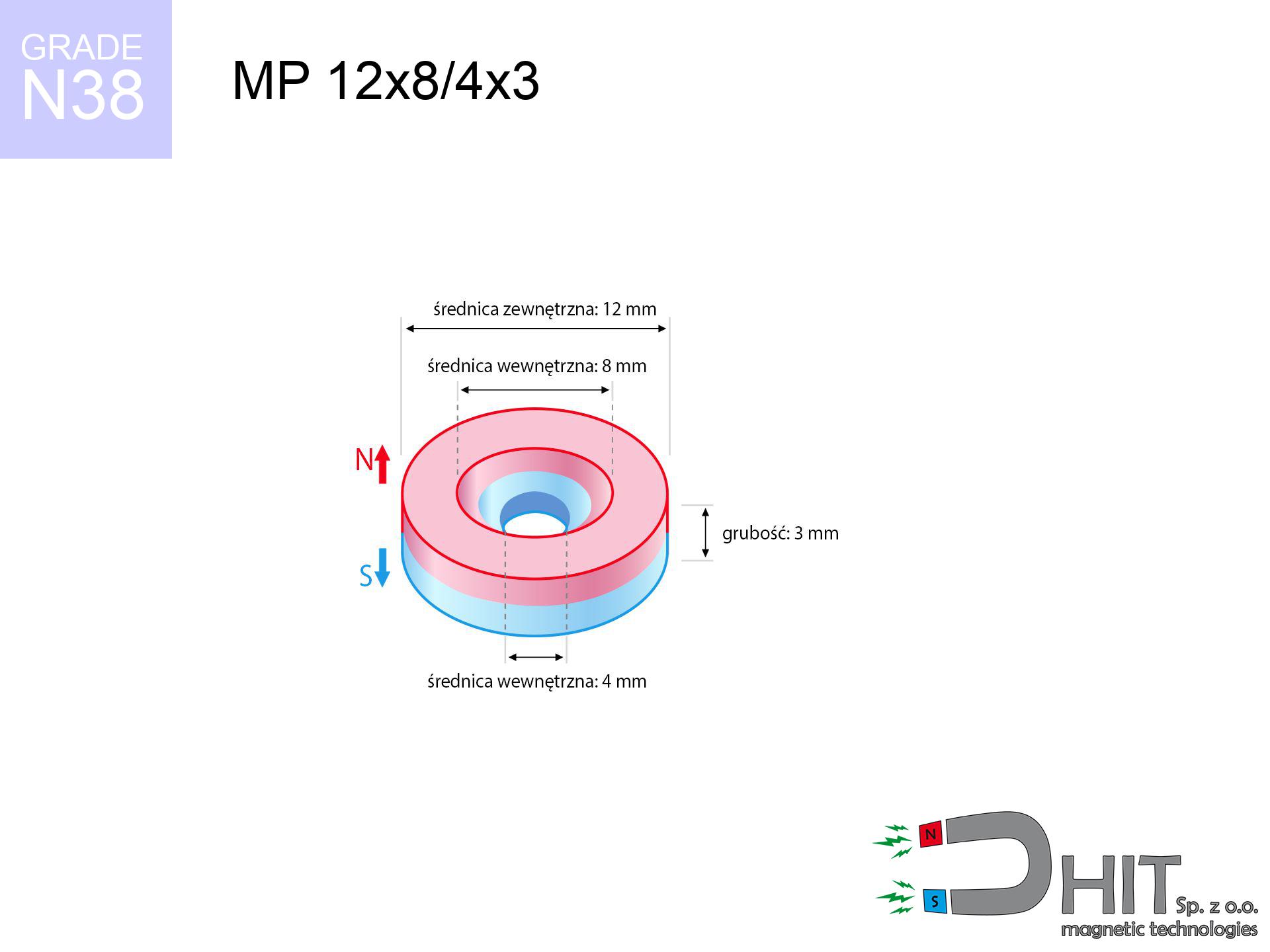

MP 12x8/4x3 / N38 - ring magnet

ring magnet

Catalog no 030395

GTIN/EAN: 5906301812326

Diameter

12 mm [±0,1 mm]

internal diameter Ø

8/4 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

2.26 g

Magnetization Direction

↑ axial

Load capacity

2.21 kg / 21.72 N

Magnetic Induction

277.09 mT / 2771 Gs

Coating

[NiCuNi] Nickel

1.427 ZŁ with VAT / pcs + price for transport

1.160 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

or contact us using

request form

our website.

Weight and shape of a neodymium magnet can be analyzed with our

power calculator.

Order by 14:00 and we’ll ship today!

Technical data - MP 12x8/4x3 / N38 - ring magnet

Specification / characteristics - MP 12x8/4x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030395 |

| GTIN/EAN | 5906301812326 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 12 mm [±0,1 mm] |

| internal diameter Ø | 8/4 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 2.26 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.21 kg / 21.72 N |

| Magnetic Induction ~ ? | 277.09 mT / 2771 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - technical parameters

The following data constitute the outcome of a engineering simulation. Values are based on algorithms for the class Nd2Fe14B. Real-world performance may differ from theoretical values. Use these data as a reference point when designing systems.

Table 1: Static force (pull vs gap) - interaction chart

MP 12x8/4x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2423 Gs

242.3 mT

|

2.21 kg / 4.87 pounds

2210.0 g / 21.7 N

|

medium risk |

| 1 mm |

2138 Gs

213.8 mT

|

1.72 kg / 3.79 pounds

1720.7 g / 16.9 N

|

safe |

| 2 mm |

1786 Gs

178.6 mT

|

1.20 kg / 2.65 pounds

1200.5 g / 11.8 N

|

safe |

| 3 mm |

1437 Gs

143.7 mT

|

0.78 kg / 1.71 pounds

777.8 g / 7.6 N

|

safe |

| 5 mm |

885 Gs

88.5 mT

|

0.29 kg / 0.65 pounds

294.7 g / 2.9 N

|

safe |

| 10 mm |

277 Gs

27.7 mT

|

0.03 kg / 0.06 pounds

28.9 g / 0.3 N

|

safe |

| 15 mm |

110 Gs

11.0 mT

|

0.00 kg / 0.01 pounds

4.6 g / 0.0 N

|

safe |

| 20 mm |

53 Gs

5.3 mT

|

0.00 kg / 0.00 pounds

1.1 g / 0.0 N

|

safe |

| 30 mm |

18 Gs

1.8 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

safe |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Shear capacity (vertical surface)

MP 12x8/4x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.44 kg / 0.97 pounds

442.0 g / 4.3 N

|

| 1 mm | Stal (~0.2) |

0.34 kg / 0.76 pounds

344.0 g / 3.4 N

|

| 2 mm | Stal (~0.2) |

0.24 kg / 0.53 pounds

240.0 g / 2.4 N

|

| 3 mm | Stal (~0.2) |

0.16 kg / 0.34 pounds

156.0 g / 1.5 N

|

| 5 mm | Stal (~0.2) |

0.06 kg / 0.13 pounds

58.0 g / 0.6 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MP 12x8/4x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.66 kg / 1.46 pounds

663.0 g / 6.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.44 kg / 0.97 pounds

442.0 g / 4.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.22 kg / 0.49 pounds

221.0 g / 2.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.11 kg / 2.44 pounds

1105.0 g / 10.8 N

|

Table 4: Steel thickness (saturation) - power losses

MP 12x8/4x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.22 kg / 0.49 pounds

221.0 g / 2.2 N

|

| 1 mm |

|

0.55 kg / 1.22 pounds

552.5 g / 5.4 N

|

| 2 mm |

|

1.11 kg / 2.44 pounds

1105.0 g / 10.8 N

|

| 3 mm |

|

1.66 kg / 3.65 pounds

1657.5 g / 16.3 N

|

| 5 mm |

|

2.21 kg / 4.87 pounds

2210.0 g / 21.7 N

|

| 10 mm |

|

2.21 kg / 4.87 pounds

2210.0 g / 21.7 N

|

| 11 mm |

|

2.21 kg / 4.87 pounds

2210.0 g / 21.7 N

|

| 12 mm |

|

2.21 kg / 4.87 pounds

2210.0 g / 21.7 N

|

Table 5: Thermal stability (stability) - thermal limit

MP 12x8/4x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.21 kg / 4.87 pounds

2210.0 g / 21.7 N

|

OK |

| 40 °C | -2.2% |

2.16 kg / 4.77 pounds

2161.4 g / 21.2 N

|

OK |

| 60 °C | -4.4% |

2.11 kg / 4.66 pounds

2112.8 g / 20.7 N

|

|

| 80 °C | -6.6% |

2.06 kg / 4.55 pounds

2064.1 g / 20.2 N

|

|

| 100 °C | -28.8% |

1.57 kg / 3.47 pounds

1573.5 g / 15.4 N

|

Table 6: Two magnets (attraction) - forces in the system

MP 12x8/4x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.09 kg / 6.82 pounds

4 010 Gs

|

0.46 kg / 1.02 pounds

464 g / 4.6 N

|

N/A |

| 1 mm |

2.77 kg / 6.12 pounds

4 589 Gs

|

0.42 kg / 0.92 pounds

416 g / 4.1 N

|

2.50 kg / 5.50 pounds

~0 Gs

|

| 2 mm |

2.41 kg / 5.31 pounds

4 276 Gs

|

0.36 kg / 0.80 pounds

361 g / 3.5 N

|

2.17 kg / 4.78 pounds

~0 Gs

|

| 3 mm |

2.03 kg / 4.48 pounds

3 930 Gs

|

0.31 kg / 0.67 pounds

305 g / 3.0 N

|

1.83 kg / 4.04 pounds

~0 Gs

|

| 5 mm |

1.36 kg / 3.00 pounds

3 216 Gs

|

0.20 kg / 0.45 pounds

204 g / 2.0 N

|

1.23 kg / 2.70 pounds

~0 Gs

|

| 10 mm |

0.41 kg / 0.91 pounds

1 770 Gs

|

0.06 kg / 0.14 pounds

62 g / 0.6 N

|

0.37 kg / 0.82 pounds

~0 Gs

|

| 20 mm |

0.04 kg / 0.09 pounds

554 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.04 kg / 0.08 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

58 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

35 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

23 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

16 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

11 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

8 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MP 12x8/4x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - warning

MP 12x8/4x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

31.79 km/h

(8.83 m/s)

|

0.09 J | |

| 30 mm |

54.63 km/h

(15.17 m/s)

|

0.26 J | |

| 50 mm |

70.52 km/h

(19.59 m/s)

|

0.43 J | |

| 100 mm |

99.73 km/h

(27.70 m/s)

|

0.87 J |

Table 9: Corrosion resistance

MP 12x8/4x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 12x8/4x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 466 Mx | 24.7 µWb |

| Pc Coefficient | 0.32 | Low (Flat) |

Table 11: Submerged application

MP 12x8/4x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.21 kg | Standard |

| Water (riverbed) |

2.53 kg

(+0.32 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical surface, the magnet retains just approx. 20-30% of its nominal pull.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) significantly limits the holding force.

3. Heat tolerance

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.32

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also deals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Pros

- Their magnetic field remains stable, and after around 10 years it drops only by ~1% (according to research),

- They retain their magnetic properties even under close interference source,

- By using a reflective coating of silver, the element has an professional look,

- Magnets have very high magnetic induction on the outer layer,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- In view of the possibility of free molding and customization to individualized solutions, magnetic components can be modeled in a broad palette of geometric configurations, which makes them more universal,

- Fundamental importance in electronics industry – they are utilized in data components, electromotive mechanisms, medical equipment, as well as multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which makes them useful in small systems

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Limited ability of producing nuts in the magnet and complex forms - preferred is casing - magnet mounting.

- Possible danger resulting from small fragments of magnets are risky, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that small elements of these devices can complicate diagnosis medical in case of swallowing.

- Due to expensive raw materials, their price is relatively high,

Holding force characteristics

Maximum lifting capacity of the magnet – what affects it?

- on a plate made of structural steel, effectively closing the magnetic flux

- with a cross-section of at least 10 mm

- with a plane free of scratches

- under conditions of no distance (metal-to-metal)

- under axial application of breakaway force (90-degree angle)

- in neutral thermal conditions

Practical lifting capacity: influencing factors

- Gap between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by veneer or dirt) significantly weakens the pulling force, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of converting into lifting capacity.

- Chemical composition of the base – mild steel gives the best results. Higher carbon content decrease magnetic permeability and holding force.

- Surface condition – smooth surfaces guarantee perfect abutment, which improves force. Rough surfaces reduce efficiency.

- Temperature influence – high temperature reduces magnetic field. Too high temperature can permanently damage the magnet.

Holding force was measured on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under shearing force the holding force is lower. Additionally, even a slight gap between the magnet’s surface and the plate decreases the load capacity.

Safety rules for work with neodymium magnets

Magnetic interference

An intense magnetic field disrupts the operation of compasses in smartphones and GPS navigation. Do not bring magnets near a smartphone to avoid breaking the sensors.

Nickel coating and allergies

Some people have a hypersensitivity to Ni, which is the common plating for NdFeB magnets. Prolonged contact may cause a rash. We suggest use protective gloves.

Serious injuries

Protect your hands. Two powerful magnets will snap together immediately with a force of several hundred kilograms, crushing everything in their path. Be careful!

Dust is flammable

Mechanical processing of NdFeB material carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Fragile material

Despite the nickel coating, the material is delicate and cannot withstand shocks. Avoid impacts, as the magnet may shatter into hazardous fragments.

Cards and drives

Very strong magnetic fields can corrupt files on credit cards, hard drives, and other magnetic media. Keep a distance of at least 10 cm.

Maximum temperature

Monitor thermal conditions. Heating the magnet to high heat will ruin its properties and strength.

Safe operation

Handle with care. Neodymium magnets act from a distance and connect with huge force, often faster than you can move away.

Warning for heart patients

For implant holders: Strong magnetic fields disrupt medical devices. Maintain minimum 30 cm distance or request help to handle the magnets.

Danger to the youngest

NdFeB magnets are not toys. Eating a few magnets can lead to them attracting across intestines, which constitutes a direct threat to life and requires immediate surgery.

![UMP 75x25 [M10x3] GW F200 PLATINIUM Lina / N52 - search holder UMP 75x25 [M10x3] GW F200 PLATINIUM Lina / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-platinium-lina-wiz.jpg)