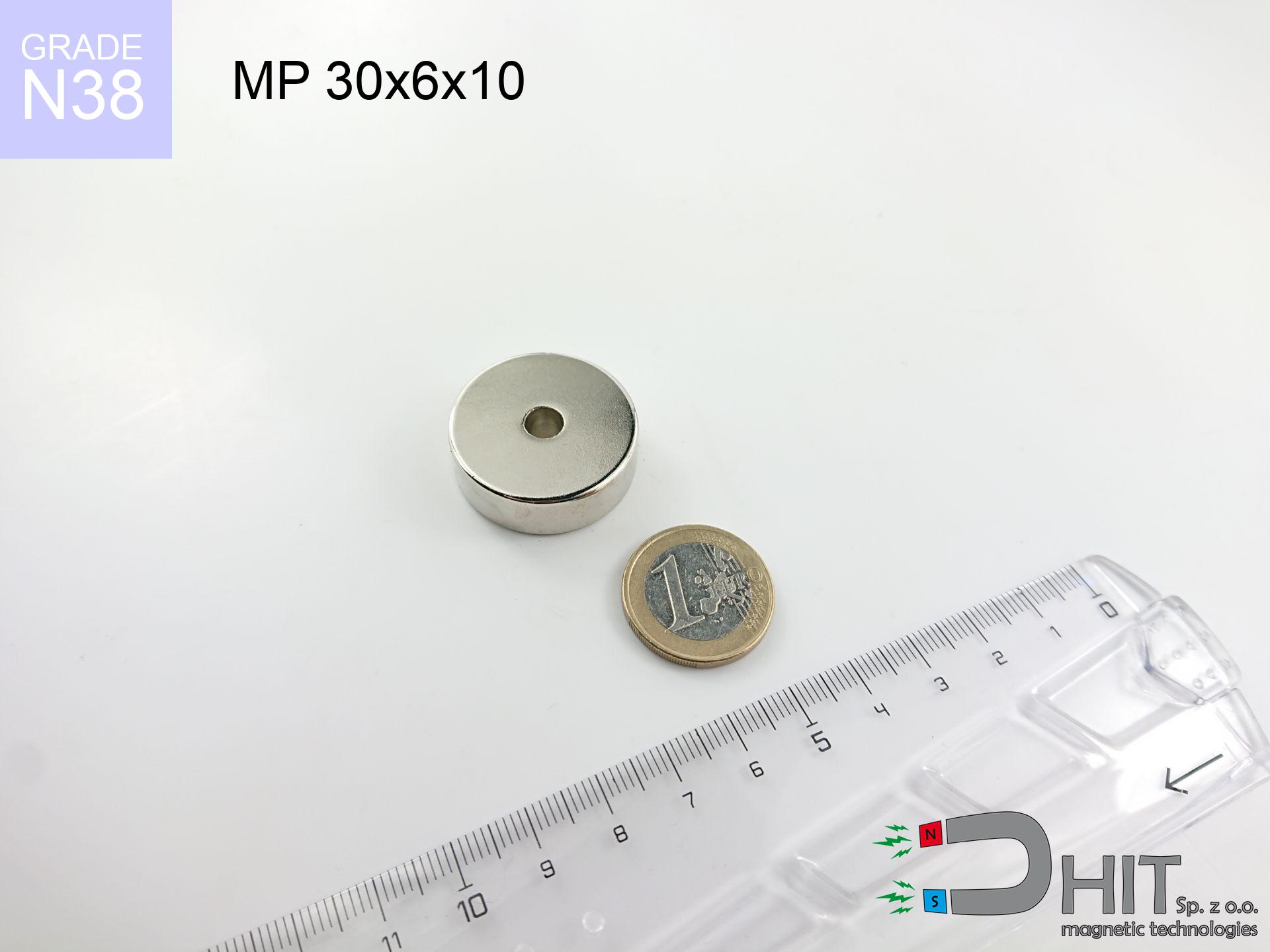

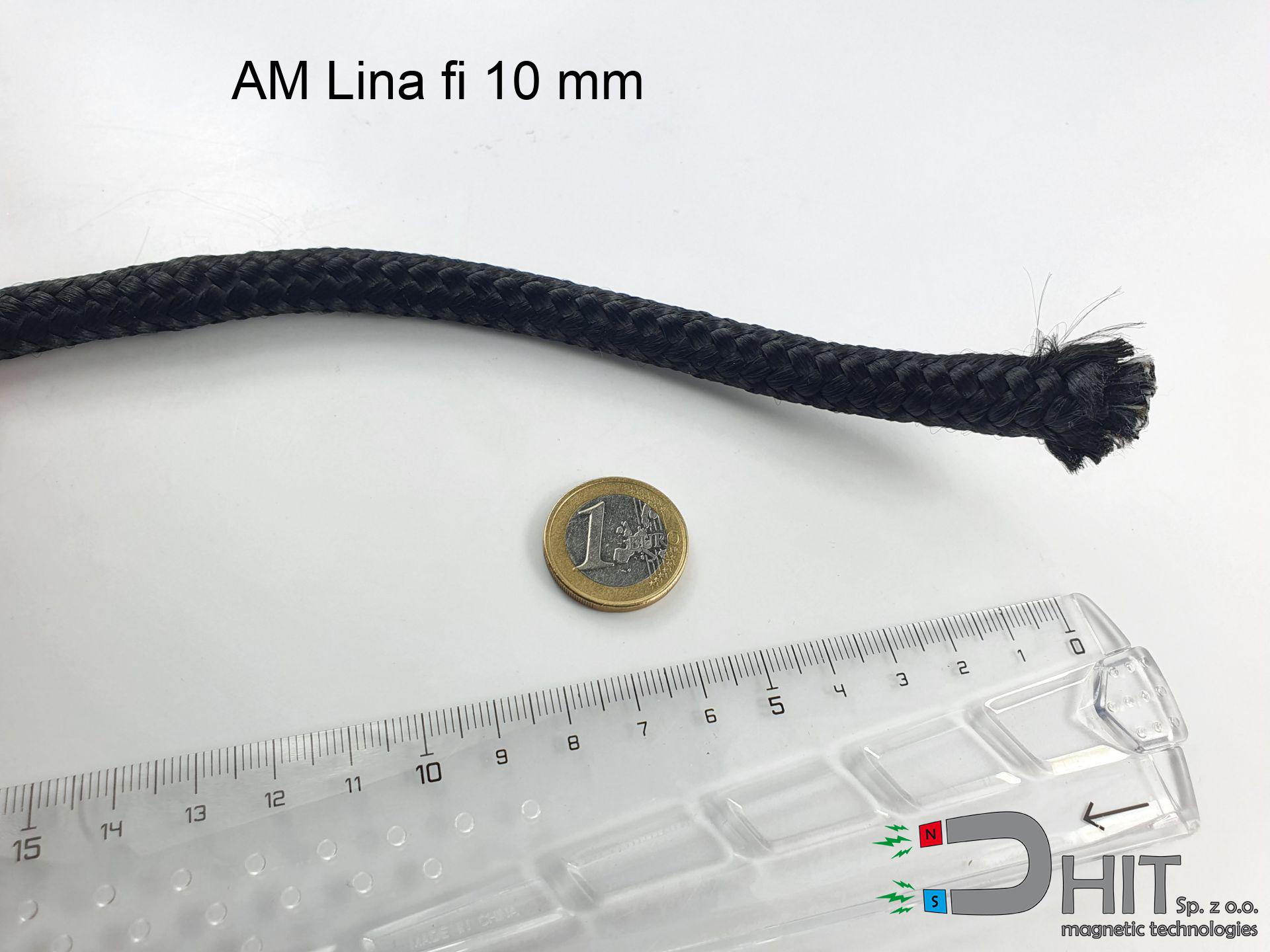

AM lina fi 10 mm - magnetic accessories

magnetic accessories

Catalog no 080216

GTIN/EAN: 5906301812456

Weight

32 g

Load capacity

1592.00 kg / 15612.19 N

1.476 ZŁ with VAT / pcs + price for transport

1.200 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

alternatively contact us using

contact form

our website.

Parameters along with shape of a magnet can be tested with our

magnetic calculator.

Order by 14:00 and we’ll ship today!

Technical details - AM lina fi 10 mm - magnetic accessories

Specification / characteristics - AM lina fi 10 mm - magnetic accessories

| properties | values |

|---|---|

| Cat. no. | 080216 |

| GTIN/EAN | 5906301812456 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 32 g |

| Load capacity ~ ? | 1592.00 kg / 15612.19 N |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also deals

Pros as well as cons of Nd2Fe14B magnets.

Pros

- Their power is maintained, and after approximately 10 years it decreases only by ~1% (theoretically),

- Magnets perfectly resist against demagnetization caused by foreign field sources,

- By applying a decorative layer of nickel, the element presents an modern look,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Possibility of individual shaping as well as adjusting to specific applications,

- Key role in high-tech industry – they are used in hard drives, motor assemblies, diagnostic systems, as well as multitasking production systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in creating threads and complex forms in magnets, we propose using casing - magnetic mechanism.

- Potential hazard related to microscopic parts of magnets pose a threat, in case of ingestion, which becomes key in the aspect of protecting the youngest. Additionally, small components of these magnets are able to disrupt the diagnostic process medical in case of swallowing.

- Due to expensive raw materials, their price exceeds standard values,

Pull force analysis

Maximum lifting capacity of the magnet – what affects it?

- with the application of a sheet made of special test steel, ensuring maximum field concentration

- with a cross-section no less than 10 mm

- with an ideally smooth touching surface

- without the slightest air gap between the magnet and steel

- under perpendicular force vector (90-degree angle)

- in temp. approx. 20°C

Practical aspects of lifting capacity – factors

- Air gap (betwixt the magnet and the metal), since even a very small clearance (e.g. 0.5 mm) can cause a decrease in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Force direction – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the maximum value.

- Plate thickness – too thin steel does not accept the full field, causing part of the power to be escaped into the air.

- Material composition – not every steel reacts the same. Alloy additives worsen the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which increases field saturation. Uneven metal reduce efficiency.

- Temperature – heating the magnet results in weakening of force. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was measured using a smooth steel plate of optimal thickness (min. 20 mm), under vertically applied force, whereas under attempts to slide the magnet the load capacity is reduced by as much as 75%. Moreover, even a slight gap between the magnet’s surface and the plate decreases the holding force.

Safety rules for work with neodymium magnets

Do not drill into magnets

Powder created during cutting of magnets is combustible. Do not drill into magnets unless you are an expert.

Life threat

Health Alert: Neodymium magnets can turn off pacemakers and defibrillators. Stay away if you have electronic implants.

Choking Hazard

Always keep magnets away from children. Risk of swallowing is high, and the effects of magnets clamping inside the body are life-threatening.

Respect the power

Use magnets consciously. Their powerful strength can surprise even professionals. Stay alert and do not underestimate their power.

Avoid contact if allergic

Studies show that nickel (standard magnet coating) is a potent allergen. If you have an allergy, refrain from touching magnets with bare hands or opt for versions in plastic housing.

Heat sensitivity

Keep cool. Neodymium magnets are sensitive to temperature. If you require operation above 80°C, inquire about HT versions (H, SH, UH).

Serious injuries

Protect your hands. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing everything in their path. Be careful!

Protect data

Avoid bringing magnets near a wallet, laptop, or TV. The magnetism can irreversibly ruin these devices and erase data from cards.

Beware of splinters

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Clashing of two magnets leads to them breaking into shards.

GPS Danger

Be aware: neodymium magnets produce a field that confuses sensitive sensors. Maintain a separation from your phone, tablet, and navigation systems.

![SM 32x125 [2xM8] / N52 - magnetic separator SM 32x125 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x125-2xm8-moj.jpg)

![SM 18x100 [2xM5] / N42 - magnetic separator SM 18x100 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x100-2xm5-pem.jpg)