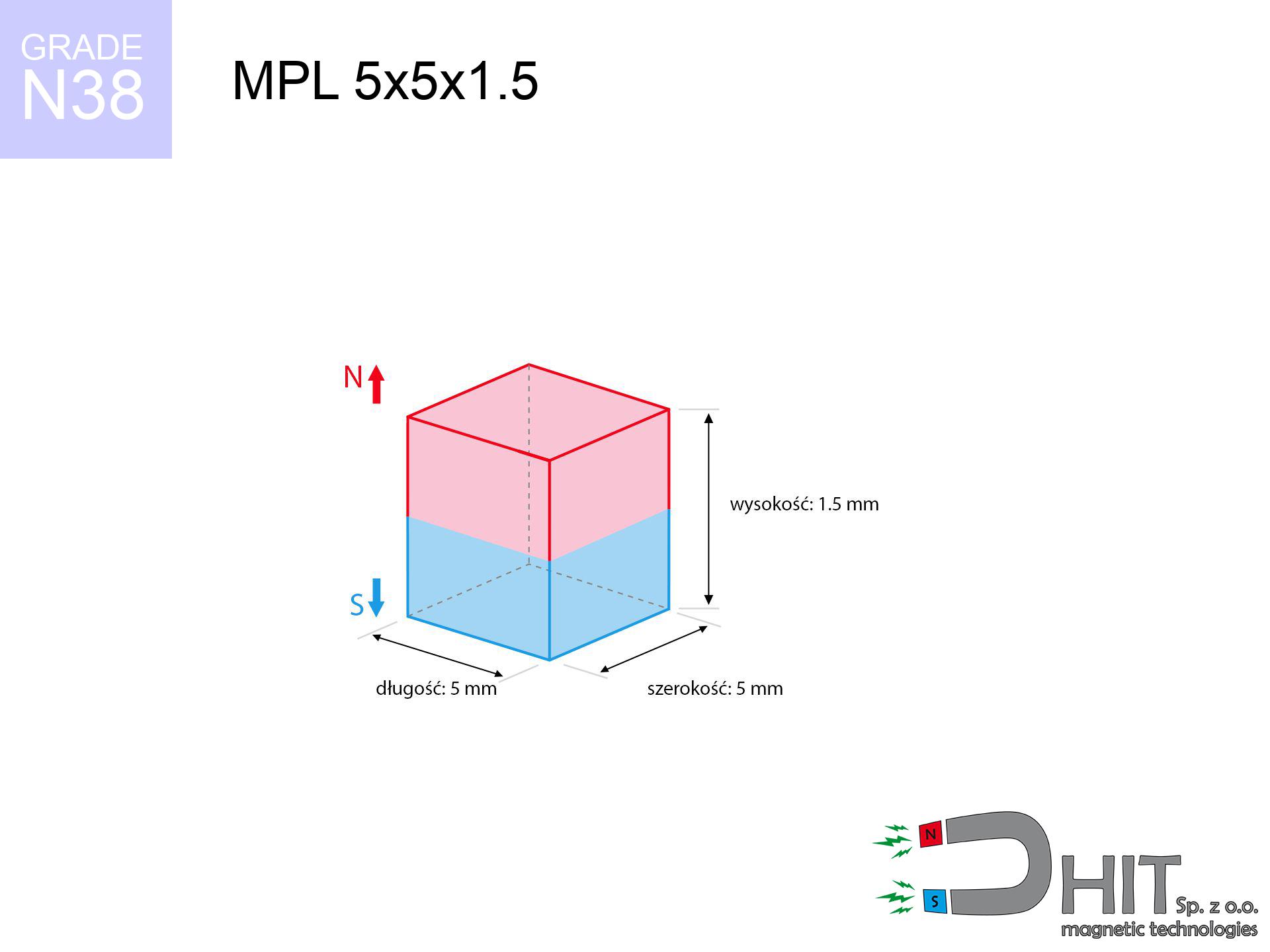

MPL 5x5x1.5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020172

GTIN/EAN: 5906301811787

length

5 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

0.28 g

Magnetization Direction

↑ axial

Load capacity

0.58 kg / 5.68 N

Magnetic Induction

293.49 mT / 2935 Gs

Coating

[NiCuNi] Nickel

0.1845 ZŁ with VAT / pcs + price for transport

0.1500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

alternatively get in touch by means of

request form

the contact form page.

Lifting power along with appearance of neodymium magnets can be calculated with our

online calculation tool.

Same-day processing for orders placed before 14:00.

Product card - MPL 5x5x1.5 / N38 - lamellar magnet

Specification / characteristics - MPL 5x5x1.5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020172 |

| GTIN/EAN | 5906301811787 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 5 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 0.28 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.58 kg / 5.68 N |

| Magnetic Induction ~ ? | 293.49 mT / 2935 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the product - data

Presented information are the result of a mathematical simulation. Values are based on models for the class Nd2Fe14B. Actual conditions may differ. Use these data as a reference point during assembly planning.

Table 1: Static pull force (force vs gap) - characteristics

MPL 5x5x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2932 Gs

293.2 mT

|

0.58 kg / 1.28 LBS

580.0 g / 5.7 N

|

low risk |

| 1 mm |

2036 Gs

203.6 mT

|

0.28 kg / 0.62 LBS

279.6 g / 2.7 N

|

low risk |

| 2 mm |

1228 Gs

122.8 mT

|

0.10 kg / 0.22 LBS

101.7 g / 1.0 N

|

low risk |

| 3 mm |

727 Gs

72.7 mT

|

0.04 kg / 0.08 LBS

35.7 g / 0.3 N

|

low risk |

| 5 mm |

285 Gs

28.5 mT

|

0.01 kg / 0.01 LBS

5.5 g / 0.1 N

|

low risk |

| 10 mm |

54 Gs

5.4 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

low risk |

| 15 mm |

18 Gs

1.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 20 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 30 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding force (wall)

MPL 5x5x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.12 kg / 0.26 LBS

116.0 g / 1.1 N

|

| 1 mm | Stal (~0.2) |

0.06 kg / 0.12 LBS

56.0 g / 0.5 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

20.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

8.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 5x5x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.17 kg / 0.38 LBS

174.0 g / 1.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.12 kg / 0.26 LBS

116.0 g / 1.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.06 kg / 0.13 LBS

58.0 g / 0.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.29 kg / 0.64 LBS

290.0 g / 2.8 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 5x5x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.06 kg / 0.13 LBS

58.0 g / 0.6 N

|

| 1 mm |

|

0.15 kg / 0.32 LBS

145.0 g / 1.4 N

|

| 2 mm |

|

0.29 kg / 0.64 LBS

290.0 g / 2.8 N

|

| 3 mm |

|

0.43 kg / 0.96 LBS

435.0 g / 4.3 N

|

| 5 mm |

|

0.58 kg / 1.28 LBS

580.0 g / 5.7 N

|

| 10 mm |

|

0.58 kg / 1.28 LBS

580.0 g / 5.7 N

|

| 11 mm |

|

0.58 kg / 1.28 LBS

580.0 g / 5.7 N

|

| 12 mm |

|

0.58 kg / 1.28 LBS

580.0 g / 5.7 N

|

Table 5: Working in heat (stability) - thermal limit

MPL 5x5x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.58 kg / 1.28 LBS

580.0 g / 5.7 N

|

OK |

| 40 °C | -2.2% |

0.57 kg / 1.25 LBS

567.2 g / 5.6 N

|

OK |

| 60 °C | -4.4% |

0.55 kg / 1.22 LBS

554.5 g / 5.4 N

|

|

| 80 °C | -6.6% |

0.54 kg / 1.19 LBS

541.7 g / 5.3 N

|

|

| 100 °C | -28.8% |

0.41 kg / 0.91 LBS

413.0 g / 4.1 N

|

Table 6: Two magnets (repulsion) - field collision

MPL 5x5x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.33 kg / 2.92 LBS

4 518 Gs

|

0.20 kg / 0.44 LBS

199 g / 1.9 N

|

N/A |

| 1 mm |

0.97 kg / 2.15 LBS

5 027 Gs

|

0.15 kg / 0.32 LBS

146 g / 1.4 N

|

0.88 kg / 1.93 LBS

~0 Gs

|

| 2 mm |

0.64 kg / 1.41 LBS

4 071 Gs

|

0.10 kg / 0.21 LBS

96 g / 0.9 N

|

0.57 kg / 1.27 LBS

~0 Gs

|

| 3 mm |

0.39 kg / 0.86 LBS

3 188 Gs

|

0.06 kg / 0.13 LBS

59 g / 0.6 N

|

0.35 kg / 0.78 LBS

~0 Gs

|

| 5 mm |

0.14 kg / 0.30 LBS

1 886 Gs

|

0.02 kg / 0.05 LBS

21 g / 0.2 N

|

0.12 kg / 0.27 LBS

~0 Gs

|

| 10 mm |

0.01 kg / 0.03 LBS

569 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

108 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

9 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MPL 5x5x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 1.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Remote | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 5x5x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

45.91 km/h

(12.75 m/s)

|

0.02 J | |

| 30 mm |

79.50 km/h

(22.08 m/s)

|

0.07 J | |

| 50 mm |

102.64 km/h

(28.51 m/s)

|

0.11 J | |

| 100 mm |

145.15 km/h

(40.32 m/s)

|

0.23 J |

Table 9: Anti-corrosion coating durability

MPL 5x5x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 5x5x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 799 Mx | 8.0 µWb |

| Pc Coefficient | 0.36 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 5x5x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.58 kg | Standard |

| Water (riverbed) |

0.66 kg

(+0.08 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains only approx. 20-30% of its max power.

2. Steel saturation

*Thin steel (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.36

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also products

Strengths and weaknesses of neodymium magnets.

Pros

- They retain magnetic properties for around ten years – the loss is just ~1% (based on simulations),

- Magnets perfectly protect themselves against loss of magnetization caused by foreign field sources,

- A magnet with a shiny nickel surface looks better,

- Magnets are distinguished by impressive magnetic induction on the outer side,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can function (depending on the shape) even at a temperature of 230°C or more...

- Possibility of accurate modeling as well as adjusting to individual needs,

- Huge importance in advanced technology sectors – they are commonly used in HDD drives, drive modules, precision medical tools, as well as industrial machines.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in producing nuts and complicated shapes in magnets, we propose using a housing - magnetic mechanism.

- Health risk to health – tiny shards of magnets pose a threat, if swallowed, which is particularly important in the context of child safety. Furthermore, tiny parts of these products can disrupt the diagnostic process medical after entering the body.

- With mass production the cost of neodymium magnets is economically unviable,

Pull force analysis

Maximum holding power of the magnet – what affects it?

- on a base made of mild steel, optimally conducting the magnetic field

- possessing a thickness of min. 10 mm to avoid saturation

- with an ground contact surface

- with total lack of distance (without impurities)

- under perpendicular force vector (90-degree angle)

- in neutral thermal conditions

What influences lifting capacity in practice

- Distance – existence of foreign body (paint, dirt, air) acts as an insulator, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of converting into lifting capacity.

- Steel grade – ideal substrate is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which increases field saturation. Uneven metal reduce efficiency.

- Operating temperature – neodymium magnets have a negative temperature coefficient. At higher temperatures they lose power, and at low temperatures gain strength (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the holding force is lower. Additionally, even a slight gap between the magnet and the plate lowers the lifting capacity.

H&S for magnets

Metal Allergy

Warning for allergy sufferers: The nickel-copper-nickel coating consists of nickel. If redness occurs, immediately stop handling magnets and wear gloves.

Danger to the youngest

These products are not toys. Swallowing several magnets can lead to them connecting inside the digestive tract, which constitutes a severe health hazard and requires urgent medical intervention.

Safe operation

Use magnets consciously. Their immense force can shock even professionals. Be vigilant and do not underestimate their power.

Phone sensors

Note: rare earth magnets produce a field that interferes with sensitive sensors. Maintain a separation from your mobile, device, and navigation systems.

Medical implants

Life threat: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Beware of splinters

Protect your eyes. Magnets can explode upon violent connection, ejecting shards into the air. Eye protection is mandatory.

Finger safety

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, destroying anything in their path. Be careful!

Demagnetization risk

Watch the temperature. Exposing the magnet above 80 degrees Celsius will destroy its properties and pulling force.

Combustion hazard

Fire warning: Rare earth powder is highly flammable. Avoid machining magnets without safety gear as this may cause fire.

Threat to electronics

Intense magnetic fields can corrupt files on credit cards, hard drives, and other magnetic media. Stay away of at least 10 cm.

![SM 19x225 [2xM6] / N50 - magnetic separator SM 19x225 [2xM6] / N50 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-19x225-2xm6-jis.jpg)

![SM 32x325 [2xM8] / N52 - magnetic separator SM 32x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-xec.jpg)