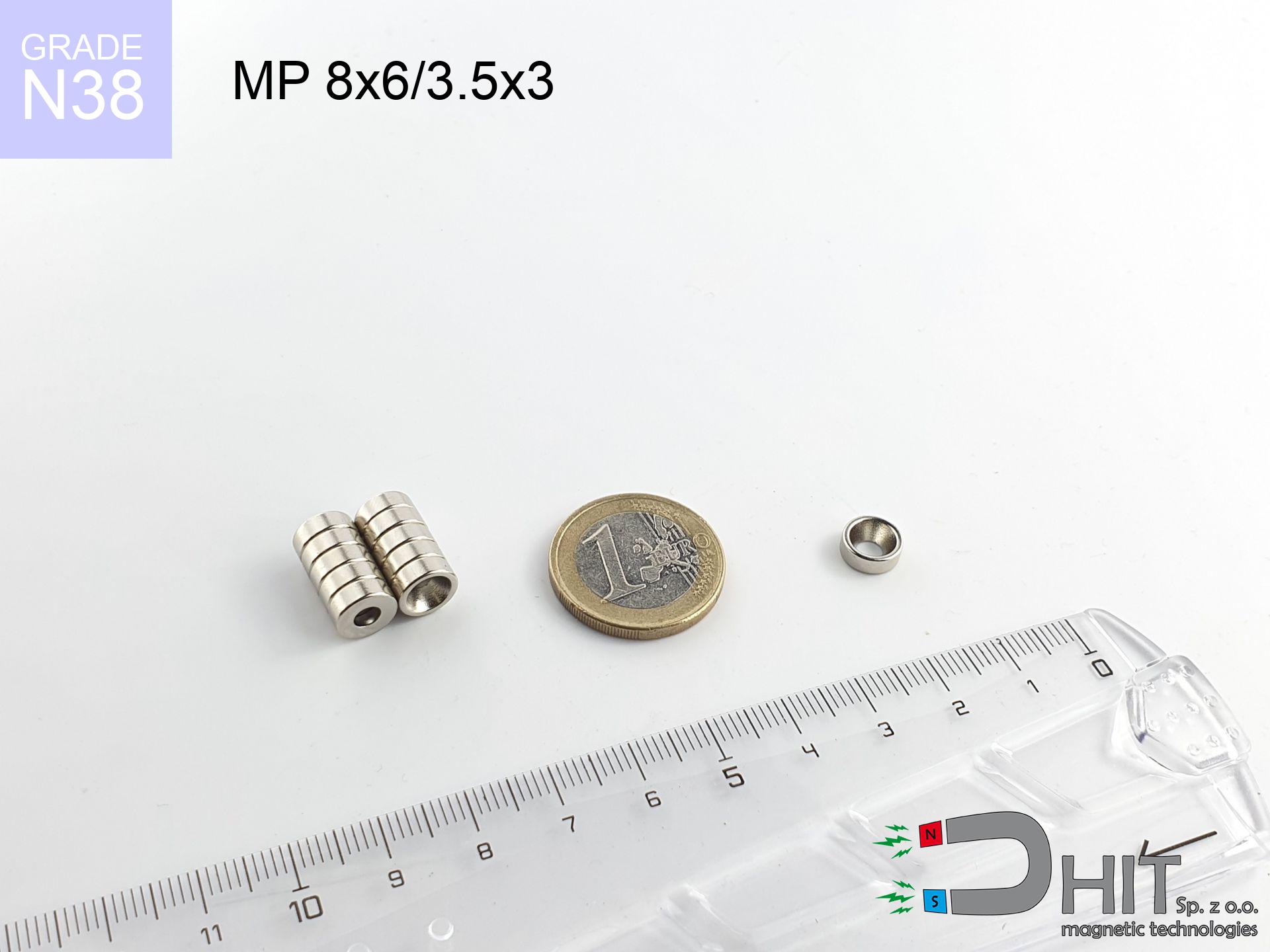

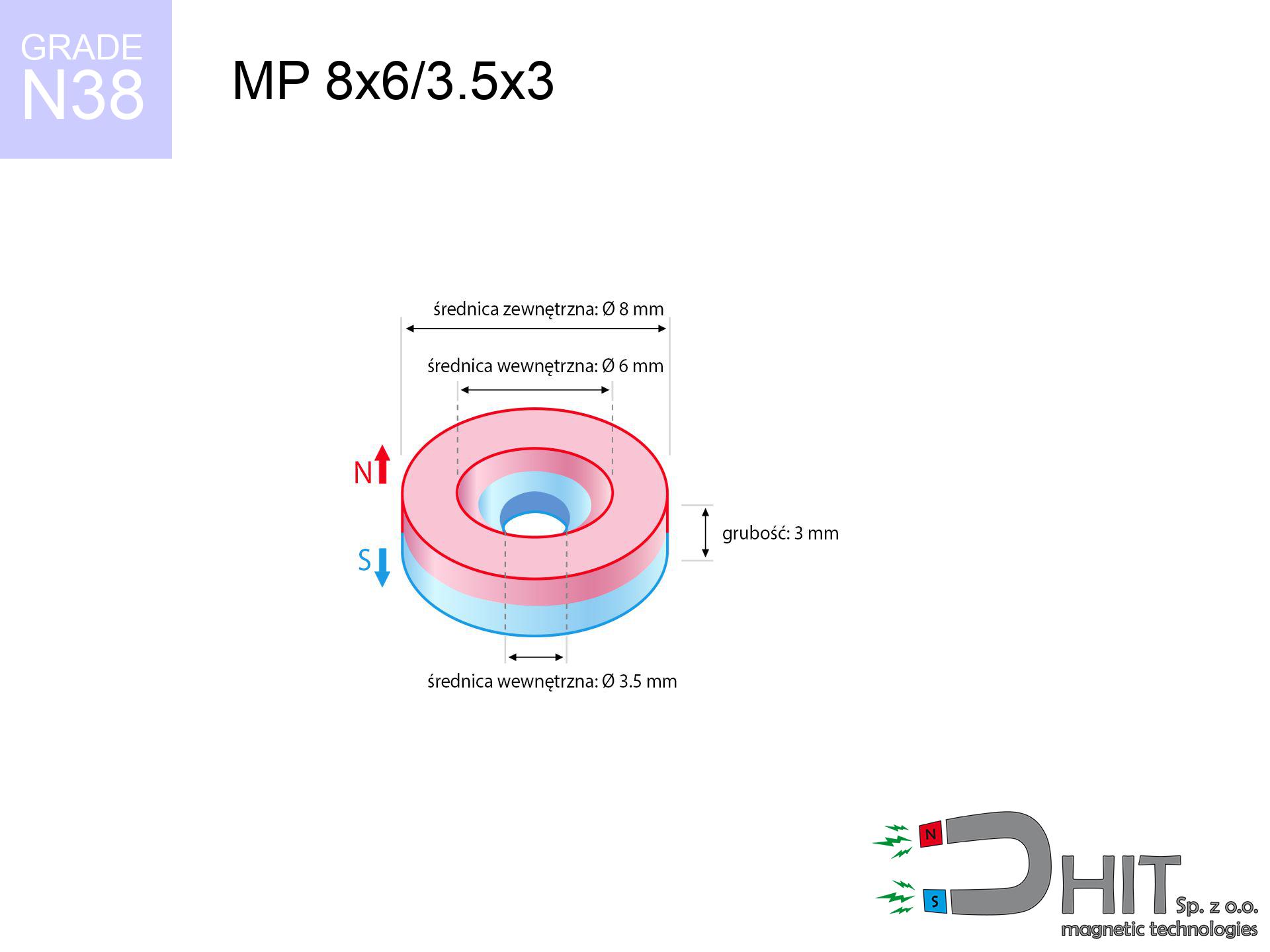

MP 8x6/3.5x3 / N38 - ring magnet

ring magnet

Catalog no 030206

GTIN/EAN: 5906301812234

Diameter

8 mm [±0,1 mm]

internal diameter Ø

6/3.5 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

0.91 g

Magnetization Direction

↑ axial

Load capacity

1.37 kg / 13.48 N

Magnetic Induction

371.53 mT / 3715 Gs

Coating

[NiCuNi] Nickel

0.701 ZŁ with VAT / pcs + price for transport

0.570 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

if you prefer get in touch through

inquiry form

the contact page.

Strength and shape of magnets can be checked on our

modular calculator.

Order by 14:00 and we’ll ship today!

Technical details - MP 8x6/3.5x3 / N38 - ring magnet

Specification / characteristics - MP 8x6/3.5x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030206 |

| GTIN/EAN | 5906301812234 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 8 mm [±0,1 mm] |

| internal diameter Ø | 6/3.5 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 0.91 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.37 kg / 13.48 N |

| Magnetic Induction ~ ? | 371.53 mT / 3715 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the assembly - technical parameters

These values constitute the direct effect of a mathematical calculation. Results are based on algorithms for the class Nd2Fe14B. Real-world parameters might slightly deviate from the simulation results. Please consider these calculations as a reference point when designing systems.

Table 1: Static force (force vs distance) - power drop

MP 8x6/3.5x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3327 Gs

332.7 mT

|

1.37 kg / 3.02 pounds

1370.0 g / 13.4 N

|

safe |

| 1 mm |

2612 Gs

261.2 mT

|

0.84 kg / 1.86 pounds

844.4 g / 8.3 N

|

safe |

| 2 mm |

1884 Gs

188.4 mT

|

0.44 kg / 0.97 pounds

439.3 g / 4.3 N

|

safe |

| 3 mm |

1310 Gs

131.0 mT

|

0.21 kg / 0.47 pounds

212.4 g / 2.1 N

|

safe |

| 5 mm |

637 Gs

63.7 mT

|

0.05 kg / 0.11 pounds

50.3 g / 0.5 N

|

safe |

| 10 mm |

151 Gs

15.1 mT

|

0.00 kg / 0.01 pounds

2.8 g / 0.0 N

|

safe |

| 15 mm |

54 Gs

5.4 mT

|

0.00 kg / 0.00 pounds

0.4 g / 0.0 N

|

safe |

| 20 mm |

25 Gs

2.5 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

safe |

| 30 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Slippage force (wall)

MP 8x6/3.5x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.27 kg / 0.60 pounds

274.0 g / 2.7 N

|

| 1 mm | Stal (~0.2) |

0.17 kg / 0.37 pounds

168.0 g / 1.6 N

|

| 2 mm | Stal (~0.2) |

0.09 kg / 0.19 pounds

88.0 g / 0.9 N

|

| 3 mm | Stal (~0.2) |

0.04 kg / 0.09 pounds

42.0 g / 0.4 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

10.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MP 8x6/3.5x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.41 kg / 0.91 pounds

411.0 g / 4.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.27 kg / 0.60 pounds

274.0 g / 2.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.14 kg / 0.30 pounds

137.0 g / 1.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.69 kg / 1.51 pounds

685.0 g / 6.7 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MP 8x6/3.5x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.14 kg / 0.30 pounds

137.0 g / 1.3 N

|

| 1 mm |

|

0.34 kg / 0.76 pounds

342.5 g / 3.4 N

|

| 2 mm |

|

0.69 kg / 1.51 pounds

685.0 g / 6.7 N

|

| 3 mm |

|

1.03 kg / 2.27 pounds

1027.5 g / 10.1 N

|

| 5 mm |

|

1.37 kg / 3.02 pounds

1370.0 g / 13.4 N

|

| 10 mm |

|

1.37 kg / 3.02 pounds

1370.0 g / 13.4 N

|

| 11 mm |

|

1.37 kg / 3.02 pounds

1370.0 g / 13.4 N

|

| 12 mm |

|

1.37 kg / 3.02 pounds

1370.0 g / 13.4 N

|

Table 5: Working in heat (stability) - thermal limit

MP 8x6/3.5x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.37 kg / 3.02 pounds

1370.0 g / 13.4 N

|

OK |

| 40 °C | -2.2% |

1.34 kg / 2.95 pounds

1339.9 g / 13.1 N

|

OK |

| 60 °C | -4.4% |

1.31 kg / 2.89 pounds

1309.7 g / 12.8 N

|

|

| 80 °C | -6.6% |

1.28 kg / 2.82 pounds

1279.6 g / 12.6 N

|

|

| 100 °C | -28.8% |

0.98 kg / 2.15 pounds

975.4 g / 9.6 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MP 8x6/3.5x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.36 kg / 5.20 pounds

4 867 Gs

|

0.35 kg / 0.78 pounds

354 g / 3.5 N

|

N/A |

| 1 mm |

1.90 kg / 4.20 pounds

5 981 Gs

|

0.29 kg / 0.63 pounds

286 g / 2.8 N

|

1.71 kg / 3.78 pounds

~0 Gs

|

| 2 mm |

1.45 kg / 3.20 pounds

5 223 Gs

|

0.22 kg / 0.48 pounds

218 g / 2.1 N

|

1.31 kg / 2.88 pounds

~0 Gs

|

| 3 mm |

1.06 kg / 2.34 pounds

4 468 Gs

|

0.16 kg / 0.35 pounds

159 g / 1.6 N

|

0.96 kg / 2.11 pounds

~0 Gs

|

| 5 mm |

0.53 kg / 1.16 pounds

3 148 Gs

|

0.08 kg / 0.17 pounds

79 g / 0.8 N

|

0.47 kg / 1.05 pounds

~0 Gs

|

| 10 mm |

0.09 kg / 0.19 pounds

1 274 Gs

|

0.01 kg / 0.03 pounds

13 g / 0.1 N

|

0.08 kg / 0.17 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 pounds

301 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

27 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

16 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

7 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

4 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MP 8x6/3.5x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MP 8x6/3.5x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

39.18 km/h

(10.88 m/s)

|

0.05 J | |

| 30 mm |

67.78 km/h

(18.83 m/s)

|

0.16 J | |

| 50 mm |

87.50 km/h

(24.31 m/s)

|

0.27 J | |

| 100 mm |

123.74 km/h

(34.37 m/s)

|

0.54 J |

Table 9: Anti-corrosion coating durability

MP 8x6/3.5x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MP 8x6/3.5x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 299 Mx | 13.0 µWb |

| Pc Coefficient | 0.46 | Low (Flat) |

Table 11: Physics of underwater searching

MP 8x6/3.5x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.37 kg | Standard |

| Water (riverbed) |

1.57 kg

(+0.20 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet retains only ~20% of its nominal pull.

2. Steel saturation

*Thin steel (e.g. computer case) significantly reduces the holding force.

3. Power loss vs temp

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.46

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Advantages as well as disadvantages of rare earth magnets.

Advantages

- They retain attractive force for almost ten years – the drop is just ~1% (in theory),

- Neodymium magnets remain highly resistant to loss of magnetic properties caused by external magnetic fields,

- Thanks to the glossy finish, the coating of Ni-Cu-Ni, gold, or silver-plated gives an aesthetic appearance,

- The surface of neodymium magnets generates a powerful magnetic field – this is one of their assets,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for operation at temperatures reaching 230°C and above...

- Considering the option of precise forming and adaptation to individualized projects, NdFeB magnets can be produced in a variety of shapes and sizes, which makes them more universal,

- Fundamental importance in high-tech industry – they serve a role in HDD drives, drive modules, diagnostic systems, and complex engineering applications.

- Thanks to efficiency per cm³, small magnets offer high operating force, in miniature format,

Limitations

- Brittleness is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a special holder, which not only secures them against impacts but also increases their durability

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- We suggest casing - magnetic holder, due to difficulties in creating nuts inside the magnet and complex shapes.

- Health risk to health – tiny shards of magnets pose a threat, when accidentally swallowed, which gains importance in the context of child health protection. Additionally, small components of these products are able to disrupt the diagnostic process medical when they are in the body.

- Due to expensive raw materials, their price exceeds standard values,

Lifting parameters

Detachment force of the magnet in optimal conditions – what affects it?

- with the use of a sheet made of low-carbon steel, ensuring maximum field concentration

- with a thickness no less than 10 mm

- with a surface perfectly flat

- with total lack of distance (without paint)

- for force acting at a right angle (pull-off, not shear)

- at room temperature

Lifting capacity in practice – influencing factors

- Gap (between the magnet and the plate), because even a very small clearance (e.g. 0.5 mm) can cause a drastic drop in force by up to 50% (this also applies to paint, corrosion or debris).

- Loading method – declared lifting capacity refers to detachment vertically. When attempting to slide, the magnet holds much less (typically approx. 20-30% of maximum force).

- Steel thickness – too thin sheet does not accept the full field, causing part of the power to be escaped into the air.

- Steel grade – the best choice is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. When it is hot they are weaker, and at low temperatures gain strength (up to a certain limit).

Lifting capacity was assessed with the use of a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, whereas under parallel forces the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet’s surface and the plate decreases the load capacity.

Safety rules for work with NdFeB magnets

GPS and phone interference

A powerful magnetic field negatively affects the operation of magnetometers in smartphones and GPS navigation. Do not bring magnets close to a device to prevent breaking the sensors.

Data carriers

Equipment safety: Strong magnets can damage payment cards and delicate electronics (heart implants, medical aids, timepieces).

Fire warning

Fire warning: Rare earth powder is explosive. Do not process magnets without safety gear as this may cause fire.

Warning for heart patients

Warning for patients: Strong magnetic fields affect medical devices. Keep at least 30 cm distance or request help to work with the magnets.

No play value

These products are not intended for children. Accidental ingestion of multiple magnets can lead to them connecting inside the digestive tract, which poses a severe health hazard and necessitates immediate surgery.

Eye protection

Despite the nickel coating, neodymium is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Crushing force

Protect your hands. Two large magnets will snap together instantly with a force of massive weight, crushing anything in their path. Exercise extreme caution!

Do not overheat magnets

Do not overheat. Neodymium magnets are susceptible to temperature. If you need operation above 80°C, inquire about HT versions (H, SH, UH).

Avoid contact if allergic

Studies show that nickel (the usual finish) is a potent allergen. If your skin reacts to metals, avoid direct skin contact or choose coated magnets.

Conscious usage

Handle magnets with awareness. Their immense force can shock even professionals. Stay alert and do not underestimate their force.

![SM 25x275 [2xM8] / N42 - magnetic separator SM 25x275 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x275-2xm8-boc.jpg)

![UMH 60x15x69 [M8] / N38 - magnetic holder with hook UMH 60x15x69 [M8] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-60x15x69-m8-nij.jpg)