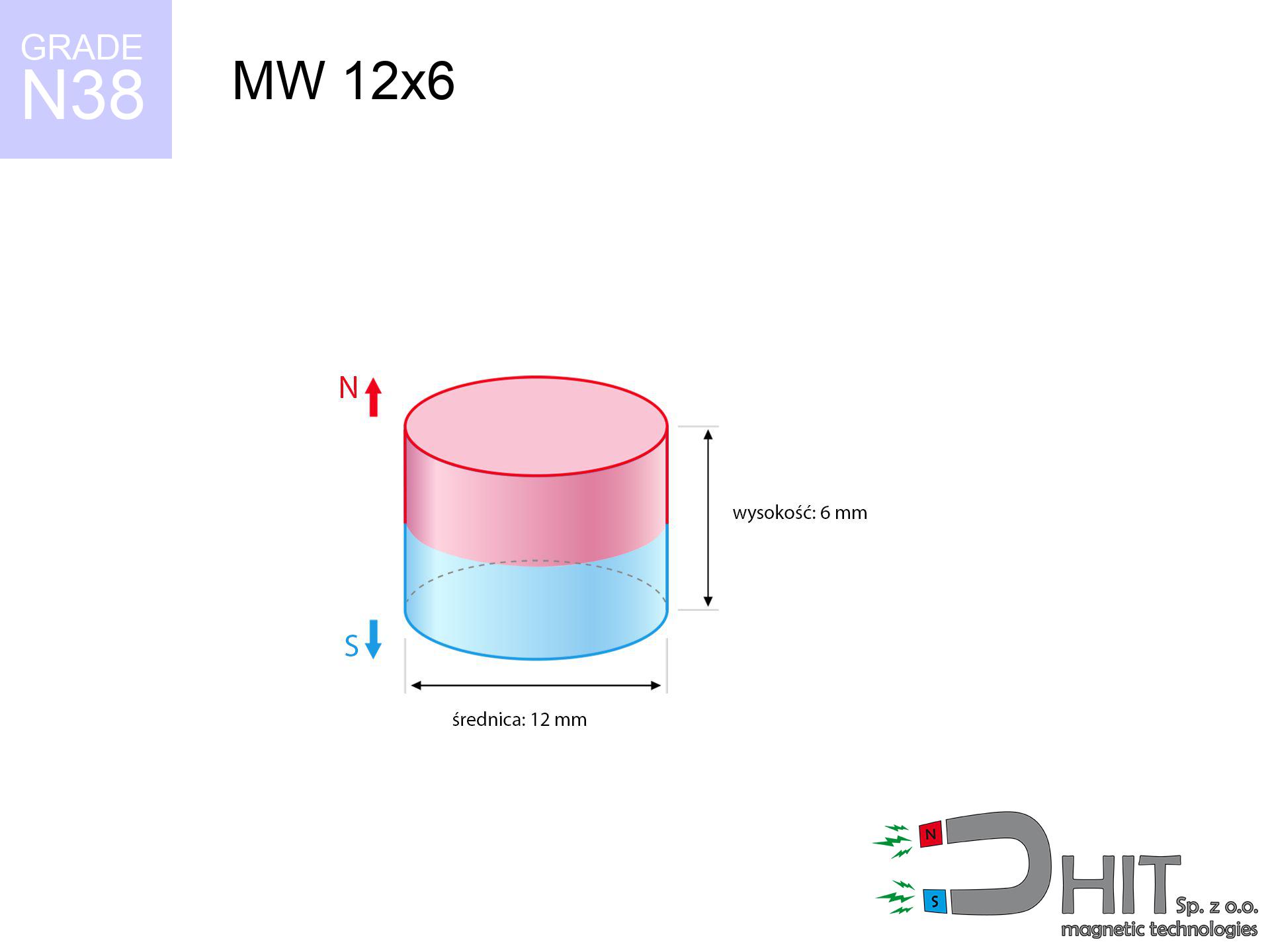

MW 12x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010021

GTIN/EAN: 5906301810209

Diameter Ø

12 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

5.09 g

Magnetization Direction

↑ axial

Load capacity

4.60 kg / 45.09 N

Magnetic Induction

437.99 mT / 4380 Gs

Coating

[NiCuNi] Nickel

1.882 ZŁ with VAT / pcs + price for transport

1.530 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

otherwise drop us a message via

form

the contact page.

Parameters as well as form of neodymium magnets can be verified with our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical parameters - MW 12x6 / N38 - cylindrical magnet

Specification / characteristics - MW 12x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010021 |

| GTIN/EAN | 5906301810209 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 5.09 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.60 kg / 45.09 N |

| Magnetic Induction ~ ? | 437.99 mT / 4380 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - technical parameters

These information are the outcome of a engineering simulation. Results rely on algorithms for the class Nd2Fe14B. Actual performance might slightly deviate from the simulation results. Use these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (pull vs gap) - power drop

MW 12x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4377 Gs

437.7 mT

|

4.60 kg / 10.14 lbs

4600.0 g / 45.1 N

|

warning |

| 1 mm |

3688 Gs

368.8 mT

|

3.27 kg / 7.20 lbs

3265.4 g / 32.0 N

|

warning |

| 2 mm |

2999 Gs

299.9 mT

|

2.16 kg / 4.76 lbs

2159.7 g / 21.2 N

|

warning |

| 3 mm |

2386 Gs

238.6 mT

|

1.37 kg / 3.01 lbs

1366.7 g / 13.4 N

|

weak grip |

| 5 mm |

1474 Gs

147.4 mT

|

0.52 kg / 1.15 lbs

521.4 g / 5.1 N

|

weak grip |

| 10 mm |

489 Gs

48.9 mT

|

0.06 kg / 0.13 lbs

57.4 g / 0.6 N

|

weak grip |

| 15 mm |

205 Gs

20.5 mT

|

0.01 kg / 0.02 lbs

10.1 g / 0.1 N

|

weak grip |

| 20 mm |

103 Gs

10.3 mT

|

0.00 kg / 0.01 lbs

2.5 g / 0.0 N

|

weak grip |

| 30 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

weak grip |

| 50 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Slippage capacity (vertical surface)

MW 12x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.92 kg / 2.03 lbs

920.0 g / 9.0 N

|

| 1 mm | Stal (~0.2) |

0.65 kg / 1.44 lbs

654.0 g / 6.4 N

|

| 2 mm | Stal (~0.2) |

0.43 kg / 0.95 lbs

432.0 g / 4.2 N

|

| 3 mm | Stal (~0.2) |

0.27 kg / 0.60 lbs

274.0 g / 2.7 N

|

| 5 mm | Stal (~0.2) |

0.10 kg / 0.23 lbs

104.0 g / 1.0 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

12.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 12x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.38 kg / 3.04 lbs

1380.0 g / 13.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.92 kg / 2.03 lbs

920.0 g / 9.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.46 kg / 1.01 lbs

460.0 g / 4.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.30 kg / 5.07 lbs

2300.0 g / 22.6 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 12x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.46 kg / 1.01 lbs

460.0 g / 4.5 N

|

| 1 mm |

|

1.15 kg / 2.54 lbs

1150.0 g / 11.3 N

|

| 2 mm |

|

2.30 kg / 5.07 lbs

2300.0 g / 22.6 N

|

| 3 mm |

|

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

| 5 mm |

|

4.60 kg / 10.14 lbs

4600.0 g / 45.1 N

|

| 10 mm |

|

4.60 kg / 10.14 lbs

4600.0 g / 45.1 N

|

| 11 mm |

|

4.60 kg / 10.14 lbs

4600.0 g / 45.1 N

|

| 12 mm |

|

4.60 kg / 10.14 lbs

4600.0 g / 45.1 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 12x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.60 kg / 10.14 lbs

4600.0 g / 45.1 N

|

OK |

| 40 °C | -2.2% |

4.50 kg / 9.92 lbs

4498.8 g / 44.1 N

|

OK |

| 60 °C | -4.4% |

4.40 kg / 9.70 lbs

4397.6 g / 43.1 N

|

|

| 80 °C | -6.6% |

4.30 kg / 9.47 lbs

4296.4 g / 42.1 N

|

|

| 100 °C | -28.8% |

3.28 kg / 7.22 lbs

3275.2 g / 32.1 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 12x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

13.36 kg / 29.45 lbs

5 536 Gs

|

2.00 kg / 4.42 lbs

2004 g / 19.7 N

|

N/A |

| 1 mm |

11.39 kg / 25.10 lbs

8 082 Gs

|

1.71 kg / 3.77 lbs

1708 g / 16.8 N

|

10.25 kg / 22.59 lbs

~0 Gs

|

| 2 mm |

9.48 kg / 20.91 lbs

7 376 Gs

|

1.42 kg / 3.14 lbs

1423 g / 14.0 N

|

8.54 kg / 18.82 lbs

~0 Gs

|

| 3 mm |

7.77 kg / 17.12 lbs

6 675 Gs

|

1.17 kg / 2.57 lbs

1165 g / 11.4 N

|

6.99 kg / 15.41 lbs

~0 Gs

|

| 5 mm |

5.01 kg / 11.05 lbs

5 361 Gs

|

0.75 kg / 1.66 lbs

752 g / 7.4 N

|

4.51 kg / 9.94 lbs

~0 Gs

|

| 10 mm |

1.51 kg / 3.34 lbs

2 948 Gs

|

0.23 kg / 0.50 lbs

227 g / 2.2 N

|

1.36 kg / 3.01 lbs

~0 Gs

|

| 20 mm |

0.17 kg / 0.37 lbs

978 Gs

|

0.02 kg / 0.06 lbs

25 g / 0.2 N

|

0.15 kg / 0.33 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 lbs

116 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

72 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

48 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

33 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

18 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 12x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - warning

MW 12x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

30.55 km/h

(8.49 m/s)

|

0.18 J | |

| 30 mm |

52.51 km/h

(14.59 m/s)

|

0.54 J | |

| 50 mm |

67.79 km/h

(18.83 m/s)

|

0.90 J | |

| 100 mm |

95.87 km/h

(26.63 m/s)

|

1.81 J |

Table 9: Surface protection spec

MW 12x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 12x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 024 Mx | 50.2 µWb |

| Pc Coefficient | 0.59 | Low (Flat) |

Table 11: Submerged application

MW 12x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.60 kg | Standard |

| Water (riverbed) |

5.27 kg

(+0.67 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet holds merely ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. computer case) drastically weakens the holding force.

3. Thermal stability

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.59

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also deals

Strengths as well as weaknesses of rare earth magnets.

Advantages

- Their magnetic field is durable, and after approximately 10 years it decreases only by ~1% (according to research),

- Neodymium magnets are remarkably resistant to demagnetization caused by magnetic disturbances,

- The use of an metallic coating of noble metals (nickel, gold, silver) causes the element to present itself better,

- They are known for high magnetic induction at the operating surface, which improves attraction properties,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to flexibility in designing and the ability to customize to client solutions,

- Fundamental importance in advanced technology sectors – they are utilized in computer drives, motor assemblies, precision medical tools, also modern systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which makes them useful in small systems

Limitations

- They are fragile upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only shields the magnet but also increases its resistance to damage

- Neodymium magnets lose power when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited ability of producing threads in the magnet and complex forms - preferred is casing - magnetic holder.

- Possible danger to health – tiny shards of magnets are risky, when accidentally swallowed, which becomes key in the context of child safety. Furthermore, small elements of these magnets can be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Maximum lifting force for a neodymium magnet – what it depends on?

- using a base made of high-permeability steel, acting as a magnetic yoke

- with a thickness of at least 10 mm

- with a plane cleaned and smooth

- under conditions of ideal adhesion (metal-to-metal)

- during pulling in a direction vertical to the plane

- at room temperature

What influences lifting capacity in practice

- Gap between magnet and steel – every millimeter of distance (caused e.g. by varnish or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Load vector – highest force is reached only during perpendicular pulling. The shear force of the magnet along the plate is typically many times smaller (approx. 1/5 of the lifting capacity).

- Base massiveness – too thin steel does not close the flux, causing part of the power to be wasted into the air.

- Material composition – different alloys reacts the same. Alloy additives weaken the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which improves force. Uneven metal weaken the grip.

- Temperature influence – hot environment weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity was measured by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under shearing force the lifting capacity is smaller. Moreover, even a slight gap between the magnet and the plate reduces the holding force.

H&S for magnets

Material brittleness

Protect your eyes. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Wear goggles.

Choking Hazard

Absolutely keep magnets away from children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are very dangerous.

Life threat

Health Alert: Neodymium magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Machining danger

Powder created during cutting of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Do not overheat magnets

Regular neodymium magnets (N-type) undergo demagnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Hand protection

Protect your hands. Two powerful magnets will snap together immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

Electronic hazard

Powerful magnetic fields can destroy records on payment cards, hard drives, and other magnetic media. Stay away of min. 10 cm.

Sensitization to coating

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If skin irritation happens, immediately stop working with magnets and use protective gear.

Keep away from electronics

Navigation devices and smartphones are highly susceptible to magnetism. Direct contact with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Caution required

Handle with care. Neodymium magnets attract from a long distance and connect with massive power, often faster than you can move away.

![SM 25x300 [2xM8] / N42 - magnetic separator SM 25x300 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x300-2xm8-kud.jpg)