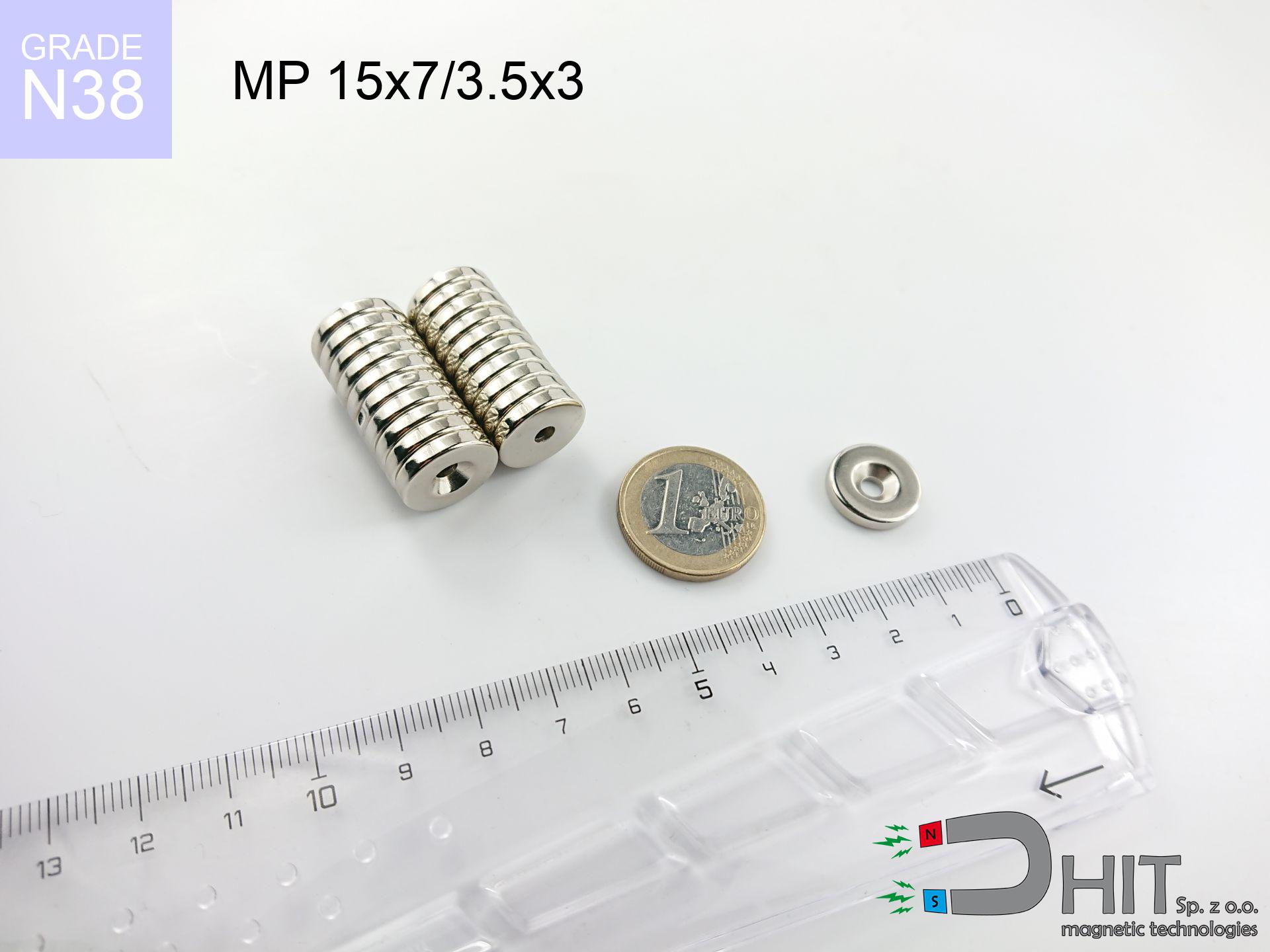

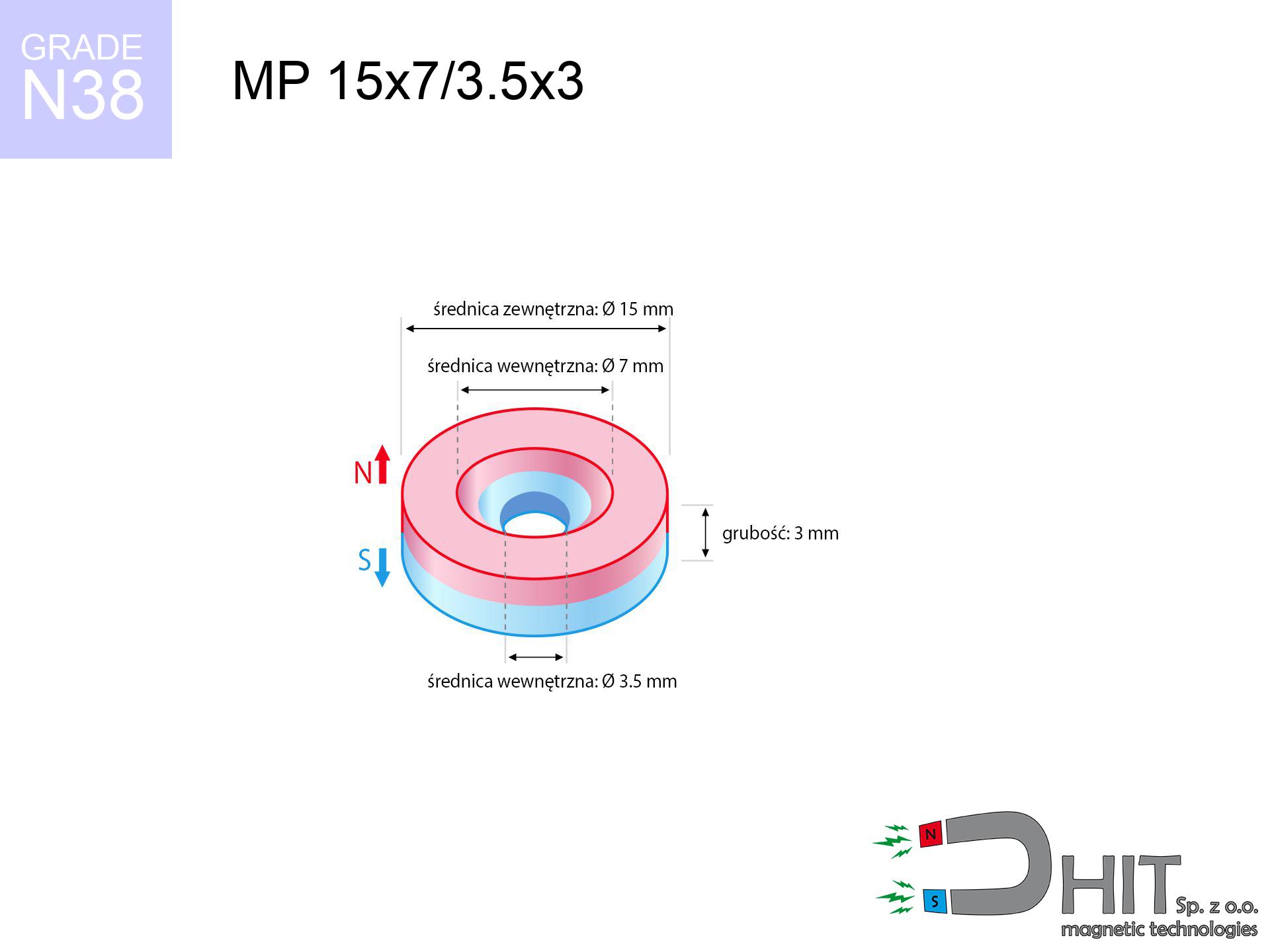

MP 15x7/3.5x3 / N38 - ring magnet

ring magnet

Catalog no 030182

GTIN/EAN: 5906301811992

Diameter

15 mm [±0,1 mm]

internal diameter Ø

7/3.5 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

3.76 g

Magnetization Direction

↑ axial

Load capacity

2.71 kg / 26.61 N

Magnetic Induction

230.16 mT / 2302 Gs

Coating

[NiCuNi] Nickel

1.747 ZŁ with VAT / pcs + price for transport

1.420 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

if you prefer get in touch through

our online form

the contact section.

Strength and form of magnets can be calculated on our

force calculator.

Same-day processing for orders placed before 14:00.

Technical - MP 15x7/3.5x3 / N38 - ring magnet

Specification / characteristics - MP 15x7/3.5x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030182 |

| GTIN/EAN | 5906301811992 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 15 mm [±0,1 mm] |

| internal diameter Ø | 7/3.5 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 3.76 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.71 kg / 26.61 N |

| Magnetic Induction ~ ? | 230.16 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - report

The following information are the direct effect of a physical calculation. Results are based on models for the material Nd2Fe14B. Real-world performance may differ from theoretical values. Treat these data as a supplementary guide for designers.

Table 1: Static force (pull vs distance) - power drop

MP 15x7/3.5x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1995 Gs

199.5 mT

|

2.71 kg / 5.97 pounds

2710.0 g / 26.6 N

|

strong |

| 1 mm |

1833 Gs

183.3 mT

|

2.29 kg / 5.05 pounds

2289.1 g / 22.5 N

|

strong |

| 2 mm |

1618 Gs

161.8 mT

|

1.78 kg / 3.93 pounds

1784.1 g / 17.5 N

|

low risk |

| 3 mm |

1385 Gs

138.5 mT

|

1.31 kg / 2.88 pounds

1307.5 g / 12.8 N

|

low risk |

| 5 mm |

959 Gs

95.9 mT

|

0.63 kg / 1.38 pounds

627.1 g / 6.2 N

|

low risk |

| 10 mm |

362 Gs

36.2 mT

|

0.09 kg / 0.20 pounds

89.3 g / 0.9 N

|

low risk |

| 15 mm |

156 Gs

15.6 mT

|

0.02 kg / 0.04 pounds

16.5 g / 0.2 N

|

low risk |

| 20 mm |

78 Gs

7.8 mT

|

0.00 kg / 0.01 pounds

4.1 g / 0.0 N

|

low risk |

| 30 mm |

27 Gs

2.7 mT

|

0.00 kg / 0.00 pounds

0.5 g / 0.0 N

|

low risk |

| 50 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical capacity (wall)

MP 15x7/3.5x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.54 kg / 1.19 pounds

542.0 g / 5.3 N

|

| 1 mm | Stal (~0.2) |

0.46 kg / 1.01 pounds

458.0 g / 4.5 N

|

| 2 mm | Stal (~0.2) |

0.36 kg / 0.78 pounds

356.0 g / 3.5 N

|

| 3 mm | Stal (~0.2) |

0.26 kg / 0.58 pounds

262.0 g / 2.6 N

|

| 5 mm | Stal (~0.2) |

0.13 kg / 0.28 pounds

126.0 g / 1.2 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

18.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MP 15x7/3.5x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.81 kg / 1.79 pounds

813.0 g / 8.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.54 kg / 1.19 pounds

542.0 g / 5.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.27 kg / 0.60 pounds

271.0 g / 2.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.36 kg / 2.99 pounds

1355.0 g / 13.3 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 15x7/3.5x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.27 kg / 0.60 pounds

271.0 g / 2.7 N

|

| 1 mm |

|

0.68 kg / 1.49 pounds

677.5 g / 6.6 N

|

| 2 mm |

|

1.36 kg / 2.99 pounds

1355.0 g / 13.3 N

|

| 3 mm |

|

2.03 kg / 4.48 pounds

2032.5 g / 19.9 N

|

| 5 mm |

|

2.71 kg / 5.97 pounds

2710.0 g / 26.6 N

|

| 10 mm |

|

2.71 kg / 5.97 pounds

2710.0 g / 26.6 N

|

| 11 mm |

|

2.71 kg / 5.97 pounds

2710.0 g / 26.6 N

|

| 12 mm |

|

2.71 kg / 5.97 pounds

2710.0 g / 26.6 N

|

Table 5: Thermal stability (material behavior) - power drop

MP 15x7/3.5x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.71 kg / 5.97 pounds

2710.0 g / 26.6 N

|

OK |

| 40 °C | -2.2% |

2.65 kg / 5.84 pounds

2650.4 g / 26.0 N

|

OK |

| 60 °C | -4.4% |

2.59 kg / 5.71 pounds

2590.8 g / 25.4 N

|

|

| 80 °C | -6.6% |

2.53 kg / 5.58 pounds

2531.1 g / 24.8 N

|

|

| 100 °C | -28.8% |

1.93 kg / 4.25 pounds

1929.5 g / 18.9 N

|

Table 6: Two magnets (repulsion) - field range

MP 15x7/3.5x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.48 kg / 7.68 pounds

3 483 Gs

|

0.52 kg / 1.15 pounds

523 g / 5.1 N

|

N/A |

| 1 mm |

3.24 kg / 7.14 pounds

3 846 Gs

|

0.49 kg / 1.07 pounds

486 g / 4.8 N

|

2.91 kg / 6.43 pounds

~0 Gs

|

| 2 mm |

2.94 kg / 6.49 pounds

3 666 Gs

|

0.44 kg / 0.97 pounds

441 g / 4.3 N

|

2.65 kg / 5.84 pounds

~0 Gs

|

| 3 mm |

2.62 kg / 5.78 pounds

3 460 Gs

|

0.39 kg / 0.87 pounds

393 g / 3.9 N

|

2.36 kg / 5.20 pounds

~0 Gs

|

| 5 mm |

1.98 kg / 4.36 pounds

3 004 Gs

|

0.30 kg / 0.65 pounds

296 g / 2.9 N

|

1.78 kg / 3.92 pounds

~0 Gs

|

| 10 mm |

0.81 kg / 1.78 pounds

1 919 Gs

|

0.12 kg / 0.27 pounds

121 g / 1.2 N

|

0.73 kg / 1.60 pounds

~0 Gs

|

| 20 mm |

0.11 kg / 0.25 pounds

724 Gs

|

0.02 kg / 0.04 pounds

17 g / 0.2 N

|

0.10 kg / 0.23 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

88 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

54 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

35 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

24 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

17 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

13 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MP 15x7/3.5x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - warning

MP 15x7/3.5x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.63 km/h

(7.67 m/s)

|

0.11 J | |

| 30 mm |

46.90 km/h

(13.03 m/s)

|

0.32 J | |

| 50 mm |

60.54 km/h

(16.82 m/s)

|

0.53 J | |

| 100 mm |

85.62 km/h

(23.78 m/s)

|

1.06 J |

Table 9: Coating parameters (durability)

MP 15x7/3.5x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MP 15x7/3.5x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 461 Mx | 34.6 µWb |

| Pc Coefficient | 0.26 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MP 15x7/3.5x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.71 kg | Standard |

| Water (riverbed) |

3.10 kg

(+0.39 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet holds just a fraction of its perpendicular strength.

2. Steel saturation

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Temperature resistance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.26

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more proposals

Advantages and disadvantages of rare earth magnets.

Benefits

- They virtually do not lose power, because even after 10 years the decline in efficiency is only ~1% (based on calculations),

- They maintain their magnetic properties even under strong external field,

- A magnet with a smooth gold surface looks better,

- Neodymium magnets generate maximum magnetic induction on a contact point, which ensures high operational effectiveness,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for operation at temperatures approaching 230°C and above...

- Possibility of custom machining and modifying to specific needs,

- Wide application in modern industrial fields – they are commonly used in computer drives, drive modules, medical devices, also industrial machines.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Cons

- At very strong impacts they can crack, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in producing nuts and complicated shapes in magnets, we propose using cover - magnetic mount.

- Possible danger resulting from small fragments of magnets are risky, when accidentally swallowed, which gains importance in the context of child safety. It is also worth noting that tiny parts of these magnets are able to disrupt the diagnostic process medical after entering the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum magnetic pulling force – what it depends on?

- with the application of a sheet made of low-carbon steel, ensuring maximum field concentration

- with a thickness minimum 10 mm

- characterized by even structure

- without the slightest clearance between the magnet and steel

- under perpendicular application of breakaway force (90-degree angle)

- at temperature room level

Determinants of lifting force in real conditions

- Gap (between the magnet and the metal), as even a microscopic distance (e.g. 0.5 mm) results in a decrease in force by up to 50% (this also applies to varnish, corrosion or debris).

- Load vector – maximum parameter is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the plate is usually several times smaller (approx. 1/5 of the lifting capacity).

- Steel thickness – insufficiently thick plate does not accept the full field, causing part of the power to be wasted into the air.

- Steel grade – the best choice is high-permeability steel. Stainless steels may attract less.

- Surface finish – full contact is obtained only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Temperature influence – hot environment weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was performed on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, however under parallel forces the lifting capacity is smaller. In addition, even a small distance between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of neodymium magnets

Heat warning

Avoid heat. NdFeB magnets are sensitive to heat. If you require resistance above 80°C, inquire about HT versions (H, SH, UH).

Impact on smartphones

An intense magnetic field negatively affects the operation of compasses in smartphones and GPS navigation. Maintain magnets near a smartphone to prevent damaging the sensors.

Medical interference

Health Alert: Neodymium magnets can deactivate heart devices and defibrillators. Do not approach if you have electronic implants.

Cards and drives

Powerful magnetic fields can erase data on credit cards, hard drives, and storage devices. Keep a distance of min. 10 cm.

This is not a toy

Always keep magnets out of reach of children. Ingestion danger is high, and the consequences of magnets clamping inside the body are very dangerous.

Physical harm

Danger of trauma: The pulling power is so immense that it can result in hematomas, pinching, and broken bones. Protective gloves are recommended.

Skin irritation risks

Nickel alert: The nickel-copper-nickel coating contains nickel. If redness happens, cease handling magnets and wear gloves.

Fire risk

Fire warning: Neodymium dust is explosive. Avoid machining magnets without safety gear as this risks ignition.

Beware of splinters

Despite metallic appearance, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into hazardous fragments.

Powerful field

Before starting, check safety instructions. Sudden snapping can destroy the magnet or hurt your hand. Think ahead.

![SM 18x275 [2xM5] / N42 - magnetic separator SM 18x275 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x275-2xm5-zep.jpg)

![UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump135x40-m10+m12-gw-f-600-kg-luz.jpg)