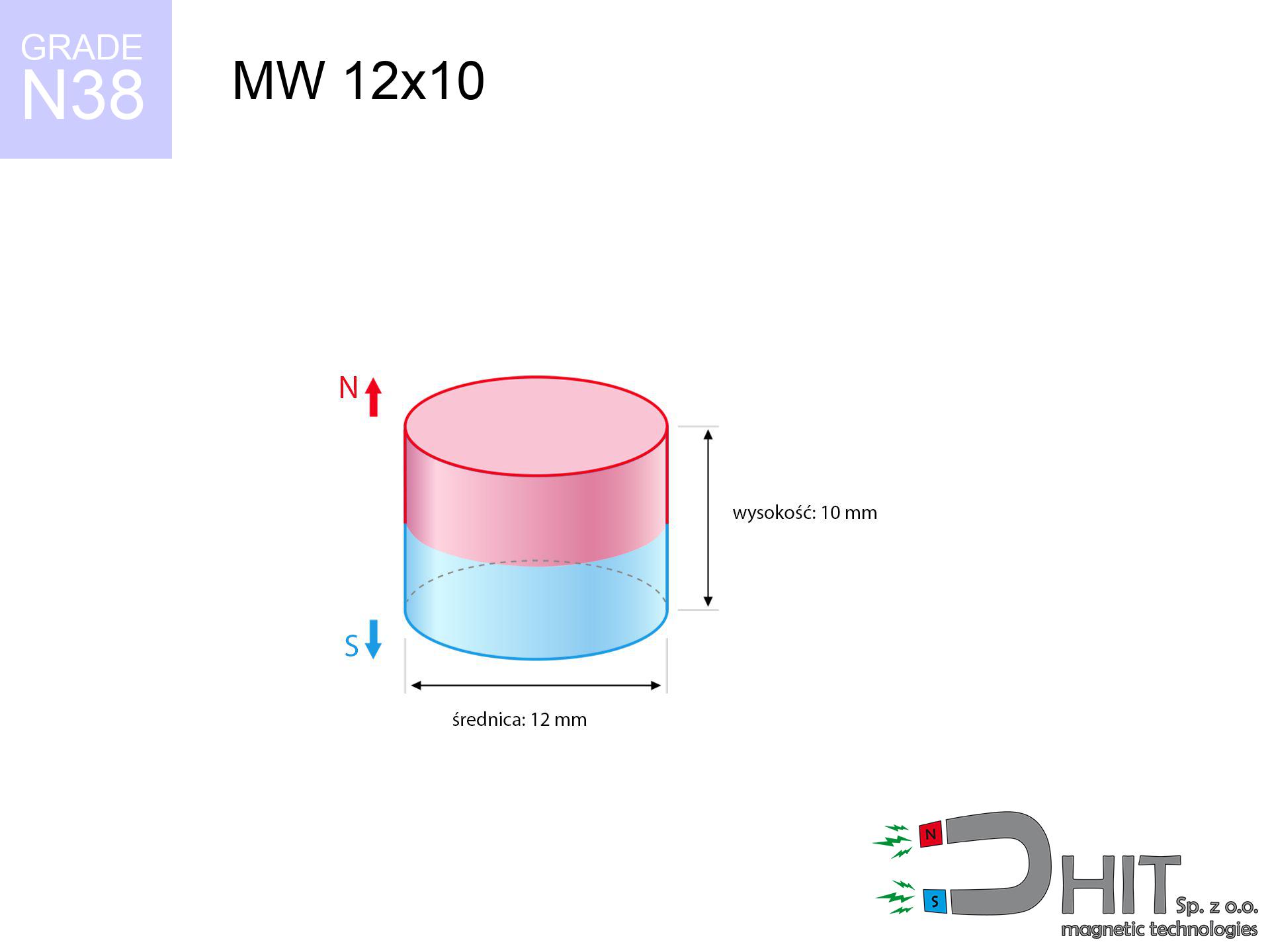

MW 12x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010016

GTIN/EAN: 5906301810155

Diameter Ø

12 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

8.48 g

Magnetization Direction

↑ axial

Load capacity

4.83 kg / 47.41 N

Magnetic Induction

531.09 mT / 5311 Gs

Coating

[NiCuNi] Nickel

3.03 ZŁ with VAT / pcs + price for transport

2.46 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

or drop us a message by means of

our online form

through our site.

Strength along with structure of magnetic components can be reviewed on our

modular calculator.

Same-day processing for orders placed before 14:00.

Product card - MW 12x10 / N38 - cylindrical magnet

Specification / characteristics - MW 12x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010016 |

| GTIN/EAN | 5906301810155 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 8.48 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.83 kg / 47.41 N |

| Magnetic Induction ~ ? | 531.09 mT / 5311 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the product - data

The following information constitute the result of a mathematical simulation. Values rely on algorithms for the material Nd2Fe14B. Operational conditions might slightly differ. Please consider these calculations as a supplementary guide for designers.

Table 1: Static pull force (pull vs distance) - power drop

MW 12x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5308 Gs

530.8 mT

|

4.83 kg / 10.65 pounds

4830.0 g / 47.4 N

|

medium risk |

| 1 mm |

4424 Gs

442.4 mT

|

3.36 kg / 7.40 pounds

3355.3 g / 32.9 N

|

medium risk |

| 2 mm |

3585 Gs

358.5 mT

|

2.20 kg / 4.86 pounds

2203.4 g / 21.6 N

|

medium risk |

| 3 mm |

2857 Gs

285.7 mT

|

1.40 kg / 3.08 pounds

1399.2 g / 13.7 N

|

weak grip |

| 5 mm |

1787 Gs

178.7 mT

|

0.55 kg / 1.21 pounds

547.8 g / 5.4 N

|

weak grip |

| 10 mm |

622 Gs

62.2 mT

|

0.07 kg / 0.15 pounds

66.3 g / 0.7 N

|

weak grip |

| 15 mm |

272 Gs

27.2 mT

|

0.01 kg / 0.03 pounds

12.7 g / 0.1 N

|

weak grip |

| 20 mm |

141 Gs

14.1 mT

|

0.00 kg / 0.01 pounds

3.4 g / 0.0 N

|

weak grip |

| 30 mm |

52 Gs

5.2 mT

|

0.00 kg / 0.00 pounds

0.5 g / 0.0 N

|

weak grip |

| 50 mm |

13 Gs

1.3 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding capacity (wall)

MW 12x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.97 kg / 2.13 pounds

966.0 g / 9.5 N

|

| 1 mm | Stal (~0.2) |

0.67 kg / 1.48 pounds

672.0 g / 6.6 N

|

| 2 mm | Stal (~0.2) |

0.44 kg / 0.97 pounds

440.0 g / 4.3 N

|

| 3 mm | Stal (~0.2) |

0.28 kg / 0.62 pounds

280.0 g / 2.7 N

|

| 5 mm | Stal (~0.2) |

0.11 kg / 0.24 pounds

110.0 g / 1.1 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

14.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 12x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.45 kg / 3.19 pounds

1449.0 g / 14.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.97 kg / 2.13 pounds

966.0 g / 9.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.48 kg / 1.06 pounds

483.0 g / 4.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.42 kg / 5.32 pounds

2415.0 g / 23.7 N

|

Table 4: Steel thickness (saturation) - power losses

MW 12x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.48 kg / 1.06 pounds

483.0 g / 4.7 N

|

| 1 mm |

|

1.21 kg / 2.66 pounds

1207.5 g / 11.8 N

|

| 2 mm |

|

2.42 kg / 5.32 pounds

2415.0 g / 23.7 N

|

| 3 mm |

|

3.62 kg / 7.99 pounds

3622.5 g / 35.5 N

|

| 5 mm |

|

4.83 kg / 10.65 pounds

4830.0 g / 47.4 N

|

| 10 mm |

|

4.83 kg / 10.65 pounds

4830.0 g / 47.4 N

|

| 11 mm |

|

4.83 kg / 10.65 pounds

4830.0 g / 47.4 N

|

| 12 mm |

|

4.83 kg / 10.65 pounds

4830.0 g / 47.4 N

|

Table 5: Working in heat (stability) - thermal limit

MW 12x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.83 kg / 10.65 pounds

4830.0 g / 47.4 N

|

OK |

| 40 °C | -2.2% |

4.72 kg / 10.41 pounds

4723.7 g / 46.3 N

|

OK |

| 60 °C | -4.4% |

4.62 kg / 10.18 pounds

4617.5 g / 45.3 N

|

OK |

| 80 °C | -6.6% |

4.51 kg / 9.95 pounds

4511.2 g / 44.3 N

|

|

| 100 °C | -28.8% |

3.44 kg / 7.58 pounds

3439.0 g / 33.7 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 12x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

19.64 kg / 43.30 pounds

5 928 Gs

|

2.95 kg / 6.50 pounds

2946 g / 28.9 N

|

N/A |

| 1 mm |

16.52 kg / 36.43 pounds

9 736 Gs

|

2.48 kg / 5.46 pounds

2479 g / 24.3 N

|

14.87 kg / 32.79 pounds

~0 Gs

|

| 2 mm |

13.64 kg / 30.08 pounds

8 847 Gs

|

2.05 kg / 4.51 pounds

2047 g / 20.1 N

|

12.28 kg / 27.07 pounds

~0 Gs

|

| 3 mm |

11.12 kg / 24.51 pounds

7 986 Gs

|

1.67 kg / 3.68 pounds

1668 g / 16.4 N

|

10.01 kg / 22.06 pounds

~0 Gs

|

| 5 mm |

7.16 kg / 15.79 pounds

6 410 Gs

|

1.07 kg / 2.37 pounds

1074 g / 10.5 N

|

6.45 kg / 14.21 pounds

~0 Gs

|

| 10 mm |

2.23 kg / 4.91 pounds

3 575 Gs

|

0.33 kg / 0.74 pounds

334 g / 3.3 N

|

2.00 kg / 4.42 pounds

~0 Gs

|

| 20 mm |

0.27 kg / 0.59 pounds

1 244 Gs

|

0.04 kg / 0.09 pounds

40 g / 0.4 N

|

0.24 kg / 0.54 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 pounds

164 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

104 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

70 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

49 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

36 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

27 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MW 12x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (kinetic energy) - warning

MW 12x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.27 km/h

(6.74 m/s)

|

0.19 J | |

| 30 mm |

41.69 km/h

(11.58 m/s)

|

0.57 J | |

| 50 mm |

53.82 km/h

(14.95 m/s)

|

0.95 J | |

| 100 mm |

76.11 km/h

(21.14 m/s)

|

1.90 J |

Table 9: Surface protection spec

MW 12x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 12x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 6 105 Mx | 61.1 µWb |

| Pc Coefficient | 0.81 | High (Stable) |

Table 11: Physics of underwater searching

MW 12x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.83 kg | Standard |

| Water (riverbed) |

5.53 kg

(+0.70 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet retains merely ~20% of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) severely limits the holding force.

3. Temperature resistance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.81

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more offers

Pros and cons of Nd2Fe14B magnets.

Advantages

- Their magnetic field is durable, and after around 10 years it decreases only by ~1% (according to research),

- They do not lose their magnetic properties even under close interference source,

- By using a decorative coating of silver, the element presents an nice look,

- They feature high magnetic induction at the operating surface, which affects their effectiveness,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, allowing for operation at temperatures reaching 230°C and above...

- Possibility of custom machining as well as adapting to defined conditions,

- Huge importance in high-tech industry – they find application in magnetic memories, brushless drives, medical devices, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which allows their use in small systems

Limitations

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a special holder, which not only protects them against impacts but also increases their durability

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in creating threads and complicated shapes in magnets, we recommend using cover - magnetic mount.

- Health risk resulting from small fragments of magnets can be dangerous, if swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, small components of these devices can be problematic in diagnostics medical in case of swallowing.

- With large orders the cost of neodymium magnets can be a barrier,

Pull force analysis

Highest magnetic holding force – what affects it?

- on a plate made of mild steel, optimally conducting the magnetic field

- whose transverse dimension equals approx. 10 mm

- with a surface cleaned and smooth

- with total lack of distance (no paint)

- for force acting at a right angle (in the magnet axis)

- at temperature room level

Lifting capacity in real conditions – factors

- Gap between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of generating force.

- Material type – the best choice is pure iron steel. Cast iron may attract less.

- Surface condition – smooth surfaces guarantee perfect abutment, which increases field saturation. Uneven metal weaken the grip.

- Thermal environment – temperature increase causes a temporary drop of force. Check the maximum operating temperature for a given model.

Lifting capacity was determined by applying a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, whereas under shearing force the load capacity is reduced by as much as 75%. Moreover, even a slight gap between the magnet and the plate reduces the lifting capacity.

Safe handling of neodymium magnets

Handling guide

Use magnets with awareness. Their immense force can surprise even professionals. Be vigilant and respect their force.

Warning for heart patients

People with a heart stimulator must keep an safe separation from magnets. The magnetic field can stop the operation of the life-saving device.

Bodily injuries

Pinching hazard: The pulling power is so immense that it can cause hematomas, pinching, and broken bones. Use thick gloves.

Cards and drives

Powerful magnetic fields can erase data on payment cards, hard drives, and storage devices. Stay away of at least 10 cm.

Compass and GPS

Remember: rare earth magnets produce a field that interferes with sensitive sensors. Maintain a safe distance from your mobile, tablet, and GPS.

Warning for allergy sufferers

It is widely known that the nickel plating (standard magnet coating) is a potent allergen. If your skin reacts to metals, avoid direct skin contact and choose encased magnets.

Machining danger

Combustion risk: Neodymium dust is highly flammable. Do not process magnets in home conditions as this may cause fire.

No play value

Adult use only. Small elements can be swallowed, leading to serious injuries. Keep out of reach of kids and pets.

Maximum temperature

Avoid heat. NdFeB magnets are susceptible to temperature. If you need resistance above 80°C, look for HT versions (H, SH, UH).

Material brittleness

Watch out for shards. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. Eye protection is mandatory.

![SM 32x150 [2xM8] / N42 - magnetic separator SM 32x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xus.jpg)