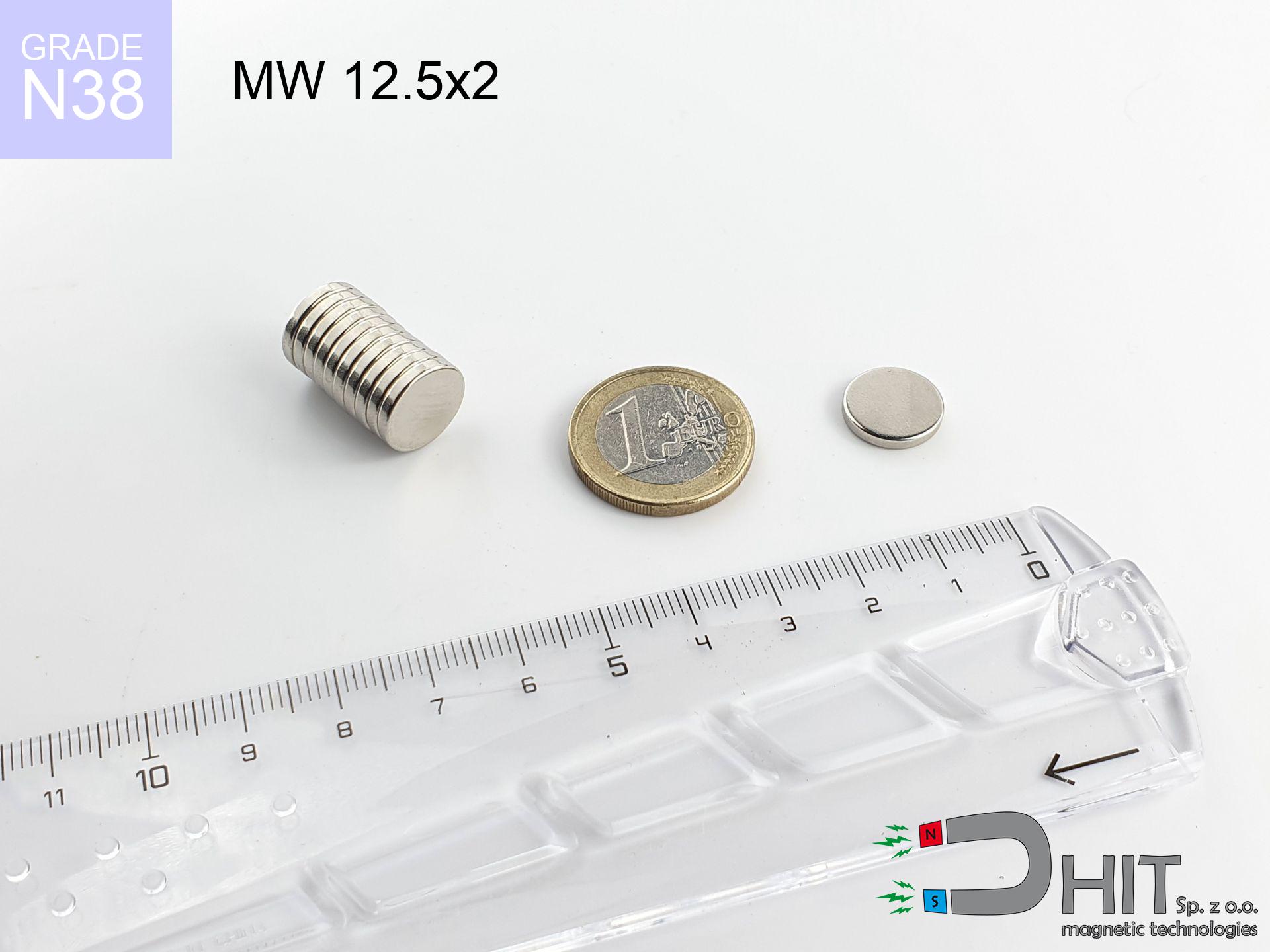

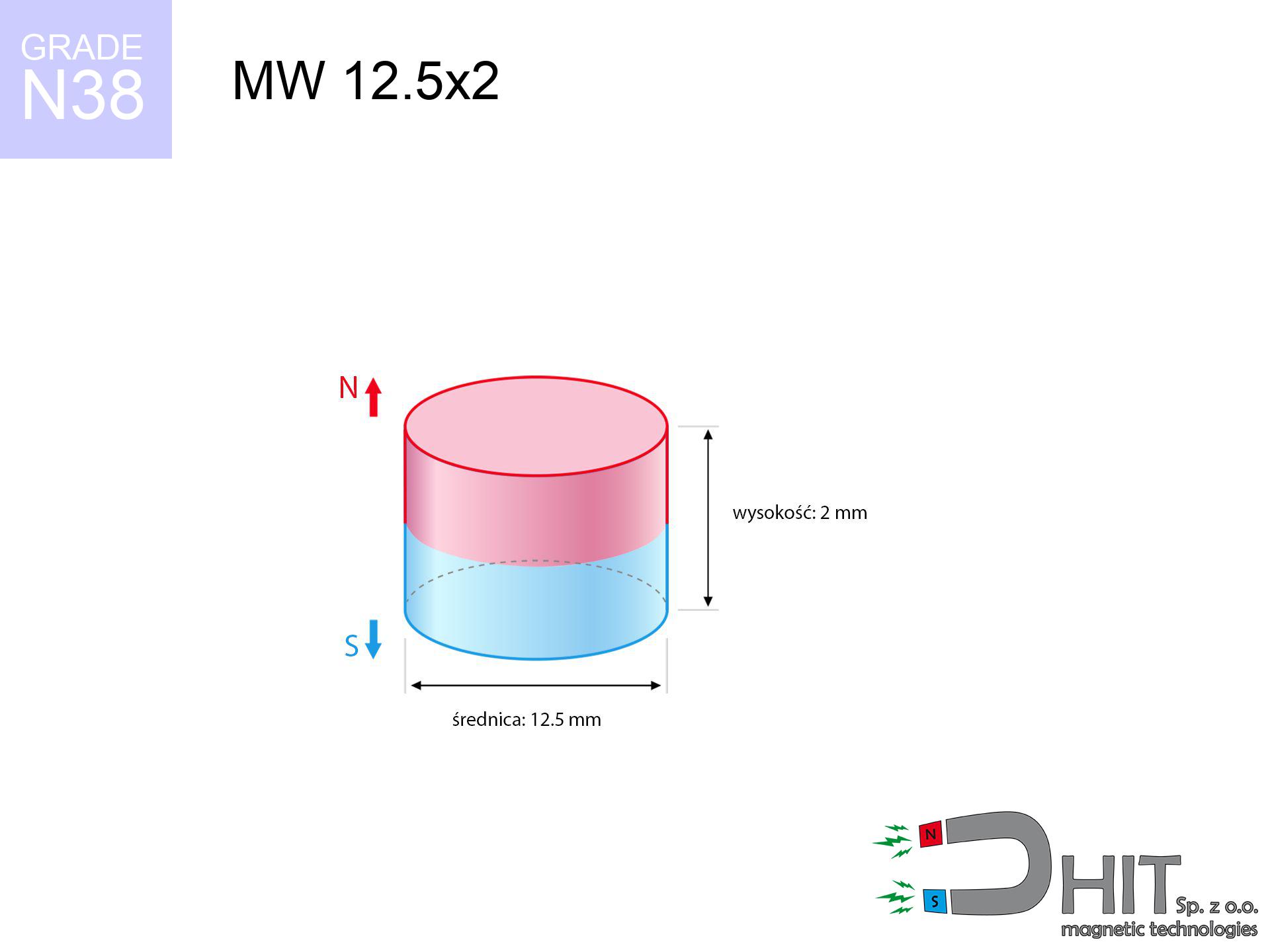

MW 12.5x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010014

GTIN/EAN: 5906301810131

Diameter Ø

12.5 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

1.84 g

Magnetization Direction

↑ axial

Load capacity

1.42 kg / 13.89 N

Magnetic Induction

188.88 mT / 1889 Gs

Coating

[NiCuNi] Nickel

0.935 ZŁ with VAT / pcs + price for transport

0.760 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or drop us a message via

inquiry form

the contact section.

Specifications and appearance of magnetic components can be reviewed on our

our magnetic calculator.

Same-day processing for orders placed before 14:00.

Technical of the product - MW 12.5x2 / N38 - cylindrical magnet

Specification / characteristics - MW 12.5x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010014 |

| GTIN/EAN | 5906301810131 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12.5 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 1.84 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.42 kg / 13.89 N |

| Magnetic Induction ~ ? | 188.88 mT / 1889 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - data

Presented data represent the outcome of a physical calculation. Results were calculated on algorithms for the class Nd2Fe14B. Actual conditions might slightly deviate from the simulation results. Please consider these data as a reference point when designing systems.

Table 1: Static pull force (pull vs distance) - characteristics

MW 12.5x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1888 Gs

188.8 mT

|

1.42 kg / 3.13 pounds

1420.0 g / 13.9 N

|

safe |

| 1 mm |

1703 Gs

170.3 mT

|

1.16 kg / 2.55 pounds

1155.6 g / 11.3 N

|

safe |

| 2 mm |

1453 Gs

145.3 mT

|

0.84 kg / 1.85 pounds

840.3 g / 8.2 N

|

safe |

| 3 mm |

1190 Gs

119.0 mT

|

0.56 kg / 1.24 pounds

564.1 g / 5.5 N

|

safe |

| 5 mm |

752 Gs

75.2 mT

|

0.23 kg / 0.50 pounds

225.0 g / 2.2 N

|

safe |

| 10 mm |

241 Gs

24.1 mT

|

0.02 kg / 0.05 pounds

23.2 g / 0.2 N

|

safe |

| 15 mm |

96 Gs

9.6 mT

|

0.00 kg / 0.01 pounds

3.7 g / 0.0 N

|

safe |

| 20 mm |

46 Gs

4.6 mT

|

0.00 kg / 0.00 pounds

0.9 g / 0.0 N

|

safe |

| 30 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

safe |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Vertical load (vertical surface)

MW 12.5x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.28 kg / 0.63 pounds

284.0 g / 2.8 N

|

| 1 mm | Stal (~0.2) |

0.23 kg / 0.51 pounds

232.0 g / 2.3 N

|

| 2 mm | Stal (~0.2) |

0.17 kg / 0.37 pounds

168.0 g / 1.6 N

|

| 3 mm | Stal (~0.2) |

0.11 kg / 0.25 pounds

112.0 g / 1.1 N

|

| 5 mm | Stal (~0.2) |

0.05 kg / 0.10 pounds

46.0 g / 0.5 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 12.5x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.43 kg / 0.94 pounds

426.0 g / 4.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.28 kg / 0.63 pounds

284.0 g / 2.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.14 kg / 0.31 pounds

142.0 g / 1.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.71 kg / 1.57 pounds

710.0 g / 7.0 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 12.5x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.14 kg / 0.31 pounds

142.0 g / 1.4 N

|

| 1 mm |

|

0.36 kg / 0.78 pounds

355.0 g / 3.5 N

|

| 2 mm |

|

0.71 kg / 1.57 pounds

710.0 g / 7.0 N

|

| 3 mm |

|

1.07 kg / 2.35 pounds

1065.0 g / 10.4 N

|

| 5 mm |

|

1.42 kg / 3.13 pounds

1420.0 g / 13.9 N

|

| 10 mm |

|

1.42 kg / 3.13 pounds

1420.0 g / 13.9 N

|

| 11 mm |

|

1.42 kg / 3.13 pounds

1420.0 g / 13.9 N

|

| 12 mm |

|

1.42 kg / 3.13 pounds

1420.0 g / 13.9 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 12.5x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.42 kg / 3.13 pounds

1420.0 g / 13.9 N

|

OK |

| 40 °C | -2.2% |

1.39 kg / 3.06 pounds

1388.8 g / 13.6 N

|

OK |

| 60 °C | -4.4% |

1.36 kg / 2.99 pounds

1357.5 g / 13.3 N

|

|

| 80 °C | -6.6% |

1.33 kg / 2.92 pounds

1326.3 g / 13.0 N

|

|

| 100 °C | -28.8% |

1.01 kg / 2.23 pounds

1011.0 g / 9.9 N

|

Table 6: Two magnets (attraction) - field range

MW 12.5x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.70 kg / 5.95 pounds

3 338 Gs

|

0.40 kg / 0.89 pounds

405 g / 4.0 N

|

N/A |

| 1 mm |

2.47 kg / 5.45 pounds

3 616 Gs

|

0.37 kg / 0.82 pounds

371 g / 3.6 N

|

2.23 kg / 4.91 pounds

~0 Gs

|

| 2 mm |

2.20 kg / 4.84 pounds

3 407 Gs

|

0.33 kg / 0.73 pounds

329 g / 3.2 N

|

1.98 kg / 4.36 pounds

~0 Gs

|

| 3 mm |

1.89 kg / 4.18 pounds

3 165 Gs

|

0.28 kg / 0.63 pounds

284 g / 2.8 N

|

1.71 kg / 3.76 pounds

~0 Gs

|

| 5 mm |

1.32 kg / 2.91 pounds

2 640 Gs

|

0.20 kg / 0.44 pounds

198 g / 1.9 N

|

1.19 kg / 2.62 pounds

~0 Gs

|

| 10 mm |

0.43 kg / 0.94 pounds

1 503 Gs

|

0.06 kg / 0.14 pounds

64 g / 0.6 N

|

0.38 kg / 0.85 pounds

~0 Gs

|

| 20 mm |

0.04 kg / 0.10 pounds

483 Gs

|

0.01 kg / 0.01 pounds

7 g / 0.1 N

|

0.04 kg / 0.09 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

51 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

31 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

20 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

14 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

7 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 12.5x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MW 12.5x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.30 km/h

(7.86 m/s)

|

0.06 J | |

| 30 mm |

48.53 km/h

(13.48 m/s)

|

0.17 J | |

| 50 mm |

62.65 km/h

(17.40 m/s)

|

0.28 J | |

| 100 mm |

88.60 km/h

(24.61 m/s)

|

0.56 J |

Table 9: Surface protection spec

MW 12.5x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 12.5x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 810 Mx | 28.1 µWb |

| Pc Coefficient | 0.24 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 12.5x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.42 kg | Standard |

| Water (riverbed) |

1.63 kg

(+0.21 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical wall, the magnet holds just approx. 20-30% of its perpendicular strength.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) severely weakens the holding force.

3. Power loss vs temp

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.24

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also offers

Strengths and weaknesses of Nd2Fe14B magnets.

Pros

- They have constant strength, and over more than ten years their attraction force decreases symbolically – ~1% (according to theory),

- They have excellent resistance to magnetic field loss as a result of external fields,

- In other words, due to the smooth layer of nickel, the element gains visual value,

- They feature high magnetic induction at the operating surface, which affects their effectiveness,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of detailed forming and modifying to concrete requirements,

- Fundamental importance in high-tech industry – they are utilized in magnetic memories, motor assemblies, diagnostic systems, as well as modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- Limited ability of creating threads in the magnet and complicated shapes - preferred is a housing - mounting mechanism.

- Health risk resulting from small fragments of magnets are risky, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Furthermore, tiny parts of these products can be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum holding power of the magnet – what affects it?

- on a block made of structural steel, perfectly concentrating the magnetic field

- whose thickness reaches at least 10 mm

- with an polished contact surface

- without the slightest air gap between the magnet and steel

- during pulling in a direction perpendicular to the plane

- in temp. approx. 20°C

Magnet lifting force in use – key factors

- Clearance – existence of any layer (rust, dirt, air) acts as an insulator, which lowers capacity rapidly (even by 50% at 0.5 mm).

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of generating force.

- Material type – the best choice is high-permeability steel. Hardened steels may have worse magnetic properties.

- Smoothness – full contact is possible only on polished steel. Rough texture create air cushions, weakening the magnet.

- Thermal factor – high temperature weakens magnetic field. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was measured using a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular detachment force, however under attempts to slide the magnet the lifting capacity is smaller. In addition, even a slight gap between the magnet and the plate lowers the load capacity.

Safe handling of neodymium magnets

Magnet fragility

Despite the nickel coating, the material is brittle and not impact-resistant. Do not hit, as the magnet may shatter into hazardous fragments.

Heat warning

Do not overheat. Neodymium magnets are susceptible to heat. If you need resistance above 80°C, inquire about HT versions (H, SH, UH).

Impact on smartphones

An intense magnetic field negatively affects the functioning of compasses in smartphones and GPS navigation. Maintain magnets close to a device to avoid damaging the sensors.

Allergic reactions

Allergy Notice: The Ni-Cu-Ni coating contains nickel. If skin irritation happens, cease working with magnets and use protective gear.

Keep away from computers

Equipment safety: Neodymium magnets can damage data carriers and sensitive devices (heart implants, hearing aids, mechanical watches).

Crushing force

Protect your hands. Two powerful magnets will snap together instantly with a force of several hundred kilograms, crushing everything in their path. Exercise extreme caution!

ICD Warning

Warning for patients: Strong magnetic fields disrupt electronics. Keep at least 30 cm distance or ask another person to work with the magnets.

Fire warning

Powder produced during cutting of magnets is self-igniting. Do not drill into magnets unless you are an expert.

Immense force

Handle with care. Neodymium magnets attract from a distance and connect with massive power, often faster than you can move away.

Product not for children

NdFeB magnets are not intended for children. Accidental ingestion of a few magnets may result in them attracting across intestines, which constitutes a severe health hazard and requires immediate surgery.