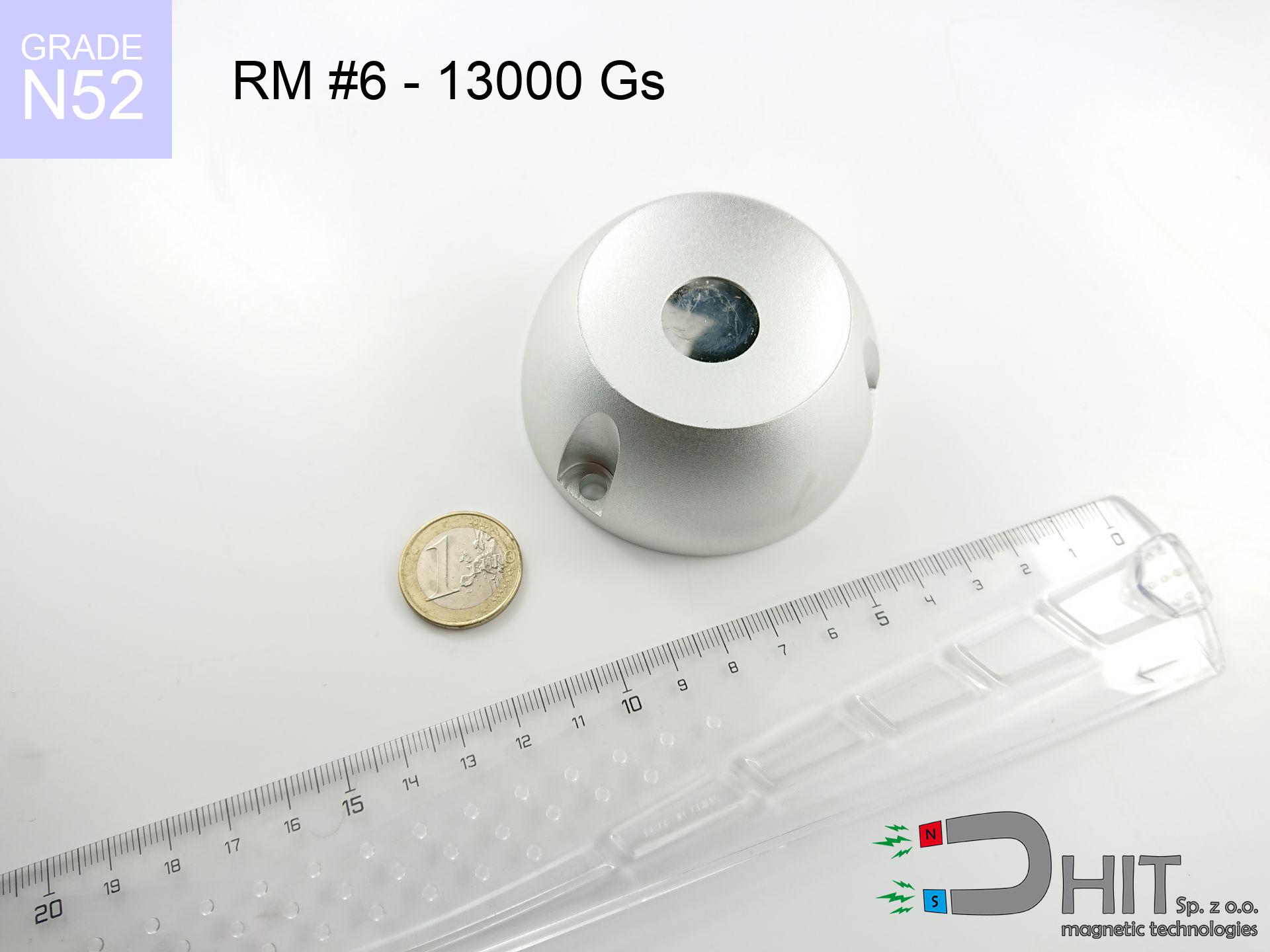

UMH 42x9x46 [M6] / N38 - magnetic holder with hook

magnetic holder with hook

Catalog no 310429

GTIN/EAN: 5906301814580

Diameter Ø

42 mm [±1 mm]

Height

46 mm [±1 mm]

Height

9 mm [±1 mm]

Weight

90 g

Magnetization Direction

↑ axial

Load capacity

66.00 kg / 647.24 N

Coating

[NiCuNi] Nickel

35.99 ZŁ with VAT / pcs + price for transport

29.26 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

or get in touch by means of

inquiry form

through our site.

Specifications as well as structure of magnets can be verified using our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Technical parameters of the product - UMH 42x9x46 [M6] / N38 - magnetic holder with hook

Specification / characteristics - UMH 42x9x46 [M6] / N38 - magnetic holder with hook

| properties | values |

|---|---|

| Cat. no. | 310429 |

| GTIN/EAN | 5906301814580 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 42 mm [±1 mm] |

| Height | 46 mm [±1 mm] |

| Height | 9 mm [±1 mm] |

| Weight | 90 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 66.00 kg / 647.24 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

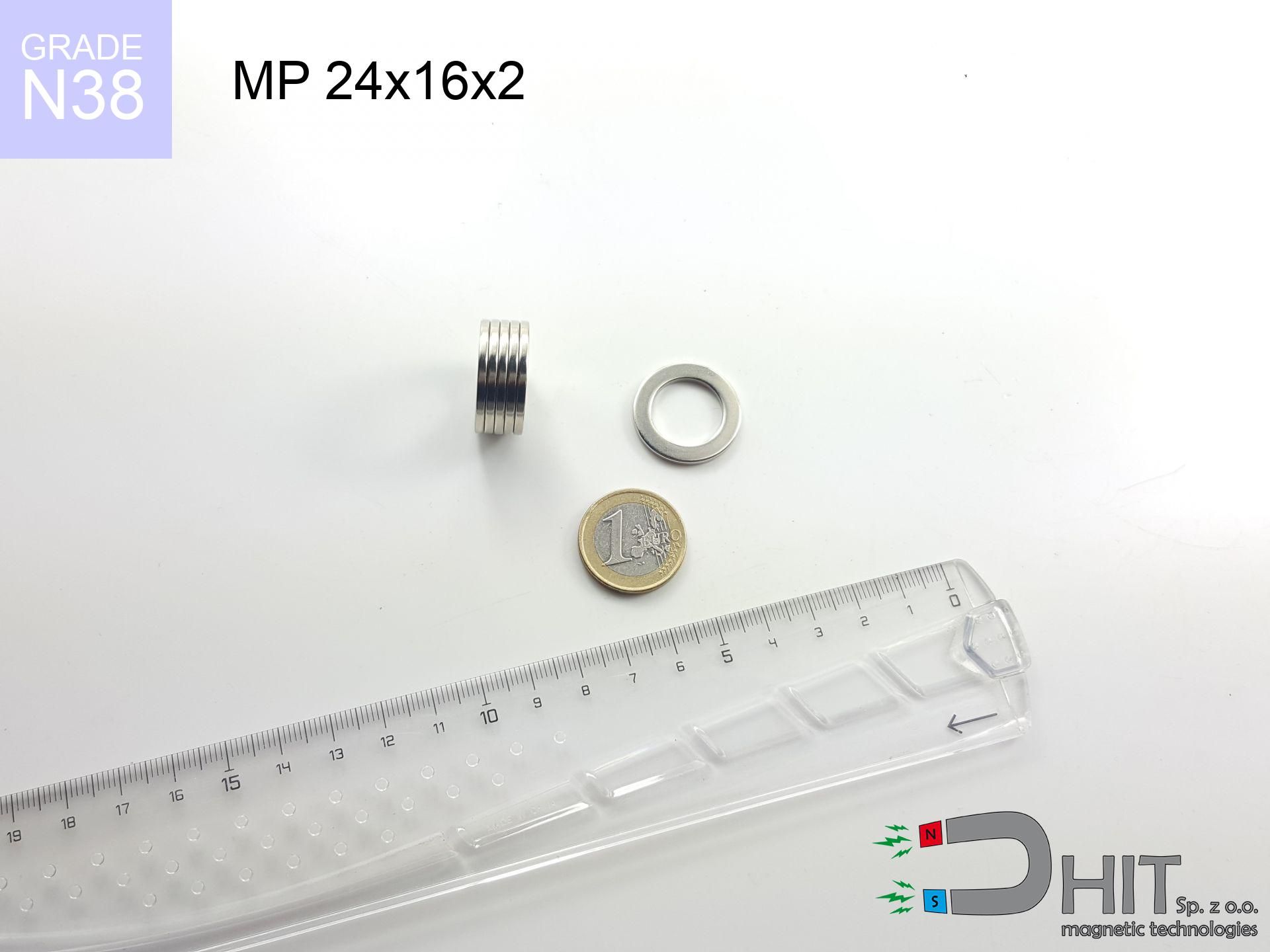

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Advantages as well as disadvantages of neodymium magnets.

Pros

- They retain magnetic properties for almost 10 years – the loss is just ~1% (according to analyses),

- They are extremely resistant to demagnetization induced by external magnetic fields,

- By covering with a reflective layer of nickel, the element acquires an modern look,

- Magnets possess maximum magnetic induction on the active area,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- In view of the ability of precise shaping and customization to individualized requirements, magnetic components can be produced in a variety of forms and dimensions, which amplifies use scope,

- Significant place in high-tech industry – they are commonly used in magnetic memories, electric drive systems, diagnostic systems, and complex engineering applications.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- They are fragile upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment - during use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We recommend a housing - magnetic mechanism, due to difficulties in producing threads inside the magnet and complicated forms.

- Health risk resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which becomes key in the context of child safety. Furthermore, tiny parts of these devices are able to be problematic in diagnostics medical when they are in the body.

- Due to expensive raw materials, their price exceeds standard values,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- using a sheet made of high-permeability steel, acting as a ideal flux conductor

- with a cross-section of at least 10 mm

- with a surface perfectly flat

- under conditions of gap-free contact (metal-to-metal)

- under perpendicular force direction (90-degree angle)

- at standard ambient temperature

What influences lifting capacity in practice

- Distance – existence of any layer (rust, dirt, air) acts as an insulator, which lowers capacity rapidly (even by 50% at 0.5 mm).

- Loading method – catalog parameter refers to pulling vertically. When slipping, the magnet exhibits significantly lower power (typically approx. 20-30% of nominal force).

- Steel thickness – too thin steel does not accept the full field, causing part of the power to be escaped into the air.

- Metal type – different alloys reacts the same. High carbon content worsen the attraction effect.

- Surface finish – full contact is obtained only on polished steel. Rough texture reduce the real contact area, weakening the magnet.

- Thermal conditions – neodymium magnets have a negative temperature coefficient. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Moreover, even a small distance between the magnet and the plate reduces the holding force.

Safe handling of NdFeB magnets

ICD Warning

Life threat: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have electronic implants.

Serious injuries

Large magnets can smash fingers in a fraction of a second. Do not put your hand between two attracting surfaces.

Compass and GPS

An intense magnetic field interferes with the operation of compasses in phones and GPS navigation. Do not bring magnets close to a device to avoid breaking the sensors.

Nickel allergy

Some people suffer from a contact allergy to Ni, which is the common plating for NdFeB magnets. Frequent touching might lead to skin redness. We strongly advise use safety gloves.

Combustion hazard

Combustion risk: Neodymium dust is highly flammable. Do not process magnets in home conditions as this risks ignition.

Safe distance

Do not bring magnets close to a purse, laptop, or TV. The magnetic field can destroy these devices and wipe information from cards.

Caution required

Handle magnets consciously. Their powerful strength can surprise even professionals. Be vigilant and do not underestimate their force.

Eye protection

Protect your eyes. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Wear goggles.

No play value

Product intended for adults. Tiny parts can be swallowed, leading to intestinal necrosis. Keep out of reach of kids and pets.

Demagnetization risk

Keep cool. Neodymium magnets are sensitive to heat. If you require resistance above 80°C, inquire about HT versions (H, SH, UH).

![Holder with hook UMH 42x9x46 [M6] / N38 Holder with hook UMH 42x9x46 [M6] / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-vat.jpg)

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook - ujęcie 2](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-dum.jpg)

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook - ujęcie 3](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-sij.jpg)

![SM 18x300 [2xM5] / N42 - magnetic separator SM 18x300 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x300-2xm5-xad.jpg)