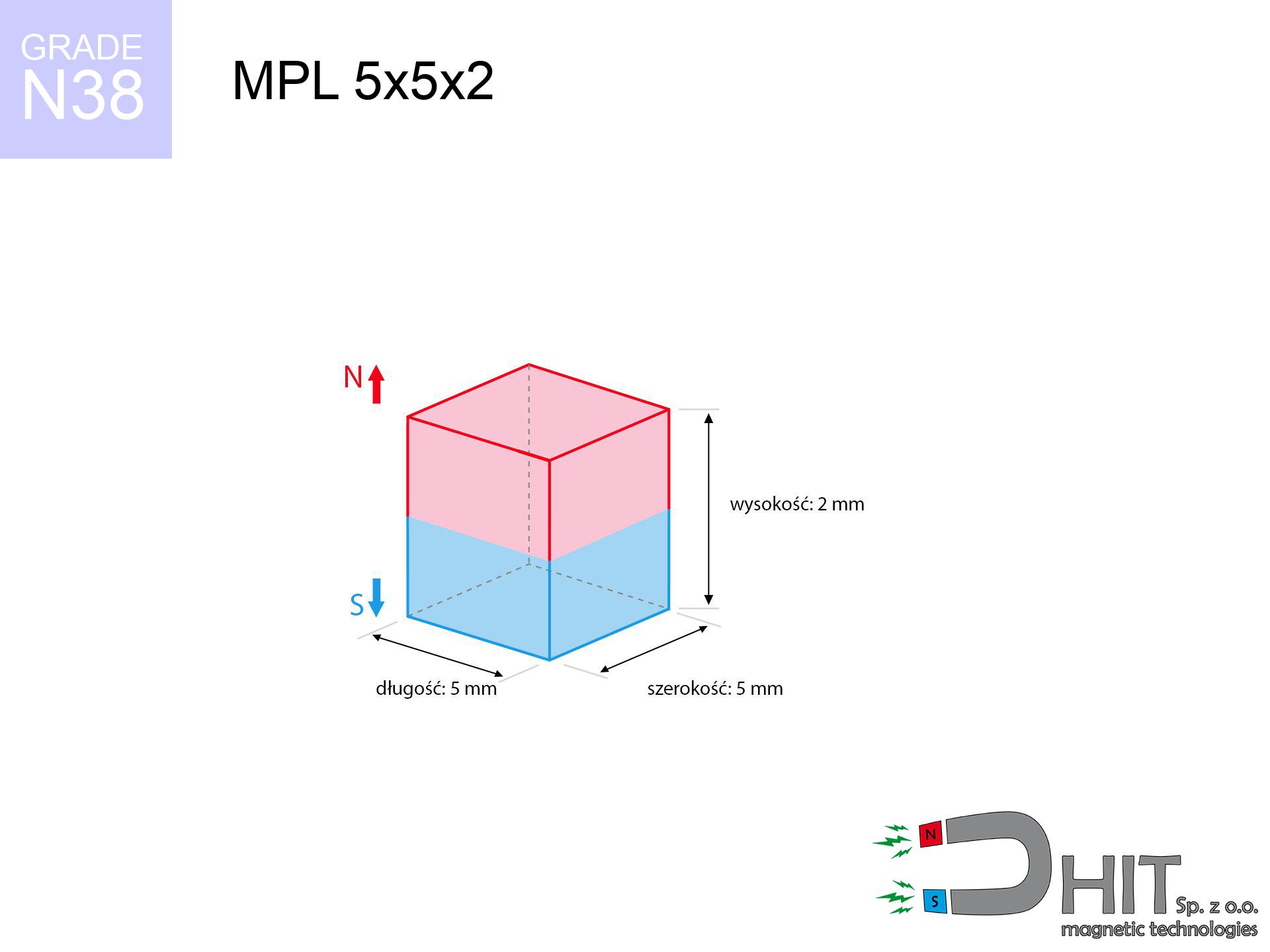

MPL 5x5x2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020173

GTIN/EAN: 5906301811794

length

5 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

0.38 g

Magnetization Direction

↑ axial

Load capacity

0.77 kg / 7.57 N

Magnetic Induction

360.52 mT / 3605 Gs

Coating

[NiCuNi] Nickel

0.308 ZŁ with VAT / pcs + price for transport

0.250 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise let us know through

form

our website.

Lifting power as well as form of neodymium magnets can be checked using our

power calculator.

Same-day processing for orders placed before 14:00.

Physical properties - MPL 5x5x2 / N38 - lamellar magnet

Specification / characteristics - MPL 5x5x2 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020173 |

| GTIN/EAN | 5906301811794 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 5 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 0.38 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.77 kg / 7.57 N |

| Magnetic Induction ~ ? | 360.52 mT / 3605 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - data

The following values are the outcome of a mathematical simulation. Results rely on algorithms for the class Nd2Fe14B. Operational performance might slightly differ. Use these calculations as a reference point during assembly planning.

Table 1: Static pull force (pull vs distance) - interaction chart

MPL 5x5x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3601 Gs

360.1 mT

|

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

safe |

| 1 mm |

2436 Gs

243.6 mT

|

0.35 kg / 0.78 LBS

352.2 g / 3.5 N

|

safe |

| 2 mm |

1464 Gs

146.4 mT

|

0.13 kg / 0.28 LBS

127.3 g / 1.2 N

|

safe |

| 3 mm |

872 Gs

87.2 mT

|

0.05 kg / 0.10 LBS

45.1 g / 0.4 N

|

safe |

| 5 mm |

347 Gs

34.7 mT

|

0.01 kg / 0.02 LBS

7.2 g / 0.1 N

|

safe |

| 10 mm |

68 Gs

6.8 mT

|

0.00 kg / 0.00 LBS

0.3 g / 0.0 N

|

safe |

| 15 mm |

23 Gs

2.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 20 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 30 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Shear load (vertical surface)

MPL 5x5x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.15 kg / 0.34 LBS

154.0 g / 1.5 N

|

| 1 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 2 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

26.0 g / 0.3 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 5x5x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.23 kg / 0.51 LBS

231.0 g / 2.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.15 kg / 0.34 LBS

154.0 g / 1.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.17 LBS

77.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.39 kg / 0.85 LBS

385.0 g / 3.8 N

|

Table 4: Material efficiency (substrate influence) - power losses

MPL 5x5x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.17 LBS

77.0 g / 0.8 N

|

| 1 mm |

|

0.19 kg / 0.42 LBS

192.5 g / 1.9 N

|

| 2 mm |

|

0.39 kg / 0.85 LBS

385.0 g / 3.8 N

|

| 3 mm |

|

0.58 kg / 1.27 LBS

577.5 g / 5.7 N

|

| 5 mm |

|

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

| 10 mm |

|

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

| 11 mm |

|

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

| 12 mm |

|

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

Table 5: Thermal stability (stability) - resistance threshold

MPL 5x5x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.77 kg / 1.70 LBS

770.0 g / 7.6 N

|

OK |

| 40 °C | -2.2% |

0.75 kg / 1.66 LBS

753.1 g / 7.4 N

|

OK |

| 60 °C | -4.4% |

0.74 kg / 1.62 LBS

736.1 g / 7.2 N

|

|

| 80 °C | -6.6% |

0.72 kg / 1.59 LBS

719.2 g / 7.1 N

|

|

| 100 °C | -28.8% |

0.55 kg / 1.21 LBS

548.2 g / 5.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MPL 5x5x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.00 kg / 4.41 LBS

5 058 Gs

|

0.30 kg / 0.66 LBS

300 g / 2.9 N

|

N/A |

| 1 mm |

1.42 kg / 3.13 LBS

6 070 Gs

|

0.21 kg / 0.47 LBS

213 g / 2.1 N

|

1.28 kg / 2.82 LBS

~0 Gs

|

| 2 mm |

0.91 kg / 2.02 LBS

4 871 Gs

|

0.14 kg / 0.30 LBS

137 g / 1.3 N

|

0.82 kg / 1.81 LBS

~0 Gs

|

| 3 mm |

0.56 kg / 1.23 LBS

3 801 Gs

|

0.08 kg / 0.18 LBS

83 g / 0.8 N

|

0.50 kg / 1.10 LBS

~0 Gs

|

| 5 mm |

0.20 kg / 0.43 LBS

2 254 Gs

|

0.03 kg / 0.06 LBS

29 g / 0.3 N

|

0.18 kg / 0.39 LBS

~0 Gs

|

| 10 mm |

0.02 kg / 0.04 LBS

695 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

136 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

4 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MPL 5x5x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (kinetic energy) - warning

MPL 5x5x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

45.41 km/h

(12.61 m/s)

|

0.03 J | |

| 30 mm |

78.63 km/h

(21.84 m/s)

|

0.09 J | |

| 50 mm |

101.51 km/h

(28.20 m/s)

|

0.15 J | |

| 100 mm |

143.56 km/h

(39.88 m/s)

|

0.30 J |

Table 9: Coating parameters (durability)

MPL 5x5x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 5x5x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 940 Mx | 9.4 µWb |

| Pc Coefficient | 0.46 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 5x5x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.77 kg | Standard |

| Water (riverbed) |

0.88 kg

(+0.11 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet retains merely ~20% of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) significantly reduces the holding force.

3. Power loss vs temp

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.46

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of Nd2Fe14B magnets.

Pros

- They do not lose power, even over approximately ten years – the drop in lifting capacity is only ~1% (according to tests),

- They retain their magnetic properties even under strong external field,

- In other words, due to the reflective finish of gold, the element gains a professional look,

- Magnetic induction on the working part of the magnet turns out to be extremely intense,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of exact machining as well as adapting to precise needs,

- Significant place in modern industrial fields – they find application in magnetic memories, electromotive mechanisms, precision medical tools, also modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Weaknesses

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Limited ability of creating threads in the magnet and complicated shapes - recommended is casing - magnet mounting.

- Potential hazard to health – tiny shards of magnets are risky, when accidentally swallowed, which gains importance in the aspect of protecting the youngest. It is also worth noting that small elements of these devices can complicate diagnosis medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Maximum lifting capacity of the magnet – what contributes to it?

- on a block made of mild steel, perfectly concentrating the magnetic flux

- whose thickness reaches at least 10 mm

- with an ground touching surface

- with direct contact (no paint)

- during pulling in a direction vertical to the plane

- in stable room temperature

Lifting capacity in practice – influencing factors

- Space between magnet and steel – every millimeter of distance (caused e.g. by veneer or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to detachment vertically. When attempting to slide, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal limits the lifting capacity (the magnet "punches through" it).

- Steel type – mild steel gives the best results. Alloy steels decrease magnetic properties and lifting capacity.

- Smoothness – ideal contact is possible only on polished steel. Any scratches and bumps create air cushions, reducing force.

- Thermal factor – hot environment reduces magnetic field. Too high temperature can permanently damage the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, in contrast under parallel forces the holding force is lower. Moreover, even a slight gap between the magnet and the plate reduces the load capacity.

Safety rules for work with NdFeB magnets

Conscious usage

Use magnets with awareness. Their huge power can surprise even professionals. Be vigilant and respect their force.

Phone sensors

Navigation devices and smartphones are extremely sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can ruin the sensors in your phone.

Do not drill into magnets

Fire warning: Rare earth powder is highly flammable. Do not process magnets in home conditions as this may cause fire.

Shattering risk

Despite metallic appearance, the material is delicate and not impact-resistant. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Demagnetization risk

Standard neodymium magnets (N-type) undergo demagnetization when the temperature surpasses 80°C. Damage is permanent.

Electronic devices

Very strong magnetic fields can corrupt files on credit cards, hard drives, and other magnetic media. Stay away of min. 10 cm.

ICD Warning

People with a ICD have to maintain an large gap from magnets. The magnetism can disrupt the functioning of the life-saving device.

Metal Allergy

Some people suffer from a contact allergy to nickel, which is the typical protective layer for neodymium magnets. Extended handling may cause an allergic reaction. We suggest wear safety gloves.

Choking Hazard

Absolutely store magnets away from children. Ingestion danger is high, and the consequences of magnets clamping inside the body are fatal.

Serious injuries

Protect your hands. Two large magnets will snap together instantly with a force of massive weight, destroying anything in their path. Exercise extreme caution!