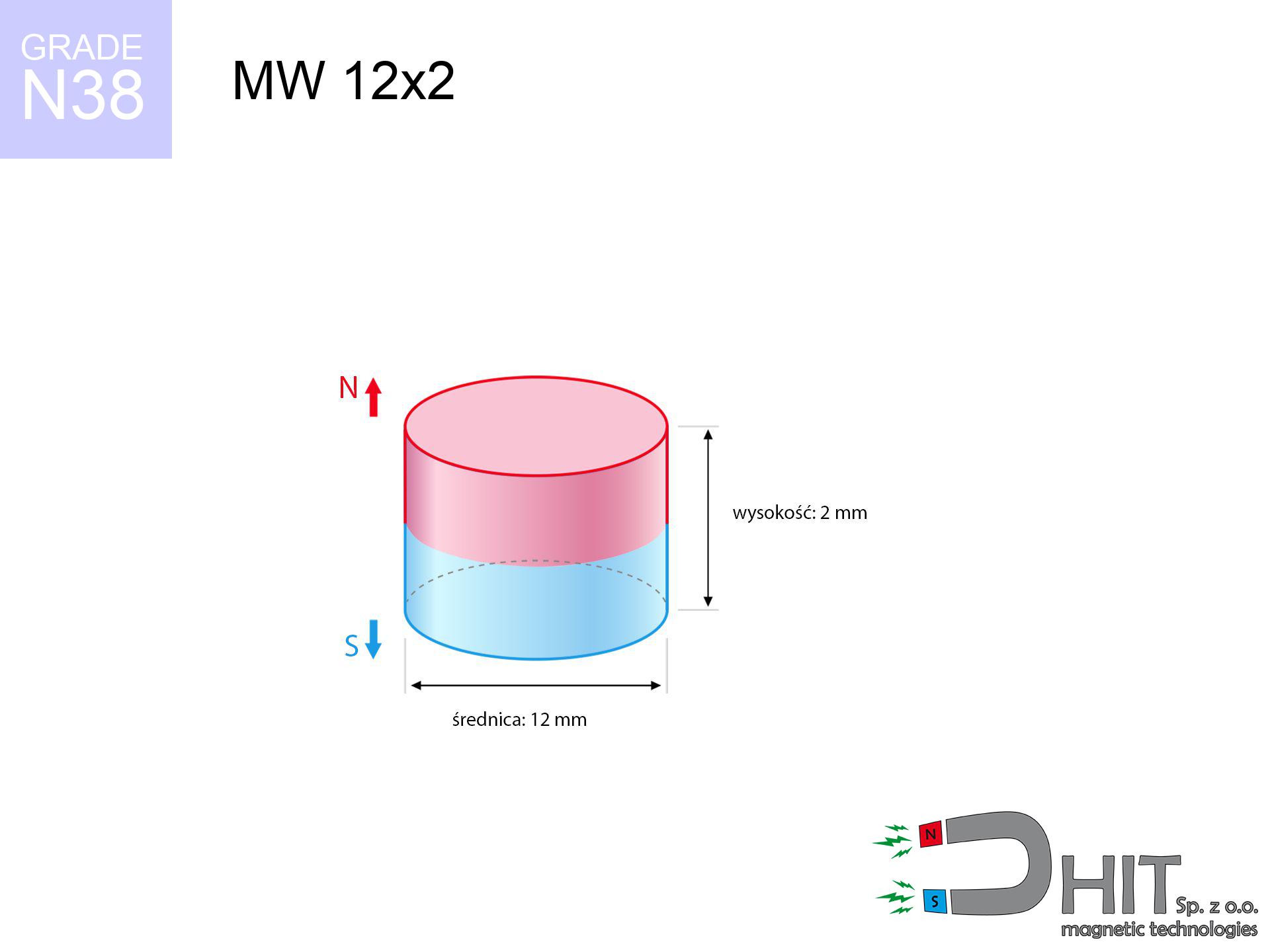

MW 12x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010017

GTIN/EAN: 5906301810162

Diameter Ø

12 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

1.7 g

Magnetization Direction

↑ axial

Load capacity

1.39 kg / 13.66 N

Magnetic Induction

195.97 mT / 1960 Gs

Coating

[NiCuNi] Nickel

1.132 ZŁ with VAT / pcs + price for transport

0.920 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or contact us through

form

the contact form page.

Lifting power as well as shape of neodymium magnets can be verified using our

modular calculator.

Same-day processing for orders placed before 14:00.

Product card - MW 12x2 / N38 - cylindrical magnet

Specification / characteristics - MW 12x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010017 |

| GTIN/EAN | 5906301810162 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 1.7 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.39 kg / 13.66 N |

| Magnetic Induction ~ ? | 195.97 mT / 1960 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - report

These values constitute the outcome of a physical analysis. Values were calculated on algorithms for the material Nd2Fe14B. Real-world conditions might slightly differ. Please consider these data as a reference point for designers.

Table 1: Static force (force vs distance) - interaction chart

MW 12x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1959 Gs

195.9 mT

|

1.39 kg / 3.06 lbs

1390.0 g / 13.6 N

|

safe |

| 1 mm |

1753 Gs

175.3 mT

|

1.11 kg / 2.45 lbs

1113.5 g / 10.9 N

|

safe |

| 2 mm |

1479 Gs

147.9 mT

|

0.79 kg / 1.75 lbs

791.7 g / 7.8 N

|

safe |

| 3 mm |

1196 Gs

119.6 mT

|

0.52 kg / 1.14 lbs

518.4 g / 5.1 N

|

safe |

| 5 mm |

738 Gs

73.8 mT

|

0.20 kg / 0.44 lbs

197.4 g / 1.9 N

|

safe |

| 10 mm |

229 Gs

22.9 mT

|

0.02 kg / 0.04 lbs

19.0 g / 0.2 N

|

safe |

| 15 mm |

90 Gs

9.0 mT

|

0.00 kg / 0.01 lbs

2.9 g / 0.0 N

|

safe |

| 20 mm |

43 Gs

4.3 mT

|

0.00 kg / 0.00 lbs

0.7 g / 0.0 N

|

safe |

| 30 mm |

14 Gs

1.4 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Shear capacity (vertical surface)

MW 12x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.28 kg / 0.61 lbs

278.0 g / 2.7 N

|

| 1 mm | Stal (~0.2) |

0.22 kg / 0.49 lbs

222.0 g / 2.2 N

|

| 2 mm | Stal (~0.2) |

0.16 kg / 0.35 lbs

158.0 g / 1.5 N

|

| 3 mm | Stal (~0.2) |

0.10 kg / 0.23 lbs

104.0 g / 1.0 N

|

| 5 mm | Stal (~0.2) |

0.04 kg / 0.09 lbs

40.0 g / 0.4 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 12x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.42 kg / 0.92 lbs

417.0 g / 4.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.28 kg / 0.61 lbs

278.0 g / 2.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.14 kg / 0.31 lbs

139.0 g / 1.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.70 kg / 1.53 lbs

695.0 g / 6.8 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 12x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.14 kg / 0.31 lbs

139.0 g / 1.4 N

|

| 1 mm |

|

0.35 kg / 0.77 lbs

347.5 g / 3.4 N

|

| 2 mm |

|

0.70 kg / 1.53 lbs

695.0 g / 6.8 N

|

| 3 mm |

|

1.04 kg / 2.30 lbs

1042.5 g / 10.2 N

|

| 5 mm |

|

1.39 kg / 3.06 lbs

1390.0 g / 13.6 N

|

| 10 mm |

|

1.39 kg / 3.06 lbs

1390.0 g / 13.6 N

|

| 11 mm |

|

1.39 kg / 3.06 lbs

1390.0 g / 13.6 N

|

| 12 mm |

|

1.39 kg / 3.06 lbs

1390.0 g / 13.6 N

|

Table 5: Working in heat (stability) - power drop

MW 12x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.39 kg / 3.06 lbs

1390.0 g / 13.6 N

|

OK |

| 40 °C | -2.2% |

1.36 kg / 3.00 lbs

1359.4 g / 13.3 N

|

OK |

| 60 °C | -4.4% |

1.33 kg / 2.93 lbs

1328.8 g / 13.0 N

|

|

| 80 °C | -6.6% |

1.30 kg / 2.86 lbs

1298.3 g / 12.7 N

|

|

| 100 °C | -28.8% |

0.99 kg / 2.18 lbs

989.7 g / 9.7 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 12x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.68 kg / 5.90 lbs

3 435 Gs

|

0.40 kg / 0.88 lbs

401 g / 3.9 N

|

N/A |

| 1 mm |

2.44 kg / 5.37 lbs

3 739 Gs

|

0.37 kg / 0.81 lbs

366 g / 3.6 N

|

2.19 kg / 4.84 lbs

~0 Gs

|

| 2 mm |

2.14 kg / 4.73 lbs

3 507 Gs

|

0.32 kg / 0.71 lbs

322 g / 3.2 N

|

1.93 kg / 4.25 lbs

~0 Gs

|

| 3 mm |

1.83 kg / 4.04 lbs

3 241 Gs

|

0.27 kg / 0.61 lbs

275 g / 2.7 N

|

1.65 kg / 3.63 lbs

~0 Gs

|

| 5 mm |

1.24 kg / 2.74 lbs

2 671 Gs

|

0.19 kg / 0.41 lbs

187 g / 1.8 N

|

1.12 kg / 2.47 lbs

~0 Gs

|

| 10 mm |

0.38 kg / 0.84 lbs

1 476 Gs

|

0.06 kg / 0.13 lbs

57 g / 0.6 N

|

0.34 kg / 0.75 lbs

~0 Gs

|

| 20 mm |

0.04 kg / 0.08 lbs

458 Gs

|

0.01 kg / 0.01 lbs

5 g / 0.1 N

|

0.03 kg / 0.07 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

47 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

28 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

18 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

13 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

9 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

7 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MW 12x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 12x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.08 km/h

(8.08 m/s)

|

0.06 J | |

| 30 mm |

49.95 km/h

(13.88 m/s)

|

0.16 J | |

| 50 mm |

64.48 km/h

(17.91 m/s)

|

0.27 J | |

| 100 mm |

91.19 km/h

(25.33 m/s)

|

0.55 J |

Table 9: Surface protection spec

MW 12x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 12x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 665 Mx | 26.7 µWb |

| Pc Coefficient | 0.25 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 12x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.39 kg | Standard |

| Water (riverbed) |

1.59 kg

(+0.20 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds just ~20% of its max power.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Power loss vs temp

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.25

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Advantages and disadvantages of neodymium magnets.

Strengths

- They do not lose power, even during around ten years – the decrease in power is only ~1% (based on measurements),

- They feature excellent resistance to weakening of magnetic properties due to external fields,

- By using a decorative coating of gold, the element presents an proper look,

- Magnetic induction on the top side of the magnet is extremely intense,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for functioning at temperatures reaching 230°C and above...

- Possibility of precise shaping and optimizing to complex needs,

- Wide application in high-tech industry – they find application in HDD drives, electric drive systems, medical devices, and complex engineering applications.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Limitations

- At very strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Due to limitations in realizing threads and complicated shapes in magnets, we recommend using a housing - magnetic mechanism.

- Health risk to health – tiny shards of magnets are risky, in case of ingestion, which becomes key in the context of child safety. Furthermore, small components of these devices can be problematic in diagnostics medical when they are in the body.

- With large orders the cost of neodymium magnets is economically unviable,

Pull force analysis

Highest magnetic holding force – what contributes to it?

- using a base made of high-permeability steel, functioning as a ideal flux conductor

- whose transverse dimension is min. 10 mm

- with an ideally smooth contact surface

- with zero gap (without paint)

- under perpendicular force vector (90-degree angle)

- at standard ambient temperature

Magnet lifting force in use – key factors

- Gap (between the magnet and the metal), because even a tiny distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to varnish, corrosion or dirt).

- Loading method – declared lifting capacity refers to detachment vertically. When slipping, the magnet holds much less (typically approx. 20-30% of nominal force).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Steel type – low-carbon steel attracts best. Alloy steels decrease magnetic properties and holding force.

- Base smoothness – the more even the surface, the larger the contact zone and higher the lifting capacity. Roughness creates an air distance.

- Heat – NdFeB sinters have a negative temperature coefficient. When it is hot they lose power, and at low temperatures gain strength (up to a certain limit).

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under shearing force the load capacity is reduced by as much as 5 times. Additionally, even a slight gap between the magnet and the plate lowers the lifting capacity.

H&S for magnets

Risk of cracking

NdFeB magnets are sintered ceramics, which means they are very brittle. Clashing of two magnets leads to them breaking into shards.

Do not overheat magnets

Keep cool. NdFeB magnets are sensitive to heat. If you require resistance above 80°C, look for HT versions (H, SH, UH).

Nickel allergy

Allergy Notice: The nickel-copper-nickel coating contains nickel. If an allergic reaction appears, cease working with magnets and wear gloves.

Immense force

Be careful. Neodymium magnets act from a distance and snap with huge force, often quicker than you can react.

Product not for children

These products are not intended for children. Eating several magnets can lead to them pinching intestinal walls, which constitutes a critical condition and requires urgent medical intervention.

GPS Danger

Remember: rare earth magnets produce a field that interferes with sensitive sensors. Keep a separation from your mobile, tablet, and navigation systems.

Warning for heart patients

Medical warning: Neodymium magnets can deactivate heart devices and defibrillators. Stay away if you have electronic implants.

Cards and drives

Equipment safety: Neodymium magnets can damage payment cards and sensitive devices (pacemakers, medical aids, timepieces).

Hand protection

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, destroying anything in their path. Exercise extreme caution!

Fire warning

Combustion risk: Rare earth powder is highly flammable. Avoid machining magnets without safety gear as this may cause fire.

![HH 42x8.8 [M6] / N38 - through hole magnetic holder HH 42x8.8 [M6] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-42x8.8-m6-hin.jpg)