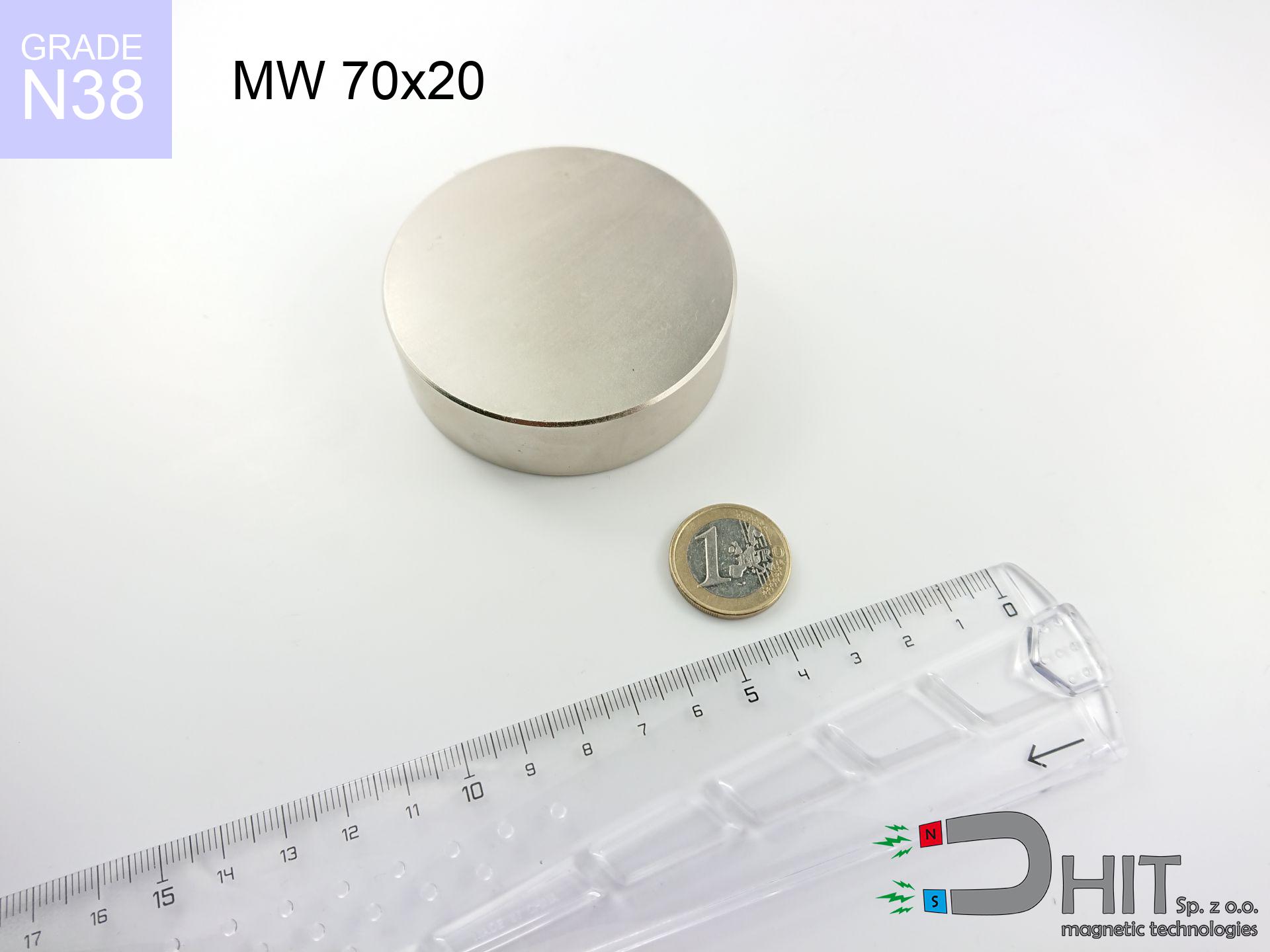

UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread

magnetic holder external thread

Catalog no 190416

GTIN/EAN: 5906301813873

Diameter Ø

60 mm [±1 mm]

Height

30 mm [±1 mm]

Height

15 mm [±1 mm]

Weight

260 g

Load capacity

140.00 kg / 1372.93 N

Call us

+48 888 99 98 98

or send us a note via

request form

through our site.

Weight as well as structure of a neodymium magnet can be calculated on our

modular calculator.

Order by 14:00 and we’ll ship today!

Technical specification of the product - UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread

Specification / characteristics - UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread

| properties | values |

|---|---|

| Cat. no. | 190416 |

| GTIN/EAN | 5906301813873 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 60 mm [±1 mm] |

| Height | 30 mm [±1 mm] |

| Height | 15 mm [±1 mm] |

| Weight | 260 g |

| Load capacity ~ ? | 140.00 kg / 1372.93 N |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths and weaknesses of rare earth magnets.

Advantages

- They retain magnetic properties for around ten years – the loss is just ~1% (based on simulations),

- Neodymium magnets are distinguished by exceptionally resistant to demagnetization caused by external interference,

- By covering with a decorative coating of nickel, the element gains an nice look,

- Magnets have very high magnetic induction on the surface,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Thanks to the possibility of accurate shaping and adaptation to specialized needs, neodymium magnets can be created in a variety of forms and dimensions, which increases their versatility,

- Versatile presence in high-tech industry – they find application in HDD drives, brushless drives, diagnostic systems, as well as multitasking production systems.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Cons

- To avoid cracks upon strong impacts, we suggest using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Limited ability of making nuts in the magnet and complicated forms - preferred is casing - magnet mounting.

- Health risk related to microscopic parts of magnets pose a threat, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. It is also worth noting that tiny parts of these devices are able to complicate diagnosis medical when they are in the body.

- Due to neodymium price, their price is relatively high,

Holding force characteristics

Optimal lifting capacity of a neodymium magnet – what it depends on?

- using a base made of high-permeability steel, serving as a ideal flux conductor

- whose transverse dimension equals approx. 10 mm

- characterized by lack of roughness

- under conditions of ideal adhesion (metal-to-metal)

- under vertical force vector (90-degree angle)

- in temp. approx. 20°C

What influences lifting capacity in practice

- Space between surfaces – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Angle of force application – maximum parameter is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is typically several times smaller (approx. 1/5 of the lifting capacity).

- Plate thickness – insufficiently thick steel causes magnetic saturation, causing part of the power to be wasted into the air.

- Material composition – different alloys reacts the same. High carbon content weaken the attraction effect.

- Surface condition – smooth surfaces guarantee perfect abutment, which increases field saturation. Rough surfaces reduce efficiency.

- Thermal factor – hot environment weakens magnetic field. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was measured by applying a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under attempts to slide the magnet the lifting capacity is smaller. In addition, even a small distance between the magnet and the plate reduces the load capacity.

Safe handling of neodymium magnets

Caution required

Handle with care. Rare earth magnets attract from a distance and snap with massive power, often faster than you can move away.

Medical interference

Life threat: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Safe distance

Intense magnetic fields can corrupt files on payment cards, HDDs, and other magnetic media. Keep a distance of at least 10 cm.

Eye protection

Despite the nickel coating, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Flammability

Powder created during cutting of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Permanent damage

Monitor thermal conditions. Heating the magnet to high heat will destroy its magnetic structure and pulling force.

Pinching danger

Danger of trauma: The attraction force is so immense that it can cause blood blisters, pinching, and broken bones. Protective gloves are recommended.

Sensitization to coating

Certain individuals experience a contact allergy to nickel, which is the typical protective layer for neodymium magnets. Frequent touching may cause a rash. We recommend wear safety gloves.

Keep away from children

Always keep magnets out of reach of children. Risk of swallowing is significant, and the consequences of magnets clamping inside the body are very dangerous.

Compass and GPS

Remember: rare earth magnets generate a field that confuses sensitive sensors. Keep a safe distance from your phone, device, and GPS.

![Magnet with screw UMGZ 60x30x15 [M10] GZ / N38 Magnet with screw UMGZ 60x30x15 [M10] GZ / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-60x30x15-m10-gz-bas.jpg)

![UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread - ujęcie 2](https://cdn3.dhit.pl/graphics/products/umgw-60x30x15-m10-gz-ner.jpg)