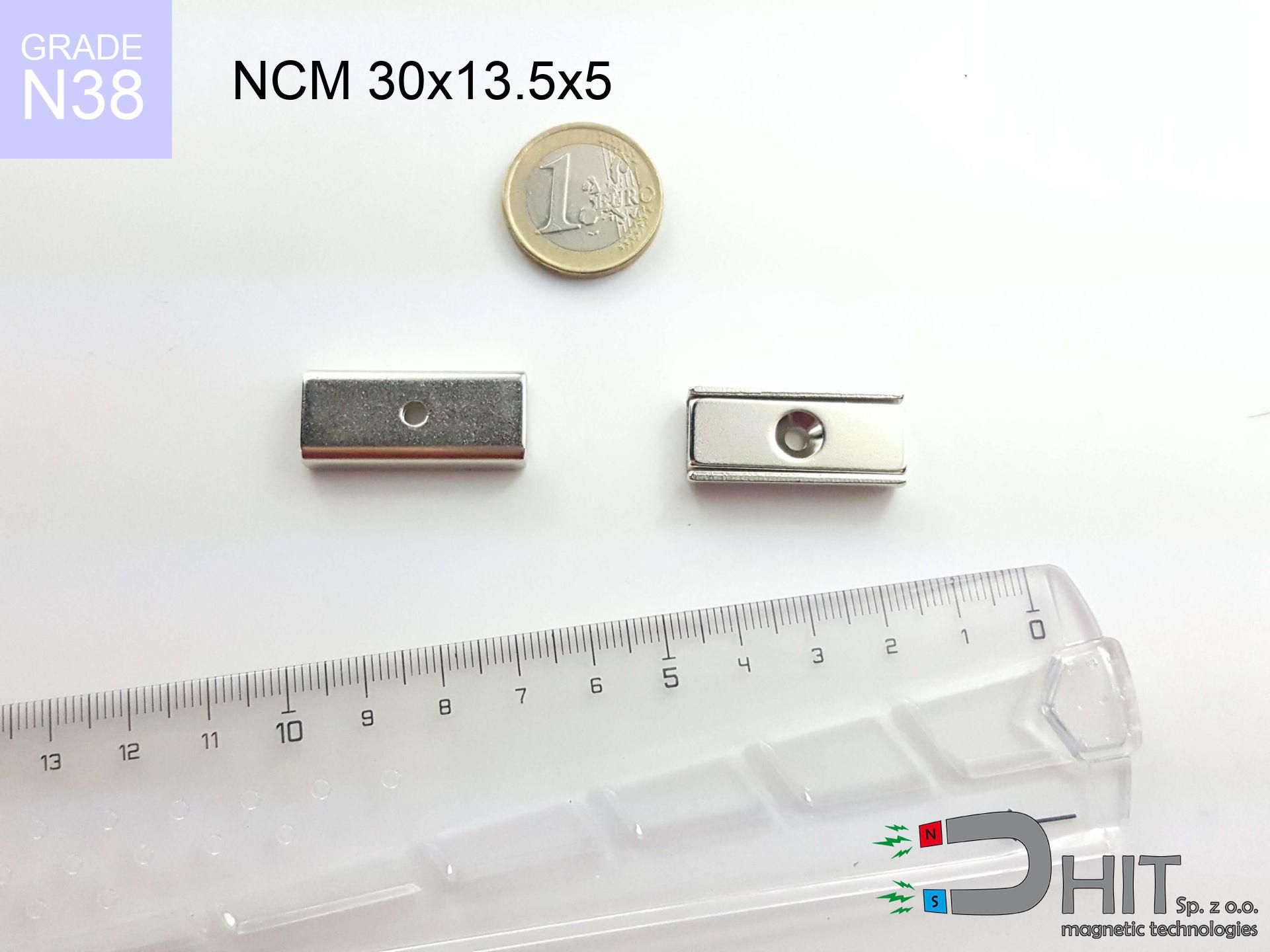

NCM 30x13.5x5 / N38 - channel magnetic holder

channel magnetic holder

Catalog no 360488

GTIN/EAN: 5906301814870

Diameter Ø

30 mm [±1 mm]

Height

13.5 mm [±1 mm]

Weight

14 g

Magnetization Direction

↑ axial

Load capacity

16.00 kg / 156.91 N

Coating

[NiCuNi] Nickel

9.40 ZŁ with VAT / pcs + price for transport

7.64 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise let us know using

form

the contact form page.

Force along with shape of a magnet can be reviewed with our

online calculation tool.

Same-day processing for orders placed before 14:00.

Detailed specification - NCM 30x13.5x5 / N38 - channel magnetic holder

Specification / characteristics - NCM 30x13.5x5 / N38 - channel magnetic holder

| properties | values |

|---|---|

| Cat. no. | 360488 |

| GTIN/EAN | 5906301814870 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 30 mm [±1 mm] |

| Height | 13.5 mm [±1 mm] |

| Weight | 14 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 16.00 kg / 156.91 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more proposals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Advantages

- They do not lose magnetism, even during nearly ten years – the decrease in strength is only ~1% (according to tests),

- They are extremely resistant to demagnetization induced by presence of other magnetic fields,

- By applying a smooth coating of nickel, the element presents an modern look,

- They are known for high magnetic induction at the operating surface, which improves attraction properties,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for functioning at temperatures approaching 230°C and above...

- Considering the ability of precise molding and adaptation to unique solutions, NdFeB magnets can be manufactured in a broad palette of shapes and sizes, which amplifies use scope,

- Wide application in innovative solutions – they are commonly used in mass storage devices, electric drive systems, diagnostic systems, also multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which allows their use in compact constructions

Limitations

- They are fragile upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- We recommend casing - magnetic holder, due to difficulties in producing threads inside the magnet and complex shapes.

- Potential hazard resulting from small fragments of magnets can be dangerous, if swallowed, which gains importance in the context of child health protection. It is also worth noting that tiny parts of these products can complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Best holding force of the magnet in ideal parameters – what contributes to it?

- with the application of a yoke made of low-carbon steel, ensuring maximum field concentration

- possessing a massiveness of at least 10 mm to avoid saturation

- characterized by lack of roughness

- with direct contact (no paint)

- under axial application of breakaway force (90-degree angle)

- in stable room temperature

Practical aspects of lifting capacity – factors

- Distance (betwixt the magnet and the metal), as even a tiny distance (e.g. 0.5 mm) can cause a reduction in lifting capacity by up to 50% (this also applies to varnish, rust or dirt).

- Angle of force application – highest force is obtained only during perpendicular pulling. The shear force of the magnet along the surface is typically several times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Plate material – mild steel gives the best results. Alloy steels decrease magnetic permeability and holding force.

- Surface finish – full contact is possible only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Thermal factor – hot environment weakens pulling force. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was assessed using a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular detachment force, however under parallel forces the lifting capacity is smaller. Moreover, even a small distance between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of neodymium magnets

Machining danger

Machining of NdFeB material poses a fire risk. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Warning for allergy sufferers

Certain individuals experience a sensitization to Ni, which is the standard coating for neodymium magnets. Extended handling may cause skin redness. We suggest wear protective gloves.

Crushing force

Big blocks can smash fingers in a fraction of a second. Do not place your hand betwixt two attracting surfaces.

Magnets are brittle

NdFeB magnets are sintered ceramics, which means they are very brittle. Collision of two magnets leads to them shattering into small pieces.

Medical implants

Health Alert: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Danger to the youngest

Neodymium magnets are not intended for children. Accidental ingestion of multiple magnets may result in them pinching intestinal walls, which poses a direct threat to life and necessitates immediate surgery.

Keep away from computers

Powerful magnetic fields can corrupt files on payment cards, HDDs, and storage devices. Keep a distance of min. 10 cm.

Compass and GPS

A strong magnetic field interferes with the operation of compasses in phones and navigation systems. Keep magnets near a smartphone to prevent breaking the sensors.

Heat warning

Standard neodymium magnets (grade N) lose power when the temperature surpasses 80°C. Damage is permanent.

Immense force

Be careful. Rare earth magnets attract from a long distance and connect with huge force, often quicker than you can react.